Numerical study on the sealing performance of shape memory alloy beam seal

-

摘要:

针对一种阴接头密封梁具有椭圆弧凹槽的形状记忆合金梁式管接头,利用ABAQUS软件建立考虑管内流体压力和温度的弹塑性有限元热力耦合模型,数值模拟得到阴、阳接头间的接触带宽和接触应力分布。基于逾渗理论与微观粗糙密封界面有限元接触分析,计算得到形状记忆合金材料密封界面泄漏概率为零的临界接触应力。结合第一道密封的接触应力分布,以

S 指数作为形状记忆合金梁式管接头密封性能的评价指标,数值模拟了预紧力、管内流体压力和温度对形状记忆合金梁式管接头密封性能影响。结果表明:在装配拧紧力矩范围内形状记忆合金梁式管接头密封性能随着预紧力增大而增强;密封性能随着管内流体压力的升高会提高,具有良好的自封性;在−50~200 ℃的管内流体温度范围内密封性能基本稳定,满足密封要求。数值分析表明在相同工作条件下形状记忆合金梁式管接头相比于不锈钢和钛合金梁式管接头具有更优的密封性能。Abstract:In view of a shape memory alloy beam seal with elliptical arc groove in the female connector, the elastoplastic finite element thermodynamic coupling model considering the fluid pressure and temperature in the pipe was established by using ABAQUS software. The contact bandwidth and contact stress distribution between the female and male connectors were obtained by numerical simulation. Based on percolation theory and finite element contact analysis of micro rough sealing interface, the critical contact stress with zero leakage probability of shape memory alloy sealing interface was calculated. Combined with the contact stress distribution on the primary seal,

S index was used as the evaluation criterion of the sealing performance of shape memory alloy beam seal. The effects of preload, fluid pressure and temperature on the sealing performance of shape memory alloy beam seal were numerically simulated. The results showed that within the range of assembly tightening torque, the sealing performance increased with the increase of preload; the sealing performance increased with the increase of fluid pressure in the pipe, indicating that it had good self-sealing feature; the sealing performance was basically stable within the fluid temperature range of −50— 200 ℃, which could meet the sealing requirements. Numerical analysis showed that shape memory alloy beam seal had better sealing performance than stainless steel and titanium alloy beam seal under the same working conditions. -

管接头是航空发动机液压系统中最基础的元件之一,其密封性能对系统安全可靠性至关重要。国内常采用的可分离74°锥和球型接头在管内压力22 MPa条件下偶有泄漏现象发生,其密封性能亟待提高。相比于传统管接头型式,梁式管接头安装尺寸更短,并具有自封能力,能承受剧烈振动和高压力脉动,密封的流体压力可达55 MPa[1]。由于具有优异的密封性能,梁式管接头在国外多款高性能战斗机中得到了成功应用,大幅提高了航空液压系统的压力和密封可靠性。

目前在国内航空领域梁式管接头的应用仍为空白,并且国内外对梁式管接头研究鲜有报道。梁式管接头的核心技术在于阴接头的构型设计,Jeon等[2]和李晓东[3]设计了双锥度的阴接头结构,数值研究表明双锥度梁式管接头仅能形成一道具有较大接触应力的密封区域。文献[4]将梁式管接头阴接头设计为带有椭圆弧凹槽的结构,采用有限元弹塑性接触力学模型,计算表明该型梁式管接头能够形成两道密封,并通过试验验证了理论数值模拟的有效性。闫洋洋等[5]以接触面积为密封性能评价指标,针对卡套式管接头试验研究了流体温度对密封性能的影响。文献[6]综合考虑梁式管接头密封面接触带宽与接触应力,提出将S指数作为定量评价梁式管接头密封性能的指标,并计算得到了梁式管接头密封性能的敏感参数及其敏感区间。文献[7]以S指数为钛合金材料的梁式管接头密封性能评价指标,利用优化软件Isight和多岛遗传算法得出密封性能最优的阴接头结构。这些工作为进一步探索新材料的梁式管接头奠定了基础。

形状记忆合金(shape memory alloy,SMA)因其具有超弹性和形状记忆功能、高阻尼、高强度和耐磨性、抗腐蚀性好等优良的力学性能被广泛应用于诸多领域[8-10]。其中,SMA永久式航空管接头是SMA工业应用的成功案例之一[11]。相比于不锈钢和钛合金材料,SMA弹性模量更小,更易于形成紧密接触的密封界面。同时,SMA特有的高阻尼特性可提高管路密封结构的抗振能力,适用于航空领域实际工程中复杂的振动工况。因而将SMA应用于梁式管接头,有望能进一步提升梁式管接头的密封性能和可靠性。

本文采用理论数值方法探索形状记忆合金NiTiFe材料的梁式管接头的密封性能。建立考虑管内流体压力和温度的SMA梁式管接头有限元热力耦合模型,计算得到两道密封界面的接触应力分布规律。基于逾渗理论和微观粗糙密封界面有限元接触分析得到SMA材料密封界面泄漏概率为零的临界接触应力。进而,以S指数作为SMA梁式管接头密封性能的评价指标,计算分析预紧力、流体压力和流体温度对SMA梁式管接头密封性能的影响。最后将SMA梁式管接头与不锈钢和钛合金梁式管接头密封性能进行对比分析。

1. SMA梁式管接头接触有限元分析

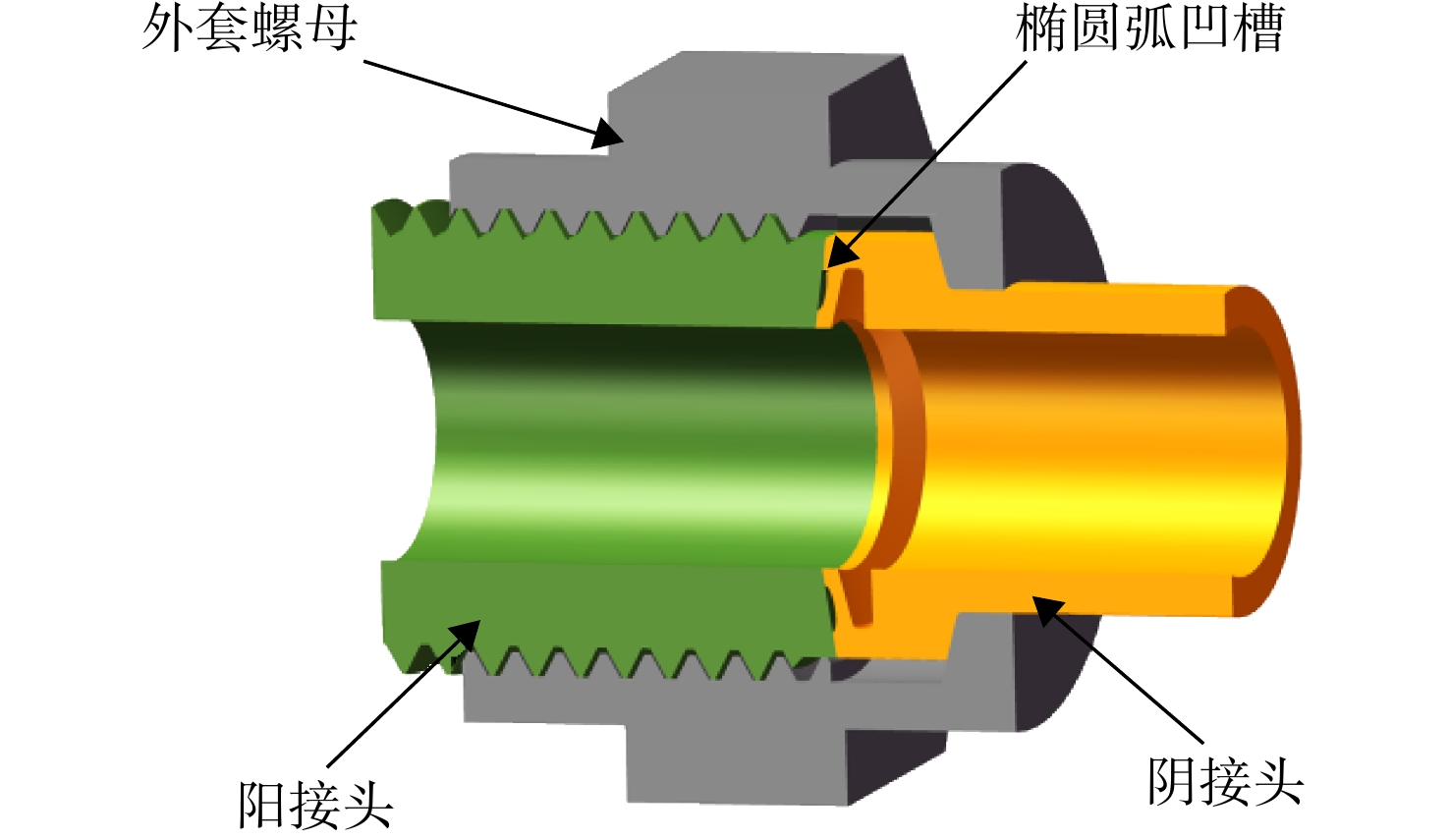

研究对象为文献[7]中经过优化设计的梁式管接头结构,管径为12 mm,如图1所示。SMA梁式管接头由外套螺母和阳接头、阴接头构成,阴接头的密封面设计有椭圆弧凹槽。在外套螺母处施加拧紧力矩,在轴向预紧力的作用下,阴、阳接头间形成两道密封,防止管内高压流体向外泄漏。

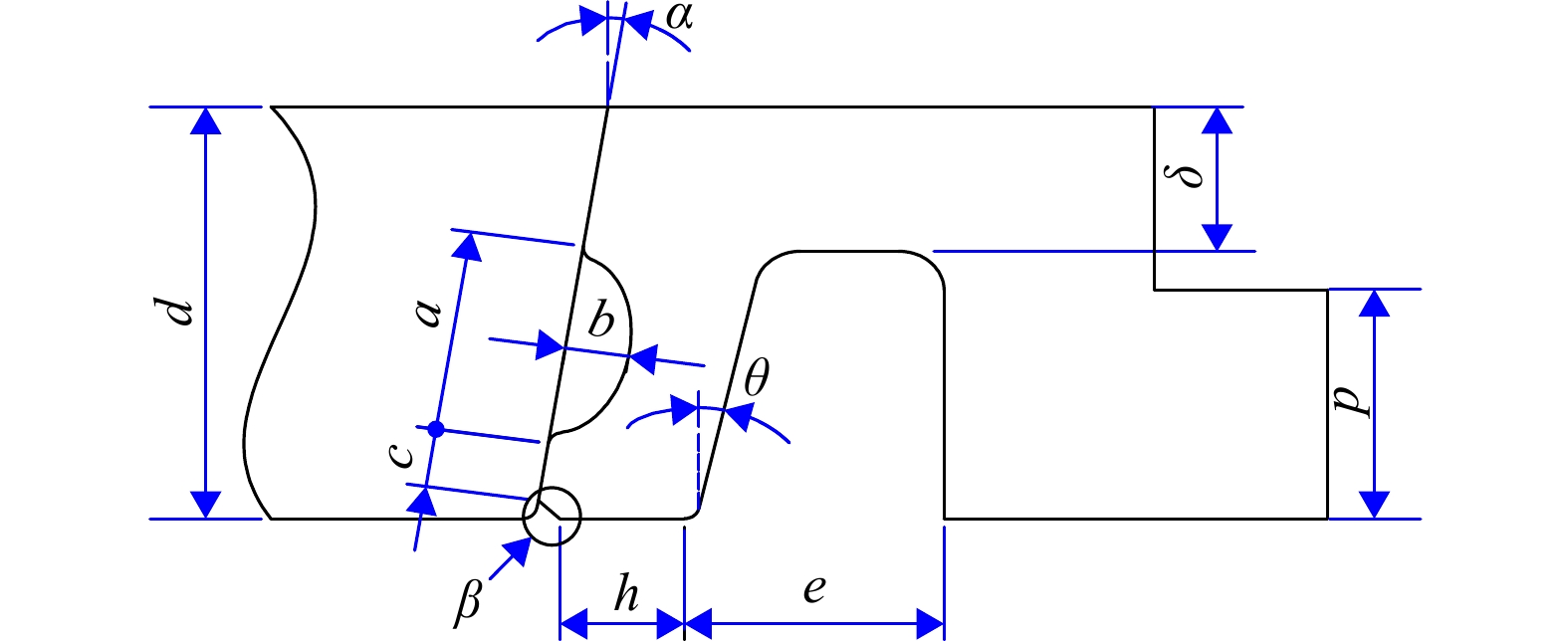

梁式管接头结构参数定义如图2所示,12 mm管径的梁式管接头的具体结构参数取值如表1所示。梁式管接头的阴、阳接头和外套螺母均采用NiTiFe形状记忆合金材料。室温下其弹性模量为89.0 GPa,密度为6440 kg/m3,泊松比为0.33,SMA材料的塑性本构关系如表2所示。

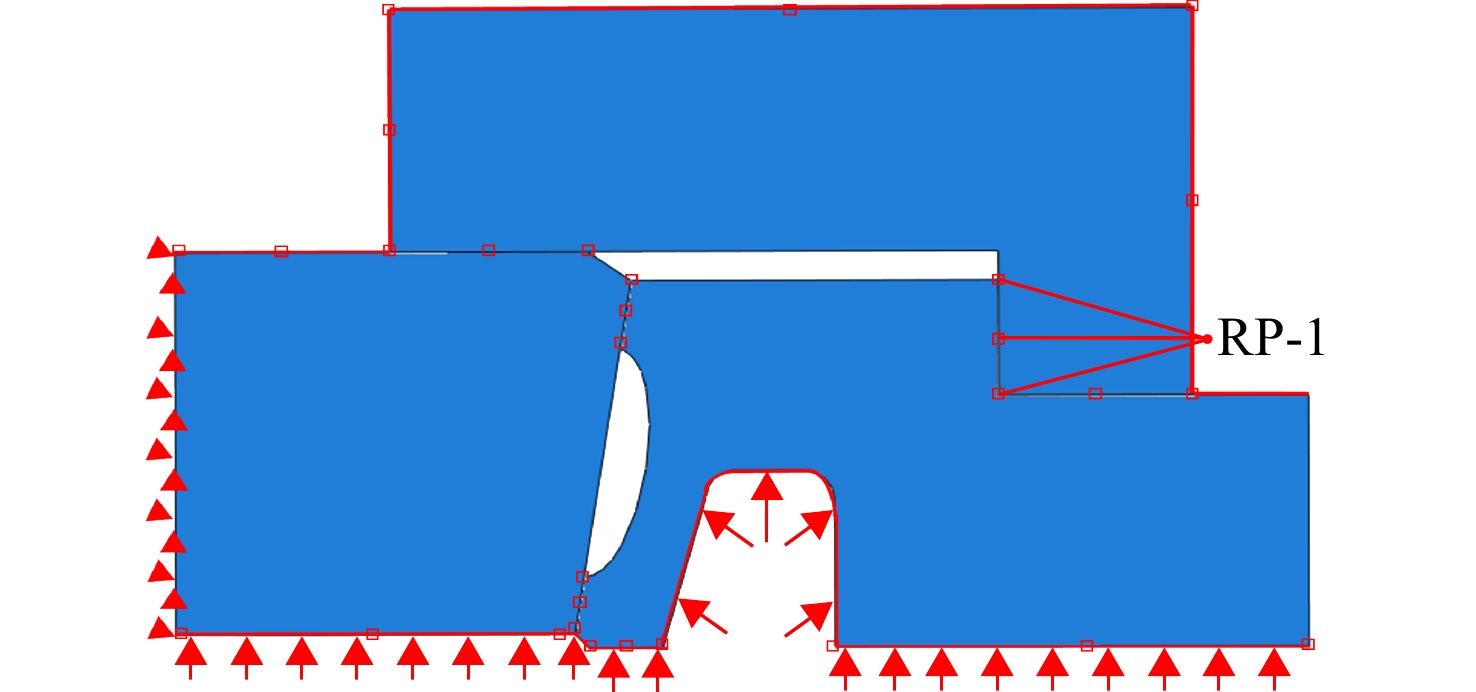

表 1 SMA梁式管接头结构参数Table 1. Geometric parameters of SMA beam seal结构参数 数值 U形梁椭圆弧凹槽的长轴a/mm 1.66 U形梁椭圆弧凹槽的短半轴b/mm 0.30 第一道密封名义接触带宽c/mm 0.49 阳接头壁厚d/mm 2.70 U形口轴向长度e/mm 1.04 密封梁截面宽度h/mm 0.50 阴接头壁厚p/mm 1.55 锥面角α/(°) 8.50 阴接头倒角角度β/(°) 45.0 U形梁底部与阴接头外径的距离δ/mm 1.10 U形梁与径向的夹角θ/(°) 15.0 表 2 NiTiFe塑性本构关系Table 2. Plastic constitutive relationship of NiTiFe真实应力/MPa 塑性应变 真实应力/MPa 塑性应变 600 0 750 0.03 650 0.01 800 0.06 700 0.02 850 0.1 SMA梁式管接头的接触有限元模型如图3所示,对外套螺母与阳接头之间的螺纹进行了省略以简化模型。根据梁式管接头实际受力情况,在阳接头底部施加固定约束,通过建立阴接头受力区域与参考点RP-1之间的分布耦合约束,模拟外套螺母拧紧过程对阴接头施加的预紧力。压力、温度载荷施加于管接头内壁。将阴接头接触面设为主面,阳接头接触面设为从面,利用面面接触模型和有限滑移公式对阴、阳接头接触面进行定义。阴、阳接头接触面库仑摩擦因数设为0.15,导热系数为20 W/(m·℃)。螺母外壁与环境之间表面传热系数为0.27×10−4 W/(mm2·℃)[12],阳接头与螺母间导热系数为15 W/(m·℃),热膨胀系数为1.1×10−5/℃。

有限元模型网格为四节点隐式热力耦合轴对称单元CAX4RT,对阴阳接头密封接触面的网格进行局部加密,如图4所示。

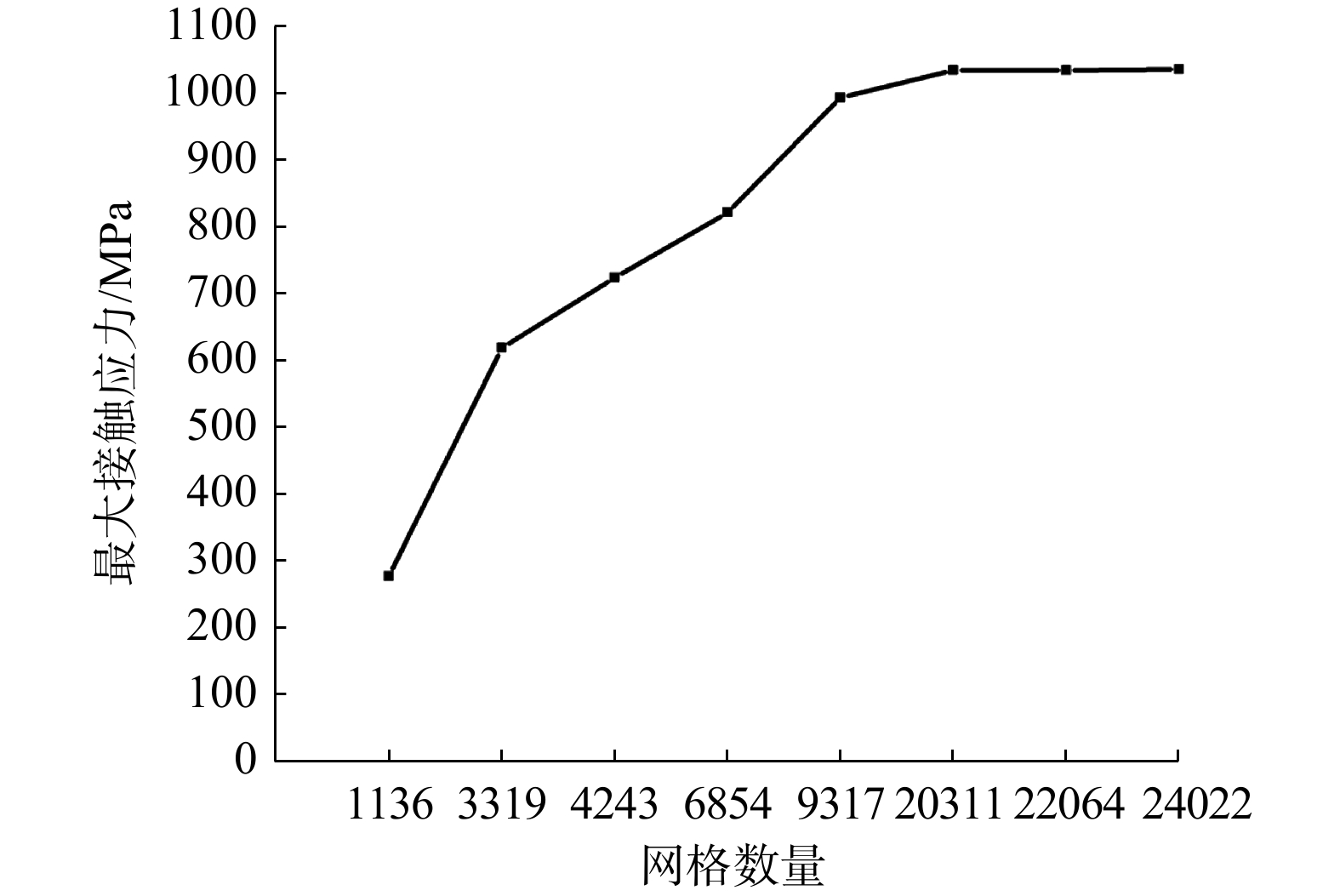

对SMA梁式管接头施加18 kN预紧力,选取流体压力28 MPa,温度20 ℃,管接头外环境温度20 ℃,计算第一道密封最大接触应力与模型网格数量的关系,进行网格无关性验证。计算结果如图5所示,当模型网格数量加密至20311个时,计算结果趋于稳定。综合计算精度与效率,阴阳接头接触面采用尺寸为8 μm的加密网格,其他部分网格尺寸为50 μm。

采用Newton-Raphson法与对称罚函数法计算阴接头接触应力分布,如图6所示。可见,梁式管接头压紧时形成两道有效密封,其中内径端的线密封为第一道主密封,外径端的面密封为第二道密封。阴接头密封梁上椭圆形凹槽的存在使得两道密封之间形成具有弹性的隔离空腔,能够有效地防止液压管路系统外部振动从第二道密封传递到密封梁端部的第一道密封,保证管路系统密封性稳定可靠[4]。

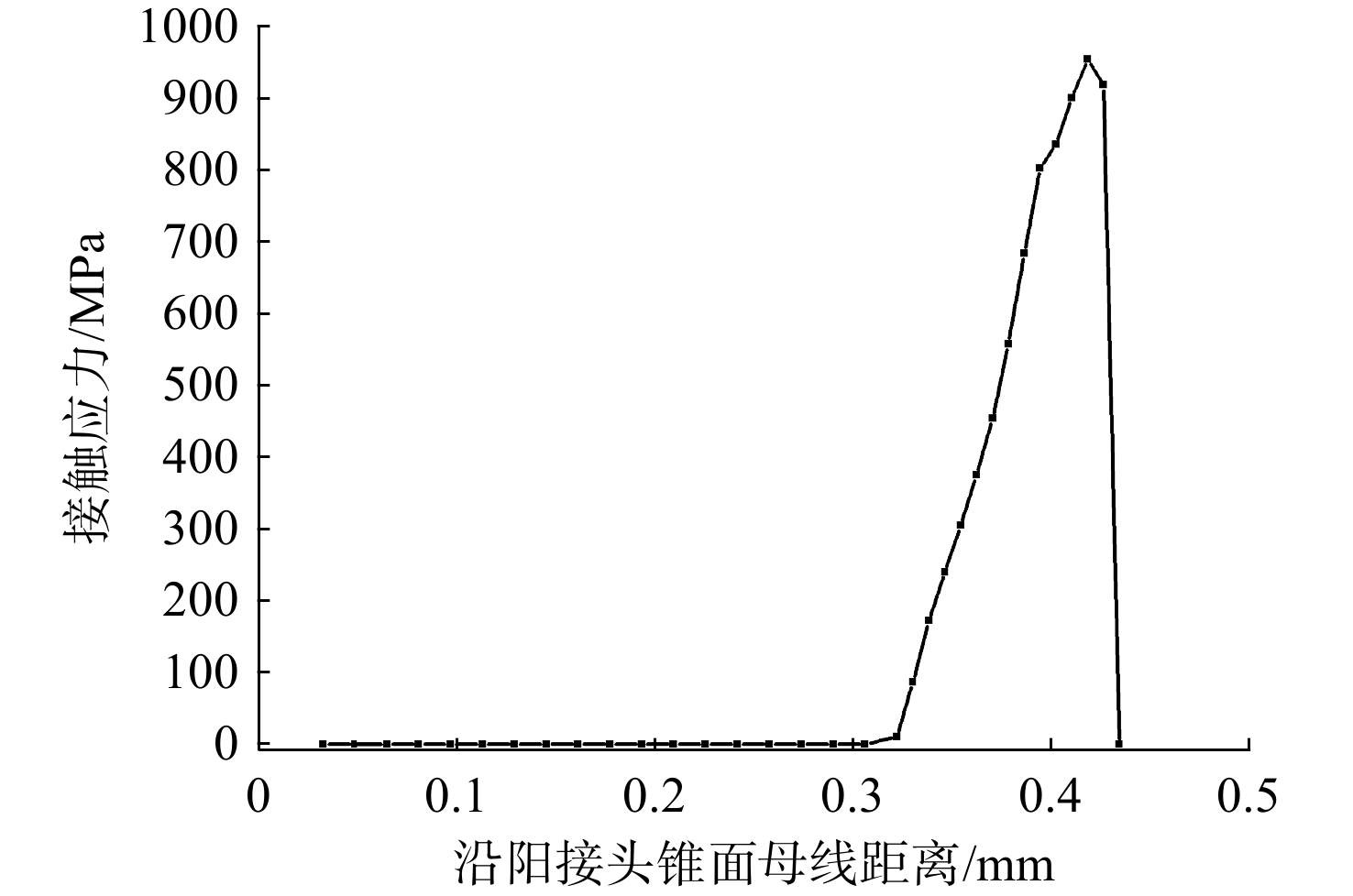

图7给出了SMA梁式管接头第一道密封接触应力分布,沿阳接头锥面母线0~0.31 mm距离范围无接触应力,在0.31~0.41 mm距离范围内产生接触应力并逐渐增大至978 MPa。梁式管接头在装配过程中,第二道密封相当于梁的固支端,施加的预紧力会使相当于悬臂端的第一道密封发生滑动,并使第一道密封内径端部发生翘曲,使得内径侧接触应力为零。

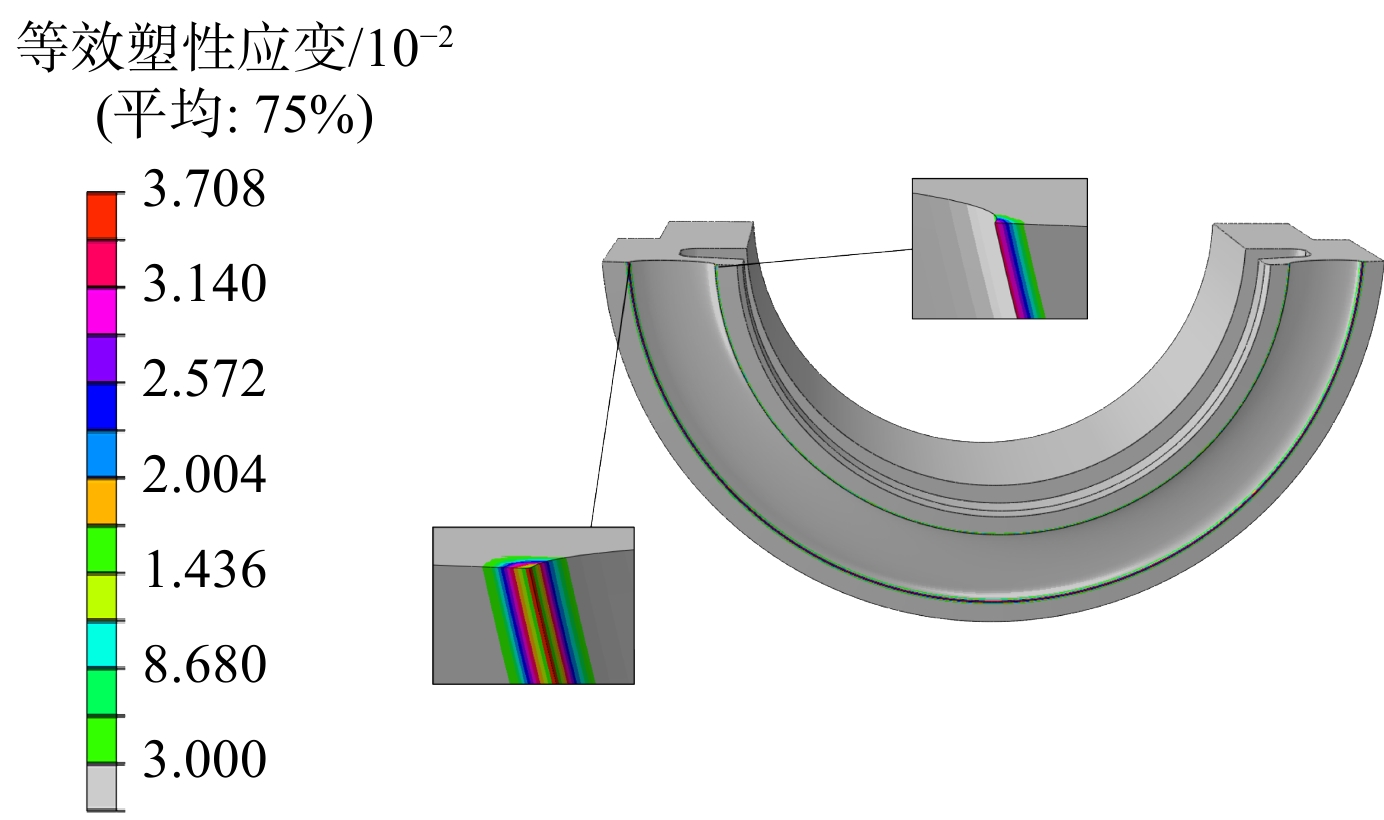

同时在该预紧力条件下,梁式管接头两道密封靠近椭圆弧处均产生塑性应变,其他位置为弹性变形,如图8所示。

2. 梁式管接头密封性能评价指标

Persson等[13]研究指出,金属粗糙接触面上存在贯通的微观通道会使密封的流体泄漏。文献[14]基于逾渗理论和自动寻径算法,计算得到密封泄漏概率随接触面积比变化的曲线,如图9 所示。当接触面积比达0.43时泄漏概率为零,将与其对应的平均接触应力定义为临界接触应力pc。

两个粗糙表面之间的接触可以等效为单个粗糙表面与刚性平面接触[15],其粗糙度的等效关系如式(1)所示。

σ20=σ21+σ22 (1) 式中

σ1 、σ2 分别为两个粗糙面的方均根粗糙度,设σ1=σ2=0.35μm ,可将其等效为方均根粗糙度为0.5 μm的粗糙面与刚性平面接触。采用自相关函数法建立了方均根粗糙度为0.5 μm的各向同性粗糙表面,自相关函数如式(2)所示[16]。R(τx,τy)=ζ2exp{−2.3[(τxβx)2+(τyβy)2]1/2} (2) 式中

R(τx,τy) 为自相关函数,ζ 为方均根粗糙度,βx 与βy 为x和y方向的自相关长度,τx 和τy 为x、y平面的坐标值。建立刚性平面与SMA粗糙面微观接触模型如图10所示,接触面尺寸为800 μm×800 μm,SMA粗糙面基底层网格为10节点四面体单元C3D10M,粗糙面表层网格为六面体非协调单元C3D8I。在粗糙面底部施加固定约束,刚性平面向下施加20 μm的位移载荷,计算得到SMA接触应力随接触面积比的变化曲线如图11所示,可见泄漏概率为零的接触面积比对应的临界接触应力pc为369.5 MPa。文献[6]提出的密封性能的S指数评价准则,如式(3)所示:

S=∫x2x1[f(x)−pc] dx (3) 式中

f(x) 为阴、阳接头间第一道密封处接触应力分布函数,x1 与x2 为f(x) 与临界接触应力pc交点的横坐标。图12给出了S指数求解的示意图,可见S指数越大梁式管接头密封可靠性越高。本文中S指数作为评价SMA梁式管接头密封性能的量化指标。3. SMA梁式管接头密封性能影响因素分析

3.1 预紧力对密封性能影响的分析

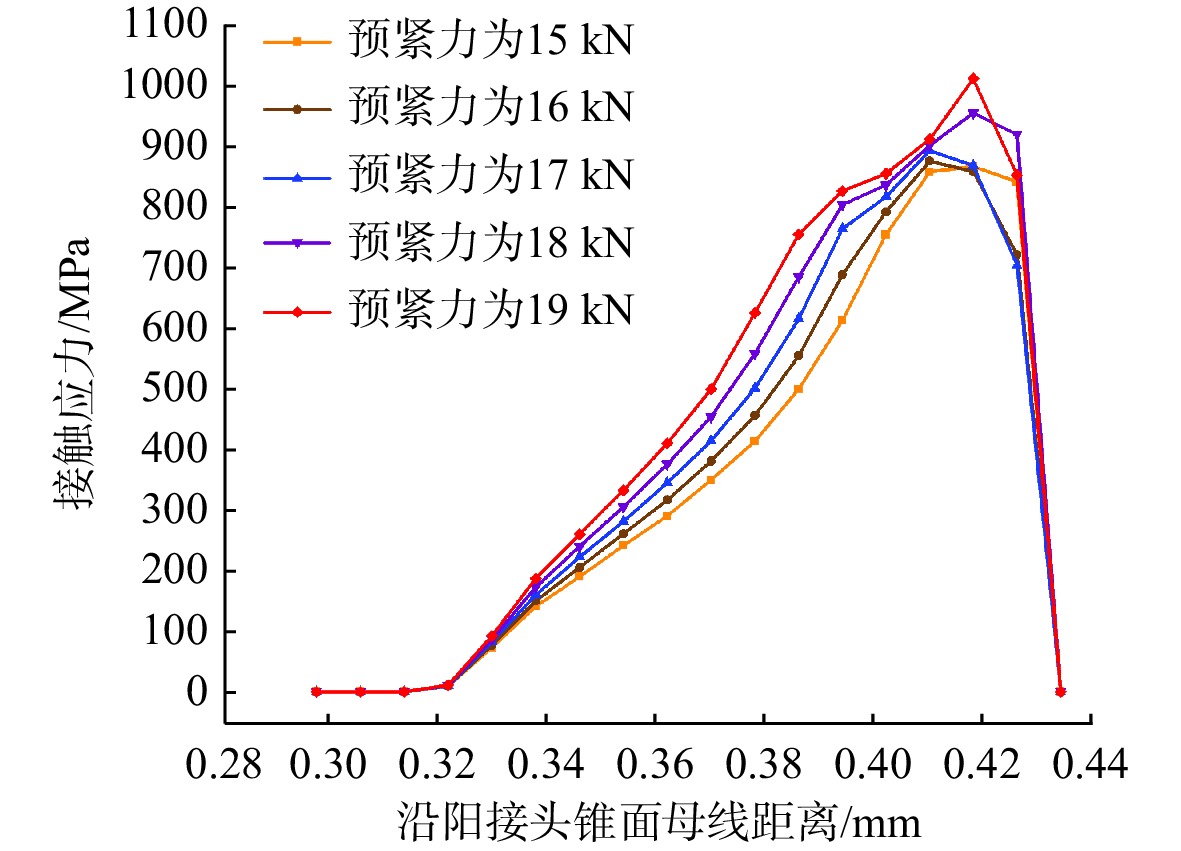

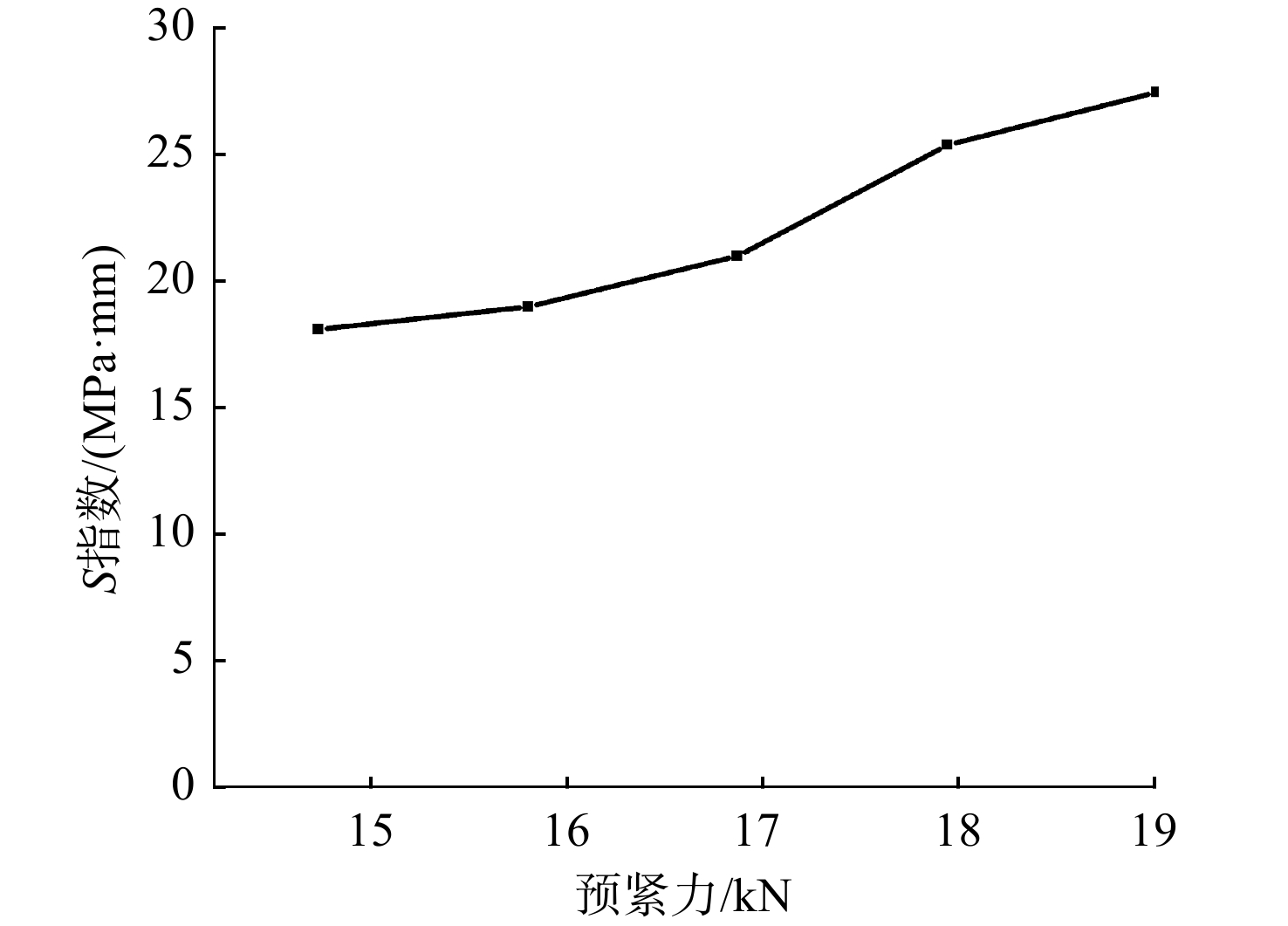

SMA梁式管接头密封性能受施加在外套螺母上的拧紧力矩所产生的轴向预紧力的影响程度有必要进行分析。管径为12 mm梁式管接头拧紧力矩施加范围为49~54 N∙m[17],由螺纹扭拉关系可计算得到预紧力范围为14700~19000 N[18]。管内流体温度为20 ℃、流体压力为22 MPa时,SMA梁式管接头第一道密封接触应力沿阳接头锥面母线距离的变化如图13所示。可见,接触应力随着预紧力增大而增大,而接触带宽基本保持不变。进而,计算得到S指数随预紧力的变化如图14所示,可见随预紧力增大,密封可靠性增强。

3.2 管内流体压力对密封性能影响分析

耐压能力是SMA梁式管接头设计的重要指标,本文计算分析预紧力为18 kN条件下,流体温度为20 ℃时,管内流体压力对密封性能的影响。在10~55 MPa压力范围内,S指数变化规律如图15所示,S指数随着流体压力增大而增大,密封性能随流体压力增大而提高。如图16所示,随着管内流体压力的增大,密封面上接触应力增大,接触应力超过临界接触应力的有效密封宽度同时增大,进而使得密封性能增强。这表明SMA梁式管接头具有良好的自封性,具有55 MPa超高耐压能力。

3.3 管内流体温度对密封性能影响分析

实际工作中管内流体温度会在高低温内变化,在热传导的作用下SMA梁式管接头温度会改变,材料的力学性能随之变化,进而会影响管接头的密封性能。值得注意的是,NiTiFe形状记忆合金对温度的变化较为敏感,其马氏体相变开始温度tMs为−109.0 ℃,马氏体相变结束温度tMf为−142.60 ℃,奥氏体相变开始温度tAs为−99 ℃,奥氏体相变结束温度tAf为−61.50 ℃[19]。实际航空管路工作温度区间为−50~200 ℃,这一温度范围在NiTiFe相变温度区间以外,使得NiTiFe形状记忆合金在管接头工作温度范围内不会发生相变,因而仅需考虑物性参数变化及热膨胀变形对梁式管接头密封性能的影响。

根据材料性能模拟软件Jmatpro,计算不同温度下NiTiFe材料性能参数,密度、比热容、热膨胀系数、泊松比等参数随温度变化较小,近似为定值,如表3所示。各温度下NiTiFe导热系数、弹性模量如表4所示。利用所建立的考虑温度与传热效应的SMA梁式管接头有限元热力耦合模型计算分析−50~200 ℃范围内管接头的温度场与密封性能。

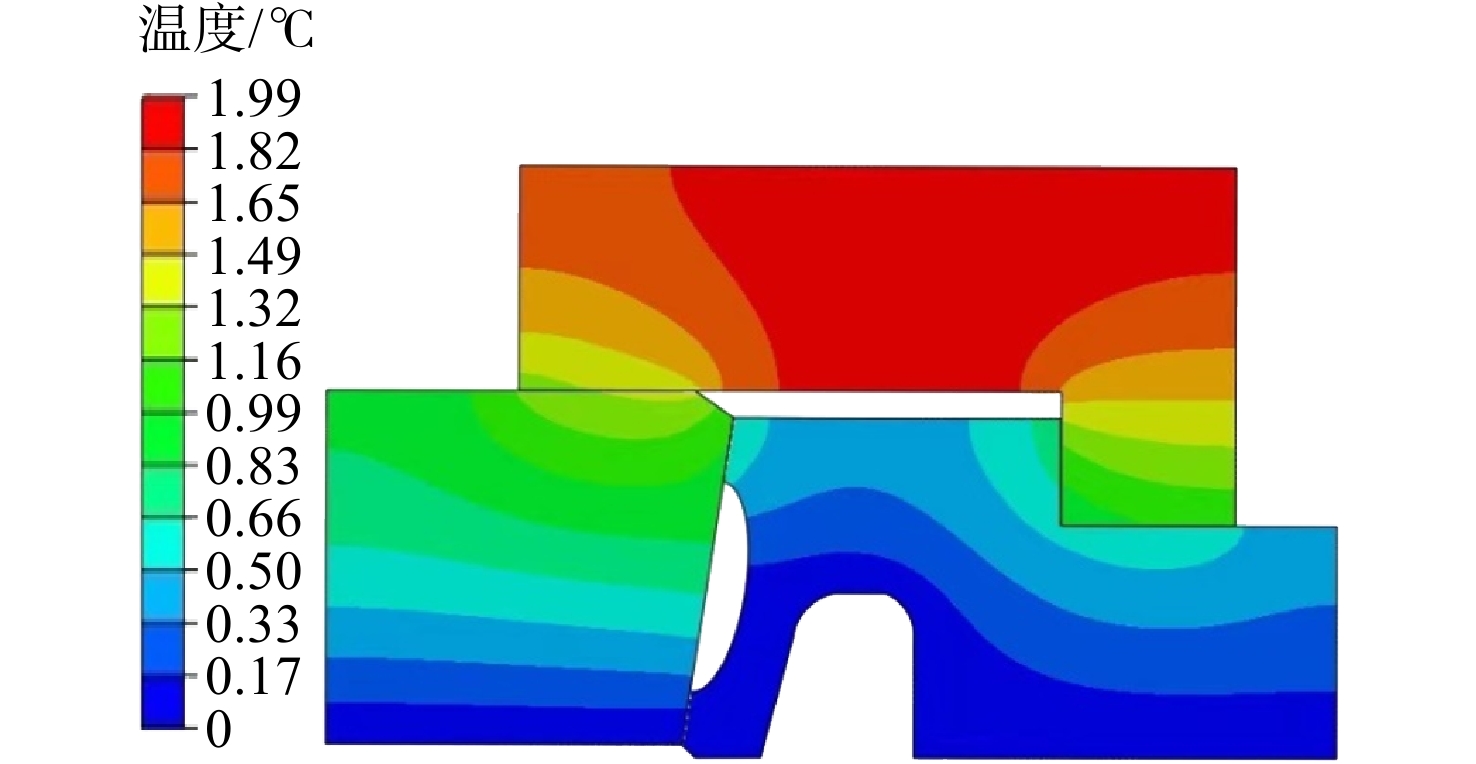

表 3 NiTiFe材料参数Table 3. Material parameters of NiTiFe密度/(g/cm3) 比热容/(J/(g·℃)) 热膨胀系数/10−5 ℃−1 泊松比 6.44 6 1.1 0.33 表 4 NiTiFe各温度下的材料参数Table 4. Material parameters of NiTiFe at various temperatures温度/℃ 导热系数/(W/(m·℃)) 弹性模量/GPa −50~0 20.09 91.27 0~50 20.90 89.00 50~100 21.71 86.28 100~150 22.68 84.47 150~200 23.49 81.75 200~250 24.46 79.48 图17给出了0 ℃流体通入管外环境温度20 ℃的SMA梁式管接头的稳态温度场,管内流体的温度低于环境温度,使得管接头结构整体温度低于环境温度,最高为1.99 ℃。这是由于阴接头具有的U形梁结构使得热传导面积增大,SMA管接头形成了具有较小温度梯度的温度场。

图18给出了SMA梁式管接头管内流体温度范围−50~200 ℃,流体压力范围22~55 MPa条件下S指数的变化情况,在各个管内流体压力条件下SMA梁式管接头在−50~200 ℃的温度范围内,S指数随温度的变化幅度很小,均满足密封要求,可认为SMA梁式管接头密封性能对温度变化并不敏感。

4. SMA与不锈钢、钛合金梁式管接头密封性能比较

目前管接头多采用不锈钢或钛合金,有必要将SMA梁式管接头与这两种材料的梁式管接头的密封性能进行对比分析。室温下304不锈钢弹性模量为210.0 GPa,泊松比为0.30,塑性本构关系如表5所示。室温下TC4钛合金弹性模量为109.0 GPa,泊松比为0.34,塑性本构关系如表6所示。

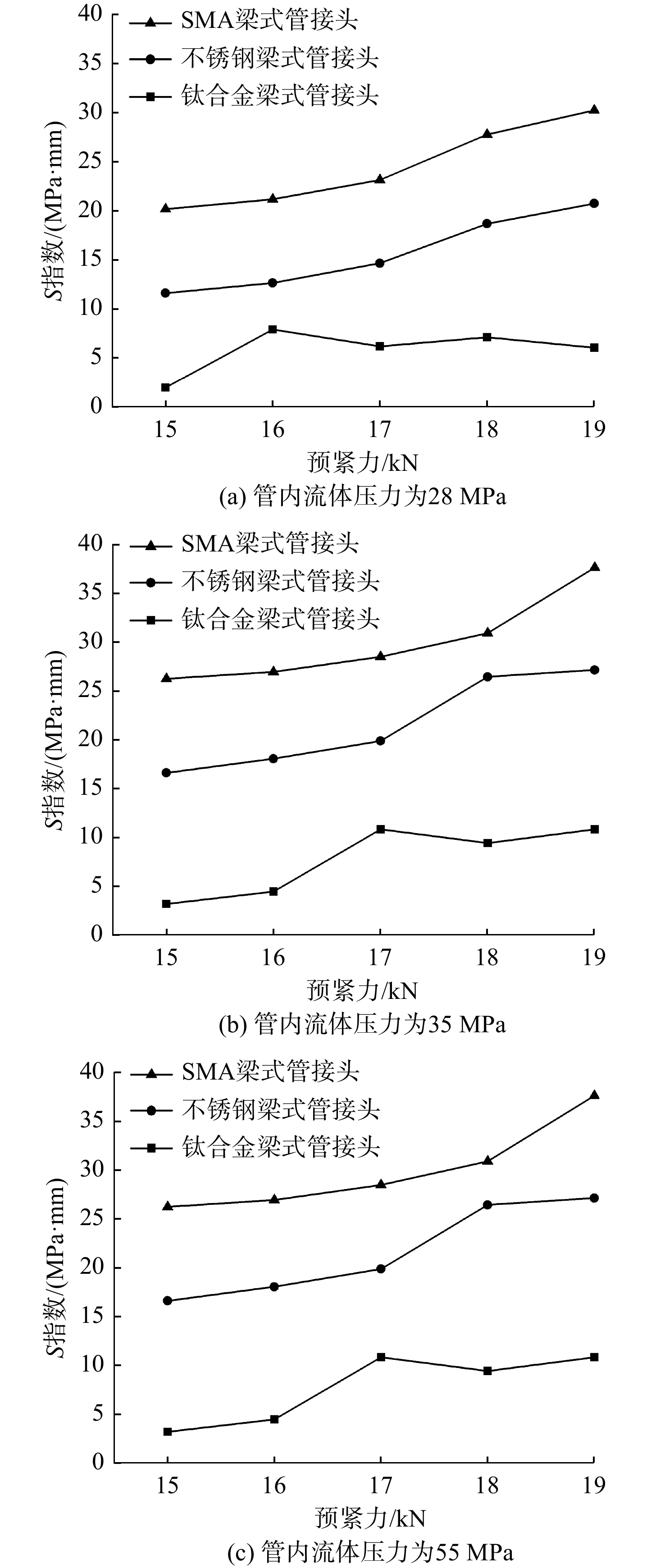

表 5 304不锈钢塑性本构关系Table 5. Plastic constitutive relationship of 304 stainless steel真实应力/MPa 塑性应变 真实应力/MPa 塑性应变 418 0 882 0.25 500 0.01581 908 0.35 605 0.02983 921 0.45 695 0.056 932 0.55 780 0.095 955 0.65 829 0.15 988 0.75 表 6 TC4钛合金塑性本构关系Table 6. Plastic constitutive relationship of TC4 titanium alloy真实应力/MPa 塑性应变 900.0 0 922.5 0.001 945.0 0.002 967.5 0.003 990.0 0.004 图19给出了管内流体温度为20 ℃、流体压力分别为28、35、55 MPa条件下SMA梁式管接头与不锈钢、钛合金梁式管接头S指数的对比结果。可见,SMA梁式管接头在各流体压力下S指数均显著高于不锈钢与钛合金梁式管接头,即其密封性能相对更优。

5. 结 论

1) 本文建立了考虑管内流体压力和流体温度的SMA梁式管接头有限元热力耦合模型。基于逾渗理论,利用SMA微观粗糙面接触界面有限元模型得到了SMA密封界面泄漏概率为零的临界接触应力,进而结合第一道密封的接触应力分布,以S指数作为SMA梁式管接头密封性能的评价指标。

2) SMA梁式管接头在预紧力范围内,密封性能与预紧力正相关;随着管内流体压力升高,SMA梁式管接头具有优异的自封性,可耐55 MPa的管内压力无泄漏;NiTiFe形状记忆合金梁式管接头的密封性能对−50~200 ℃范围内的工作温度并不敏感,表现出良好的密封性能稳定性。

3) 在不同的管内流体压力条件下,SMA梁式管接头的S指数均显著大于不锈钢和钛合金梁式管接头,表明其密封性能更优于不锈钢和钛合金的梁式管接头。本文研究为进一步开展SMA梁式管接头密封性能试验工作及其工程设计应用提供了理论仿真基础。

-

表 1 SMA梁式管接头结构参数

Table 1. Geometric parameters of SMA beam seal

结构参数 数值 U形梁椭圆弧凹槽的长轴a/mm 1.66 U形梁椭圆弧凹槽的短半轴b/mm 0.30 第一道密封名义接触带宽c/mm 0.49 阳接头壁厚d/mm 2.70 U形口轴向长度e/mm 1.04 密封梁截面宽度h/mm 0.50 阴接头壁厚p/mm 1.55 锥面角α/(°) 8.50 阴接头倒角角度β/(°) 45.0 U形梁底部与阴接头外径的距离δ/mm 1.10 U形梁与径向的夹角θ/(°) 15.0 表 2 NiTiFe塑性本构关系

Table 2. Plastic constitutive relationship of NiTiFe

真实应力/MPa 塑性应变 真实应力/MPa 塑性应变 600 0 750 0.03 650 0.01 800 0.06 700 0.02 850 0.1 表 3 NiTiFe材料参数

Table 3. Material parameters of NiTiFe

密度/(g/cm3) 比热容/(J/(g·℃)) 热膨胀系数/10−5 ℃−1 泊松比 6.44 6 1.1 0.33 表 4 NiTiFe各温度下的材料参数

Table 4. Material parameters of NiTiFe at various temperatures

温度/℃ 导热系数/(W/(m·℃)) 弹性模量/GPa −50~0 20.09 91.27 0~50 20.90 89.00 50~100 21.71 86.28 100~150 22.68 84.47 150~200 23.49 81.75 200~250 24.46 79.48 表 5 304不锈钢塑性本构关系

Table 5. Plastic constitutive relationship of 304 stainless steel

真实应力/MPa 塑性应变 真实应力/MPa 塑性应变 418 0 882 0.25 500 0.01581 908 0.35 605 0.02983 921 0.45 695 0.056 932 0.55 780 0.095 955 0.65 829 0.15 988 0.75 表 6 TC4钛合金塑性本构关系

Table 6. Plastic constitutive relationship of TC4 titanium alloy

真实应力/MPa 塑性应变 900.0 0 922.5 0.001 945.0 0.002 967.5 0.003 990.0 0.004 -

[1] 欧阳小平,方旭,朱莹,等. 航空液压管接头综述[J]. 中国机械工程,2015,26(16): 2262-2271. doi: 10.3969/j.issn.1004-132X.2015.16.023OUYANG Xiaoping,FANG Xu,ZHU Ying,et al. Overview of aviation hydraulic fitting[J]. China Mechanical Engineering,2015,26(16): 2262-2271. (in Chinese) doi: 10.3969/j.issn.1004-132X.2015.16.023 [2] JEON J Y,KIM B T. A study on contact characteristics by the geometry variation of beam seal fitting of an aircraft fuel hose[J]. Journal of the Korean Society of Manufacturing Process Engineers,2013,12(6): 101-108. doi: 10.14775/ksmpe.2013.12.6.101 [3] 李晓东. 可分离式航空液压管接头密封特性研究[D]. 辽宁 大连: 大连理工大学, 2018.LI Xiaodong. Study on sealing characteristics of separable aviation hydraulic pipe fittings[D]. Dalian Liaoning: Dalian University of Technology, 2018. (in Chinese) [4] 崔颖,于颖嘉,王永亮,等. 一种梁式管接头密封性能与结构参数敏感性分析[J]. 机械工程学报,2021,57(3): 147-155. doi: 10.3901/JME.2021.03.147CUI Ying,YU Yingjia,WANG Yongliang,et al. Sealing performance and sensitivity analysis of structure parameters for a new beam seal[J]. Journal of Mechanical Engineering,2021,57(3): 147-155. (in Chinese) doi: 10.3901/JME.2021.03.147 [5] 闫洋洋,庄保顺,高培鑫,等. 航空管路接头密封特性及流体温度影响[J]. 航空动力学报,2019,34(11): 2414-2422. doi: 10.13224/j.cnki.jasp.2019.11.013YAN Yangyang,ZHUANG Baoshun,GAO Peixin,et al. Sealing characteristics and fluid temperature influence of aviation pipeline joints[J]. Journal of Aerospace Power,2019,34(11): 2414-2422. (in Chinese) doi: 10.13224/j.cnki.jasp.2019.11.013 [6] CUI Ying, YU Yingjia. Parameter sensitivity analysis of a beam seal based on a new sealing criterion and orthogonal array method[C]//ASME 2020 Pressure Vessels and Piping Conference. Minneapolis, US: ASME, 2020: 4-14. [7] 崔颖,于颖嘉,张宏翔,等. 钛合金梁式管接头密封性能的结构优化设计[J]. 哈尔滨工业大学学报,2022,54(1): 73-79. doi: 10.11918/202108015CUI Ying,YU Yingjia,ZHANG Hongxiang,et al. Structural optimization design of sealing performance for titanium alloy beam seal[J]. Journal of Harbin Institute of Technology,2022,54(1): 73-79. (in Chinese) doi: 10.11918/202108015 [8] 李瀚宇, 周震涛, 唐江龙. 形状记忆合金宽温区超弹性的研究进展[J]. 热加工工艺, 2021, 50(17): 1-5, 11.LI Hanyu, ZHOU Zhentao, TANG Jianglong. Research progress on superelasticity of shape memory alloy at wide temperature zone[J]. Hot Working Technology, 201, 50(17): 1-5, 11. (in Chinese) [9] 牛豪杰, 林成新. 形状记忆合金的应用现状综述[J]. 天津理工大学学报, 2020, 36(4): 1-6.NIU Haojie, LIN Chengxin. Review of shape memory alloy application status[J]. Journal of Tianjin University of Technology, 2020, 36 (4): 1-6. (in Chinese) [10] 任文杰,王利强,穆蒙蒙. SMA阻尼器控制单自由度结构在地震激励下的平稳随机振动研究[J]. 工程力学,2016,33(4): 98-103.REN Wenjie,WANG Liqiang,MU Mengmeng. Study on steady random vibration of single-dof structure controlled by SMA damper under seismic excitation[J]. Engineering Mechanics,2016,33(4): 98-103. (in Chinese) [11] 康泽天,周博,薛世峰. 形状记忆合金管接头热机耦合行为的有限元数值模拟[J]. 机械工程学报,2018,54(18): 68-75. doi: 10.3901/JME.2018.18.068KANG Zetian,ZHOU Bo,XUE Shifeng. Research progress on superelasticity of shape memory alloy at wide temperature zone[J]. Journal of Mechanical Engineering,2018,54(18): 68-75. (in Chinese) doi: 10.3901/JME.2018.18.068 [12] 刘雪峰,何勇,毕重武,等. 镍钛形状记忆合金线材无模拉拔成形过程的电磁场和温度场模拟[J]. 稀有金属,2005,29(5): 762-767. doi: 10.3969/j.issn.0258-7076.2005.05.037LIU Xuefeng,HE Yong,BI Zhongwu,et al. Simulation of electromagnetic field and temperature field in formless drawing of nickel-titanium shape memory alloy wire[J]. Rare Metals,2005,29(5): 762-767. (in Chinese) doi: 10.3969/j.issn.0258-7076.2005.05.037 [13] PERSSON B,ALBOHR O,CRETON C,et al. Contact area between a viscoelastic solid and a hard, randomly rough, substrate[J]. The Journal of Chemical Physics,2004,120(18): 8779-8793. doi: 10.1063/1.1697376 [14] 崔颖, 孙唯一, 于颖嘉, 等. 基于正交实验的粗糙表面接触密封性能预测方法[J]. 大连海事大学学报, 2019, 45(3): 53-58CUI Ying, SUN Weiyi, YU Yingjia, et al. Prediction method of contact sealing performance of rough surface based on orthogonal experiments[J]. Journal of Dalian Maritime University, 2019, 45(3): 53-58. (in Chinese) [15] GREENWOOD J A,TRIPP J H. The contact of two nominally flat rough surfaces[J]. Proceedings of the Institution of Mechanical Engineers,1970,185(1): 625-633. doi: 10.1243/PIME_PROC_1970_185_069_02 [16] SHI X,ZOU Y. A comparative study on equivalent modeling of rough surfaces contact[J]. Journal of Tribology,2018,140(4): 402-424. [17] US-SAE. Fitting, tube, fluid systems, separable, beam seal, 3 000/4 000 psi, general specification: AS85421(R) [S]. Warrendale, US: SAE, 2018: 1-5. [18] 熊影辉,丁晓宇,刘检华,等. 扩口式管接头拧紧过程扭拉关系研究[J]. 润滑与密封,2017,42(5): 46-52. doi: 10.3969/j.issn.0254-0150.2017.05.009XIONG Yinghui,DING Xiaoyu,LIU Jianhua,et al. Study on relationship between preload and tightening torque of flared coupling in tightening process[J]. Lubrication Engineering,2017,42(5): 46-52. (in Chinese) doi: 10.3969/j.issn.0254-0150.2017.05.009 [19] 陈志伟,敬云兵,甘春雷,等. Fe含量对等原子比NiTi形状记忆合金微观组织、相变行为和显微硬度的影响[J]. 材料研究与应用,2021,15(2): 118-124. doi: 10.3969/j.issn.1673-9981.2021.02.006CHEN Zhiwei,JING Yunbing,GAN Chunlei,et al. Effect of Fe content on microstructure, phase transformation behavior and microhardness of the equiatomic NiTi shape memory alloy[J]. Materials Research and Application,2021,15(2): 118-124. (in Chinese) doi: 10.3969/j.issn.1673-9981.2021.02.006 期刊类型引用(1)

1. 杨航,于超. 形状记忆合金管接头装配过程的有限元模拟. 四川轻化工大学学报(自然科学版). 2025(01): 30-38 .  百度学术

百度学术其他类型引用(6)

-

下载:

下载:

下载:

下载:

百度学术

百度学术