Influence of injector structure details on mixing characteristics of continuous detonation engine

-

摘要:

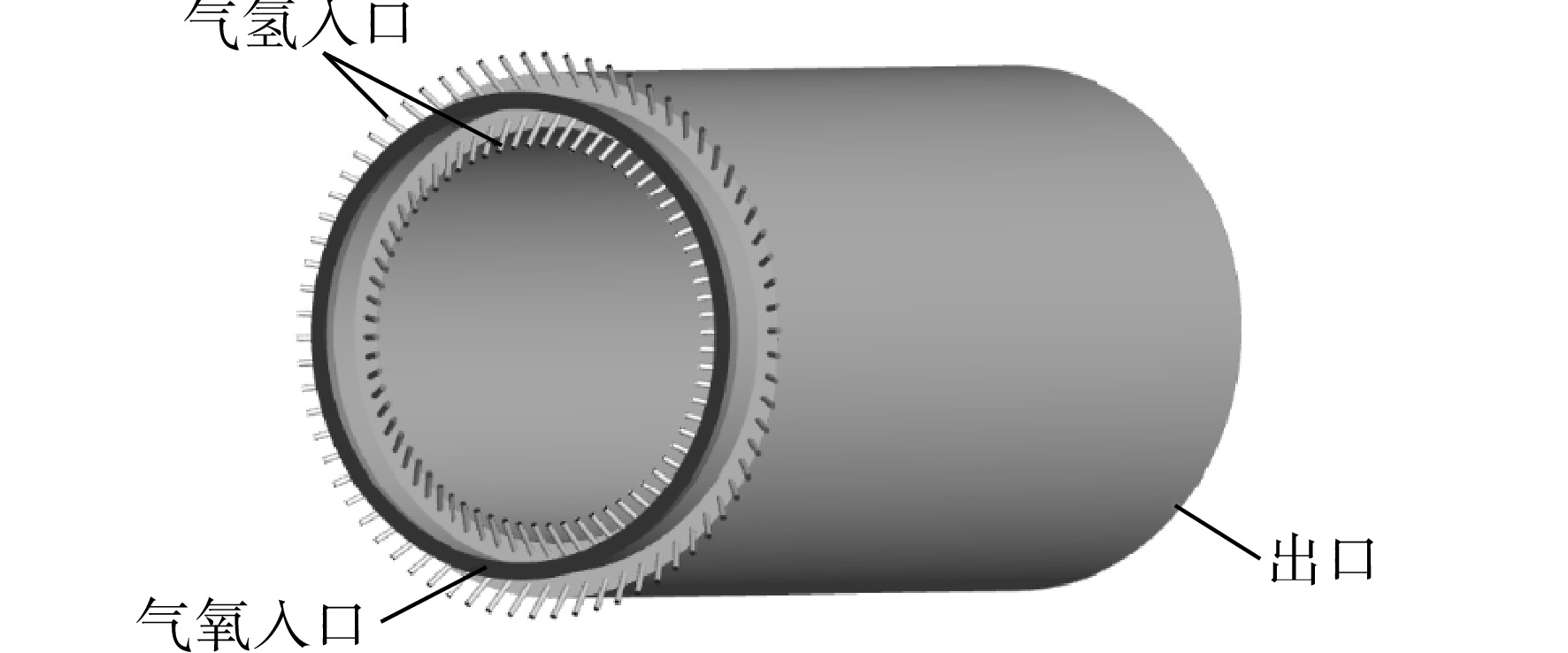

为研究不同喷嘴结构细节对气氢/气氧连续爆轰发动机冷态掺混特性的影响,采用商业软件Fluent对其冷态掺混流场进行了数值仿真研究。以环缝-喷孔式喷注结构为基础,设计了12种不同喷嘴结构的连续爆轰发动机,研究了在入口条件相同的情况下,不同气氧喷嘴出口扩张角、不同气氢喷注角度、不同气氢喷嘴出口扩张角以及单双侧喷注对掺混特性的影响。结果表明:气氧喷嘴出口扩张角在0°~20°范围内,掺混效果呈现先下降后上升的趋势,气氧喷嘴出口扩张角最佳值为20°;气氢喷注角度在30°~90°范围内,掺混效果呈现先上升后下降的趋势,气氢喷注角度最佳值为45°;在0°~10°范围内,增大气氢喷嘴出口扩张角使得掺混效果下降;气氢双侧喷注的掺混效果明显优于单侧喷注。

Abstract:In order to study the influence of different injector structure details on the cold mixing characteristics of GH2/GO2 continuous detonation engine, the cold flow field of GH2/GO2 continuous detonation engine was numerically simulated with commercial software Fluent. Based on the annular-hole injector structure, 12 different engines with different injector structures were designed. The influences of different oxygen injector outlet expansion angles, different hydrogen injection angles, different hydrogen injector outlet expansion angles, and unilateral injection on the mixing characteristics were studied under the same inlet conditions. The results showed that the mixing effect decreased first and then increased when the expansion angle of oxygen injector outlet was within the range of 0°−20°, and the optimum expansion angle was 20°. When the hydrogen injection angle was within the range of 30°−90°, the mixing effect increased first and then decreased, and the optimal injection angle was 45°. Within the range of 0°−10°, increasing the expansion angle of the hydrogen injector outlet reduced the mixing effect. The mixing effect of gas-hydrogen bilateral injection was obviously better than that of unilateral injection.

-

表 1 不同发动机喷注器结构尺寸

Table 1. Structure dimension of different engine injectors

编号 α/(°) β/(°) γ/(°) 喷注方式 1 0 45 0 双侧 2 5 45 0 双侧 3 10 45 0 双侧 4 15 45 0 双侧 5 20 45 0 双侧 6 20 30 0 双侧 7 20 60 0 双侧 8 20 90 0 双侧 9 20 45 5 双侧 10 20 45 10 双侧 11 20 45 0 外侧 12 20 45 0 内侧 -

[1] 王健平, 姚松柏. 连续爆轰发动机原理与技术[M]. 北京: 科学出版社, 2018. [2] 谢峤峰,王兵,董琨. 基于连续旋转爆震的推进技术研究进展[J]. 气体物理,2020,5(1): 1-23.XIE Qiaofeng,WANG Bing,DONG Kun. Progress in research of rotating detonation propulsion[J]. Physics of Gases,2020,5(1): 1-23. (in Chinese) [3] 王兵,谢峤峰,闻浩诚,等. 爆震发动机研究进展[J]. 推进技术,2021,42(4): 721-737, 716.WANG Bing,XIE Qiaofeng,WEN Haocheng,et al. Research progress of detonation engines[J]. Journal of Propulsion Technology,2021,42(4): 721-737, 716. (in Chinese) [4] FROLOV S M,AKSENOV V S,DUBROVSKII A V,et al. Energy efficiency of a continuous-detonation combustion chamber[J]. Combustion, Explosion, and Shock Waves,2015,51(2): 232-245. doi: 10.1134/S0010508215020070 [5] SCHWER D, KAILASANATH K. Numerical study of the effects of engine size on rotating detonation engines[R]. AIAA 2011-581, 2011 [6] YI T H,LOU Jing,TURANGAN C,et al. Propulsive performance of a continuously rotating detonation engine[J]. Journal of Propulsion and Power,2011,27(1): 171-181. doi: 10.2514/1.46686 [7] 刘世杰,林志勇,孙明波,等. 旋转爆震波发动机二维数值模拟[J]. 推进技术,2010,31(5): 634-640.LIU Shijie,LIN Zhiyong,SUN Mingbo,et al. Two-dimensional numerical simulation of rotating detonation wave engine[J]. Journal of Propulsion Technology,2010,31(5): 634-640. (in Chinese) [8] 武丹,刘岩,王健平. 连续旋转爆轰发动机参数特性的三维数值模拟[J]. 航空动力学报,2015,30(7): 1576-1582.WU Dan,LIU Yan,WANG Jianping. Three-dimensional numerical simulation of the parametric properties of continuously rotating detonation engine[J]. Journal of Aerospace Power,2015,30(7): 1576-1582. (in Chinese) [9] YAO S,HAN X,LIU Y,et al. Numerical study of rotating detonation engine with an array of injection holes[J]. Shock Waves,2017,27(3): 467-476. doi: 10.1007/s00193-016-0692-6 [10] 刘倩,郑洪涛,李智明,等. 连续旋转爆轰燃烧室的性能[J]. 航空动力学报,2015,30(6): 1328-1336.LIU Qian,ZHENG Hongtao,LI Zhiming,et al. Performance of continuously rotating detonation combustor[J]. Journal of Aerospace Power,2015,30(6): 1328-1336. (in Chinese) [11] TANG Xinmeng,WANG Jianping,SHAO Yetao. Three-dimensional numerical investigations of the rotating detonation engine with a hollow combustor[J]. Combustion and Flame,2015,162(4): 997-1008. doi: 10.1016/j.combustflame.2014.09.023 [12] 孙健,周进,林志勇,等. 燃烧室轴向长度对旋转爆震发动机性能的影响[J]. 航空动力学报,2016,31(9): 2080-2086.SUN Jian,ZHOU Jin,LIN Zhiyong,et al. Influence of chamber length on rotating detonation engine performance[J]. Journal of Aerospace Power,2016,31(9): 2080-2086. (in Chinese) [13] 祁磊,赵宁波,郑洪涛,等. 当量比对连续旋转爆轰燃烧室特性的影响[J]. 航空动力学报,2018,33(11): 2703-2713.QI Lei,ZHAO Ningbo,ZHENG Hongtao,et al. Influence of equivalence ratio on characteristics of continuously rotating detonation combustor[J]. Journal of Aerospace Power,2018,33(11): 2703-2713. (in Chinese) [14] MENG Qingyang,ZHAO Ningbo,ZHENG Hongtao,et al. A numerical study of rotating detonation wave with different numbers of fuel holes[J]. Aerospace Science and Technology,2019,93: 105301. doi: 10.1016/j.ast.2019.105301 [15] ZHENG Hongtao,MENG Qingyang,ZHAO Ningbo,et al. Numerical investigation on H2/Air non-premixed rotating detonation engine under different equivalence ratios[J]. International Journal of Hydrogen Energy,2020,45: 2289-2307. doi: 10.1016/j.ijhydene.2019.11.014 [16] ZHAO Majie,ZHANG Huangwei. Large eddy simulation of non-reacting flow and mixing fields in a rotating detonation engine[J]. Fuel,2020,280: 118534. doi: 10.1016/j.fuel.2020.118534 [17] 周蕊,李晓鹏. 连续旋转爆轰发动机冷流场的混合特性研究[J]. 航空学报,2016,37(12): 3668-3674.ZHOU Rui,LI Xiaopeng. Numerical investigation of mixing characteristic of cold continuously rotating detonation engine[J]. Acta Aeronautica et Astronautica Sinica,2016,37(12): 3668-3674. (in Chinese) [18] 戴勇强. 氢气/空气非预混喷注及旋转爆轰燃烧数值模拟研究[D]. 哈尔滨: 哈尔滨工程大学, 2021.DAI Yongqiang. Numerical study of hydrogen/air injection and rotating detonation combustion under non-premixed condition[D]. Harbin: Harbin Engineering University, 2021. (in Chinese) -

下载:

下载: