Review on shape memory alloys’ application in field of aerospace

-

摘要:

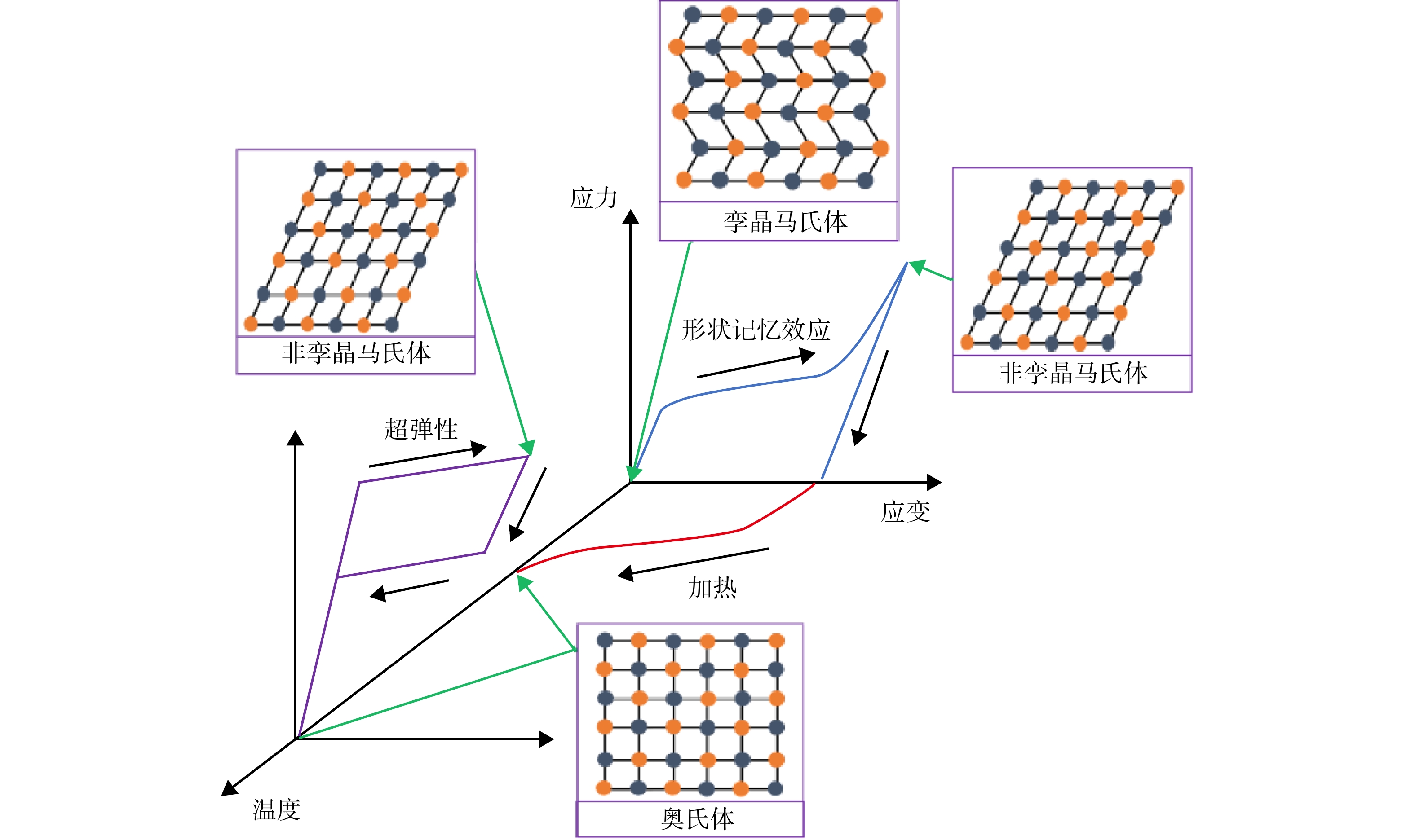

为了在航空航天领域更好地利用形状记忆合金(shape memory alloys, SMA)的形状记忆效应和超弹性两方面的突出力学特性,综述了SMA在材料与工艺、本构模型、形状记忆效应应用和超弹性应用方面的研究进展。主要探讨了NiTiHf、NiTiAu等三元高温合金、SMA热处理工艺和3D打印工艺、形状记忆效应和超弹性本构模型、利用形状记忆效应设计的SMA丝、管、弹簧和带驱动器、利用超弹性设计的减振器、自适应结构等在航空航天领域的应用研究特点,并指出当前存在的不足。该研究结果表明:随着材料、工艺、控制、信息技术的融合发展,SMA的应用研究将向着更宽的工作温度范围、结构多样化以及智能化方向发展。

Abstract:In order to better utilize the outstanding mechanical properties of shape memory alloys (SMA) in both shape memory effect and superelasticity in aerospace field, the research progress of SMA in terms of materials and process, constitutive model, shape memory effect application and superelasticity application was reviewed. The research features of the ternary high-temperature alloys, such as NiTiHf and NiTiAu, SMA heat treatment process and 3D printing process, shape memory effect and superelasticity constitutive model, SMA wire, tube, spring and belt actuators designed by using shape memory effect, vibration dampers and adaptive structures designed by using superelasticity in aerospace field were mainly discussed, and their current shortcomings were presented. The future trend of SMA application was proposed: with the integrated development of materials, process, control, and information technology, the structures with SMA could show more structure diversity and work in a wider range of working temperature with more intelligence.

-

表 1 国内外SMA丝驱动的压紧释放机构

Table 1. Domestic and foreign SMA wire actuated hold-down and release mechanism

型号 载荷/

kN释放时间/

s质量/

g包络尺寸

(直径×高度)/

(mm×mm)TiNi拔销器 0.45 0.1 360 KAIST 15 0.05 275 35×72 NEHRA 20 1 400 70×38 REACT 35 10 354 78×78 REACT V2 5 1.1 230 SUNVR 0.78 SMA-30000 30 14 430 46×84 SMA-10000 10 0.1 240 41×60 SMA-3600 3.6 0.3 250 42×61 RLLPD 0.35 8 表 2 SMA弹簧驱动的压紧释放机构

Table 2. SMA spring driving hold-down and release mechanism

型号 载荷/

kN释放时间/

s质量/

g包络尺寸/

(mm×mm)LFN 12~13 10 250 38×89(直径×高度) TSN 25~80 0.05 300 38×76(直径×高度) KAU 1.597 0.022 50×30(长度×宽度) -

[1] ÖLANDER A. An electrochemical investigation of solid cadmium-gold alloys[J]. Journal of the American Chemical Society,1932,54(10): 3819-3833. doi: 10.1021/ja01349a004 [2] CHANG L C,READ T A. Plastic deformation and diffusionless phase changes in metals-the gold-cadmium beta phase[J]. Transactions of AIME Journal of Metals,1951,47(191): 47-52. [3] BUEHLER W J,GILFRICH J V,WILEY R C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi[J]. Journal of Applied Physics,1963,34(5): 1475-1477. doi: 10.1063/1.1729603 [4] 刘永康,蒋娜云,李微. 铜基形状记忆合金专利技术分析[J]. 中国科技信息,2018(11): 29-30.LIU Yongkang,JIANG Nayun,LI Wei. Analysis of patent technology of copper base shape memory alloy[J]. China Science and Technology Information,2018(11): 29-30. (in Chinese) [5] 任彦. 铁基形状记忆合金研究与应用的新进展[J]. 新材料产业,2014(6): 42-45.REN Yan. New progress in research and application of iron - based shape memory alloys[J]. Advanced Materials Industry,2014(6): 42-45. (in Chinese) [6] 闫晓军, 张小勇. 形状记忆合金智能结构[M]. 北京: 科学出版社, 2015. [7] STÉPHANE L. Issues in the design of shape memory alloy actuators[D]. Cambridge, US: Massachusetts Institute of Technology, 2002. [8] HOLLERBACH J M, HUNTER I W, BALLANTYNE J. A comparative analysis of actuator technologies for robotics[M]. Cambridge, US: Massachusetts Institute of Technology (MIT) Press, 1992. [9] LIU D Z,LIU W X,GONG F Y. Engineering application of Fe-based shape memory alloy on connecting pipe line[J]. Journal De Physique: Ⅳ,1995,5(C8): 1241-1246. [10] 谷凡,张玲,王伟,等. 形状记忆合金管道连接件综述[J]. 建筑与预算,2017(12): 30-37.GU Fan,ZHANG Ling,WANG Wei,et al. A review of shape memory alloy pipe fittings[J]. Construction and Budget,2017(12): 30-37. (in Chinese) [11] HARTL D J,LAGOUDAS D C. Aerospace applications of shape memory alloys[J]. Proceedings of the Institution of Mechanical Engineers,2014,221(4): 535-552. [12] HUMBEECK J V. Non-medical applications of shape memory alloys[J]. Materials Science Engineering: A,1999,273/274/275: 134-148. [13] MCDONALD S L. Shape memory alloy applications in space systems[J]. Materials Design,1991,12(1): 29-32. doi: 10.1016/0261-3069(91)90089-M [14] YAMAUCHI K, OHKATA I, TSUCHIYA K, et al. Shape memory and superelastic alloys: technologies and applications[M]. Sawston Cambridge, England: Woodhead Publishing, 2011. [15] FRANK S, SUBHASH G. The effect of alloy formulation on the transformation temperature range of Ni-Ti shape memory alloys[C]// Shape Memory and Superelastic Technologies (SMST-2003). New Hartford, US: Special Metals Corporation, 2004: 13413.1-13413.9 [16] 李涛,易忠,高鸿. 航天器材料空间环境适应性评价技术[J]. 装备环境工程,2012,9(3): 37-40. doi: 10.3969/j.issn.1672-9242.2012.03.009LI Tao,YI Zhong,GAO Hong. Summarization space environmental worthiness evaluation technology for spacecraft material[J]. Equipment Environmental Engineering,2012,9(3): 37-40. (in Chinese) doi: 10.3969/j.issn.1672-9242.2012.03.009 [17] KARAKOC O,ATLI K C,BENAFAN O,et al. Actuation fatigue performance of NiTiZr and comparison to NiTiHf high temperature shape memory alloys[J]. Materials Science and Engineering:A,2021,829: 142154.1-142154.9. [18] KARAKOC O,HAYRETTIN C,CANADINC D,et al. Role of applied stress level on the actuation fatigue behavior of NiTiHf high temperature shape memory alloys[J]. Acta Materialia,2018,153: 156-168. doi: 10.1016/j.actamat.2018.04.021 [19] MONROE J A,KARAMAN I,LAGOUDAS D C,et al. Determining recoverable and irrecoverable contributions to accumulated strain in a NiTiPd high-temperature shape memory alloy during thermomechanical cycling[J]. Scripta Materialia,2011,65(2): 123-126. doi: 10.1016/j.scriptamat.2011.03.019 [20] CASALENA L,BIGELOW G S,GAO Y,et al. Mechanical behavior and microstructural analysis of NiTi-40Au shape memory alloys exhibiting work output above 400 ℃[J]. Intermetallics,2017,86: 33-44. doi: 10.1016/j.intermet.2017.03.005 [21] DREXEL M, SELVADURAY G, PELTON A. The effects of cold work and heat treatment on the properties of nitinol wire[R]. Irvine, US: the 2nd ASME Frontiers in Biomedical Devices Conference, 2007. [22] KOK M,DAGDELEN F,AYDOGDU A,et al. The change of transformation temperature on NiTi shape memory alloy by pressure and thermal ageing[J]. Journal of Physics Conference Series,2016,667(1): 012011.1-012011.8. [23] BENAFAN O, MOHOLT M. Spanwise adaptive wing: an overview and challenges of in-flight wing folding using shape memory alloys[R]. Konstanz, Germany: the International Conference on Shape Memory and Superelastic Technologies (SMST), 2019. [24] BENAFAN O, NOEBE R D. Shape memory alloy rock splitters (SMARS): US9649780B1 [P]. 2017-05-16. [25] BENAFAN O, NOEBE R D, HALSMER T J. Shape memory alloy rock splitters (SMARS): a non-explosive method for fracturing planetary rocklike materials and minerals[R]. NASA/TM-2015-218832, 2015. [26] BENAFAN O,NOEBE R D,HALSMER T J. Static rock splitters based on high temperature shape memory alloys for planetary explorations[J]. Acta Astronautica,2016,118: 137-157. doi: 10.1016/j.actaastro.2015.10.009 [27] RAO Zhixiang,WANG Xiaoyuan,LENG Jiaming,et al. Design methodology of the Ni50Ti50 shape memory alloy beam actuator: heat treatment, training and numerical simulation[J]. Materials and Design,2022,217: 110615-110630. doi: 10.1016/j.matdes.2022.110615 [28] YAN Xiaojun,HUANG Dawei,ZHANG Xiaoyong. Note: a novel curvature-driven shape memory alloy torsional actuator[J]. The Review of Scientific Instruments,2014,85(12): 126109.1-126109.4. [29] LIU Xiaopeng, WANG Yinong, QI Min, et al. Effects of heat treatment on shape-setting and non-linearmechanical properties of Nitinol stent[C]// Proceedings of International Conference on Smart Materials and Nanotechnology in Engineering. Harbin, China: SPIE(Society of Photo-optical Instrumentation Engineers), 2007: 64233.1-64233.7. [30] MAHMUD A S,HONG Y,TEE S,et al. Effect of annealing on deformation-induced martensite stabilisation of NiTi[J]. Intermetallics,2008,16(2): 209-214. doi: 10.1016/j.intermet.2007.09.003 [31] BEN F B,GAHBICHE A,ZGHAL S,et al. On the influence of the heat treatment temperature on the superelastic compressive behavior of the Ni-rich NiTi shape memory alloy[J]. Journal of Materials Engineering Performance,2017,26: 5660-5668. doi: 10.1007/s11665-017-2974-2 [32] 胡励. NiTi形状记忆合金包套压缩塑性变形机理及局部非晶化机制研究[D]. 哈尔滨: 哈尔滨工程大学, 2017.HU Li. Investigation of plastic deformation mechanism and local amorphization mechamism of NiTi shape memory alloy based on canning compression[D]. Harbin: Harbin Engineering University, 2017. (in Chinese) [33] DADBAKHSH S,SPEIRS M,KRUTH J,et al. Effect of SLM parameters on transformation temperatures of shape memory Nickel Titanium parts[J]. Advanced Engineering Materials,2014,16(9): 1140-1146. doi: 10.1002/adem.201300558 [34] NEMATOLLAHI M,TOKER G,SAGHAIAN S E,et al. Additive manufacturing of Ni-rich NiTiHf20: manufacturability, composition, density, and transformation behavior[J]. Shape Memory Superelasticity,2019,5: 113-124. doi: 10.1007/s40830-019-00214-9 [35] XIONG Zhiwei,LI Meng,HAO Shijie,et al. 3D-printing damage-tolerant architected metallic materials with shape recoverability via special deformation design of constituent material[J]. ACS Applied Materials and Interfaces,2021,15(33): 39915-39924. [36] 何贝贝. 选区激光熔化TiNi形状记忆合金热—力耦合数值模拟及实验研究[D]. 南京: 南京航空航天大学, 2016.HE Beibei. Numerical simulation and experimental investigation on thermal-mechanical behavior during selective laser melting of Ti Ni shape memory alloy[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016. (in Chinese) [37] ARGHAVANI J. Thermo-mechanical behavior of shape memory alloys under multiaxial loadings: constitutive modeling and numerical implementation at small and finite strains[D]. Teheran, Iran: Sharif University of Technology, 2010. [38] 张小勇. 用于疲劳寿命预测的SMA本构模型及其工程应用[D]. 北京: 北京航空航天大学, 2012.ZHANG Xiaoyong. Development and applications of a SMA constitutive model for actuators fatigue life prediction[D]. Beijing: Beihang University, 2012. (in Chinese) [39] TANAKA K,KOBAYASHI S,SATO Y. Thermomechanics of transformation pseudoelasticity and shape memory effect in alloys[J]. International Journal of Plasticity,1986,2(1): 59-72. doi: 10.1016/0749-6419(86)90016-1 [40] LIANG C,ROGERS C. One-dimentional theromechanical constitutive relations for shape memory materials[J]. Journal of Intelligent Material Systems and Structures,1990,1(2): 207-234. doi: 10.1177/1045389X9000100205 [41] BRINSON L. One-dimentional constitutive behavior for shape memory alloys[J]. Materials and Design,2002,23(1): 11-19. [42] ZHANG Xiaoyong,YAN Xiaojun,XIE Huimin,et al. Modeling evolutions of plastic strain, maximum transformation strain and transformation temperatures in SMA under superelastic cycling[J]. Computational Materials Science,2014,81: 113-122. doi: 10.1016/j.commatsci.2013.07.022 [43] LAGOUDAS D C,ZHONGHE B O,QIDWAI M A. Unified thermodynamic constitutive model and finite element analysis of active metal matrix composites[J]. The International Society for Optical Engineering,1995,3(2): 153-179. [44] QIDWAI M A,LAGOUDAS D C. Numerical implementation of a shape memory alloy thermomechanical constitutive model using return mapping algorithms[J]. International Journal for Numerical Methods in Engineering,2000,47(6): 1123-1168. doi: 10.1002/(SICI)1097-0207(20000228)47:6<1123::AID-NME817>3.0.CO;2-N [45] HARTL D J,LAGOUDAS D C. Constitutive modeling and structural analysis considering simultaneous phase transformation and plastic yield in shape memory alloys[J]. Smart Materials Structures,2009,18(10): 104017.1-104017.32. [46] MIRZAEIFAR R,DESROCHES R,YAVARI A,et al. On superelastic bending of shape memory alloy beams[J]. International Journal of Solids Structures,2013,50(10): 1664-1680. doi: 10.1016/j.ijsolstr.2013.01.035 [47] XU L,SOLOMOU A,BAXEVANIS T,et al. Finite strain constitutive modeling for shape memory alloys considering transformation-induced plasticity and two-way shape memory effect[J]. International Journal of Solids and Structures,2020,221: 42-59. [48] 于超. NiTi形状记忆合金宏细观热-力耦合循环本构模型研究[D]. 成都: 西南交通大学, 2015.YU Chao. Thermo-mechanically coupled macro-and micro-scopic constitutive models of NiTi shape memory alloy[D]. Chengdu: Southwest Jiaotong University, 2015. (in Chinese) [49] PATOOR E,EBERHARDT A,BERVEILLER M. Micromechanical modelling of superelasticity in shape memory alloys[J]. Journal de Physique: Ⅳ,1996,6(C1): 277-292. [50] THAMBURAJA P,ANAND L. Polycrystalline shape-memory materials: effect of crystallographic texture[J]. Journal of the Mechanics Physics of Solids,2001,49(4): 709-737. doi: 10.1016/S0022-5096(00)00061-2 [51] THAMBURAJA P,ANAND L. Superelastic behavior in tension–torsion of an initially-textured Ti-Ni shape-memory alloy[J]. International Journal of Plasticity,2002,18(11): 1607-1617. doi: 10.1016/S0749-6419(02)00031-1 [52] GALL K,SEHITOGLU H. The role of texture in tension–compression asymmetry in polycrystalline NiTi[J]. International Journal of Plasticity,1999,15(1): 69-92. doi: 10.1016/S0749-6419(98)00060-6 [53] 朱祎国,张杨,赵聃. 多晶NiTi形状记忆合金相变的细观力学本构模型[J]. 金属学报,2013,49(1): 123-128. doi: 10.3724/SP.J.1037.2012.00319ZHU Yiguo,ZHANG Yang,ZHAO Dan. Micromechanical constitutive model for phaes transformation of NiTi polycrystal SMA[J]. Acta Metallurgica Sinica,2013,49(1): 123-128. (in Chinese) doi: 10.3724/SP.J.1037.2012.00319 [54] MIRZAEIFAR R,DESROCHES R,YAVARI A,et al. A micromechanical analysis of the coupled thermomechanical superelastic response of textured and untextured polycrystalline NiTi shape memory alloys[J]. Acta Materialia,2013,61(12): 4542-4558. doi: 10.1016/j.actamat.2013.04.023 [55] GRAESSER E J,COZZARELLI F A. A proposed three-dimensional constitutive model for shape memory alloys[J]. Journal of Intelligent Material Systems Structures,1994,5(1): 78-89. doi: 10.1177/1045389X9400500109 [56] WEN Y K. Method for random vibration of hysteretic systems[J]. Journal of the Engineering Mechanics Division,1976,102(2): 249-263. doi: 10.1061/JMCEA3.0002106 [57] WEN Y K. Equivalent linearization for hysteretic systems under random excitation[J]. Journal of Applied Mechanics,1980,47(1): 150-154. doi: 10.1115/1.3153594 [58] 闫晓军. 随机载荷下SMA减振器及磁吸振器理论与试验研究[D]. 北京: 北京航空航天大学, 2000.YAN Xiaojun. Theoretical and experimental study on SMA damper and magnetic vibration absorber under random excitation[D]. Beijing: Beihang University, 2000. (in Chinese) [59] 张景业. 超弹性形状记忆合金混杂复合材料振动特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.ZHANG Jingye. Study on vibration of superelastic shape memory alloy hybrid composite structure[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [60] 牛健. 新型SMA-SMP阻尼装置对风电塔结构的减震研究[D]. 辽宁 大连: 大连理工大学, 2021.NIU Jian. Research on seismic response reduction of wind turbine tower structures using new SMA-SMP damping device[D]. Dalian Liaoning: Dalian University of Technology, 2021. (in Chinese) [61] GARDI R. Final improvements and tests on a SMA actuated, lightweight mechanism for microsatellite[R]. Bremen, Germany: the 54th International Astronautical Congress of the International Astronautical Federation and the International Academy of Astronautics, and the International Institute of Space Law, 2003. [62] YAN Xiaojun,HUANG Dawei,ZHANG Xiaoyong,et al. A one-stage, high-load capacity separation actuator using anti-friction rollers and redundant shape memory alloy wires[J]. Review of entific Instruments,2015,86: 125005.1-125005.8. [63] OKAIE M D, BUSCH J D, JOHNSON A D, et al. Release device for retaining pin: US5771742 [P]. 1998-06-30. [64] YOO Y I,JEONG J W,LIM J H,et al. Development of a non-explosive release actuator using shape memory alloy wire[J]. Review of Scientific Instruments,2013,84(1): 015005.1-015005.8. [65] VÁZQUEZ J, BUENO J I. Non explosive low shock reusable 20 kN Hold-down release actuator[R]. Liege, Belgium: the 9th European Space Mechanisms and Tribology Symposium, 2001. [66] NAVA N,COLLADO M,CABÁS R. REACT: resettable hold down and release actuator for space applications[J]. Journal of Materials Engineering Performance,2014,23(7): 2704-2711. doi: 10.1007/s11665-014-0964-1 [67] COLLADO M, RIVERA C, INES J. Evolution of a resettable hold-down and release actuator based on SMA technology[R]. Munich, Bavaria, Germany: the 18 European Space Mechanisms and Tribology Symposium, 2019. [68] 张小勇,闫晓军,杨巧龙. 形状记忆合金分瓣螺母空间解锁机构的设计与试验研究[J]. 机械工程学报,2010,46(17): 145-150. doi: 10.3901/JME.2010.17.145ZHANG Xiaoyong,YAN Xiaojun,YANG Qiaolong. Design and experimental research of a shape memory alloy space release device with segmented nut form[J]. Journal of Mechanical Engineering,2010,46(17): 145-150. (in Chinese) doi: 10.3901/JME.2010.17.145 [69] HUANG Dawei,YAN Xiaojun,ZHANG Xiaoyong,et al. Note: A SMA wire actuated extremely long-lifetime release actuator using two ball-lock mechanisms[J]. Review of Scientific Instruments,2017,88(5): 056107.1-056107.3. [70] RAO Zhixiang,YAN Xiaojun,ZHANG Xiaoyong,et al. Detailed design and life prediction methodology of novel SMA actuated repeatable launch locking protective device (RLLPD) for magnetically suspended flywheel (MSFW)[J]. Smart Materials Structures,2021,30(5): 057001-057017. doi: 10.1088/1361-665X/abed41 [71] CALKINS F T,MABE J H. Shape memory alloybased morphing aerostructures[J]. Journal of Mechanical Design,2010,132(11): 111012.1-111012.7. [72] 谭慧俊,王子运,张悦. 形状记忆合金在飞行器进气道中的应用研究进展[J]. 南京航空航天大学学报,2019,51(4): 438-448.TAN Huijun,WANG Ziyun,ZHANG Yue. Review of Applications of shape memory alloy in Inlets[J]. Journal of Nanjing University of Aeronautics and Astronautics,2019,51(4): 438-448. (in Chinese) [73] COSTANZA G,TATA M E. Shape memory alloys for aerospace, recent developments, and new applications: A short review[J]. Materials,2020,13(8): 1856.1-1856.16. [74] ASHIR M,HINDAHL J,NOCKE A,et al. Development of an adaptive morphing wing based on fiber-reinforced plastics and shape memory alloys[J]. Journal of Industrial Textiles,2020,50(1): 114-129. doi: 10.1177/1528083718823295 [75] MCKINNIS D N. Fastening apparatus having shape memory alloy actuator: US5160233 A [P]. 1992-11-03. [76] KAISER F. Shape memory alloy (SMA)[J]. Fkaiserpbworks,1998,64(1): 44-46. [77] BUSCH J D, BOKAIE M. Implementation of heaters on thermally actuated spacecraft mechanisms[R]. Cleveland, US: the 28th Aerospace Mechanisms Symposium, 1994. [78] BUSCH J D, PURDY W E, JOHNSON A D. Development of a non-explosive release device for aerospace applications[R]. Greenbelt, US : the 26th Aerospace Mechanisms Symposium, 1992. [79] RUGGERI R T, BUSSOM, R. C., AND ARBOGAST, D. J. Development of a 1/4-scale nitinol actuator for reconfigurable structures[C]// Proceedings of Industrial and Commercial Applications of Smart Structures Technologies. San Diego, US: SPIE (Society of Photo-optical Instrumentation Engineers), 2008: 69300L. 1-69300L. 12. [80] HERRINGTON J S, HODGE L H, STEIN C A, et al. Development of a twisting wing powered by a shape memory alloy actuator[R]. Kissimmee, US: the 23rd AIAA/AHS Adaptive Structures Conference AIAA Journal, 2015. [81] BENAFAN O. Spanwise adaptive wing[EB/OL]. [2022-06-29]. https://ntrs.nasa.gov/api/citations/20170009544/downloads/20170009544.pdf. [82] 王垚,李春福,林元华,等. SMA在石油工程中的应用研究进展[J]. 材料导报: 纳米与新材料专辑,2016,30(S2): 98-102,107.WANG Yao,LI Chunfu,LIN Yuanhua,et al. Research progress of application of SMA in petroleum engineering[J]. Materials Review,2016,30(S2): 98-102,107. (in Chinese) [83] TAK W,LEE M,KIM B. Ultimate load and release time controllable non-explosive separation device using a shape memory alloy actuator[J]. Journal of Mechanical Science Technology,2011,25(5): 1141-1147. doi: 10.1007/s12206-011-0304-4 [84] CARPENTER B F. Shape memory actuated release devices[C]// Proceedings of Smart Structures and Materials 1996: Industrial and Commercial Applications of Smart Structures Technologies. San Diego, US: SPIE ( Society of Photo-optical Instrumentation Engineers), 1996: 420-426. [85] PEFFER A, DENOYER K, FOSNESS E, et al. Development and transition of low-shock spacecraft release devices[C]// Proceedings of IEEE Aerospace Conference. Big Sky, US: IEEE, 2000: 277-284. [86] CARPENTER B, LYONS J. Validation report for the EO-1 lightweight flexible solar array experiment[R]. Greenbelt , US: EO-1 Technology Infusion Forum, 2001. [87] PECORA R,BARBARINO S,CONCILIO A,et al. Design and functional test of a morphing high-lift device for a regional aircraft[J]. Journal of Intelligent Material Systems Structures,2011,22(10): 1005-1023. doi: 10.1177/1045389X11414083 [88] LEAL P B,SAVI M A,HARTL D J. Aero-structural optimization of shape memory alloy-based wing morphing via a class/shape transformation approach[J]. Journal of Aerospace Engineering,2018,232(15): 2745-2759. [89] YOUN S H,JANG Y S,HAN J H,et al. Compressed mesh washer isolators using the pseudoelasticity of SMA for pyroshock attenuation[J]. Journal of Intelligent Material Systems Structures,2010,21(4): 407-421. doi: 10.1177/1045389X09355665 [90] KWON S C,JEON S H,OH H U. Performance evaluation of spaceborne cryocooler micro-vibration isolation system employing pseudoelastic SMA mesh washer[J]. Cryogenics,2015,67: 19-27. doi: 10.1016/j.cryogenics.2015.01.002 [91] [92] PADULA S, CREAGER C. Shape memory alloy (SMA) tires: a new paradigm in tire performance[R]. Akron, US: the 7th Annual Meeting and Conference on Tire Science and Technology, 2018. -

下载:

下载: