Modeling and robust optimization of grinding and polishing parameters of support casing

-

摘要:

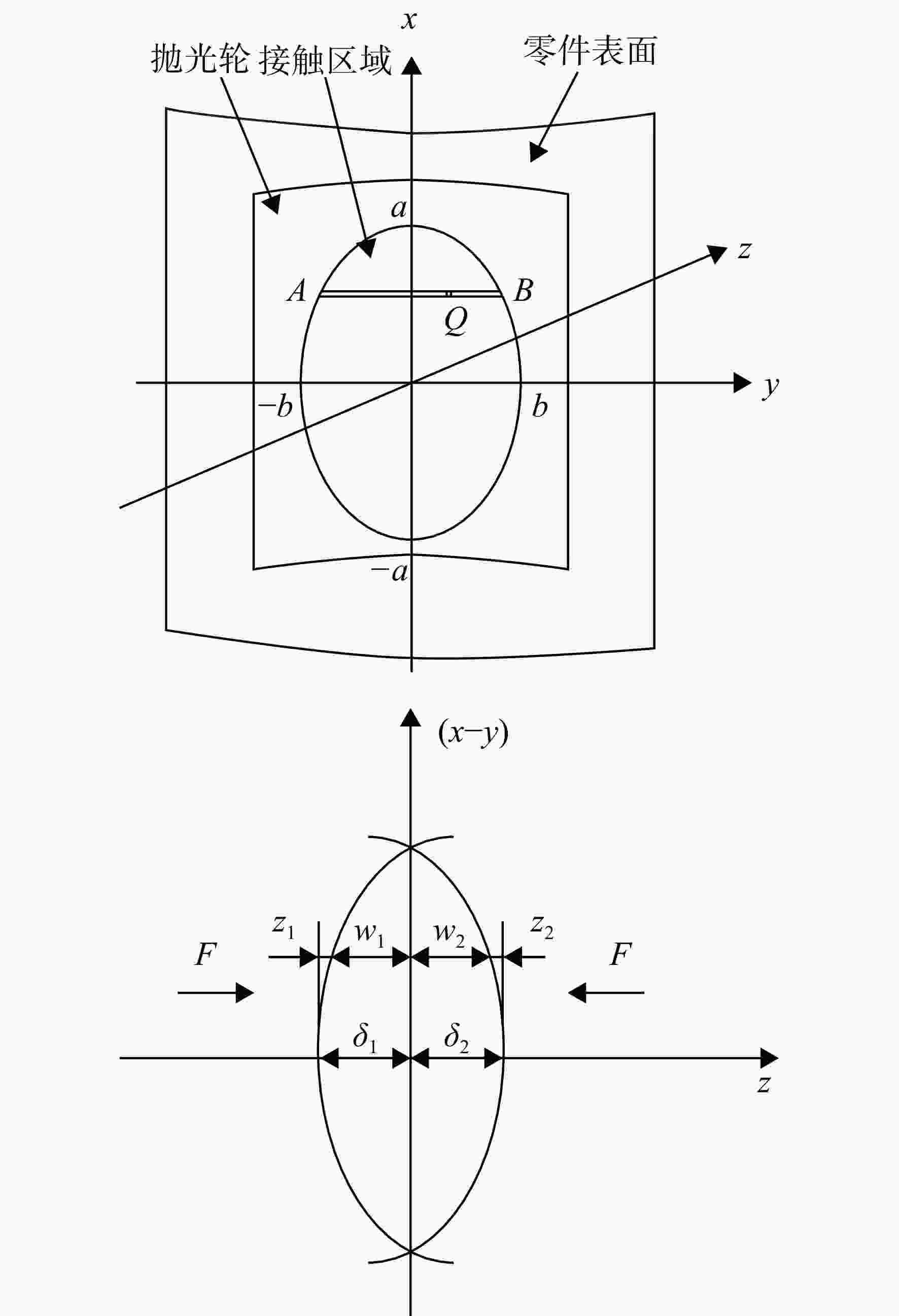

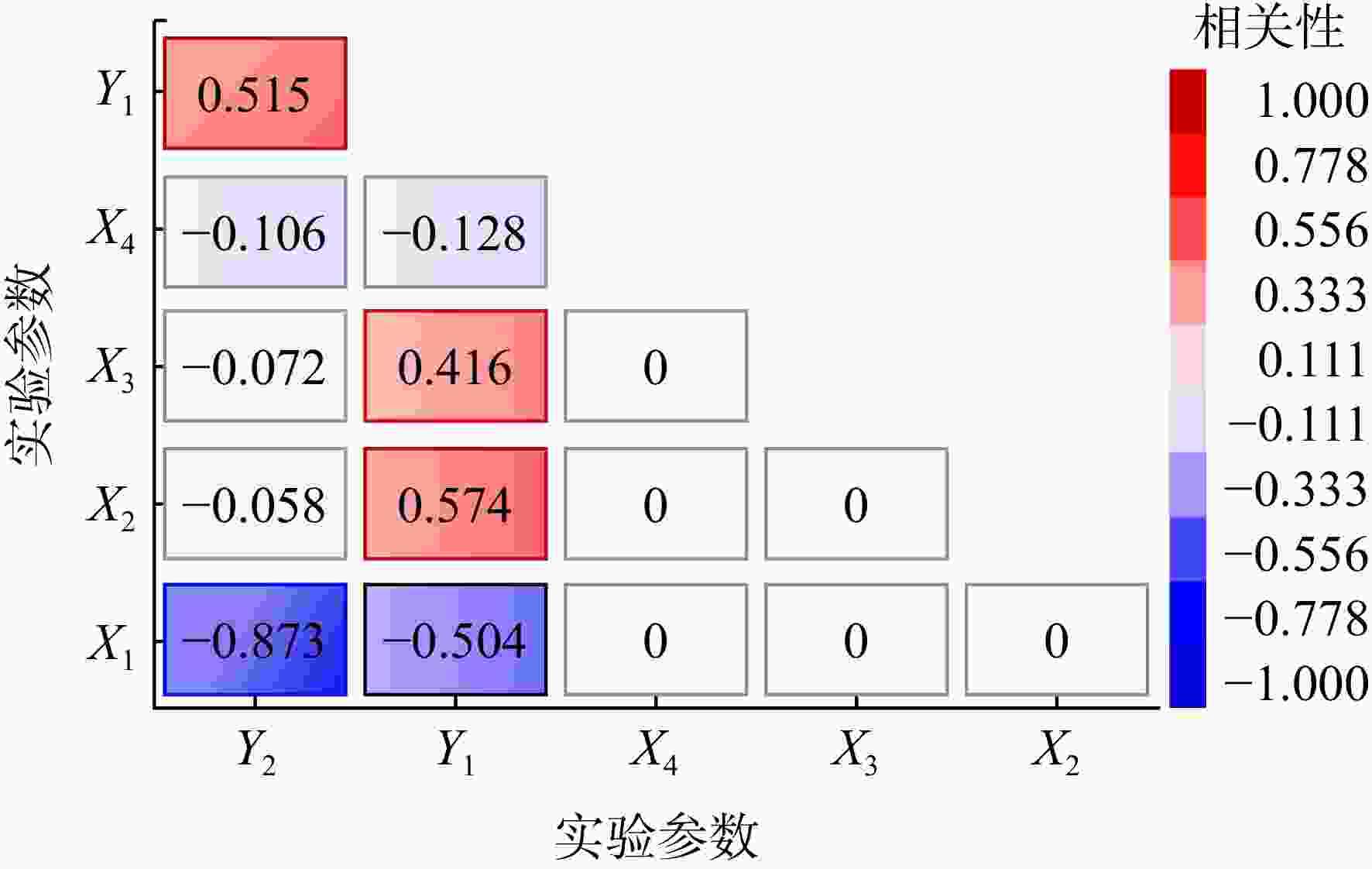

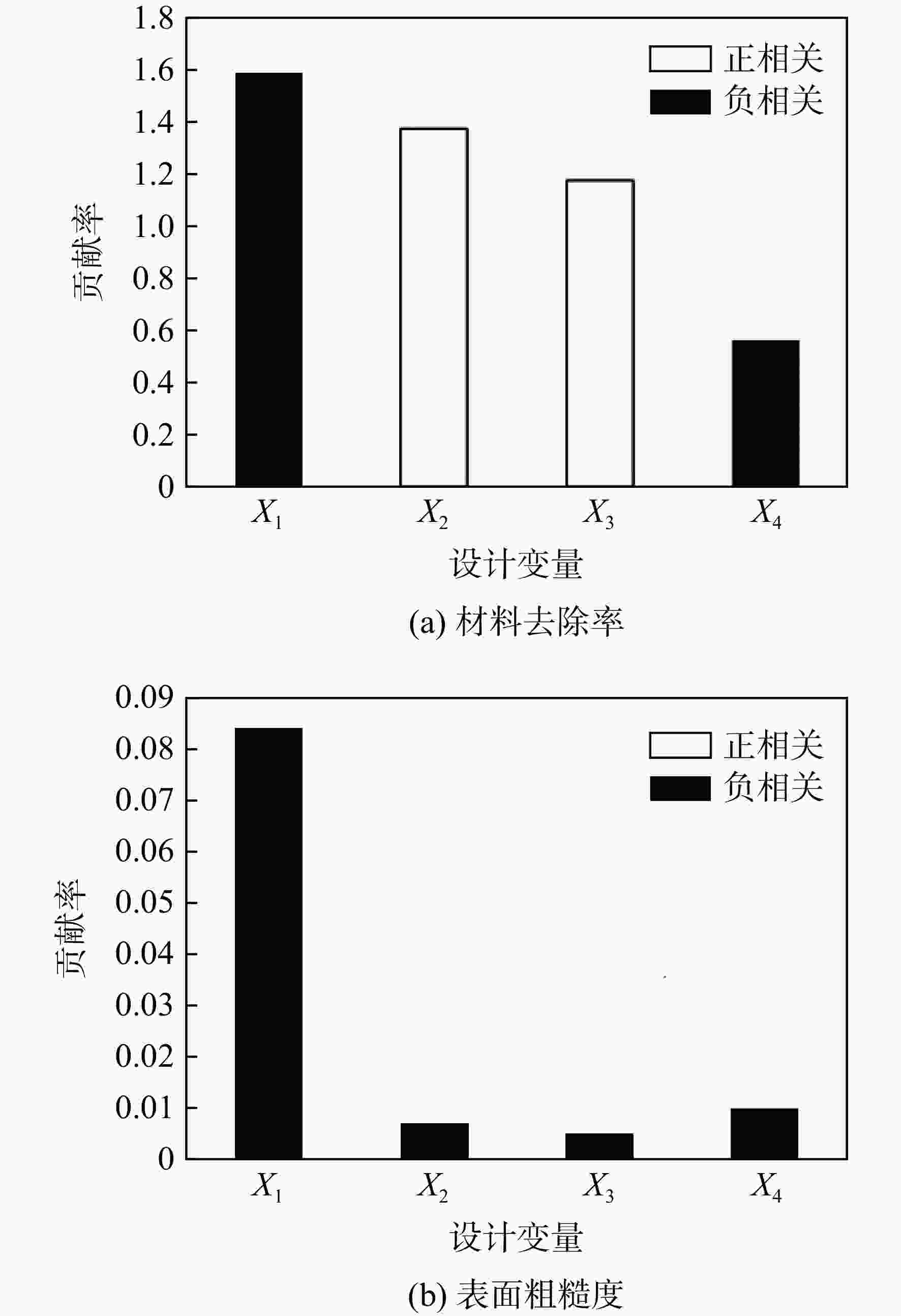

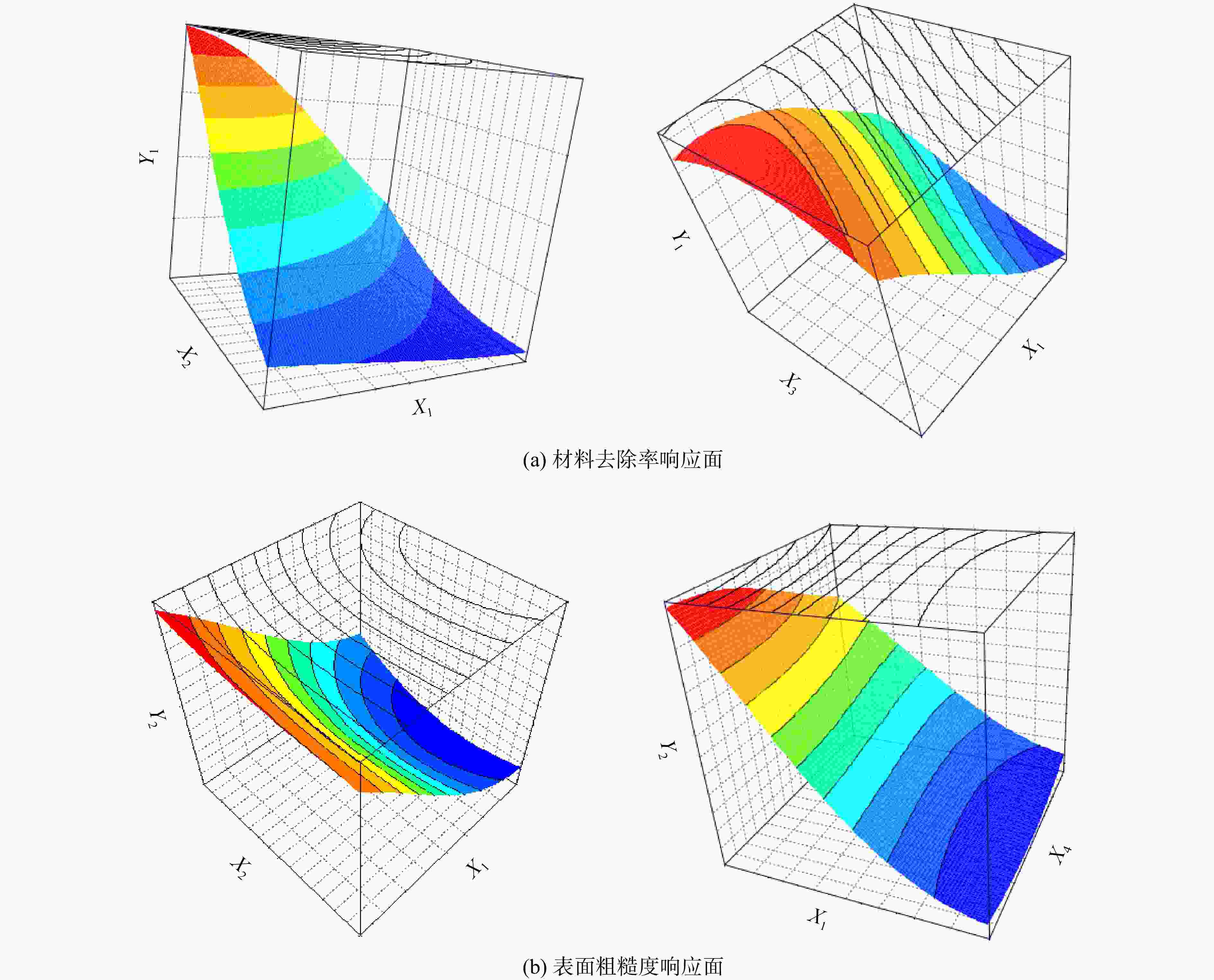

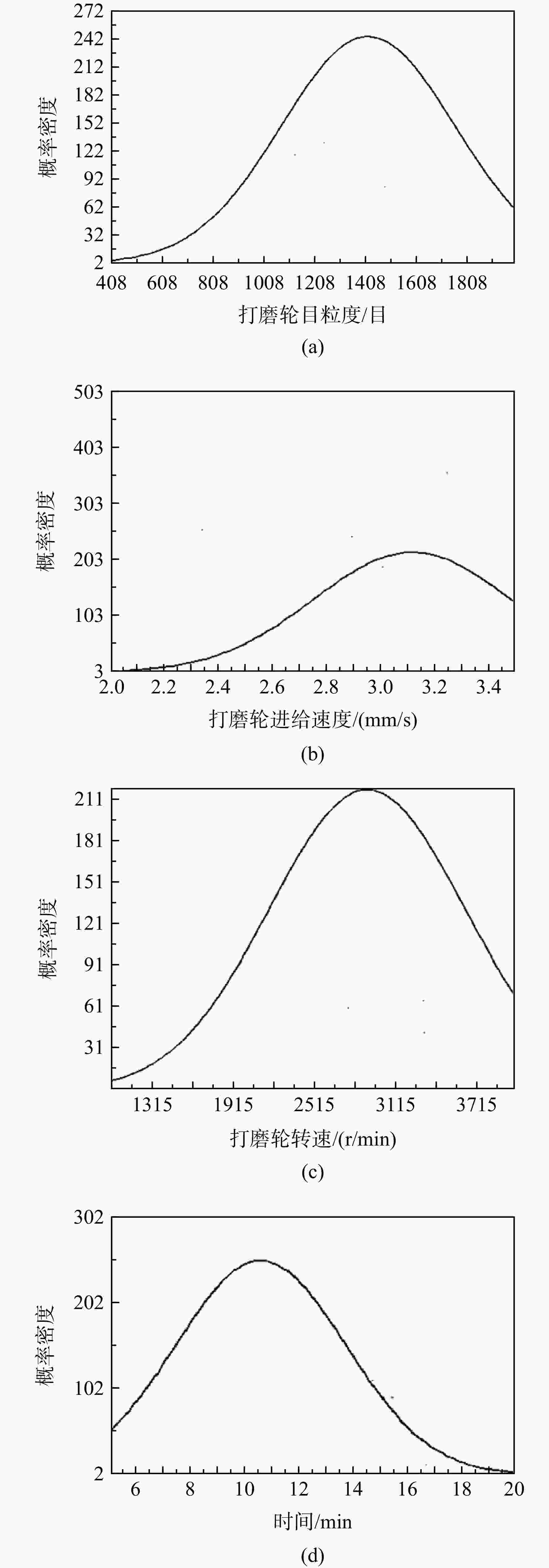

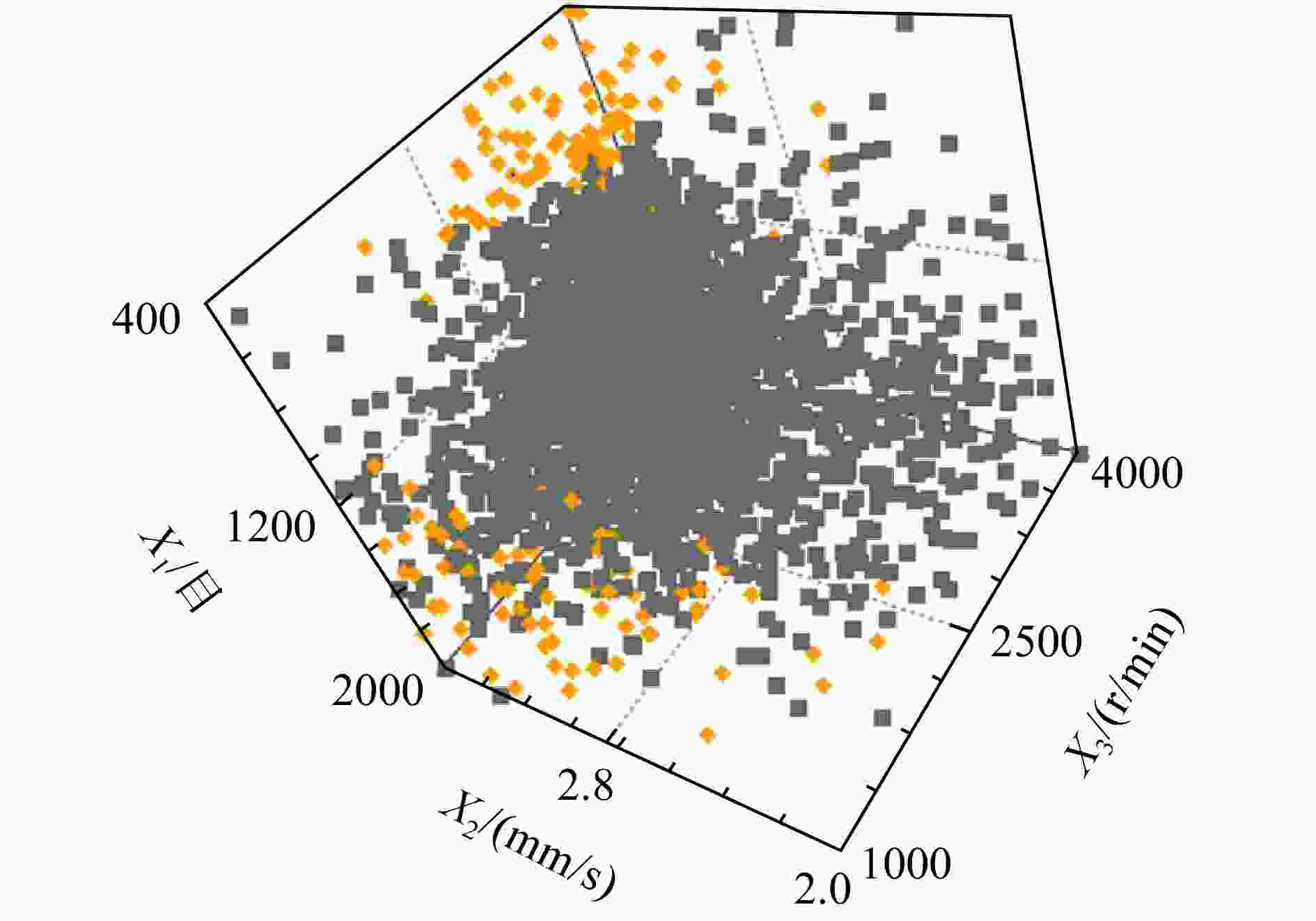

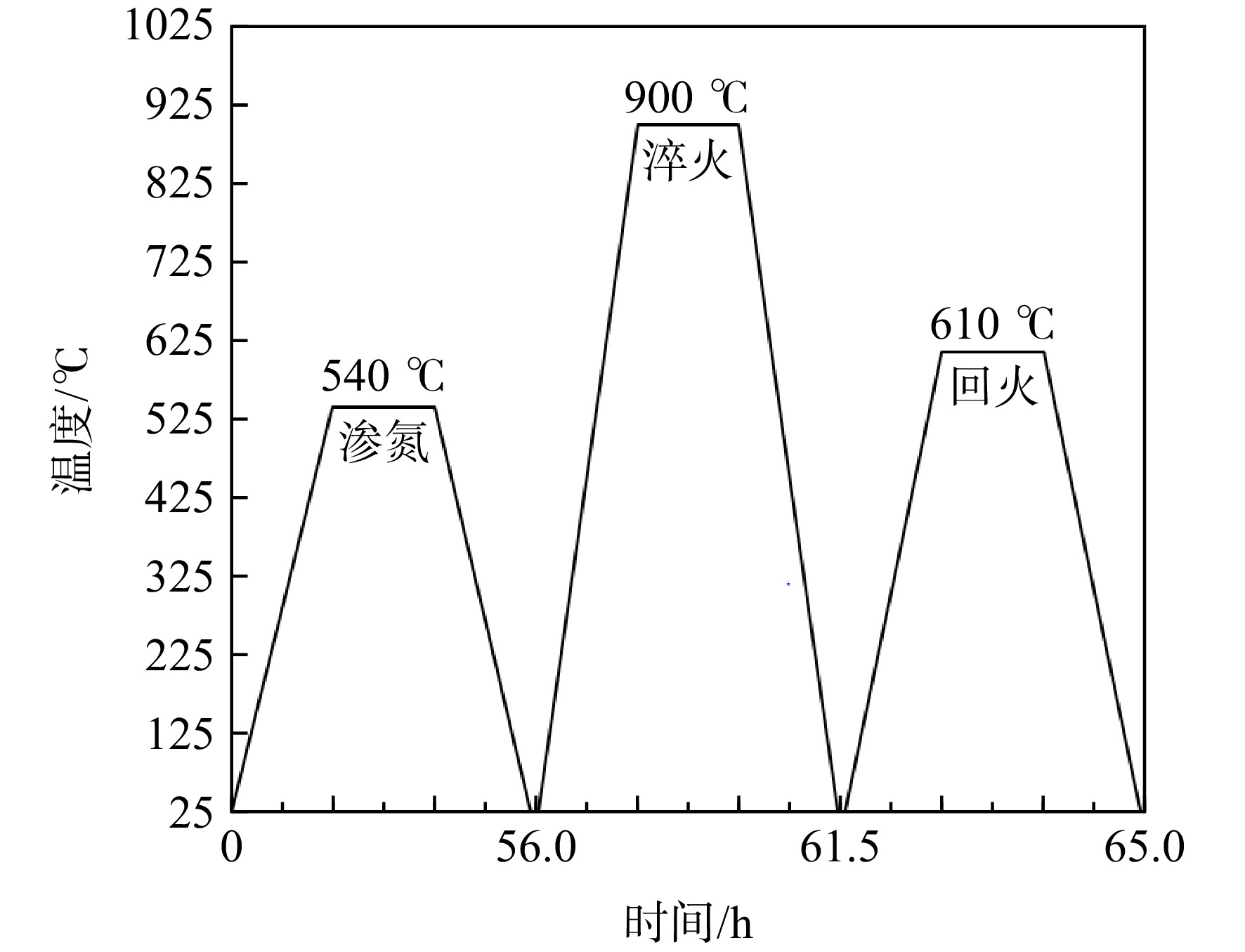

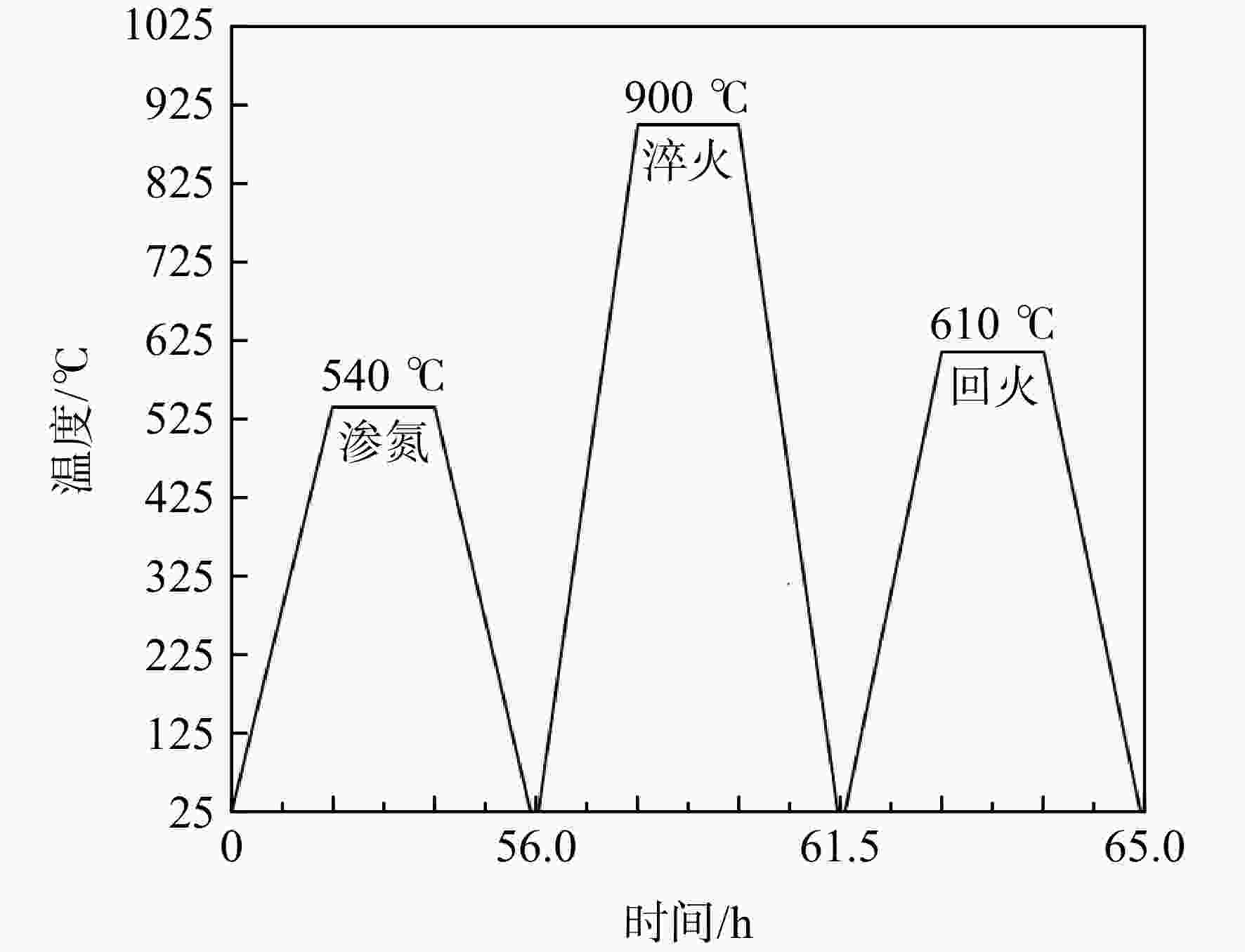

针对支承机匣内孔磨抛表面质量难以保证及磨抛效率低问题,开展了磨抛工艺参数对表面质量影响研究。基于Preston理论建立了螺旋式磨抛材料去除量方程,理论上揭示了螺旋式磨抛工艺参数对表面质量的影响规律。通过正交实验进行方差灵敏度分析,探寻出打磨轮目粒度、打磨轮进给速度、打磨轮转速和抛光时间等影响因子对材料去除率和表面粗糙度影响规律及贡献率,在此基础上以材料去除率和表面粗糙度为优化研究目标,构建了基于Kriging响应面近似模型的稳健优化设计数学模型,采用粒子群算法进行计算求解,计算出2611组优化解。结合实际工程要求,最佳的工艺参数为目粒度1400目、进给速度3 mm/s、转速3600 r/min、抛光时间9 min,为磨抛工程领域的工艺质量改善提供技术支撑。

Abstract:Considering the difficulty of guaranteeing the surface quality of grinding and polishing of the inner hole of the support casing and the low grinding and polishing efficiency, the research on the influence of grinding and polishing process parameters on the surface quality was carried out. Based on Preston's theory, the material removal equation of spiral grinding and polishing was established, and the influence law of spiral grinding and polishing process parameters on surface quality was theoretically revealed. The variance sensitivity analysis was carried out through orthogonal experiments, and the influencing factors such as grinding wheel particle size, grinding wheel feed speed, grinding wheel rotation speed and polishing time on the material removal rate and roughness were found out. On this basis, taking the material removal rate and roughness as the optimization research objectives, a robust optimization design mathematical model based on the Kriging response surface approximation model was constructed, and the particle swarm algorithm was used for calculation and solving, bringing about 2611 sets of optimization solutions. Combined with practical engineering requirements, the optimal process parameters include target particle size 1400, feed speed 3 mm/s, rotational speed 3600 r/min, and polishing time 9 min, providing a technical support for the improvement of process quality in the field of grinding and polishing engineering.

-

表 1 设计空间

Table 1. Design space

设计变量 X1/目 X2/(mm/s) X3/(r/min) X4/min 下限 400 2 1000 5 上限 2 000 3.5 4000 20 表 2 工艺参数水平表

Table 2. Process parameters level table

水平 $ {X}_{1} $/目 $ {X}_{2} $/(mm/s) $ {X}_{3} $/(r/min) $ {X}_{4} $/min 1 400 2 1000 5 2 800 2.5 2 000 10 3 1200 3 3000 15 4 2 000 3.5 4000 20 表 3 实验结果

Table 3. Test results

序号 X1/目 X2/(mm/s) X3/(r/min) X4/min Y1/

(μm/min)Y2/

μm1 1 1 1 1 0.191 0.150 2 1 2 2 2 1.794 0.130 3 1 3 3 3 2.010 0.104 4 1 4 4 4 2.850 0.108 5 2 1 2 3 0.288 0.080 6 2 2 1 4 0.569 0.091 7 2 3 4 1 3.476 0.088 8 2 4 3 2 4.239 0.103 9 3 1 3 4 0.080 0.025 10 3 2 4 3 0.490 0.027 11 3 3 1 2 0.531 0.021 12 3 4 2 1 0.782 0.026 13 4 1 4 2 0.119 0.019 14 4 2 3 1 0.252 0.022 15 4 3 2 4 0.410 0.020 16 4 4 1 3 0.425 0.018 -

[1] 袁巨龙,吴喆,吕冰海,等. 非球面超精密抛光技术研究现状[J]. 机械工程学报,2012,48(23): 167-177. YUAN Julong,WU Zhe,LYU Binghai,et al. Review on ultra-precision polishing technology of aspheric surface[J]. Journal of Mechanical Engineering,2012,48(23): 167-177. (in Chinese doi: 10.3901/JME.2012.23.167 YUAN Julong, WU Zhe, LYU Binghai, et al . Review on ultra-precision polishing technology of aspheric surface[J]. Journal of Mechanical Engineering,2012 ,48 (23 ):167 -177 . (in Chinese) doi: 10.3901/JME.2012.23.167[2] 徐小虎. 压气机叶片机器人砂带磨抛加工关键技术研究[D]. 武汉: 华中科技大学,2019. XU Xiaohu. Research on the key technology of robotic abrasive belt grinding of compressor blade[D]. Wuhan: Huazhong University of Science and Technology,2019. (in ChineseXU Xiaohu. Research on the key technology of robotic abrasive belt grinding of compressor blade[D]. Wuhan: Huazhong University of Science and Technology, 2019. (in Chinese) [3] 王文广. 渗碳淬硬钢18CrNiMo7-6的研抛工艺试验研究[D]. 郑州: 郑州大学,2019. WANG Wenguang. Experimental study on lapping and polishing process of carburized and hardened steel 18CrNiMo7-6[D]. Zhengzhou: Zhengzhou University,2019. (in ChineseWANG Wenguang. Experimental study on lapping and polishing process of carburized and hardened steel 18CrNiMo7-6[D]. Zhengzhou: Zhengzhou University, 2019. (in Chinese) [4] 李春丽,李欢欢,卢虎生. 铈基抛光粉抛光工艺的多响应稳健优化设计[J]. 有色金属科学与工程,2021,12(4): 75-81. LI Chunli,LI Huanhuan,LU Husheng. Multi-response robust optimization design of cerium-based polishing powder’s polishing process[J]. Nonferrous Metals Science and Engineering,2021,12(4): 75-81. (in Chinese doi: 10.13264/j.cnki.ysjskx.2021.04.010 LI Chunli, LI Huanhuan, LU Husheng . Multi-response robust optimization design of cerium-based polishing powder’s polishing process[J]. Nonferrous Metals Science and Engineering,2021 ,12 (4 ):75 -81 . (in Chinese) doi: 10.13264/j.cnki.ysjskx.2021.04.010[5] 吴昌林,王韦,李强,等. 基于Preston方程的不锈钢曲面抛磨工艺参数分析[J]. 机械制造与自动化,2012,41(4): 102-105. WU Changlin,WANG Wei,LI Qiang,et al. Analysis of polishing processing parameters of stainless steel curved surface based on Preston equation[J]. Machine Building & Automation,2012,41(4): 102-105. (in Chinese WU Changlin, WANG Wei, LI Qiang, et al . Analysis of polishing processing parameters of stainless steel curved surface based on Preston equation[J]. Machine Building & Automation,2012 ,41 (4 ):102 -105 . (in Chinese)[6] SONG Ci,DAI Yifan,PENG Xiaoqiang. Model and algorithm based on accurate realization of dwell time in magnetorheological finishing[J]. Applied Optics,2010,49(19): 3676-3683. doi: 10.1364/AO.49.003676 [7] HU Xiaokai,SONG Zhitang,LIU Weili,et al. Chemical mechanical polishing of stainless steel foil as flexible substrate[J]. Applied Surface Science,2012,258(15): 5798-5802. doi: 10.1016/j.apsusc.2012.02.100 [8] 张如刚. 基于稳健性方法的汽车覆盖件冲压成形优化设计[D]. 长沙: 湖南大学,2012. ZHANG Rugang. Optimization design of sheet metal forming based on robustness method[D]. Changsha: Hunan University,2012. (in ChineseZHANG Rugang. Optimization design of sheet metal forming based on robustness method[D]. Changsha: Hunan University, 2012. (in Chinese) [9] WANG G,WANG Y,XU Z. Modeling and analysis of the material removal depth for stone polishing[J]. Journal of Materials Processing Technology,2009,209(5): 2453-2463. [10] 刘随建,吴伟东. 整体叶盘叶片光饰抛光试验及发展应用探析[J]. 航空制造技术,2010,53(5): 84-86. LIU Suijian,WU Weidong. Research of development and application of polishing test for blisk blade[J]. Aeronautical Manufacturing Technology,2010,53(5): 84-86. (in Chinese doi: 10.16080/j.issn1671-833x.2010.05.013 LIU Suijian, WU Weidong . Research of development and application of polishing test for blisk blade[J]. Aeronautical Manufacturing Technology,2010 ,53 (5 ):84 -86 . (in Chinese) doi: 10.16080/j.issn1671-833x.2010.05.013[11] 张景强. 超高速纳米陶瓷结合剂CBN砂轮制备技术及其特性实验研究[D]. 沈阳: 东北大学,2013. ZHANG Jingqiang. Experimental study on preparation technology and characteristics of nano-ceramic vitrified bond super-high speed CBN wheel[D]. Shenyang: Northeastern University,2013. (in ChineseZHANG Jingqiang. Experimental study on preparation technology and characteristics of nano-ceramic vitrified bond super-high speed CBN wheel[D]. Shenyang: Northeastern University, 2013. (in Chinese) [12] 刘瑞江,张业旺,闻崇炜,等. 正交试验设计和分析方法研究[J]. 实验技术与管理,2010,27(9): 52-55. LIU Ruijiang,ZHANG Yewang,WEN Chongwei,et al. Study on the design and analysis methods of orthogonal experiment[J]. Experimental Technology and Management,2010,27(9): 52-55. (in Chinese doi: 10.3969/j.issn.1002-4956.2010.09.016 LIU Ruijiang, ZHANG Yewang, WEN Chongwei, et al . Study on the design and analysis methods of orthogonal experiment[J]. Experimental Technology and Management,2010 ,27 (9 ):52 -55 . (in Chinese) doi: 10.3969/j.issn.1002-4956.2010.09.016[13] 李明星,王显会,周云波,等. 基于神经网络的车辆抗冲击防护组件优化[J]. 爆炸与冲击,2020,40(2): 110-118. LI Mingxing,WANG Xianhui,ZHOU Yunbo,et al. Research on optimization of vehicle anti-shock protection components based on neural network[J]. Explosion and Shock Waves,2020,40(2): 110-118. (in Chinese LI Mingxing, WANG Xianhui, ZHOU Yunbo, et al . Research on optimization of vehicle anti-shock protection components based on neural network[J]. Explosion and Shock Waves,2020 ,40 (2 ):110 -118 . (in Chinese)[14] NATARAJ C,HARSHA S P. The effect of bearing cage run-out on the nonlinear dynamics of a rotating shaft[J]. Communications in Nonlinear Science and Numerical Simulation,2008,13(4): 822-838. doi: 10.1016/j.cnsns.2006.07.010 [15] WANG Hongchao,CHEN Jin. Performance degradation assessment of rolling bearing based on bispectrum and support vector data description[J]. Journal of Vibration and Control,2014,20(13): 2032-2041. doi: 10.1177/1077546313483653 [16] UPADHYAY S H,HARSHA S P,JAIN S C. Vibration signature analysis of high speed unbalanced rotating shaft supported on ball bearings[J]. International Journal of Design Engineering,2009,2(2): 191-204. doi: 10.1504/IJDE.2009.028651 [17] 唐云冰,高德平,罗贵火. 滚动轴承非线性轴承力及其对轴承系统振动特性的影响[J]. 航空动力学报,2006,21(2): 366-373. TANG Yunbing,GAO Deping,LUO Guihuo. Non-linear bearing force of the rolling ball bearing and its influence on vibration of bearing system[J]. Journal of Aerospace Power,2006,21(2): 366-373. (in Chinese doi: 10.3969/j.issn.1000-8055.2006.02.024 TANG Yunbing, GAO Deping, LUO Guihuo . Non-linear bearing force of the rolling ball bearing and its influence on vibration of bearing system[J]. Journal of Aerospace Power,2006 ,21 (2 ):366 -373 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2006.02.024[18] 姜彦翠,刘献礼,吴石,等. 基于铣削稳定性的淬硬钢铣削加工工艺参数优化[J]. 大连交通大学学报,2016,37(6): 26-30. JIANG Yancui,LIU Xianli,WU Shi,et al. Optimization of milling process parameters for hardened steel considering milling stability[J]. Journal of Dalian Jiaotong University,2016,37(6): 26-30. (in Chinese doi: 10.13291/j.cnki.djdxac.2016.06.005 JIANG Yancui, LIU Xianli, WU Shi, et al . Optimization of milling process parameters for hardened steel considering milling stability[J]. Journal of Dalian Jiaotong University,2016 ,37 (6 ):26 -30 . (in Chinese) doi: 10.13291/j.cnki.djdxac.2016.06.005[19] 张紫煊. 基于粒子群算法的旅行商问题解决方案研究[J]. 中国科技投资,2016(33): 360-361. ZHANG Zixuan. Research on solution of traveling salesman problem based on particle swarm optimization[J]. China Venture Capital,2016(33): 360-361. (in Chinese doi: 10.3969/j.issn.1673-5811.2016.33.320 ZHANG Zixuan . Research on solution of traveling salesman problem based on particle swarm optimization[J]. China Venture Capital,2016 (33 ):360 -361 . (in Chinese) doi: 10.3969/j.issn.1673-5811.2016.33.320 -

下载:

下载: