Flow field in clearance of dynamic pressure gas foil bearing withpartical slip

-

摘要:

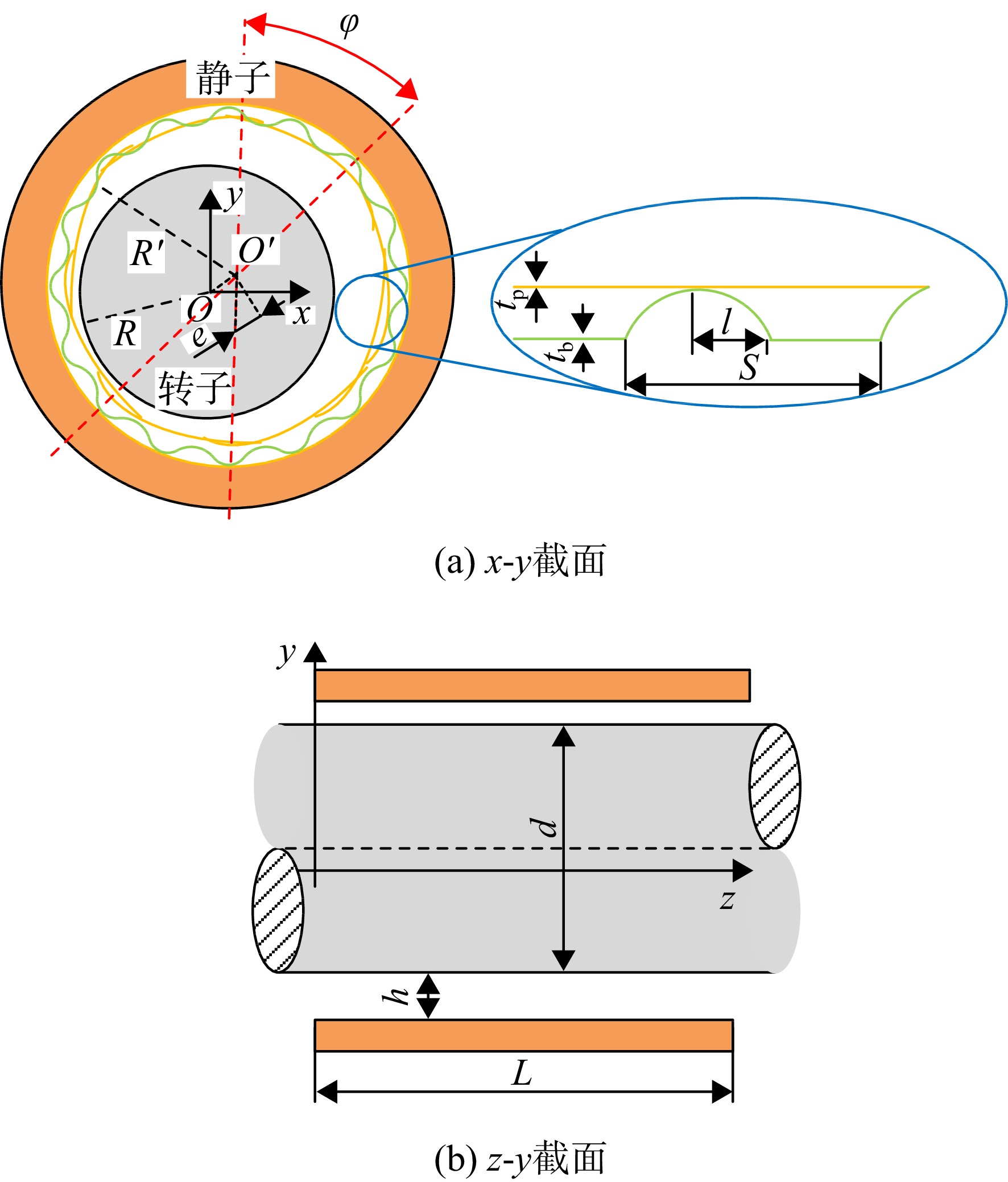

为揭示界面滑移对动压气体轴承间隙流场的影响机理,以波箔型动压气体径向轴承为研究对象,建立周向非一致滑移修正雷诺方程并采用超松弛迭代法进行求解,分析了转速、偏心率、间隙高度和箔片变形等因素变化下滑移对轴承间隙内流场的影响。结果表明:随着转速的增大或间隙高度的减小,流固界面由无滑移状态转变为静子侧滑移状态,并最终达到两侧均滑移状态,转子侧从压力上升区、静子侧从压力下降区向两侧滑移区域面积和速度逐渐增大;而偏心率的增大仅会导致滑移速度增大,而滑移区域面积几乎不变;箔片变形使滑移速度场呈现阶梯状分布。非一致滑移对最高气膜压力最大影响可达17%。速度梯度和压力场显著变化诱导界面剪应力和极限剪应力复杂演化而产生上述规律。

Abstract:In order to reveal the effects of the slip state on the flow field evolution under different working conditions of the dynamic pressure gas foil bearing, taking the dynamic pressure gas foil bearing as the research object, the modified Reynolds equation for circumferential partial slip was established and solved by the over-relaxation iteration method. The influence of slip on the flow field in the bearing clearance was analyzed under the change of rotating speed, eccentricity, clearance height and foil deformation. The results showed that with the increase of rotating speed or the decrease of clearance height, the fluid-solid interface changed from no slip state to the stator side slip state, and finally reached the slip state at both sides. The area and velocity of the slip region on the rotor side from the pressure rise region and the stator side from the pressure drop region to both sides gradually increased. However, as the eccentricity increased, the slip velocity on both sides increased gradually, and the slip area was almost unchanged. The deformation of the foil caused the slip velocity field to exhibit a stepped distribution. Partial slip had a maximum effect of 17% on the highest film pressure. The reason for the above law is that the changes of velocity gradient and pressure field make the interface shear stress and ultimate shear stress change complexly.

-

Key words:

- dynamic pressure gas bearing /

- microscale /

- foil /

- interface slip /

- flow field

-

表 1 计算工况

Table 1. Calculation conditions

参数 数值 间隙高度c/µm 40~160 转速N/104 (r/min) 4~13 偏心率ε 0.2~0.8 箔片数量M 8 长径比L/d 0.8 转子半径R/mm 30 平箔厚度tp/µm 76.2 波箔厚度tb/µm 76.2 单位波箔长度S/mm 4.064 单位波长跨度2l/mm 3.434 弹性模量Et/GPa 207 -

[1] ZHANG Chuanbing,AO Hongrui,JIANG Hongyuan. Static and dynamic bearing performances of hybrid gas dynamic bearings[J]. Tribology International,2021,160: 107036. doi: 10.1016/j.triboint.2021.107036 [2] 冯凯,张俊,王法义. 径向间隙及加工工艺对气体箔片轴承性能的影响[J]. 航空动力学报,2016,31(11): 2773-2780. FENG Kai,ZHANG Jun,WANG Fayi. Influence of radial clearance and processing technology on structural properties of gas foil bearing[J]. Journal of Aerospace Power,2016,31(11): 2773-2780. (in Chinese doi: 10.13224/j.cnki.jasp.2016.11.028 FENG Kai, ZHANG Jun, WANG Fayi . Influence of radial clearance and processing technology on structural properties of gas foil bearing[J]. Journal of Aerospace Power,2016 ,31 (11 ):2773 -2780 . (in Chinese) doi: 10.13224/j.cnki.jasp.2016.11.028[3] 康伟,张家忠,刘雁,等. 气体动压轴承-转子动力系统稳定性及分岔[J]. 航空动力学报,2007,22(9): 1537-1543. KANG Wei,ZHANG Jiazhong,LIU Yan,et al. Stability and bifurcation of symmetrical rotor in self-acting gas journal bearings[J]. Journal of Aerospace Power,2007,22(9): 1537-1543. (in Chinese doi: 10.3969/j.issn.1000-8055.2007.09.023 KANG Wei, ZHANG Jiazhong, LIU Yan, et al . Stability and bifurcation of symmetrical rotor in self-acting gas journal bearings[J]. Journal of Aerospace Power,2007 ,22 (9 ):1537 -1543 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2007.09.023[4] BAIR S,WINER W O. Shear strength measurements of lubricants at high pressure[J]. Journal of Lubrication Technology,1979,101(3): 251-257. doi: 10.1115/1.3453339 [5] NDIAYE S N,MARTINIE L,PHILIPPON D,et al. A quantitative friction-based approach of the limiting shear stress pressure and temperature dependence[J]. Tribology Letters,2017,65(4): 1-14. [6] WU Lin. A slip model for rarefied gas flows at arbitrary Knudsen number[J]. Applied Physics Letters,2008,93(25): 1-4. [7] 燕震雷,伍林. 稀薄效应对可倾瓦动压气体轴承性能的影响[J]. 航空动力学报,2020,35(7): 1496-1505. YAN Zhenlei,WU Lin. Effect of rarefied effect on the performance of tilting pad dynamic pressure gas bearings[J]. Journal of Aerospace Power,2020,35(7): 1496-1505. (in Chinese doi: 10.13224/j.cnki.jasp.2020.07.018 YAN Zhenlei, WU Lin . Effect of rarefied effect on the performance of tilting pad dynamic pressure gas bearings[J]. Journal of Aerospace Power,2020 ,35 (7 ):1496 -1505 . (in Chinese) doi: 10.13224/j.cnki.jasp.2020.07.018[8] ZHANG Yongbin,WEN Shizhu. An analysis of elastohydrodynamic lubrication with limiting shear stress: Part Ⅰ theory and solutions[J]. Tribology Transactions,2002,45(2): 135-144. doi: 10.1080/10402000208982532 [9] 王丽丽. 高速滑动轴承的界面滑移及空穴机理研究[D]. 济南: 山东大学,2012. WANG Lili. Study on wall slip and cavitation mechanism of a high speed journal bearing[D]. Jinan: Shandong University,2012. (in ChineseWANG Lili. Study on wall slip and cavitation mechanism of a high speed journal bearing[D]. Jinan: Shandong University, 2012. (in Chinese) [10] 胡嘉麟,高金海,黄恩亮,等. 滑移边界对空气轴承性能的影响研究[J]. 推进技术,2017,38(6): 1359-1369. HU Jialin,GAO Jinhai,HUANG Enliang,et al. Effects of slip boundary on air bearing performance[J]. Journal of Propulsion Technology,2017,38(6): 1359-1369. (in Chinese doi: 10.13675/j.cnki.tjjs.2017.06.020 HU Jialin, GAO Jinhai, HUANG Enliang, et al . Effects of slip boundary on air bearing performance[J]. Journal of Propulsion Technology,2017 ,38 (6 ):1359 -1369 . (in Chinese) doi: 10.13675/j.cnki.tjjs.2017.06.020[11] AKBARI M,GHASEMI M. A novel kinetic-based slip velocity boundary condition suitable for compressible gas flows in micro-/ nanochannels[J]. Acta Mechanica,2018,229(11): 4471-4484. doi: 10.1007/s00707-018-2236-x [12] ZHANG Yaoguang,WANG Wenzhong,LIANG He,et al. Layered oil slip model for investigation of film thickness behaviours at high speed conditions[J]. Tribology International,2019,131: 137-147. doi: 10.1016/j.triboint.2018.10.035 [13] PORRAS-VAZQUEZ A,MARTINIE L,VERGNE P,et al. Independence between friction and velocity distribution in fluids subjected to severe shearing and confinement[J]. Physical Chemistry Chemical Physics,2018,20(43): 27280-27293. doi: 10.1039/C8CP04620D [14] 张镜洋,赵晓荣,常海萍,等. 边界滑移对波箔型动压气体轴承静特性的影响[J]. 推进技术,2018,39(2): 388-395. ZHANG Jingyang,ZHAO Xiaorong,CHANG Haiping,et al. Effects of sliding boundary on static characteristics of aerodynamic compliant foil bearing[J]. Journal of Propulsion Technology,2018,39(2): 388-395. (in Chinese doi: 10.13675/j.cnki.tjjs.2018.02.018 ZHANG Jingyang, ZHAO Xiaorong, CHANG Haiping, et al . Effects of sliding boundary on static characteristics of aerodynamic compliant foil bearing[J]. Journal of Propulsion Technology,2018 ,39 (2 ):388 -395 . (in Chinese) doi: 10.13675/j.cnki.tjjs.2018.02.018[15] 李旺. 动压气体轴承周向变截面间隙内流动特性研究[D]. 南京: 南京航空航天大学,2019. LI Wang. Research on flow characteristics of aerodynamic bearings with variable cross sectional clearance[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2019. (in ChineseLI Wang. Research on flow characteristics of aerodynamic bearings with variable cross sectional clearance[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019. (in Chinese) [16] 石卓奇. 波箔动压气体轴承承载特性的理论与实验研究[D]. 哈尔滨: 哈尔滨工业大学,2016. SHI Zhuoqi. Theoretical and experimental research on bearing performance of bump foil gas bearings[D]. Harbin: Harbin Institute of Technology,2016. (in ChineseSHI Zhuoqi. Theoretical and experimental research on bearing performance of bump foil gas bearings[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [17] GRANICK S,ZHU Yingxi,LEE H. Slippery questions about complex fluids flowing past solids[J]. Nature Materials,2003,2(4): 221-227. doi: 10.1038/nmat854 [18] ZHU B,LI Y P,WANG W G,et al. Boundary slippage modeling and optimization of hydrophobic tilting pad thrust bearing with elastic deformation[J]. Tribology International,2019,136: 299-316. doi: 10.1016/j.triboint.2019.03.060 [19] ZHANG Haijun,ZHU Changsheng,YANG Qin. Characteristics of micro gas journal bearings based on effective viscosity[J]. Journal of Tribology,2009,131(4): 1-5. [20] 马国军. 微纳米间隙流动的边界滑移及其流体动力学研究[D]. 大连: 大连理工大学,2007. MA Guojun. Boundary slip and hydrodynamics of fluid flow in a micro/nano-gap[D]. Dalian: Dalian University of Technology,2007. (in ChineseMA Guojun. Boundary slip and hydrodynamics of fluid flow in a micro/nano-gap[D]. Dalian: Dalian University of Technology, 2007. (in Chinese) [21] WU Yao,YANG Lihua,XU Tengfei,et al. Combined effect of rarefaction and effective viscosity on micro-elasto-aerodynamic lubrication performance of gas microbearings[J]. Micromachines,2019,10(10): 657-676. doi: 10.3390/mi10100657 -

下载:

下载: