Online actuator parameter estimation method for aero-engine control system

-

摘要:

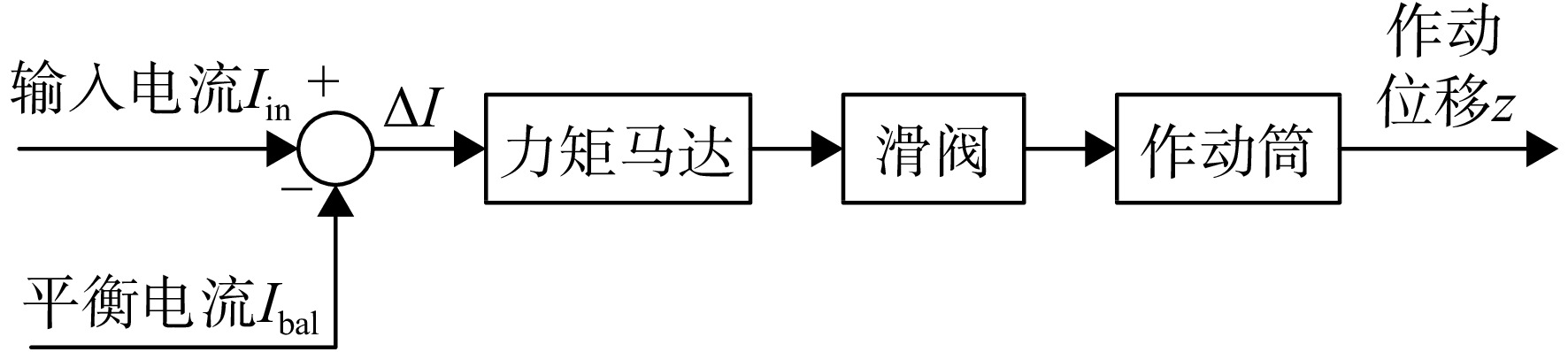

针对航空发动机控制系统因为执行机构性能退化而导致发动机控制品质降低或者严重时威胁发动机运行安全的状况,开展执行机构状态参数在线估计方法研究。在航空发动机实际执行机构控制回路实测信号较少的情况下,提出一种组合参数在线估计方法,通过作动模式识别分类,基于无迹卡尔曼滤波以稳态模式输出估计电液伺服阀平衡电流,基于拟牛顿算法(BFGS)以动态模式输出估计执行机构增益和作动延迟时间,实现模型参数的在线更新,建立实时自适应执行机构模型。以某涡扇发动机导叶作动控制回路为对象进行仿真,结果表明:在只有作动位置单一参数可测的条件下,在不同作动状态下对执行机构控制回路的平衡电流估计误差优于±0.2 mA,执行机构增益估计误差优于±4%,作动延迟周期估计误差不超过1个控制周期,能够实时跟踪并较为准确地估计执行机构的工作状态,为航空发动机执行机构控制回路设计与故障诊断提供技术支撑。

Abstract:In order to solve the problem of performance degradation that consequently reduces the engine control quality and even endangers the engine operation safety, a method of estimating the real-time state and performance variation trend for the actuator was proposed. Considering the measurable signals of practical aero-engine servo actuator were less than the performance parameters, a adaptive estimation method of combined state was put forward by means of recognition and classification of the actuation pattern, the balanced current of electro-hydraulic servo in the steady state was estimated by unscented Kalman filter, the actuation gain and actuation time delay in the dynamic state were estimated by the method of Broyden-Fletcher-Goldforb-Shanno (BFGS) , the performance parameters were updated in real time, and the adaptive model of servo actuator was established. A vane servo actuator loop of turbofan engine was simulated. The simulation results showed that, when single servo parameter can be measured, the absolute error of balance current estimation was less than ±0.2 mA, the relative error of actuation gain estimation was less than 4%, and the absolute error of actuation delay period estimation was less than one control period in different actuation states, and the adaptive model can estimate the state of actuator accurately and track the performance variation trend in real time, so the method can provide technical support of the control loop design and fault diagnosis for aero-engine servo actuator.

-

表 1 阶跃响应下参数在线估计效果

Table 1. Online parameters estimation effect in the step response process

模拟特征参数 试验序号 作动增益/(%/(s·mA)) 平衡电流/mA 作动延迟周期 估计值 相对误差/% 估计值 绝对误差 估计值 绝对误差 $ \begin{gathered}I_{\text{bal}}=5\; \mathrm{mA} \\ K_{\rm{\mathrm{v}}}=5\text{%}/ (\mathrm{s}\cdot\mathrm{mA}) \\ t_{\text{delay}}=5 \\ \end{gathered} $ 1 4.83 −3.4 4.99 −0.01 5 0 2 5.03 0.6 5.00 0 5 0 3 5.03 0.6 4.99 −0.01 5 0 4 5.01 0.2 5.01 0.01 5 0 5 5.00 0 5.00 0 5 0 $ \begin{gathered} {I_{{\text{bal}}}} = 7.5 \;{\mathrm{mA}} \\ {K_{\rm{v}} }= 7.5 {\text{%}}/ ({\mathrm{s}}\cdot {\mathrm{mA}}) \\ {t_{{\text{delay}}}} = 10 \\ \end{gathered} $ 6 7.42 −1.0 7.49 −0.01 10 0 7 7.48 −0.3 7.50 0 10 0 8 7.51 0.1 7.51 0.01 10 0 9 7.50 0 7.51 0.01 10 0 10 7.49 −0.1 7.50 0 10 0 -

[1] 杨刚,臧军. 航空发动机液压执行机构模型时域辨识方法研究[C]//中国自动化学会控制理论专业委员会B卷. 山东烟台: 中国自动化学会控制理论专业委员会,2011: 786-790. [2] BERTIN M,PLUMMER A,BOWEN C,et al. A dual lane piezoelectric ring bender actuated nozzle-flapper servo valve for aero engine fuel metering[J]. Smart Materials and Structures,2019,28(11): 115015-115019. doi: 10.1088/1361-665X/ab32b0 [3] LIU Chunqiang,LUO Guangzhao,CHEN Zhe,et al. A linear ADRC-based robust high-dynamic double-loop servo system for aircraft electro-mechanical actuators[J]. Chinese Journal of Aeronautics,2019,32(9): 2174-2187. doi: 10.1016/j.cja.2019.03.036 [4] 董蒙,栾希亭,梁俊龙,等. 冲压发动机连续可调喷管模糊控制研究[J]. 推进技术,2021,42(2): 449-458. DONG Meng,LUAN Xiting,LIANG Junlong,et al. Fuzzy control of continuous adjustable nozzle in ramjet[J]. Journal of Propulsion Technology,2021,42(2): 449-458. (in Chinese doi: 10.13675/j.cnki.tjjs.190437 DONG Meng, LUAN Xiting, LIANG Junlong, et al . Fuzzy control of continuous adjustable nozzle in ramjet[J]. Journal of Propulsion Technology,2021 ,42 (2 ):449 -458 . (in Chinese) doi: 10.13675/j.cnki.tjjs.190437[5] 孙浩,郭迎清,赵万里. 航空发动机传感器与执行机构信息重构算法[J]. 北京航空航天大学学报,2020,46(2): 331-339. SUN Hao,GUO Yingqing,ZHAO Wanli. Information reconstruction algorithm of aero-engine sensors and actuators[J]. Journal of Beijing University of Aeronautics and Astronautics,2020,46(2): 331-339. (in Chinese doi: 10.13700/j.bh.1001-5965.2019.0240 SUN Hao, GUO Yingqing, ZHAO Wanli . Information reconstruction algorithm of aero-engine sensors and actuators[J]. Journal of Beijing University of Aeronautics and Astronautics,2020 ,46 (2 ):331 -339 . (in Chinese) doi: 10.13700/j.bh.1001-5965.2019.0240[6] 王志臻. 某型小涵道比双轴涡扇发动机执行机构建模研究[D]. 沈阳: 东北大学,2012. WANG Zhizhen. Modeling study for actuating mechanism of twin-spool low by-pass turbofan engine[D]. Shenyang: Northeastern University,2012. (in ChineseWANG Zhizhen. Modeling study for actuating mechanism of twin-spool low by-pass turbofan engine[D]. Shenyang: Northeastern University, 2012. (in Chinese) [7] 赵世荣. 航空发动机自适应建模及故障诊断[D]. 南京: 南京航空航天大学,2007. ZHAO Shirong. The research on aeroengine adaptive modeling and fault diagnosis[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2007. (in ChineseZHAO Shirong. The research on aeroengine adaptive modeling and fault diagnosis[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007. (in Chinese) [8] 朱之丽,李东. 变几何涡扇发动机几何调节对性能的影响[J]. 航空动力学报,1999,14(1): 35-38. ZHU Zhili,LI Dong. Influence of geometric variation on performance of VGE[J]. Journal of Aerospace Power,1999,14(1): 35-38. (in Chinese doi: 10.3969/j.issn.1000-8055.1999.01.009 ZHU Zhili, LI Dong . Influence of geometric variation on performance of VGE[J]. Journal of Aerospace Power,1999 ,14 (1 ):35 -38 . (in Chinese) doi: 10.3969/j.issn.1000-8055.1999.01.009[9] 张磊,苏为洲. 伺服系统的反馈控制设计研究综述[J]. 控制理论与应用,2014,31(5): 545-559. ZHANG Lei,SU Weizhou. Feedback control design of servo systems: a review[J]. Control Theory & Applications,2014,31(5): 545-559. (in Chinese doi: 10.7641/CTA.2014.30005 ZHANG Lei, SU Weizhou . Feedback control design of servo systems: a review[J]. Control Theory & Applications,2014 ,31 (5 ):545 -559 . (in Chinese) doi: 10.7641/CTA.2014.30005[10] 王景霖,李艳军,陆亦彬,等. 航空发动机健康监测技术研究[J]. 飞机设计,2009,29(3): 56-60,70. WANG Jinglin,LI Yanjun,LU Yibin,et al. Recent advancement in aero-engine health monitoring[J]. Aircraft Design,2009,29(3): 56-60,70. (in Chinese doi: 10.3969/j.issn.1673-4599.2009.03.013 WANG Jinglin, LI Yanjun, LU Yibin, et al . Recent advancement in aero-engine health monitoring[J]. Aircraft Design,2009 ,29 (3 ):56 -60, 70 . (in Chinese) doi: 10.3969/j.issn.1673-4599.2009.03.013[11] LIU Y T,KUNG T T,CHANG Kuoming,et al. Observer-based adaptive sliding mode control for pneumatic servo system[J]. Precision Engineering,2013,37(3): 522-530. doi: 10.1016/j.precisioneng.2012.12.003 [12] FU Qiang,FAN Ding. Simulation research on centrifugal flyweight servo components working principle of turboshaft engine[J]. Computer Measurement & Control,2013,21(2): 509-511. [13] 葛红娟,王道波. 自适应模型跟踪控制在仿真伺服系统中的应用[J]. 中国空间科学技术,2003,23(5): 39-44. GE Hongjuan,WANG Daobo. The application of adaptive model following control in flight simulation servo system[J]. Chinese Space Science and Technology,2003,23(5): 39-44. (in Chinese doi: 10.3321/j.issn:1000-758X.2003.05.008 GE Hongjuan, WANG Daobo . The application of adaptive model following control in flight simulation servo system[J]. Chinese Space Science and Technology,2003 ,23 (5 ):39 -44 . (in Chinese) doi: 10.3321/j.issn:1000-758X.2003.05.008[14] 刘渊,张天宏,周俊. 航空发动机燃油调节执行机构及其传感器的故障诊断与半物理仿真[J]. 推进技术,2016,37(11): 2165-2172. LIU Yuan,ZHANG Tianhong,ZHOU Jun. Fault diagnosis and semi-physical simulation for actuator and sensor of aero-engine fuel regulator[J]. Journal of Propulsion Technology,2016,37(11): 2165-2172. (in Chinese doi: 10.13675/j.cnki.tjjs.2016.11.022 LIU Yuan, ZHANG Tianhong, ZHOU Jun . Fault diagnosis and semi-physical simulation for actuator and sensor of aero-engine fuel regulator[J]. Journal of Propulsion Technology,2016 ,37 (11 ):2165 -2172 . (in Chinese) doi: 10.13675/j.cnki.tjjs.2016.11.022[15] 杨晓伟,葛曜文,邓文翔,等. 航空发动机导叶控制机构作动筒主动容错控制[J]. 航空学报,2022,43(9): 625464. YANG Xiaowei,GE Yaowen,DENG Wenxiang,et al. Active fault-tolerant control for hydraulic actuating cylinders of aeroengine guide vane control mechanisms[J]. Acta Aeronautica et Astronautica Sinica,2022,43(9): 625464. (in Chinese YANG Xiaowei, GE Yaowen, DENG Wenxiang, et al . Active fault-tolerant control for hydraulic actuating cylinders of aeroengine guide vane control mechanisms[J]. Acta Aeronautica et Astronautica Sinica,2022 ,43 (9 ):625464 . (in Chinese)[16] WOS P,DINDORF R. Adaptive control of the electro-hydraulic servo-system with external disturbances[J]. Asian Journal of Control,2013,15(4): 1065-1080. doi: 10.1002/asjc.602 [17] WANG Huawei,WANG Xi,DANG Wei,et al. Generic design methodology for electro-hydraulic servo actuator in aero-engine main fuel control system[R]. ASME Paper GT2014-27337,2014. [18] YUAN Yuan,ZHANG Tianhong,LIN Zhonglin,et al. An investigation into factors determining the metering performance of a fuel control unit in an aero engine[J]. Flow Measurement and Instrumentation,2020,71: 101672. doi: 10.1016/j.flowmeasinst.2019.101672 [19] 郑斐华. 基于系统辨识的航空发动机建模研究[D]. 北京: 中国科学院大学,2018. ZHENG Feihua. Aeroengine modeling research based on system identification[D]. Beijing: University of Chinese Academy of Sciences,2018. (in ChineseZHENG Feihua. Aeroengine modeling research based on system identification[D]. Beijing: University of Chinese Academy of Sciences, 2018. (in Chinese) [20] 孙健国. 现代航空动力装置控制[M]. 修订版. 北京: 航空工业出版社,2009. [21] 蒋平国,姚华,孙健国. 航空发动机数控系统执行机构回路故障诊断和容错控制方法[J]. 航空动力学报,2005,20(2): 282-286. JIANG Pingguo,YAO Hua,SUN Jianguo. Method of fault diagnosis and fault-tolerant control for actuator loop in aeroengine digital control system[J]. Journal of Aerospace Power,2005,20(2): 282-286. (in Chinese doi: 10.3969/j.issn.1000-8055.2005.02.022 JIANG Pingguo, YAO Hua, SUN Jianguo . Method of fault diagnosis and fault-tolerant control for actuator loop in aeroengine digital control system[J]. Journal of Aerospace Power,2005 ,20 (2 ):282 -286 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2005.02.022[22] 郑宏,徐红兵,朱贵平. 变论域自适应模糊控制在航机发电中的应用[J]. 控制理论与应用,2008,25(2): 253-256. ZHENG Hong,XU Hongbing,ZHU Guiping. Adaptive fuzzy control based on variable universe and its application to aero engine turbine power generator[J]. Control Theory & Applications,2008,25(2): 253-256. (in Chinese ZHENG Hong, XU Hongbing, ZHU Guiping . Adaptive fuzzy control based on variable universe and its application to aero engine turbine power generator[J]. Control Theory & Applications,2008 ,25 (2 ):253 -256 . (in Chinese)[23] GIANNITRAPANI A,CECCARELLI N,SCORTECCI F,et al. Comparison of EKF and UKF for spacecraft localization via angle measurements[J]. IEEE Transactions on Aerospace and Electronic Systems,2011,47(1): 75-84. doi: 10.1109/TAES.2011.5705660 [24] BATTITI R,MASULLI F. BFGS optimization for faster and automated supervised learning[M]// International Neural Network Conference. Dordrecht, the Netherlands: Springer,1990: 757-760. -

下载:

下载: