Numerical analysis on performance of hydrodynamic-hydrostatic hybrid mechanical seals for turbopumps

-

摘要:

针对密封端面液氧的低动力黏度难以成膜的特性,提出一种动静压结合型机械端面密封。考虑节流孔的静压效应和液膜空化效应,建立了液膜的有限元分析模型,研究了动静压型机械密封的工作原理,分析了端面动静压结构几何参数对密封性能的影响规律。研究结果表明:动静压型机械密封的节流孔将静压效应引入密封端面,螺旋槽在提高液膜动压效应基础上将经节流孔流入的介质泵送回密封腔,提高了上游泵送量。在研究范围内,推荐的动静压结构几何参数的优选范围如下:螺旋槽槽台宽比为0.6~0.7、槽坝比为0.6~0.7、槽深为12~15 μm、螺旋角为15°~18°,静压节流孔孔径为0.4~0.5 mm、节流孔个数为6~12 个。

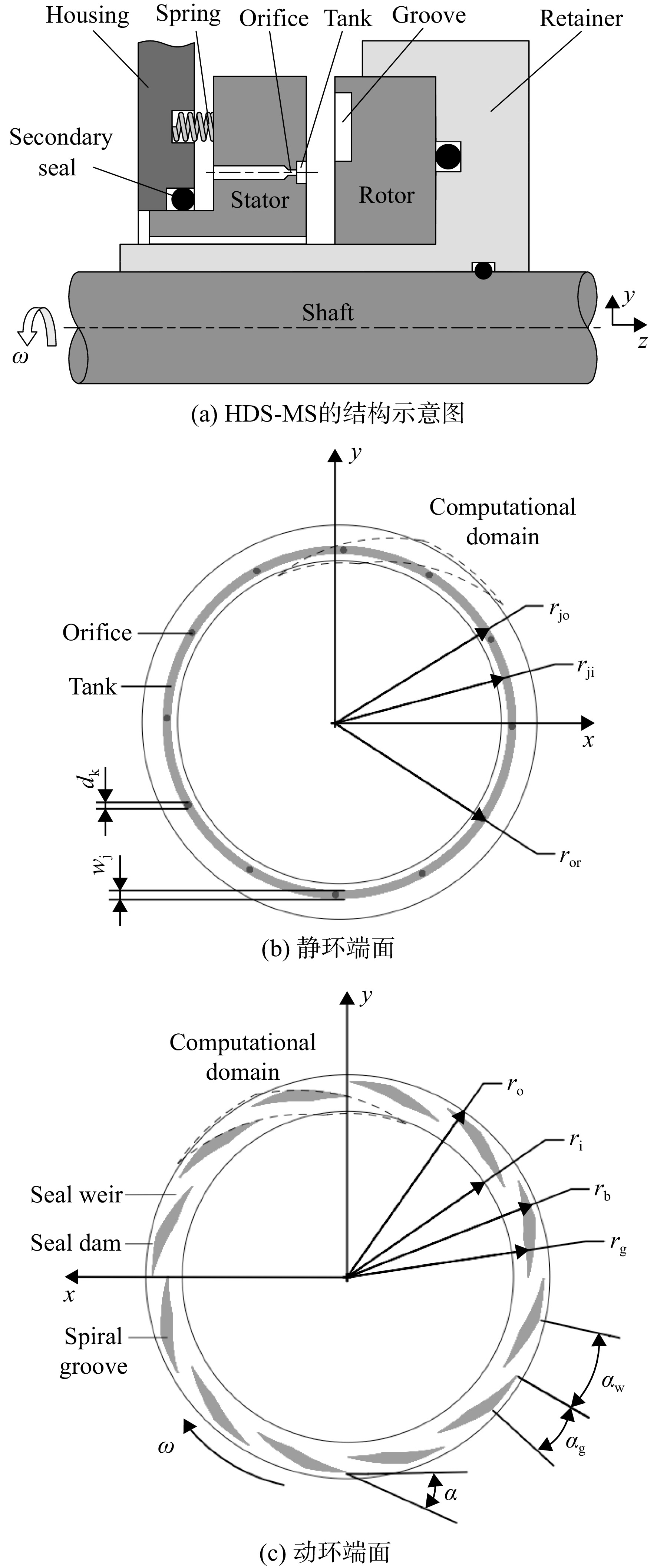

Abstract:In view of the characteristics of low dynamic viscosity and hard film forming of liquid oxygen on the sealing face, a hydrodynamic-hydrostatic hybrid mechanical seal was proposed. Considering the hydrostatic effect of the orifice and the cavitation effect of the liquid film, the finite element analysis model of the liquid film was established to study the working principle of the hydrodynamic-hydrostatic hybrid mechanical seal and analyze the influences of the geometrical parameters of the hydrodynamic and hydrostatic structure on the sealing performance. Within the research scope, the optimum range of the geometrical parameters of the spiral groove and hydrostatic structure was as follows: the groove-weir ratio was 0.6—0.7, the groove-dam ratio was 0.6—0.7, the groove depth was 12—15 μm, the spiral angle was 15°—18°, the orifice diameter was 0.4—0.5 mm, and the orifice number was 6—12.

-

表 1 几何参数与工况参数

Table 1. Geometrical parameters and operating parameters

参数 数值 参数 数值 端面外径 ro/mm 55.5 螺旋槽槽数Ng 15 端面内径 ri/mm 45.5 节流孔孔径dk/mm 0.5 螺旋槽槽台宽比β1 0.5 均压槽槽宽wj/mm 1.5 螺旋槽槽坝比β2 0.7 均压槽槽深hj/μm 200 螺旋槽槽底半径比β3 0.4 节流孔孔数m 15 螺旋角α/(°) 15 转速 n/104 (r/min) 2 螺旋槽槽深hg/μm 5 外径侧压力po/MPa 0.5 密封间隙hc/μm 5 内径侧压力pi/MPa 0.1 -

[1] ZHANG Guoyuan,CHEN Guozhong,ZHAO Weigang,et al. An experimental test on a cryogenic high-speed hydrodynamic non-contact mechanical seal[J]. Tribology Letters,2017,65(3): 1-11. [2] 张国渊,陈国忠,赵伟刚,等. 高速低温动静结合型机械密封结构优化及运转试验[J]. 航空动力学报,2018,33(5): 1093-1102.ZHANG Guoyuan,CHEN Guozhong,ZHAO Weigang,et al. Optimization and test of parameters of the cryogenic hydrodynamic mechanical seal[J]. Journal of Aerospace Power,2018,33(5): 1093-1102. (in Chinese) [3] ROWE W B,XU S X,CHONG F S,et al. Hybrid journal bearings with particular reference to hole-entry configurations[J]. Tribology International,1982,15(6): 339-348. doi: 10.1016/0301-679X(82)90143-8 [4] YOSHIMOTO S,KUME T,SHITARA T. Axial load capacity of water-lubricated hydrostatic conical bearings with spiral grooves for high speed spindles[J]. Tribology International,1998,31(6): 331-338. doi: 10.1016/S0301-679X(98)00043-7 [5] SU J C T,LIE K N. Rotation effects on hybrid hydrostatic/hydrodynamic journal bearings[J]. Industrial Lubrication and Tribology,2001,53(6): 261-269. doi: 10.1108/EUM0000000006009 [6] 王彬,郝木明. 新型动静压混合润滑机械密封流场数值研究[J]. 润滑与密封,2009,34(7): 62-65,73. doi: 10.3969/j.issn.0254-0150.2009.07.015WANG Bin,HAO Muming. Numerical study on flow field of new-type hydrostatic-dynamic hybrid lubrication seal[J]. Lubrication Engineering,2009,34(7): 62-65,73. (in Chinese) doi: 10.3969/j.issn.0254-0150.2009.07.015 [7] 王彬. 新型动静压混合润滑机械密封性能研究[D]. 山东 青岛: 中国石油大学, 2010.WANG Bin. Study on properties of new-type hydrostatic-dynamic hybrid lubrication mechanical seal[D]. Qingdao, Shandong: China University of Petroleum, 2010. (in Chinese) [8] 郝木明,王彬. 新型动静压混合润滑机械密封结构参数优化[J]. 润滑与密封,2010,35(2): 71-75.HAO Muming,WANG Bin. Structural parameter optimization of new-type hydrostatic-dynamic hybrid lubrication seal[J]. Lubrication Engineering,2010,35(2): 71-75. (in Chinese) [9] 周敏,孙见君,马晨波,等. 自泵送流体动压型机械密封性能分析[J]. 化工学报,2015,66(2): 687-694.ZHOU Min,SUN Jianjun,MA Chenbo,et al. Performance analysis of hydrodynamic mechanical seals based on self-pumping principle[J]. CIESC Journal,2015,66(2): 687-694. (in Chinese) [10] 陈群,孙见君. 自泵送流体动静压型机械密封自清洁性分析[J]. 摩擦学学报,2019,39(3): 259-268.CHEN Qun,SUN Jianjun. Analysis of self-cleaning for self-pumping hydrodynamic and hydrostatic mechanical seal[J]. Tribology,2019,39(3): 259-268. (in Chinese) [11] 张琛. 火箭发动机涡轮泵机械密封的磨损机理及性能优化[D]. 西安: 西安理工大学, 2019.ZHANG Chen. Wear menchanism and performance optimization of mechanical seal of rocket engine turbo pump[D]. Xi’an: Xi’an University of Technology, 2019. (in Chinese) [12] 陈杰, 赵伟刚, 王良. 液体火箭发动机涡轮泵用非接触式密封研究现状及展望[C]//中国航天第三专业信息网第三十七届技术交流会暨第一届空天动力联合会议论文集. 西安: 西安航天动力研究所, 2016: 151-158. [13] 张国渊,赵伟刚,陈垚,等. 非接触动静结合型机械密封的主动可控性及其脱开机理[J]. 航空动力学报,2014,29(10): 2515-2522.ZHANG Guoyuan,ZHAO Weigang,CHEN Yao,et al. Active controllability and separation mechanics of non-contact hydrostatic mechanical seal[J]. Journal of Aerospace Power,2014,29(10): 2515-2522. (in Chinese) [14] 赵伟刚,张树强,陈杰,等. 液氧泵用动静压混合式密封关键技术研究[J]. 润滑与密封,2017,42(1): 111-115, 136.ZHAO Weigang,ZHANG Shuqiang,CHEN Jie,et al. Key technologies of dynamic-hydrostatic hybrid seals used in liquid oxygen pump[J]. Lubrication Engineering,2017,42(1): 111-115, 136. (in Chinese) [15] QIU Y,KHONSARI M M. On the prediction of cavitation in dimples using a mass-conservative algorithm[J]. Journal of Tribology,2009,131(4): 041702. doi: 10.1115/1.3176994 [16] MENG Xiangkai,BAI Shaoxian,PENG Xudong. Lubrication film flow control by oriented dimples for liquid lubricated mechanical seals[J]. Tribology International,2014,77: 132-141. doi: 10.1016/j.triboint.2014.04.020 [17] 马学忠,孟祥铠,王玉明,等. 机械端面密封反向螺旋槽空化效应与泄漏控制机理[J]. 化工学报,2018,69(4): 1558-1568.MA Xuezhong,MENG Xiangkai,WANG Yuming,et al. Cavitation effect and leakage control mechanism of reverse spiral grooves mechanical end face seals[J]. CIESC Journal,2018,69(4): 1558-1568. (in Chinese) [18] 詹永麒. 液压传动[M]. 上海: 上海交通大学出版社, 1999: 28 [19] 杜家磊,闫攀运,梁国柱. 涡轮泵流体静压轴承性能计算与试验研究[J]. 北京航空航天大学学报,2018,44(2): 322-332.DU Jialei,YAN Panyun,LIANG Guozhu. Performance calculation and experimental study on a hydrostatic journal bearing for turbopumps[J]. Journal of Beijing University of Aeronautics and Astronautics,2018,44(2): 322-332. (in Chinese) [20] 闻邦椿. 机械设计手册[M]. 5版. 北京: 机械工业出版社, 2010: 13-82. [21] SHAPIRO W, MCNICKLE A. Performance predictions of hydrostatic gas seals[R]. AIAA 1996-2804, 1996. [22] 刘雨川. 端面气膜密封特性研究[D]. 北京: 北京航空航天大学, 1999.LIU Yuchuan. Study on characteristics of end-face gas film seal[D]. Beijing: Beihang University, 1999. (in Chinese) [23] 孟祥铠,江莹莹,赵文静,等. 考虑空化效应的螺旋槽机械密封液膜动力学特性研究[J]. 摩擦学学报,2019,39(2): 171-180.MENG Xiangkai,JIANG Yingying,ZHAO Wenjing,et al. Fluid film dynamic characteristics of spiral-grooved mechanical seals with cavitation effect[J]. Tribology,2019,39(2): 171-180. (in Chinese) [24] 车健,江锦波,李纪云,等. 节流孔截面形状对静压干气密封稳态性能和压力波动特性影响[J]. 摩擦学学报,2019,39(6): 669-679.CHE Jian,JIANG Jinbo,LI Jiyun,et al. Effect of orifice cross-section shape on steady performance and pressure fluctuation characteristics of hydrostatic dry gas seal[J]. Tribology,2019,39(6): 669-679. (in Chinese) -

下载:

下载: