Feature extraction of bearing outer ring fault for encoder installation error suppression

-

摘要:

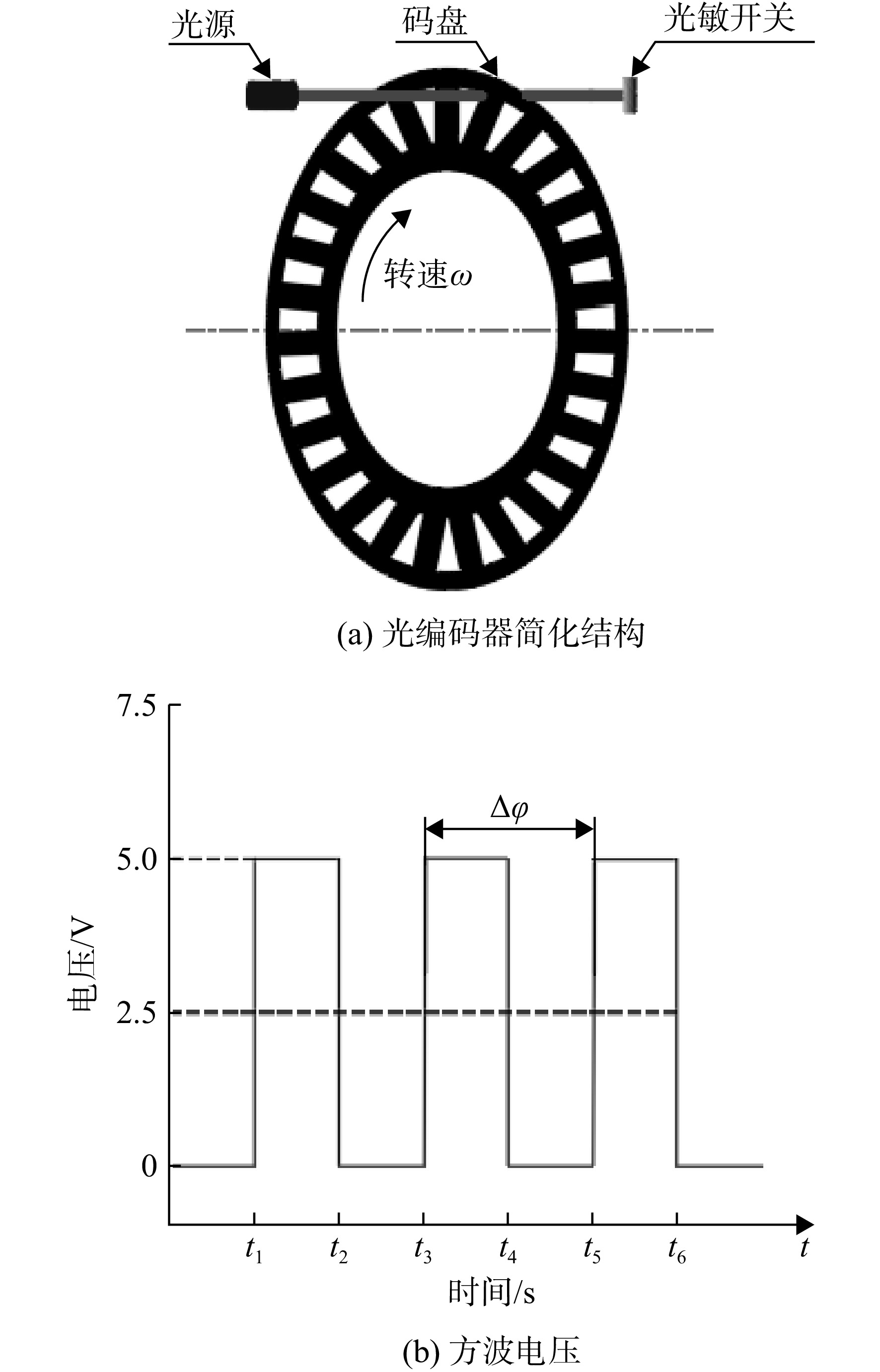

针对编码器信号中安装误差导致轴承外圈故障特征提取困难的难题,提出一种编码器安装误差抑制方法。该方法依据编码器安装误差特性,结合方均根包络技术,获得原始瞬时角速度信号上包络线。基于分段逐步逼近技术和绝对平均差指标,结合反斜率修正方法,进一步拟合编码器安装误差分量。采用改进能量比指标自适应确定优化包络线窗长,并获得对应的剩余信号。通过剩余信号的包络谱,获取轴承外圈故障特征频率,揭示故障特征。与传统抑制周期性分量的倒谱预白化方法相对比,该方法清晰地提取出滚动轴承外圈的前3阶故障特征阶次,证明了该方法对编码器误差有较好的抑制效果,仿真和实验验证了所提方法的有效性。

Abstract:To address the problem that the installation error in the encoder signal makes it difficult to extract the bearing outer race fault features, an error suppression scheme for encoder installation was proposed. According to the method, the envelope on the original instantaneous angular speed signal was obtained based on the encoder mounting error characteristics combined with the root mean square envelope technique. The encoder installation error components were further fitted based on the segmented stepwise approximation technique and the absolute mean difference index combined with the inverse slope correction method. The optimized envelope window length was determined adaptively by improving the energy ratio index, and the corresponding residual signal was obtained. Through the envelope spectrum of the residual signal, the fault characteristics order of the bearing outer race was obtained and the fault characteristics were revealed. Compared with the traditional cepstral pre-whitening method which suppressed periodic components, the first 3 fault characteristic orders of the outer ring of rolling bearing were clearly extracted by this method, proving that the proposed method has better suppression effect on encoder error. The effectiveness of the proposed scheme was verified by simulation and experiment.

-

[1] 梅宏斌. 滚动轴承振动监测与诊断: 理论·方法·系统[M]. 北京: 机械工业出版社,1995. [2] 郭瑜,郑华文,高艳,等. 基于谱峭度的滚动轴承包络分析[J]. 振动 测试与诊断,2011,31(4): 517-521,539. GUO Yu,ZHENG Huawen,GAO Yan,et al. Envelope analysis of rolling bearings based on spectral kurtosis[J]. Journal of Vibration,Measurement & Diagnosis,2011,31(4): 517-521,539. (in ChineseGUO Yu, ZHENG Huawen, GAO Yan, et al. Envelope analysis of rolling bearings based on spectral kurtosis[J]. Journal of Vibration, Measurement & Diagnosis, 2011, 31(4): 517-521, 539. (in Chinese) [3] 向丹,岑健. 基于EMD熵特征融合的滚动轴承故障诊断方法[J]. 航空动力学报,2015,30(5): 1149-1155. XIANG Dan,CEN Jian. Method of roller bearing fault diagnosis based on feature fusion of EMD entropy[J]. Journal of Aerospace Power,2015,30(5): 1149-1155. (in Chinese doi: 10.13224/j.cnki.jasp.2015.05.016 XIANG Dan, CEN Jian . Method of roller bearing fault diagnosis based on feature fusion of EMD entropy[J]. Journal of Aerospace Power,2015 ,30 (5 ):1149 -1155 . (in Chinese) doi: 10.13224/j.cnki.jasp.2015.05.016[4] ZHENG Kai,LI Tianliang,SU Zuqiang,et al. Sparse elitist group lasso denoising in frequency domain for bearing fault diagnosis[J]. IEEE Transactions on Industrial Informatics,2021,17(7): 4681-4691. doi: 10.1109/TII.2020.3011065 [5] RENAUDIN L,BONNARDOT F,MUSY O,et al. Natural roller bearing fault detection by angular measurement of true instantaneous angular speed[J]. Mechanical Systems and Signal Processing,2010,24(7): 1998-2011. doi: 10.1016/j.ymssp.2010.05.005 [6] MOUSTAFA W,COUSINARD O,BOLAERS F,et al. Low speed bearings fault detection and size estimation using instantaneous angular speed[J]. Journal of Vibration and Control,2016,22(15): 3413-3425. doi: 10.1177/1077546314560600 [7] COATS M D,RANDALL R B. Single and multi-stage phase demodulation based order-tracking[J]. Mechanical Systems and Signal Processing,2014,44(1/2): 86-117. [8] ZENG Qiang,FENG Guojin,SHAO Yimin,et al. An accurate instantaneous angular speed estimation method based on a dual detector setup[J]. Mechanical Systems and Signal Processing,2020,140: 106674. doi: 10.1016/j.ymssp.2020.106674 [9] DENG Fang,CHEN Jie,WANG Yanyong,et al. Measurement and calibration method for an optical encoder based on adaptive differential evolution-Fourier neural networks[J]. Measurement Science and Technology,2013,24(5): 055007. doi: 10.1088/0957-0233/24/5/055007 [10] JIAO Yang,DING Ye,DONG Zeguang,et al. Optimal-arrangement-based four-scanning-heads error separation technique for self-calibration of angle encoders[J]. Measurement Science and Technology,2018,29(8): 085005. doi: 10.1088/1361-6501/aacc8a [11] BORGHESANI P,PENNACCHI P,RANDALL R B,et al. Application of cepstrum pre-whitening for the diagnosis of bearing faults under variable speed conditions[J]. Mechanical Systems and Signal Processing,2013,36(2): 370-384. doi: 10.1016/j.ymssp.2012.11.001 [12] QIN Shiqiao,HUANG Zongsheng,WANG Xingshu. Optical angular encoder installation error measurement and calibration by ring laser gyroscope[J]. IEEE Transactions on Instrumentation and Measurement,2010,59(3): 506-511. doi: 10.1109/TIM.2009.2022104 [13] GECKELER R D,FRICKE A,ELSTER C. Calibration of angle encoders using transfer functions[J]. Measurement Science and Technology,2006,17(10): 2811-2818. doi: 10.1088/0957-0233/17/10/036 [14] 陈鑫,郭瑜,伍星,等. 改进IESFOgram的滚动轴承故障特征提取[J]. 振动工程学报,2021,34(4): 861-868. CHEN Xin,GUO Yu,WU Xing,et al. Feature extraction of faulty rolling element bearing based on improved IESFOgram[J]. Journal of Vibration Engineering,2021,34(4): 861-868. (in Chinese doi: 10.16385/j.cnki.issn.1004-4523.2021.04.023 CHEN Xin, GUO Yu, WU Xing, et al . Feature extraction of faulty rolling element bearing based on improved IESFOgram[J]. Journal of Vibration Engineering,2021 ,34 (4 ):861 -868 . (in Chinese) doi: 10.16385/j.cnki.issn.1004-4523.2021.04.023[15] 曾强. 相位差分编码器原理及其行星轮系故障诊断应用研究[D]. 重庆: 重庆大学,2020. ZENG Qiang. Phase differential encoder theory and its application on planetary gear set fault diagnosis[D]. Chongqing: Chongqing University,2020. (in ChineseZENG Qiang. Phase differential encoder theory and its application on planetary gear set fault diagnosis[D]. Chongqing: Chongqing University, 2020. (in Chinese) [16] 尹学慧. 基于Envelope包络与阶次分析的滚动轴承故障诊断[D]. 太原: 中北大学,2019. YIN Xuehui. Based on the envelope and order analysis of the rolling bearing fault diagnosis[D]. Taiyuan: North University of China,2019. (in ChineseYIN Xuehui. Based on the envelope and order analysis of the rolling bearing fault diagnosis[D]. Taiyuan: North University of China, 2019. (in Chinese) [17] GOMEZ J L,KHELF I,BOURDON A,et al. Angular modeling of a rotating machine in non-stationary conditions: application to monitoring bearing defects of wind turbines with instantaneous angular speed[J]. Mechanism and Machine Theory,2019,136: 27-51. doi: 10.1016/j.mechmachtheory.2019.01.028 [18] 王平,廖明夫. 滚动轴承故障诊断的自适应共振解调技术[J]. 航空动力学报,2005,20(4): 606-612. WANG Ping,LIAO Mingfu. Adaptive demodulated resonance technique for the rolling bearing fault diagnosis[J]. Journal of Aerospace Power,2005,20(4): 606-612. (in Chinese doi: 10.3969/j.issn.1000-8055.2005.04.015 WANG Ping, LIAO Mingfu . Adaptive demodulated resonance technique for the rolling bearing fault diagnosis[J]. Journal of Aerospace Power,2005 ,20 (4 ):606 -612 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2005.04.015 -

下载:

下载: