Analysis of vibration characteristics of inter-shaft bearing with local defects based on multi-body dynamics

-

摘要:

为研究中介轴承存在局部缺陷时的振动特性及接触应力,基于多体动力学方法建立了中介轴承单点及复合故障二维全柔性动力学模型。应用该模型分析了中介轴承存在局部缺陷时的时频分布特性及接触应力变化规律,并与基于非线性Hertz接触理论的集中参数模型和实验测试结果进行对比分析,验证了多体动力学模型的准确性。研究结果表明:依据所建模型求得的故障特征频率与集中参数模型和实验结果误差均小于1%。轴承的等效应力最大值出现在故障裂痕处,且向四周扩散并减小;轴承承载区内的应力明显高于非承载区,应力变化的时间间隔为中介轴承故障特征频率基频的倒数。

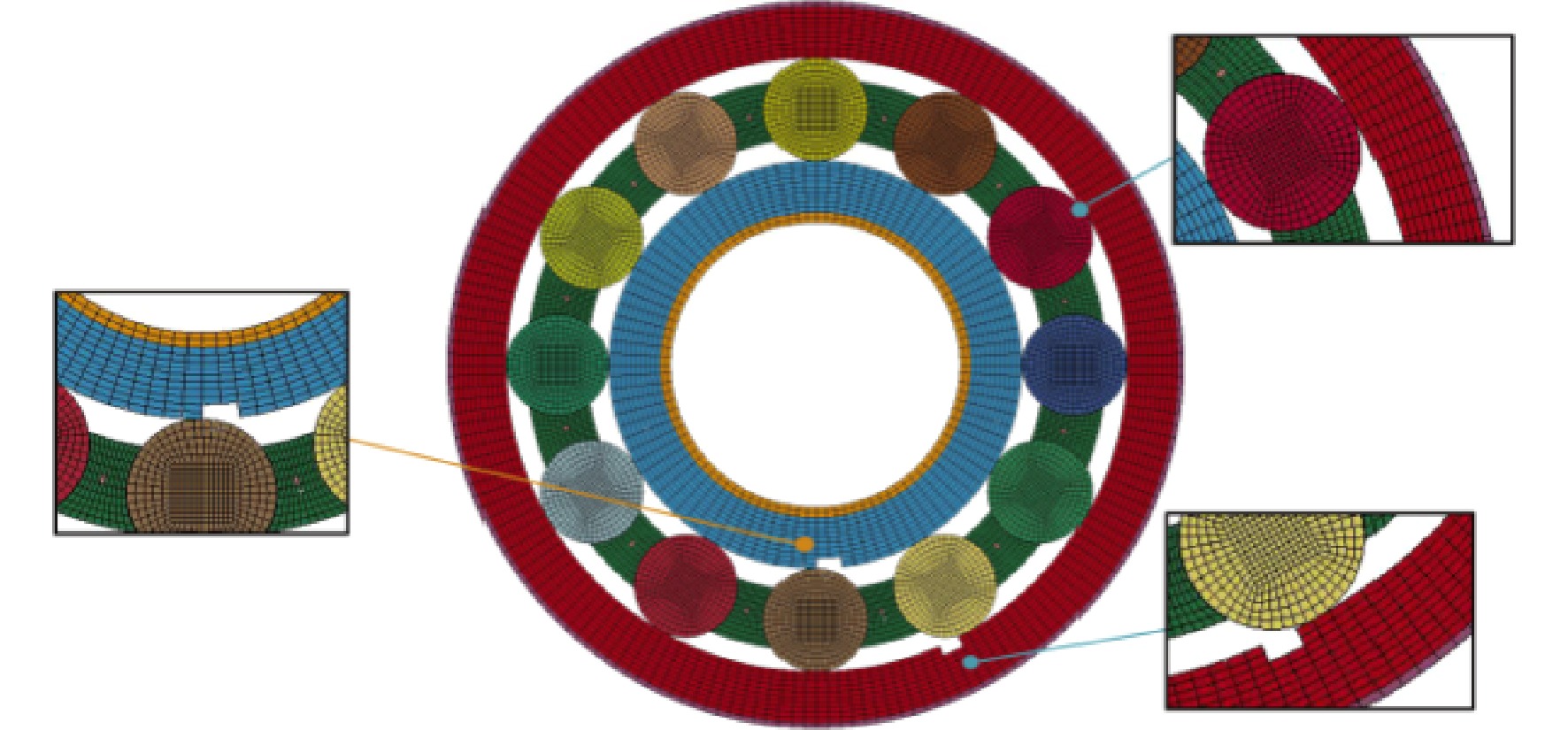

Abstract:In order to study the vibration characteristics and contact stress of an inter-shaft bearing with local defects, a two-dimensional fully flexible dynamic model of the inter-shaft bearing with single and compound faults was established based on the multi-body dynamics method. With this model, the time-frequency distribution characteristics and contact stress variation law of the inter-shaft bearing with local defects were analyzed. Compared with the lumped parameter model based on nonlinear Hertz contact theory and the experimental results, the accuracy of the multi-body dynamics model was verified. The research results showed that the error between the fault characteristic frequency obtained based on the established model and the lumped parameter model and the experimental results was less than 1%. The maximum value of the equivalent contact stress of the bearing appeared at the fault crack, spread around and reduced; the contact stress in the bearing area was significantly higher than that in the non bearing area, and the time interval of the change of the equivalent stress was the reciprocal of the fundamental frequency of the inter-shaft bearing fault characteristic frequency.

-

Key words:

- inter-shaft bearing /

- multi-point faults /

- multi-body dynamics /

- contact stress /

- fault characteristics

-

表 1 中介轴承模型参数

Table 1. Inter-shaft bearing model parameters

参数 数值 内圈直径/mm 15 外圈直径/mm 35 节圆直径/mm 25 滚子直径/mm 5 滚子数目 11 接触角/(°) 0 径向间隙/μm 12 结构阻尼系数/(N·s/m) 300 表 2 各部件材料参数

Table 2. Material parameters of each component

轴承元件 密度/

(kg/m3)泊松比 弹性模量/

MPa内圈、外圈、滚子 7830 0.3 206 保持架 8500 0.324 105 表 3 轴承接触对系数

Table 3. Bearing contact pair coefficient

接触部件 接触类型 $ {F_{\text{s}}} $ $ {F_{\text{d}}} $ 内圈与滚子 面-面(自动ASTS) 0.1 0.05 外圈与滚子 面-面(自动ASTS) 0.1 0.05 保持架与滚子 面-面(自动ASTS) 0.05 0.02 表 4 中介轴承理论故障特征频率

Table 4. Characteristic frequency of theoretical failure of inter-shaft bearing

参数 故障类型 外圈故障 内圈故障 特征频率/Hz 80.67 121 -

[1] TANDON N,CHOUDHURY A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings[J]. Tribology International,1999,32(8): 469-480. doi: 10.1016/S0301-679X(99)00077-8 [2] JONES A B. Ball motion and sliding friction in ball bearings[J]. Journal of Basic Engineering,1959,81(1): 1-12. doi: 10.1115/1.4008346 [3] JONES A B. A general theory for elastically constrained ball and radial roller bearings under arbitrary load and speed conditions[J]. Wear,1960,3(6): 484. [4] GUPTA P K,PAUL B. Advanced dynamics of rolling elements[J]. Journal of Applied Mechanics,1986,53(3): 731-732. [5] GUPTA P K. On the geometrical imperfections in cylindrical roller bearings[J]. Journal of Tribology,1988,110(1): 13-18. doi: 10.1115/1.3261553 [6] PATIL M S,MATHEW J,RAJENDRAKUMAR P K,et al. A theoretical model to predict the effect of localized defect on vibrations associated with ball bearing[J]. International Journal of Mechanical Sciences,2010,52(9): 1193-1201. doi: 10.1016/j.ijmecsci.2010.05.005 [7] LIU Jing. A dynamic modelling method of a rotor-roller bearing-housing system with a localized fault including the additional excitation zone[J]. Journal of Sound and Vibration,2020,469: 115144. doi: 10.1016/j.jsv.2019.115144 [8] 陈果. 含复杂滚动轴承建模的航空发动机整机振动耦合动力学模型[J]. 航空动力学报,2017,32(9): 2193-2204. CHEN Guo. Whole aero-engine vibration coupling dynamics model including modeling of complex ball and roller bearings[J]. Journal of Aerospace Power,2017,32(9): 2193-2204. (in Chinese CHEN Guo . Whole aero-engine vibration coupling dynamics model including modeling of complex ball and roller bearings[J]. Journal of Aerospace Power,2017 ,32 (9 ):2193 -2204 . (in Chinese)[9] CHEN Aoyu,KURFESS T R. A new model for rolling element bearing defect size estimation[J]. Measurement,2018,114: 144-149. doi: 10.1016/j.measurement.2017.09.018 [10] 徐可君,董芳华,秦海勤. 内圈带缺陷中介轴承的动力学建模与振动响应分析[J]. 海军航空工程学院学报,2015,30(1): 36-42. XU Kejun,DONG Fanghua,QIN Haiqin. Dynamics model and vibration response analysis of defect inner ring of intershaft bearing[J]. Journal of Naval Aeronautical and Astronautical University,2015,30(1): 36-42. (in Chinese XU Kejun, DONG Fanghua, QIN Haiqin . Dynamics model and vibration response analysis of defect inner ring of intershaft bearing[J]. Journal of Naval Aeronautical and Astronautical University,2015 ,30 (1 ):36 -42 . (in Chinese)[11] 田晶,王志,张凤玲,等. 中介轴承外圈故障动力学建模及仿真分析[J]. 推进技术,2019,40(3): 660-666. TIAN Jing,WANG Zhi,ZHANG Fengling,et al. Dynamic modeling and simulation analysis on outer race fault of inter-shaft bearing[J]. Journal of Propulsion Technology,2019,40(3): 660-666. (in Chinese TIAN Jing, WANG Zhi, ZHANG Fengling, et al . Dynamic modeling and simulation analysis on outer race fault of inter-shaft bearing[J]. Journal of Propulsion Technology,2019 ,40 (3 ):660 -666 . (in Chinese)[12] 贾丰瑞,张保强,冯吴俊,等. 基于谐振器激励的轴承故障动力学建模研究[J]. 应用力学学报,2022,39(3): 482-489,497. JIA Fengrui,ZHANG Baoqiang,FENG Wujun,et al. Dynamic modeling method of bearing fault based on resonance changer excitation[J]. Chinese Journal of Applied Mechanics,2022,39(3): 482-489,497. (in Chinese JIA Fengrui, ZHANG Baoqiang, FENG Wujun, et al . Dynamic modeling method of bearing fault based on resonance changer excitation[J]. Chinese Journal of Applied Mechanics,2022 ,39 (3 ):482 -489, 497 . (in Chinese)[13] MCFADDEN P D,SMITH J D. Model for the vibration produced by a single point defect in a rolling element bearing[J]. Journal of Sound and Vibration,1984,96(1): 69-82. doi: 10.1016/0022-460X(84)90595-9 [14] ZHAO Hua. Analysis of load distributions within solid and hollow roller bearings[J]. Journal of Tribology,1998,120(1): 134-139. doi: 10.1115/1.2834176 [15] KUNC R,PREBIL I. Numerical determination of carrying capacity of large rolling bearings[J]. Journal of Materials Processing Technology,2004,155/156: 1696-1703. doi: 10.1016/j.jmatprotec.2004.04.125 [16] 李国超,彭炜,李勇才,等. 滚动轴承外圈故障的显式有限元动态仿真分析[J]. 中国机械工程,2012,23(23): 2825-2829. LI Guochao,PENG Wei,LI Yongcai,et al. Simulation and dynamic analysis of outer ring fault on rolling bearings using explicit finite element method[J]. China Mechanical Engineering,2012,23(23): 2825-2829. (in Chinese LI Guochao, PENG Wei, LI Yongcai, et al . Simulation and dynamic analysis of outer ring fault on rolling bearings using explicit finite element method[J]. China Mechanical Engineering,2012 ,23 (23 ):2825 -2829 . (in Chinese)[17] SINGH S,KÖPKE U G,HOWARD C Q,et al. Analyses of contact forces and vibration response for a defective rolling element bearing using an explicit dynamics finite element model[J]. Journal of Sound and Vibration,2014,333(21): 5356-5377. doi: 10.1016/j.jsv.2014.05.011 [18] 杨子臻,左彦飞,邵化金,等. 基于显式有限元的转子不平衡与轴承故障耦合分析[J]. 轴承,2021(2): 8-13,16. YANG Zizhen,ZUO Yanfei,SHAO Huajin,et al. Analysis on coupling between rotor unbalance and bearing fault based on explicit finite element[J]. Bearing,2021(2): 8-13,16. (in Chinese YANG Zizhen, ZUO Yanfei, SHAO Huajin, et al . Analysis on coupling between rotor unbalance and bearing fault based on explicit finite element[J]. Bearing,2021 (2 ):8 -13, 16 . (in Chinese)[19] 涂文兵,杨本梦,杨锦雯,等. 考虑滚动轴承故障处塑性变形的有限元建模与动力学特性分析[J]. 西安交通大学学报,2022,56(5): 85-94. TU Wenbing,YANG Benmeng,YANG Jinwen,et al. Finite element modeling and dynamic characteristics analysis with plastic deformation at rolling bearing failure considered[J]. Journal of Xi’an Jiaotong University,2022,56(5): 85-94. (in Chinese TU Wenbing, YANG Benmeng, YANG Jinwen, et al . Finite element modeling and dynamic characteristics analysis with plastic deformation at rolling bearing failure considered[J]. Journal of Xi’an Jiaotong University,2022 ,56 (5 ):85 -94 . (in Chinese)[20] 丁东升,刘永强,杨绍普. 外圈滚道剥离故障对滚动轴承动力学响应的影响分析[J]. 振动与冲击,2022,41(8): 141-148,216. DING Dongsheng,LIU Yongqiang,YANG Shaopu. Analysis of the influence of outer ring raceway peeling fault on the dynamic response of a rolling bearing[J]. Journal of Vibration and Shock,2022,41(8): 141-148,216. (in Chinese DING Dongsheng, LIU Yongqiang, YANG Shaopu . Analysis of the influence of outer ring raceway peeling fault on the dynamic response of a rolling bearing[J]. Journal of Vibration and Shock,2022 ,41 (8 ):141 -148, 216 . (in Chinese) -

下载:

下载: