Sloshing analysis and anti-sloshing structure optimization of a wing fuel tank

-

摘要:

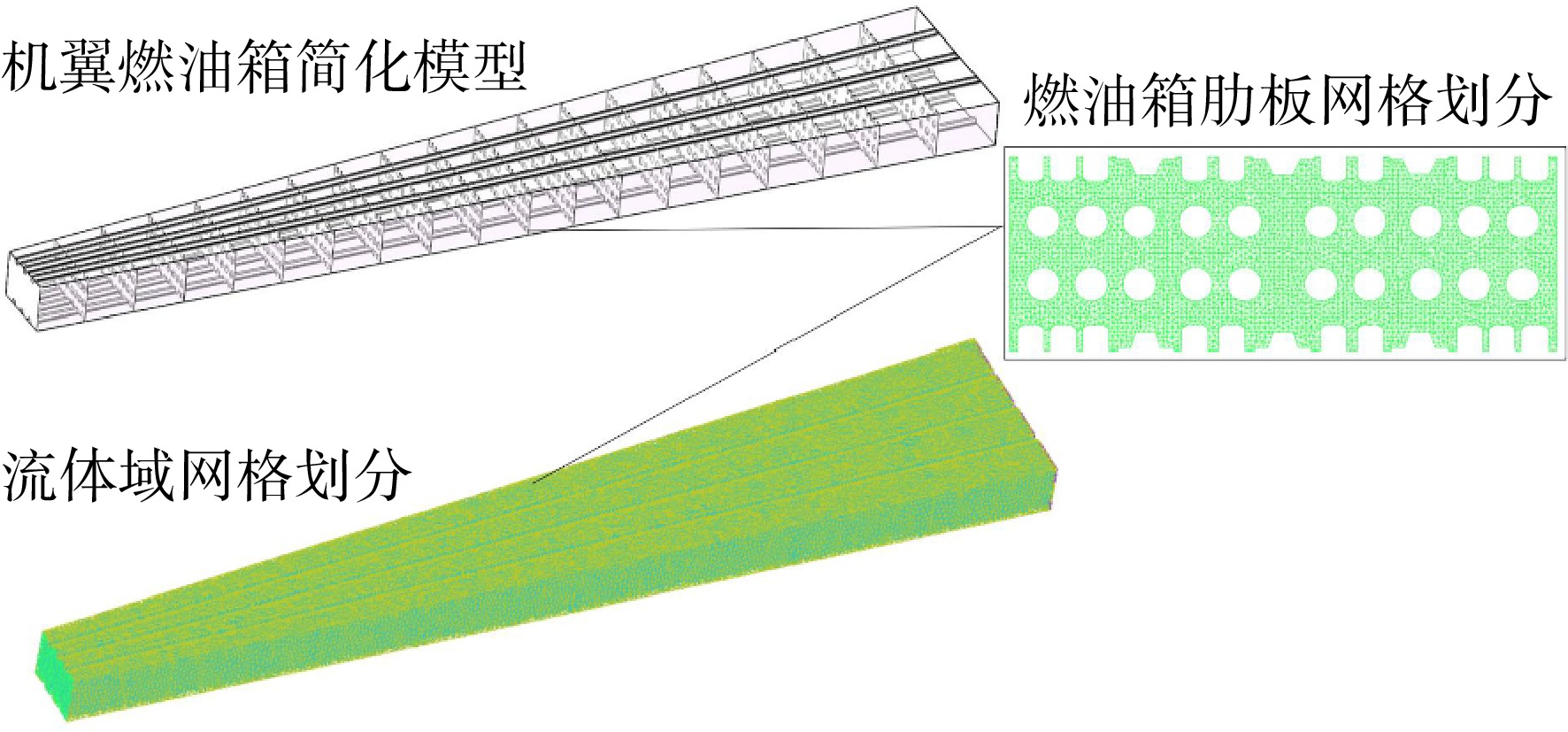

针对某型多隔仓机翼整体燃油箱,基于流体体积(VOF)方法模拟燃油晃动自由液面变化,分析了燃油箱在多工况下的燃油晃动特性;根据分析结果,选取肋板溢油口构型,串油孔直径与肋板数量为设计变量,以燃油质心相对位移幅值为优化目标,设计正交实验设计,通过极差分析与方差分析法对油箱肋板构型进行优化,得出最优肋板构型。结果表明:VOF法可以准确有效的模拟燃油流动特性,燃油箱肋板可有效抑制燃油晃动;优化肋油箱与初始油箱对比,平均燃油质心相对位移幅值降低66.54%,最大位移幅值降低46.43%;燃油质心位移得到有效控制,机翼油箱的防晃效果得到提升。

-

关键词:

- 液体晃动 /

- 机翼整体油箱 /

- 流体体积(VOF)方法 /

- 正交实验 /

- 肋板结构优化

Abstract:Volume of fluid (VOF) method was used to simulate the free level change of fuel sloshing in a multi-compartment wing fuel tank. Fuel sloshing characteristics of the tank under multiple operating conditions were analyzed. According to the analysis results, the rib spill port configuration, the diameter of oil strings and the number of ribs were selected as design variables, and the relative displacement amplitude of fuel mass center was taken as the optimization objective to design the orthogonal experimental design. The rib configuration of the tank was optimized by range analysis and ANOVA, and the optimal rib configuration was obtained. The results showed that VOF method can accurately and effectively simulate the fuel flow characteristics, and the fuel tank rib can effectively restrain fuel sloshing. By comparing the optimized rib tank with the initial tank, the average relative displacement of the fuel mass center was reduced by 66.54% and the maximum displacement by 46.43%. The displacement of fuel mass center was effectively controlled and the anti-sloshing effect of wing tank was improved.

-

表 1 实验因素及水平

Table 1. Experimental factors and level

因素 参数 水平1 水平2 水平3 X1(因素A) 溢油口构型 宽体 窄体 传统 X2(因素B) 串油孔直径/mm 70 90 110 X3(因素C) 肋板数量 18 16 14 表 2 正交实验设计及仿真计算结果

Table 2. Orthogonal experimental design and simulation calculation results

试验号 因素水平 误差列 燃油质心相对

位移幅值y因素A 因素B 因素C 1 1 1 1 1 0.4741 2 1 2 3 2 0.6074 3 1 3 2 3 0.4185 4 2 1 3 3 0.6684 5 2 2 2 2 0.3528 6 2 3 1 1 0.3986 7 3 1 2 2 0.3750 8 3 2 1 1 0.4011 9 3 3 3 3 0.6525 表 3 正交实验极差分析表

Table 3. Range analysis of orthogonal experimental

参数 因素A 因素B 因素C 误差列 K1 1.5000 1.5175 1.2738 1.2738 K2 1.4198 1.3613 1.1463 1.3352 K3 1.4286 1.4696 1.9283 1.7394 $\bar K_1 $ 0.5000 0.5058 0.4246 0.4246 $\bar K_2 $ 0.4732 0.4538 0.3821 0.4451 $\bar K_3 $ 0.4762 0.4899 0.6428 0.5798 R 0.0267 0.0521 0.2607 0.1552 表 4 正交实验方差分析表

Table 4. Variance analysis of orthogonal experiments

方差来源 离差平方和 自由度 均方差 F P Fcrit 因素A 0.001 2 0.0005 0.381123 0.724048 19 因素B 0.0043 2 0.0021 1.617216 0.382085 19 因素C 0.1174 2 0.0587 44.45443 0.022 19 误差/组内 0.0026 2 0.0013 综合 0.1253 8 -

[1] RAFIEE A,PISTANI F,THIAGARAJAN K. Study of liquid sloshing: numerical and experimental approach[J]. Computational Mechanics,2011,47(1): 65-75. doi: 10.1007/s00466-010-0529-6 [2] DELORME L,COLAGROSSI A,SOUTO-IGLESIAS A,et al. A set of canonical problems in sloshing,Part I: Pressure field in forced roll-comparison between experimental results and SPH[J]. Ocean Engineering,2009,36(2): 168-178. doi: 10.1016/j.oceaneng.2008.09.014 [3] SOUTO-IGLESIAS A,BOTIA-VERA E,MARTÍN A,et al. A set of canonical problems in sloshing. Part 0: experimental setup and data processing[J]. Ocean Engineering,2011,38(16): 1823-1830. doi: 10.1016/j.oceaneng.2011.09.008 [4] SOUTO-IGLESIAS A,BULIAN G,BOTIA-VERA E. A set of canonical problems in sloshing. Part 2: influence of tank width on impact pressure statistics in regular forced angular motion[J]. Ocean Engineering,2015,105: 136-159. doi: 10.1016/j.oceaneng.2015.06.016 [5] 张健,方杰,范波芹. VOF方法理论与应用综述[J]. 水利水电科技进展,2005,25(2): 67-70. ZHANG Jian,FANG Jie,FAN Boqin. Advances in research of VOF method[J]. Advances in Science and Technology of Water Resources,2005,25(2): 67-70. (in Chinese ZHANG Jian, FANG Jie, FAN Boqin . Advances in research of VOF method[J]. Advances in Science and Technology of Water Resources,2005 ,25 (2 ):67 -70 . (in Chinese)[6] 晋永华,厉彦忠,王磊,等. 简谐激励下大型低温贮箱防晃设计[J]. 航空动力学报,2015,30(6): 1478-1485. JIN Yonghua,LI Yanzhong,WANG Lei,et al. Design of slosh baffle in large cryogenic tank under harmonic excitation[J]. Journal of Aerospace Power,2015,30(6): 1478-1485. (in Chinese JIN Yonghua, LI Yanzhong, WANG Lei, et al . Design of slosh baffle in large cryogenic tank under harmonic excitation[J]. Journal of Aerospace Power,2015 ,30 (6 ):1478 -1485 . (in Chinese)[7] 袁雄飞. 基于VOF方法的机翼油箱燃油晃动分析与防晃研究[D]. 哈尔滨: 哈尔滨工业大学,2017. YUAN Xiongfei. Research of fuel sloshing in aircraft wing tank based on VOF method and sloshing suppression[D]. Harbin: Harbin Institute of Technology,2017. (in ChineseYUAN Xiongfei. Research of fuel sloshing in aircraft wing tank based on VOF method and sloshing suppression[D]. Harbin: Harbin Institute of Technology, 2017. (in Chinese) [8] CAVALAGLI N,BISCARINI C,FACCI A L,et al. Experimental and numerical analysis of energy dissipation in a sloshing absorber[J]. Journal of Fluids and Structures,2017,68: 466-481. doi: 10.1016/j.jfluidstructs.2016.11.020 [9] LYU Wenjing,EL MOCTAR O,POTTHOFF R,et al. Experimental and numerical investigation of sloshing using different free surface capturing methods[J]. Applied Ocean Research,2017,68: 307-324. doi: 10.1016/j.apor.2017.09.008 [10] 杨唱,孙冰,方杰. 航天器贮箱出流过程液体晃动及防晃[J]. 航空动力学报,2018,33(12): 3065-3072. YANG Chang,SUN Bing,FANG Jie. Liquid sloshing and anti-sloshing of spacecraft tank during outflow[J]. Journal of Aerospace Power,2018,33(12): 3065-3072. (in Chinese doi: 10.13224/j.cnki.jasp.2018.12.029 YANG Chang, SUN Bing, FANG Jie . Liquid sloshing and anti-sloshing of spacecraft tank during outflow[J]. Journal of Aerospace Power,2018 ,33 (12 ):3065 -3072 . (in Chinese) doi: 10.13224/j.cnki.jasp.2018.12.029[11] SAGHI H,MIKKOLA T,HIRDARIS S. The influence of obliquely perforated dual-baffles on sway induced tank sloshing dynamics[J]. Proceedings of the Institution of Mechanical Engineers,Part M: Journal of Engineering for the Maritime Environment,2021,235(4): 905-920. [12] 张恩慧,何仁,苏卫东. 不同挡板结构对油箱内油液晃动特性的数值分析[J]. 吉林大学学报(工学版),2021,51(1): 83-95. ZHANG Enhui,HE Ren,SU Weidong. Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures[J]. Journal of Jilin University (Engineering and Technology Edition),2021,51(1): 83-95. (in Chinese ZHANG Enhui, HE Ren, SU Weidong . Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures[J]. Journal of Jilin University (Engineering and Technology Edition),2021 ,51 (1 ):83 -95 . (in Chinese)[13] 张凯凯. 基于SPH方法的液舱内液体晃动分析及防晃研究[D]. 哈尔滨: 哈尔滨工业大学,2016. ZHANG Kaikai. Analysis and research of the liquid sloshing and sloshing suppression intanks based on sph method[D]. Harbin: Harbin Institute of Technology,2016. (in ChineseZHANG Kaikai. Analysis and research of the liquid sloshing and sloshing suppression intanks based on sph method[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [14] 杨瑞. 基于ALE有限元法的飞机整体油箱燃油晃动特性研究[D]. 哈尔滨: 哈尔滨工业大学,2016. YANG Rui. Research of fuel sloshing in aircraft integral tanks by the ALE finite element method[D]. Harbin: Harbin Institute of Technology,2016. (in ChineseYANG Rui. Research of fuel sloshing in aircraft integral tanks by the ALE finite element method[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [15] 邹喜聪. 飞机机身油箱燃油晃动分析[D]. 哈尔滨: 哈尔滨工业大学,2012. ZOU Xicong. Fuel sloshing analysis in tanks of aircraft[D]. Harbin: Harbin Institute of Technology,2012. (in ChineseZOU Xicong. Fuel sloshing analysis in tanks of aircraft[D]. Harbin: Harbin Institute of Technology, 2012. (in Chinese) [16] 刘富. 贮箱内液体晃动动力学分析及结构防晃技术研究[D]. 南京: 南京航空航天大学,2010. LIU Fu. Dynamic analysis of liquid sloshing and sloshing suppression design for a tank[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2010. (in ChineseLIU Fu. Dynamic analysis of liquid sloshing and sloshing suppression design for a tank[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010. (in Chinese) [17] 曾宇,汪洪波,孙明波,等. SST湍流模型改进研究综述[J]. 航空学报,2023,44(9): 103-134. ZENG Yu,WANG Hongbo,SUN Mingbo,et al. SST turbulence model improvements: review[J]. Acta Aeronautica et Astronautica Sinica,2023,44(9): 103-134. (in Chinese ZENG Yu, WANG Hongbo, SUN Mingbo, et al . SST turbulence model improvements: review[J]. Acta Aeronautica et Astronautica Sinica,2023 ,44 (9 ):103 -134 . (in Chinese)[18] 中国民用航空局. 运输类飞机适航标准: CCAR-25-R4[S]. 北京: 航空工业出版社,2011: 106-110. Civil Aviation Administration of China. Airworthiness standard for transport aircraft: CCAR-25-R4 [S]. Beijing: Aviation Industry Press, 2011:106-110. (in ChineseCivil Aviation Administration of China. Airworthiness standard for transport aircraft: CCAR-25-R4 [S]. Beijing: Aviation Industry Press, 2011:106-110. (in Chinese) [19] SEBERRY J. Orthogonal designs[M]. Berlin,Germany: Springer,2017. -

下载:

下载: