Research on crimping parameters of civil aircraft hydraulic pipeline and analysis of its high pressure vibration characteristics

-

摘要:

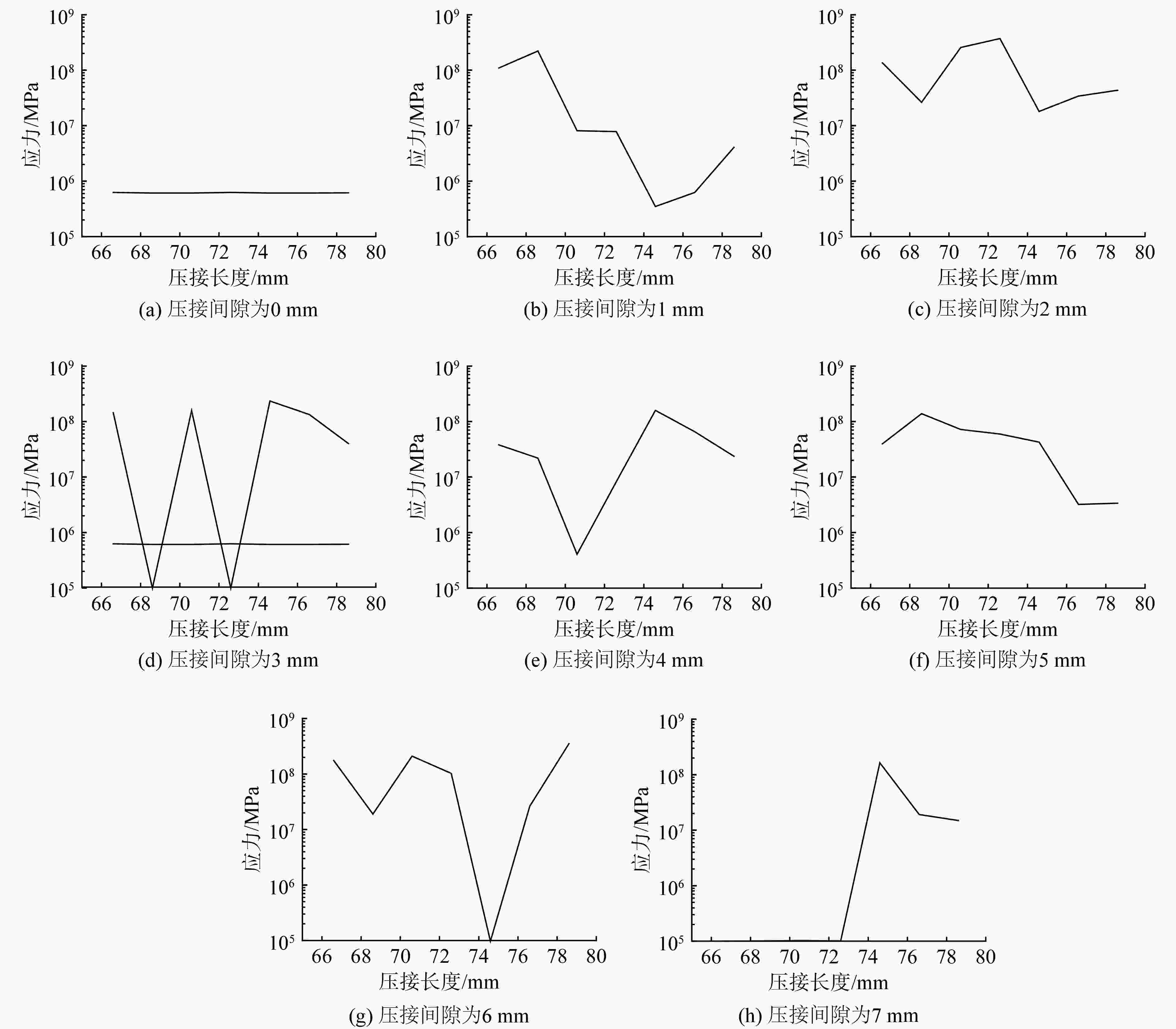

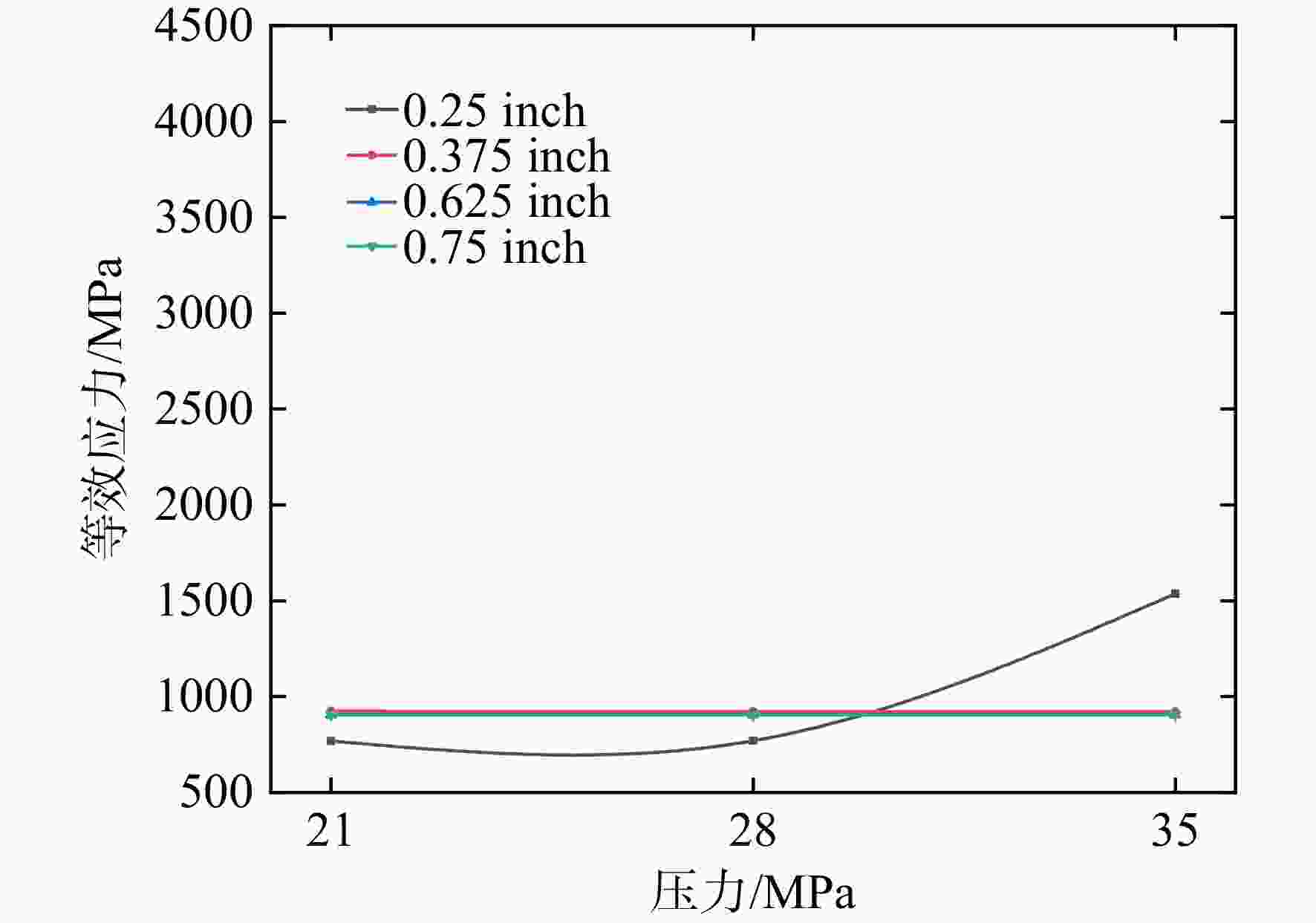

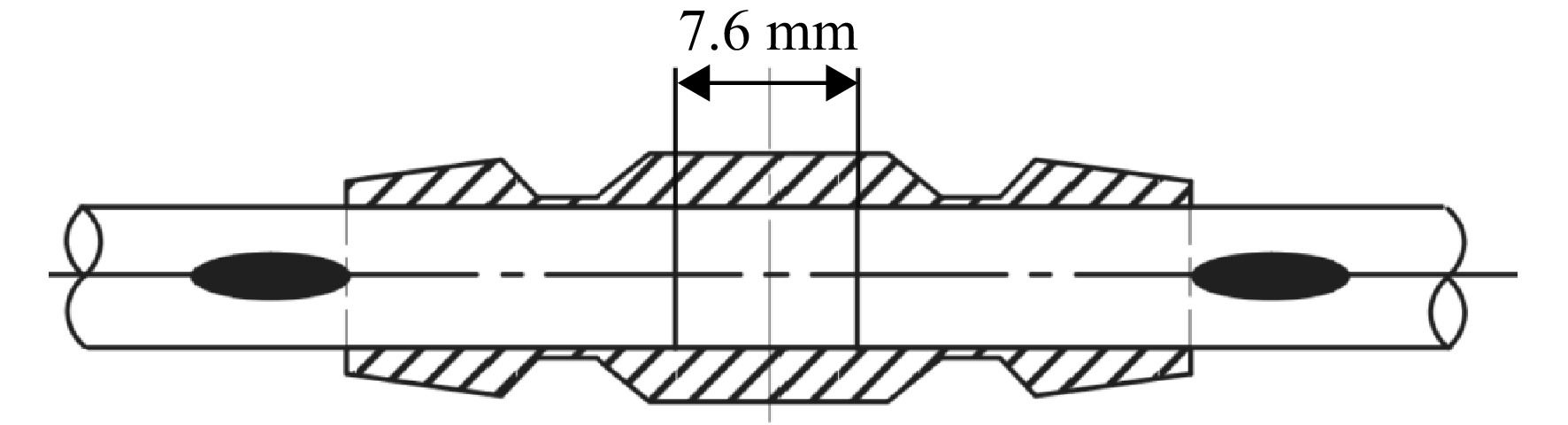

研究4种规格液压管路的压接修理参数,并分析其在3种压力级别下的动力学特性变化规律。首先建立压接修理后液压管路的有限元模型,通过模态分析可知,当压接间隙为0 mm时,管路的各阶固有频率不随压接长度的改变发生明显变化,在0~1580 Hz频率范围内,随管路直径增大,管路所承受的最大范式应力值减小。因此,4种规格液压管路的压接间隙应为0 mm,压接长度根据飞机维修手册而定。在3种压力级别下对4种规格液压管路进行动力学特性分析,管路各阶固有频率均随压力增加而变大,最大变形量在3种压力级别下均小于5 mm,0.25 inch管路在35 MPa下的等效应力远大于21 MPa和28 MPa下的等效应力,且大于其余3种规格液压管路,管路等效应力最大的部位在压接接头处。

Abstract:The crimping repair parameters of four specifications of hydraulic pipelines were studied, and their dynamic characteristics under three pressure levels were analyzed. Firstly, the finite element model of the hydraulic pipeline after crimping repair was established. The modal analysis of the pipeline showed that when the crimping gap was 0 mm, the natural frequencies of each order of the pipeline did not change significantly with the crimping length. Within the frequency range of 0—1580 Hz, the maximum normal stress value withstood by the pipeline decreased with the increase of pipeline diameter. Therefore, the crimping clearance of the four specifications of hydraulic pipelines should be 0 mm, and the crimping length should be determined according to the aircraft maintenance manual. The dynamic characteristics of four specifications of hydraulic pipelines were analyzed under three pressure levels. The natural frequencies of each order of the pipeline increased with the increasing pressure. The maximum deformation was less than 5 mm under three pressure levels. The equivalent stress of 0.25 inch pipeline under 35 MPa was much greater than that under 21 MPa and 28 MPa, and greater than that of the other three specifications of hydraulic pipeline. The position with the maximum equivalent stress of the pipeline was at the crimping joint.

-

Key words:

- crimp repair parameters /

- modal analysis /

- natural frequency /

- crimping clearance /

- crimping length /

- equivalent stress

-

表 1 液压管规格及压接长度

Table 1. Specification and crimping length of hydraulic pipe

参数 数值 0.25 inch 0.375 inch 0.625 inch 0.75 inch 导管外径D/mm 6.35 9.53 15.88 19.05 导管壁厚δ/mm 0.41 0.51 0.84 0.99 压接长度(L/2)/mm 17.5+5 19.6+5 33.3+5 35.1+5 表 2 某型飞机液压系统激励源频率分布

Table 2. Frequency distribution of excitation source of a certain aircraft hydraulic system

频率范围f/Hz 激励源频率分布 0~200 发动机、机体结构等振源频率 300~600 发动机驱动泵(engine-driven pump,EDP)压力脉动频率 800~1580 电动马达驱动泵(electric moter-driven pump,EMP)压力脉动频率 -

[1] 郭庆. 飞机液压系统管道流固耦合分析[D]. 上海: 上海交通大学,2010: 1-2. GUO Qing. The Analysis of Fluid-structure Interaction in Pipelines of Aircraft Hydraulic System[D]. Shanghai: Shanghai Jiao Tong University,2010: 1-2. (in ChineseGUO Qing. The Analysis of Fluid-structure Interaction in Pipelines of Aircraft Hydraulic System[D]. Shanghai: Shanghai Jiao Tong University, 2010: 1-2. (in Chinese) [2] 王占林. 飞机高压液压能源系统[M]. 北京: 北京航空航天大学出版社,2004: 201-232. [3] 陈果,罗云,郑其辉,等. 复杂空间载流管道系统流固耦合动力学模型及其验证[J]. 航空学报,2013,34(3): 597-609. CHEN Guo,LUO Yun,ZHENG Qihui,et al. Fluid-structure coupling dynamic model of complex spatial fluid-conveying pipe system and its verification[J]. Acta Aeronautica et Astronautica Sinica,2013,34(3): 597-609. (in ChineseCHEN Guo, LUO Yun, ZHENG Qihui, et al. Fluid-structure coupling dynamic model of complex spatial fluid-conveying pipe system and its verification[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(3): 597-609. (in Chinese) [4] 党锡淇,黄幼玲. 工程中的管道振动问题[J]. 力学与实践,1993,15(4): 9-16. DANG Xiqi,HUANG Youling. Pipeline vibration in engineering[J]. Mechanics and Engineering,1993,15(4): 9-16. (in ChineseDANG Xiqi, HUANG Youling. Pipeline vibration in engineering[J]. Mechanics and Engineering, 1993, 15(4): 9-16. (in Chinese) [5] PITTARD M T,EVANS R P,MAYNES R D,et al. Experimental and numerical investigation of turbulent flow induced pipe vibration in fully developed flow[J]. Review of Scientific Instruments,2004,75(7): 2393-2401. doi: 10.1063/1.1763256 [6] BEZBORODOV S A,ULANOV A M. Calculation of vibration of pipeline bundle with damping support made of MR material[J]. Procedia Engineering,2017,176: 169-174. doi: 10.1016/j.proeng.2017.02.285 [7] 权凌霄,孙冰江,赵劲松,等. 航空弯曲液压管路流固耦合振动频响分析[J]. 西北工业大学学报,2018,36(3): 487-495. QUAN Lingxiao,SUN Bingjiang,ZHAO Jinsong,et al. Frequency response analysis of fluid-structure interaction vibration in aircraft bending hydraulic pipe[J]. Journal of Northwestern Polytechnical University,2018,36(3): 487-495. (in Chinese doi: 10.3969/j.issn.1000-2758.2018.03.012QUAN Lingxiao, SUN Bingjiang, ZHAO Jinsong, et al. Frequency response analysis of fluid-structure interaction vibration in aircraft bending hydraulic pipe[J]. Journal of Northwestern Polytechnical University, 2018, 36(3): 487-495. (in Chinese) doi: 10.3969/j.issn.1000-2758.2018.03.012 [8] 钟林林. 飞机液压管路系统振动仿真分析[D]. 沈阳: 沈阳航空航天大学,2018: 1-8. ZHONG Linlin. Vibration Simulation Analysis of Aircraft Hydraulic Pipeline System[D]. Shenyang: Shenyang Aerospace University,2018: 1-8. (in ChineseZHONG Linlin. Vibration Simulation Analysis of Aircraft Hydraulic Pipeline System[D]. Shenyang: Shenyang Aerospace University, 2018: 1-8. (in Chinese) [9] 丁旭. 飞机液压管路系统振动传递路径及规律研究[D]. 秦皇岛: 燕山大学,2017: 5-10. DING Xu. Study on Vibration Transfer Path and Regularity of Aircraft Hydraulic Pipeline System[D]. Qinhuangdao: Yanshan University,2017: 5-10. (in ChineseDING Xu. Study on Vibration Transfer Path and Regularity of Aircraft Hydraulic Pipeline System[D]. Qinhuangdao: Yanshan University, 2017: 5-10. (in Chinese) [10] 宋玉山,任孝东,任峰. 液压管路动态特性分析与试验[J]. 锻压装备与制造技术,2018,53(4): 79-82. SONG Yushan,REN Xiaodong,REN Feng. Analysis and test of dynamic characteristics of hydraulic pipeline[J]. China Metalforming Equipment & Manufacturing Technology,2018,53(4): 79-82. (in ChineseSONG Yushan, REN Xiaodong, REN Feng. Analysis and test of dynamic characteristics of hydraulic pipeline[J]. China Metalforming Equipment & Manufacturing Technology, 2018, 53(4): 79-82. (in Chinese) [11] 桑勇,邵利来,王旭东. 基于ANSYS大流量管路流固耦合振动分析[J]. 液压气动与密封,2018,38(7): 1-5. SANG Yong,SHAO Lilai,WANG Xudong. Vibration analysis of fluid-structure interaction for large flow pipeline with ANSYS[J]. Hydraulics Pneumatics & Seals,2018,38(7): 1-5. (in Chinese doi: 10.3969/j.issn.1008-0813.2018.07.001SANG Yong, SHAO Lilai, WANG Xudong. Vibration analysis of fluid-structure interaction for large flow pipeline with ANSYS[J]. Hydraulics Pneumatics & Seals, 2018, 38(7): 1-5. (in Chinese) doi: 10.3969/j.issn.1008-0813.2018.07.001 [12] 袁航,张建宇. 筒盖液压系统管路振动分析[J]. 橡塑技术与装备,2017,43(20): 55-57. YUAN Hang,ZHANG Jianyu. Pipe vibration analysis of cylinder cover hydraulic system[J]. China Rubber/Plastics Technology and Equipment,2017,43(20): 55-57. (in ChineseYUAN Hang, ZHANG Jianyu. Pipe vibration analysis of cylinder cover hydraulic system[J]. China Rubber/Plastics Technology and Equipment, 2017, 43(20): 55-57. (in Chinese) [13] 赵千里,孙志礼,柴小冬. 具有弹性支承输流管路的振动分析[J]. 振动 测试与诊断,2017,37(6): 1222-1226,1284. ZHAO Qianli,SUN Zhili,CHAI Xiaodong. Vibration analysis of fluid conveying pipe with elastic support[J]. Journal of Vibration,Measurement & Diagnosis,2017,37(6): 1222-1226,1284. (in ChineseZHAO Qianli, SUN Zhili, CHAI Xiaodong. Vibration analysis of fluid conveying pipe with elastic support[J]. Journal of Vibration, Measurement & Diagnosis, 2017, 37(6): 1222-1226, 1284. (in Chinese) [14] 夏永胜,张成龙. 基于ANSYS Workbench的液压管道流固耦合振动分析[J]. 流体传动与控制,2017(3): 38-41,57. XIA Yongsheng,ZHANG Chenglong. Hydraulic pipeline fluid-structure interaction vibration calculation based on ANSYS workbench[J]. Fluid Power Transmission & Control,2017(3): 38-41,57. (in Chinese doi: 10.3969/j.issn.1672-8904.2017.03.010XIA Yongsheng, ZHANG Chenglong. Hydraulic pipeline fluid-structure interaction vibration calculation based on ANSYS workbench[J]. Fluid Power Transmission & Control, 2017(3): 38-41, 57. (in Chinese) doi: 10.3969/j.issn.1672-8904.2017.03.010 [15] 赵孟文,樊泽明. 振动及液压脉冲影响下的管路应力分析[J]. 山东工业技术,2017(6): 284-285. ZHAO Mengwen,FAN Zeming. 振动及液压脉冲影响下的管路应力分析[J]. Journal of Shandong Industrial Technology,2017(6): 284-285. (in Chinese [16] 韩涛,刘伟,张子骏,等. 基于直曲组集算法的复杂液压管路固有频率分析[J]. 振动与冲击,2018,37(7): 13-22,61. HAN Tao,LIU Wei,ZHANG Zijun,et al. Natural frequency analysis of complex hydraulic pipelines based on straight-curved pipeline assembly algorithm[J]. Journal of Vibration and Shock,2018,37(7): 13-22,61. (in ChineseHAN Tao, LIU Wei, ZHANG Zijun, et al. Natural frequency analysis of complex hydraulic pipelines based on straight-curved pipeline assembly algorithm[J]. Journal of Vibration and Shock, 2018, 37(7): 13-22, 61. (in Chinese) [17] 高亚坤,靖红顺,张生乐,等. 船舶蒸汽系统管路振动试验及分析[J]. 船海工程,2017,46(4): 65-68. GAO Yakun,JING Hongshun,ZHANG Shengle,et al. Experimental analysis on vibration of ship’s steam pipeline system[J]. Ship & Ocean Engineering,2017,46(4): 65-68. (in ChineseGAO Yakun, JING Hongshun, ZHANG Shengle, et al. Experimental analysis on vibration of ship’s steam pipeline system[J]. Ship & Ocean Engineering, 2017, 46(4): 65-68. (in Chinese) [18] 于韶明,芦田,卫国,等. 基于应变分析的管路振动研究[J]. 动力学与控制学报,2017,15(6): 512-517. YU Shaoming,LU Tian,WEI Guo,et al. Research on pipeliine’s vibration based on strain analysis[J]. Journal of Dynamics and Control,2017,15(6): 512-517. (in Chinese doi: 10.6052/1672-6553-2017-44YU Shaoming, LU Tian, WEI Guo, et al. Research on pipeliine’s vibration based on strain analysis[J]. Journal of Dynamics and Control, 2017, 15(6): 512-517. (in Chinese) doi: 10.6052/1672-6553-2017-44 [19] 朴学奎. 民用飞机液压系统压力级别选取论证研究[J]. 流体传动与控制,2011(6): 22-24. PIAO Xuekui. Research about pressure selection of hydraulic system in civil aircraft[J]. Fluid Power Transmission & Control,2011(6): 22-24. (in Chinese doi: 10.3969/j.issn.1672-8904.2011.06.006PIAO Xuekui. Research about pressure selection of hydraulic system in civil aircraft[J]. Fluid Power Transmission & Control, 2011(6): 22-24. (in Chinese) doi: 10.3969/j.issn.1672-8904.2011.06.006 [20] 白欢欢. 基于变刚度弹性支承的液压管路流固耦合振动的数值分析[D]. 秦皇岛: 燕山大学,2014: 1-3. BAI Huanhuan. Numerical analysis on the fluid-solid coupling vibration of hydraulic pipeline with elastic support[D]. Qinhuangdao: Yanshan University,2014: 1-3. (in ChineseBAI Huanhuan. Numerical analysis on the fluid-solid coupling vibration of hydraulic pipeline with elastic support[D]. Qinhuangdao: Yanshan University, 2014: 1-3. (in Chinese) [21] 权凌霄,孔祥东,高英杰,等. 不考虑进口特性的蓄能器吸收冲击理论及试验[J]. 机械工程学报,2007,43(9): 28-32. QUAN Lingxiao,KONG Xiangdong,GAO Yingjie,et al. Theory and experiment of accumulator absorbing pressure pulsation without regard to its entrance characteristics[J]. Chinese Journal of Mechanical Engineering,2007,43(9): 28-32. (in Chinese doi: 10.3321/j.issn:0577-6686.2007.09.007QUAN Lingxiao, KONG Xiangdong, GAO Yingjie, et al. Theory and experiment of accumulator absorbing pressure pulsation without regard to its entrance characteristics[J]. Chinese Journal of Mechanical Engineering, 2007, 43(9): 28-32. (in Chinese) doi: 10.3321/j.issn:0577-6686.2007.09.007 [22] 于灵杰. 压接修理民机液压管路振动特性分析[D]. 天津: 中国民航大学,2019: 20-39. YU Lingjie. Vibration characteristics analysis of civil aircraft hydraulic pipeline repaired by pressure welding[D]. Tianjin: Civil Aviation University of China,2019: 20-39. (in ChineseYU Lingjie. Vibration characteristics analysis of civil aircraft hydraulic pipeline repaired by pressure welding[D]. Tianjin: Civil Aviation University of China, 2019: 20-39. (in Chinese) [23] 国防科学技术工业委员会. 飞机装配工艺导管安装标准: HB/Z223.20-2002[S]. 北京: 中国航空综合技术研究所,2003: 13-14. [24] 蒋红旗,王繁生. 起重机吊臂结构有限元模态分析[J]. 农业机械学报,2006,37(3): 20-22. JIANG Hongqi,WANG Fansheng. Vibration mode analysis of crane jib using finite element method[J]. Transactions of the Chinese Society for Agricultural Machinery,2006,37(3): 20-22. (in Chinese doi: 10.3969/j.issn.1000-1298.2006.03.006JIANG Hongqi, WANG Fansheng. Vibration mode analysis of crane jib using finite element method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(3): 20-22. (in Chinese) doi: 10.3969/j.issn.1000-1298.2006.03.006 [25] 李春润,王春林. 小口径内涂层管道机械压接技术研究[J]. 石油工程建设,1996,22(3): 9-14,61. LI Chunrun,WANG Chunlin. The research on mechanical crimp-connection technique for small diameter pipelines with internal coating[J]. Petroleum Engineering Construction,1996,22(3): 9-14,61. (in ChineseLI Chunrun, WANG Chunlin. The research on mechanical crimp-connection technique for small diameter pipelines with internal coating[J]. Petroleum Engineering Construction, 1996, 22(3): 9-14, 61. (in Chinese) [26] 赵运才,黄书烽. 立式粉磨机立柱模态与谐响应分析[J]. 矿业研究与开发,2012,32(6): 94-97. ZHAO Yuncai,HUANG Shufeng. Vibration modal and harmonic response analysis on vertical pillar of vertical mill[J]. Mining Research and Development,2012,32(6): 94-97. (in ChineseZHAO Yuncai, HUANG Shufeng. Vibration modal and harmonic response analysis on vertical pillar of vertical mill[J]. Mining Research and Development, 2012, 32(6): 94-97. (in Chinese) [27] 焦宗夏. 飞机液压能源管路系统的振动特性分析[J]. 北京航空航天大学学报,1997,23(3): 316-321. JIAO Zongxia. Vibration analysis of the aircraft fluid power and pipeline systems[J]. Journal of Beijing University of Aeronautics and Astronautics,1997,23(3): 316-321. (in ChineseJIAO Zongxia. Vibration analysis of the aircraft fluid power and pipeline systems[J]. Journal of Beijing University of Aeronautics and Astronautics, 1997, 23(3): 316-321. (in Chinese) [28] 潘陆原,王占林,裘丽华. 飞机液压能源系统管路振动特性分析[J]. 机床与液压,2000,28(6): 20-21. PAN Luyuan,WANG Zhanlin,QIU Lihua. “,” issue_id “: ” jcyyy_2000_6[J]. Machine Tool & Hydraulics,2000,28(6): 20-21. (in ChinesePAN Luyuan, WANG Zhanlin, QIU Lihua. “, ” issue_id “: ” jcyyy_2000_6[J]. Machine Tool & Hydraulics, 2000, 28(6): 20-21. (in Chinese) [29] 杨斌,张建波. 民机液压系统振动技术研究[J]. 液压与气动,2018(3): 101-105. YANG Bin,ZHANG Jianbo. Study on vibration of civil aircraft hydraulic system[J]. Chinese Hydraulics & Pneumatics,2018(3): 101-105. (in Chinese doi: 10.11832/j.issn.1000-4858.2018.03.016YANG Bin, ZHANG Jianbo. Study on vibration of civil aircraft hydraulic system[J]. Chinese Hydraulics & Pneumatics, 2018(3): 101-105. (in Chinese) doi: 10.11832/j.issn.1000-4858.2018.03.016 -

下载:

下载: