Design and experiment of simulated specimen for fretting fatigue of turbine attachment

-

摘要:

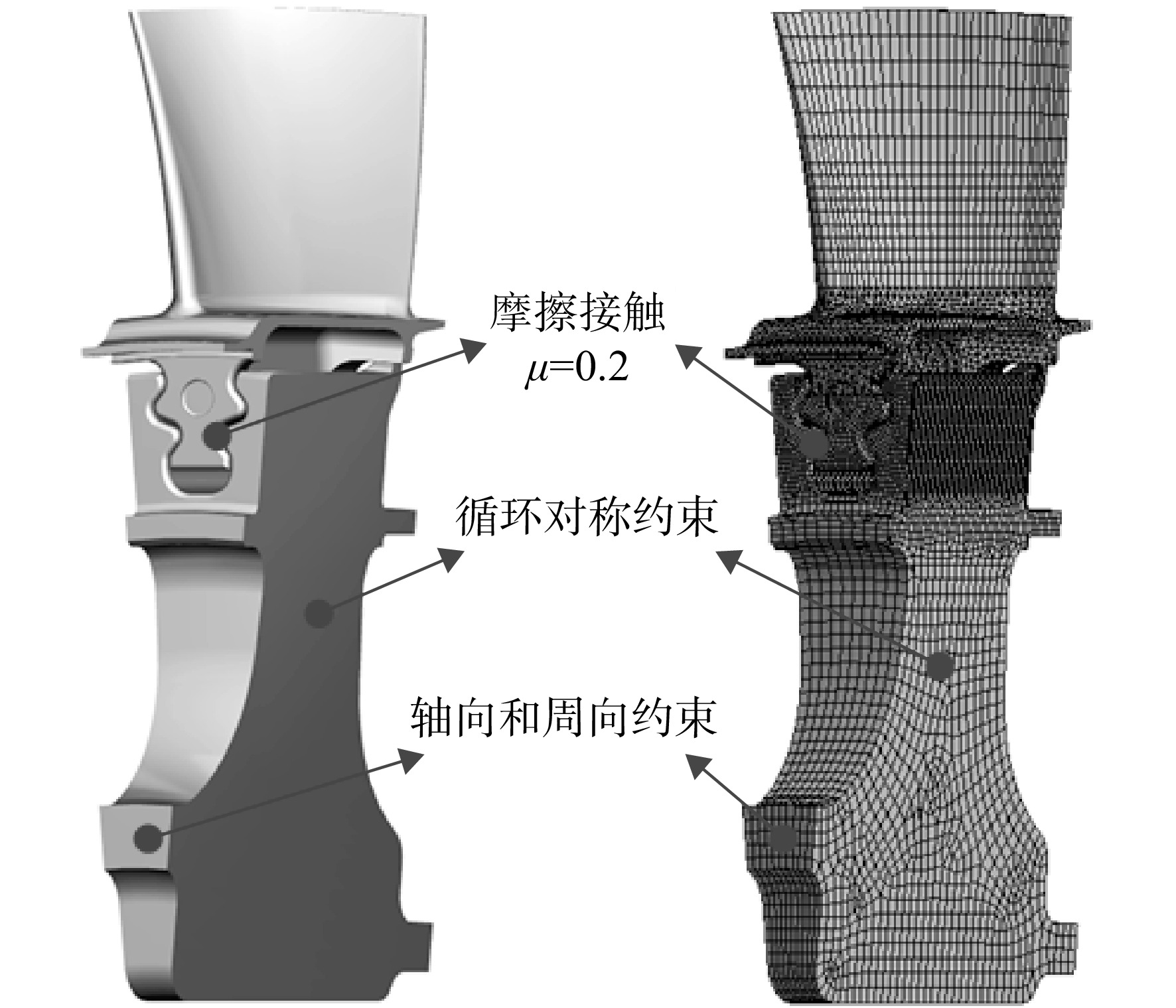

提出了基于损伤控制参量一致的榫连接结构微动疲劳模拟件设计方法。在几何相似的基础上,保证最大相对滑移距离与临界距离内等效应力分布的一致性,确定模拟件的二维结构尺寸;在此基础上,以临界裂纹长度内应力强度因子一致为目标,优化分析确定模拟件的三维结构尺寸;开展了某型发动机涡轮榫连接结构模拟件的微动疲劳试验,试验观测到裂纹萌生于接触面边缘,裂纹初期扩展方向垂直于接触面,断裂时的裂纹长度与仿真结果相比误差小于5%,由此验证模拟件设计方法的合理性。

Abstract:A method was proposed to design the simulated specimen for fretting fatigue of turbine attachment based on the consistency of damage control parameters. Afterwards, a simulated specimen for the turbine attachment of a certain aero-engine was designed. Firstly, based on geometric similarity, two-dimensional structural dimension of the simulated specimen was determined by ensuring the consistency of the maximum relative slip distance and the equivalent stress distribution within the critical distance; and then, three-dimensional structural dimension of the simulated specimen was determined by optimization analysis with the objective of consistency of the stress intensity factor within the critical crack length. Finally, fretting fatigue test of the simulated specimen was performed. It was found that the crack was initiated at the edge of the contact surface, the direction of the crack growth was perpendicular to the contact surface and the crack length at fracture was within 5% in error with the simulation, thus verifying the rationality of the design method of the simulated specimen.

-

Key words:

- turbine attachment /

- simulated specimen /

- fretting fatigue /

- crack initiation /

- crack growth

-

表 1 涡轮盘及叶片材料力学性能

Table 1. Material properties of the turbine disc and blade

材料 温度/℃ 弹性模量/GPa 切变模量/GPa 泊松比 线膨胀系数/10−6 ℃−1 GH4720Li 400 201 0.36 11.94 GH4720Li 600 190 0.37 12.55 DD6 650 107.5 100 0.37 13.34 DD6 980 80.5 74.2 0.38 14.88 表 2 榫连接结构模拟件榫头部分的试验结果

Table 2. Test results for the tenon part of the simulated specimen

编号 温度/℃ 最大载荷/kN 载荷比 寿命(循环次数)/104 T1 600 12.98 0.1 8.89 T2 600 12.98 0.1 8.59 T3 600 12.98 0.1 6.80 T4 600 12.98 0.1 8.17 T5 600 12.98 0.1 11.90 T6 600 12.98 0.1 7.68 T7 600 12.98 0.1 8.16 T8 600 12.98 0.1 6.38 T9 600 12.98 0.1 14.69 表 3 榫连接结构模拟件榫槽部分的试验结果

Table 3. Test results for the groove part of the simulated specimen

编号 温度/℃ 最大载荷/kN 载荷比 寿命(循环次数)/104 C1 600 12.98 0.1 27.49 C2 600 12.98 0.1 25.72 C6 600 12.98 0.1 29.49 -

[1] 周仲荣,LEO V. 微动磨损[M]. 北京: 科学出版社,2002. ZHOU Zhongrong,LEO V. Fretting wear[M]. Beijing: Science Press,2002. (in ChineseZHOU Zhongrong, LEO V. Fretting wear[M]. Beijing: Science Press, 2002. (in Chinese) [2] 何明鉴. 机械构件的微动疲劳[M]. 北京: 国防工业出版社,1994. HE Mingjian. Fretting fatigue of mechanical components [M]. Beijing: National Defence Industry Press,1994. (in ChineseHE Mingjian. Fretting fatigue of mechanical components [M]. Beijing: National Defence Industry Press, 1994. (in Chinese) [3] WATERHOUSE R B. Fretting fatigue[J]. Materials Science and Engineering,1976,25: 201-206. doi: 10.1016/0025-5416(76)90071-9 [4] 黄致建,朱如鹏,潘升材. 单向加载疲劳机上燕尾形榫联接微动损伤试验件设计[J]. 航空学报,1994,15(8): 1015-1023. HUANG Zhijian,ZHU Rupeng,PAN Shengcai. The designing of the specimen of dovetail joint in unidirectionally-loaded fatigue test rig[J]. Acta Aeronautica et Astronautica Sinica,1994,15(8): 1015-1023. (in ChineseHUANG Zhijian, ZHU Rupeng, PAN Shengcai. The designing of the specimen of dovetail joint in unidirectionally-loaded fatigue test rig[J]. Acta Aeronautica et Astronautica Sinica, 1994, 15(8): 1015-1023. (in Chinese) [5] 由美雁,何雪浤,谢里阳. 发动机轮盘模拟技术理论与方法[J]. 机械设计,2007,24(2): 62-64. YOU Meiyan,HE Xuehong,XIE Liyang. Research on simulative technical theory and methodology of turbine rotor[J]. Journal of Machine Design,2007,24(2): 62-64. (in ChineseYOU Meiyan, HE Xuehong, XIE Liyang. Research on simulative technical theory and methodology of turbine rotor[J]. Journal of Machine Design, 2007, 24(2): 62-64. (in Chinese) [6] 赵福星,杨兴宇. 发动机构件低循环疲劳模拟试验件设计方法[J]. 燃气涡轮试验与研究,2003,16(2): 50-52. ZHAO Fuxing,YANG Xingyu. A design method of simulation samples for aero-engine components used in low cycle fatigue test[J]. Gas Turbine Experiment and Research,2003,16(2): 50-52. (in ChineseZHAO Fuxing, YANG Xingyu. A design method of simulation samples for aero-engine components used in low cycle fatigue test[J]. Gas Turbine Experiment and Research, 2003, 16(2): 50-52. (in Chinese) [7] 刘廷毅,耿瑞,张峻峰. 发动机轮盘低循环疲劳寿命试验模拟件设计[J]. 航空动力学报,2008,23(1): 32-36. LIU Tingyi,GENG Rui,ZHANG Junfeng. Design of simulated specimen for low-cycle fatigue of turbine engine disk[J]. Journal of Aerospace Power,2008,23(1): 32-36. (in ChineseLIU Tingyi, GENG Rui, ZHANG Junfeng. Design of simulated specimen for low-cycle fatigue of turbine engine disk[J]. Journal of Aerospace Power, 2008, 23(1): 32-36. (in Chinese) [8] 陆山,王春光,陈军. 任意最大应力梯度路径轮盘模拟件设计方法[J]. 航空动力学报,2010,25(9): 2000-2005. LU Shan,WANG Chunguang,CHEN Jun. Design method of imitation specimen for engine disk with any maximum stress gradient path[J]. Journal of Aerospace Power,2010,25(9): 2000-2005. (in ChineseLU Shan, WANG Chunguang, CHEN Jun. Design method of imitation specimen for engine disk with any maximum stress gradient path[J]. Journal of Aerospace Power, 2010, 25(9): 2000-2005. (in Chinese) [9] 杨兴宇,董立伟,耿中行,等. 某压气机轮盘榫槽低循环疲劳模拟件设计与试验[J]. 航空动力学报,2008,23(10): 1829-1834. YANG Xingyu,DONG Liwei,GENG Zhongxing,et al. Design and experimentation of simulation specimen for aero-engine compressor disk slot used in low cycle fatigue test[J]. Journal of Aerospace Power,2008,23(10): 1829-1834. (in ChineseYANG Xingyu, DONG Liwei, GENG Zhongxing, et al. Design and experimentation of simulation specimen for aero-engine compressor disk slot used in low cycle fatigue test[J]. Journal of Aerospace Power, 2008, 23(10): 1829-1834. (in Chinese) [10] 郑小梅,孙燕涛,杨兴宇,等. 某涡扇发动机高压涡轮盘螺栓孔低循环疲劳模拟件设计[J]. 航空动力学报,2018,33(10): 2351-2358. ZHENG Xiaomei,SUN Yantao,YANG Xingyu,et al. Design of low cycle fatigue simulating specimen for bolt holes of a turbofan engine high pressure turbine disc[J]. Journal of Aerospace Power,2018,33(10): 2351-2358. (in ChineseZHENG Xiaomei, SUN Yantao, YANG Xingyu, et al. Design of low cycle fatigue simulating specimen for bolt holes of a turbofan engine high pressure turbine disc[J]. Journal of Aerospace Power, 2018, 33(10): 2351-2358. (in Chinese) [11] 况成玉,刘奕斐. 某型航空发动机钛合金轮盘模拟疲劳试验件设计[J]. 装备制造技术,2020(1): 36-40. KUANG Chengyu,LIU Yifei. Design of simulated specimen for low-cycle fatigue of aircraft engine titanium alloy disk[J]. Equipment Manufacturing Technology,2020(1): 36-40. (in ChineseKUANG Chengyu, LIU Yifei. Design of simulated specimen for low-cycle fatigue of aircraft engine titanium alloy disk[J]. Equipment Manufacturing Technology, 2020(1): 36-40. (in Chinese) [12] 魏大盛,冯俊淇,马梦弟,等. 航空发动机轮盘中心孔模拟试验件设计方法及试验验证[J]. 航空动力学报,2022,37(10): 2157-2166. WEI Dasheng,FENG Junqi,MA Mengdi,et al. Design method and test verification of simulated specimen of aeroengine disc center hole[J]. Journal of Aerospace Power,2022,37(10): 2157-2166. (in ChineseWEI Dasheng, FENG Junqi, MA Mengdi, et al. Design method and test verification of simulated specimen of aeroengine disc center hole[J]. Journal of Aerospace Power, 2022, 37(10): 2157-2166. (in Chinese) [13] RAJASEKARAN R,NOWELL D. Fretting fatigue in dovetail blade roots: experiment and analysis[J]. Tribology International,2006,39(10): 1277-1285. doi: 10.1016/j.triboint.2006.02.044 [14] CONNER B P,NICHOLAS T. Using a dovetail fixture to study fretting fatigue and fretting palliatives[J]. Journal of Engineering Materials and Technology,2006,128(2): 133-141. doi: 10.1115/1.2172272 [15] 古远兴. 高低周复合载荷下燕尾榫结构微动疲劳寿命研究[D]. 南京: 南京航空航天大学,2007. GU Yuanxing. Research on fretting fatigue life of dovetail joint under HCF-LCF load[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2007. (in ChineseGU Yuanxing. Research on fretting fatigue life of dovetail joint under HCF-LCF load[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007. (in Chinese) [16] GOLDEN P J. Development of a dovetail fretting fatigue fixture for turbine engine materials[J]. International Journal of Fatigue,2009,31(4): 620-628. doi: 10.1016/j.ijfatigue.2008.03.017 [17] SUN Shouyi,LI Lei,YUE Zhufeng,et al. Fretting fatigue failure behavior of nickel-based single crystal superalloy dovetail specimen in contact with powder metallurgy pads at high temperature[J]. Tribology International,2020,142: 105986. doi: 10.1016/j.triboint.2019.105986 [18] QU Zhen,LIU Kaicheng,WANG Baizhi,et al. Fretting fatigue experiment and finite element analysis for dovetail specimen at high temperature[J]. Applied Sciences,2021,11(21): 9913. doi: 10.3390/app11219913 [19] RUIZ C,BODDINGTON P H B,CHEN K C. An investigation of fatigue and fretting in a dovetail joint[J]. Experimental Mechanics,1984,24(3): 208-217. doi: 10.1007/BF02323167 [20] SUSMEL L,TAYLOR D. The theory of critical distances to estimate lifetime of notched components subjected to variable amplitude uniaxial fatigue loading[J]. International Journal of Fatigue,2011,33(7): 900-911. doi: 10.1016/j.ijfatigue.2011.01.012 [21] HU Chen,WEI Dasheng,WANG Yanrong,et al. Experimental and numerical study of fretting fatigue in dovetail assembly using a total life prediction model[J]. Engineering Fracture Mechanics,2019,205: 301-318. doi: 10.1016/j.engfracmech.2018.08.001 -

下载:

下载: