Numerical simulation of saturated fuel preparation for fuel icing tests

-

摘要:

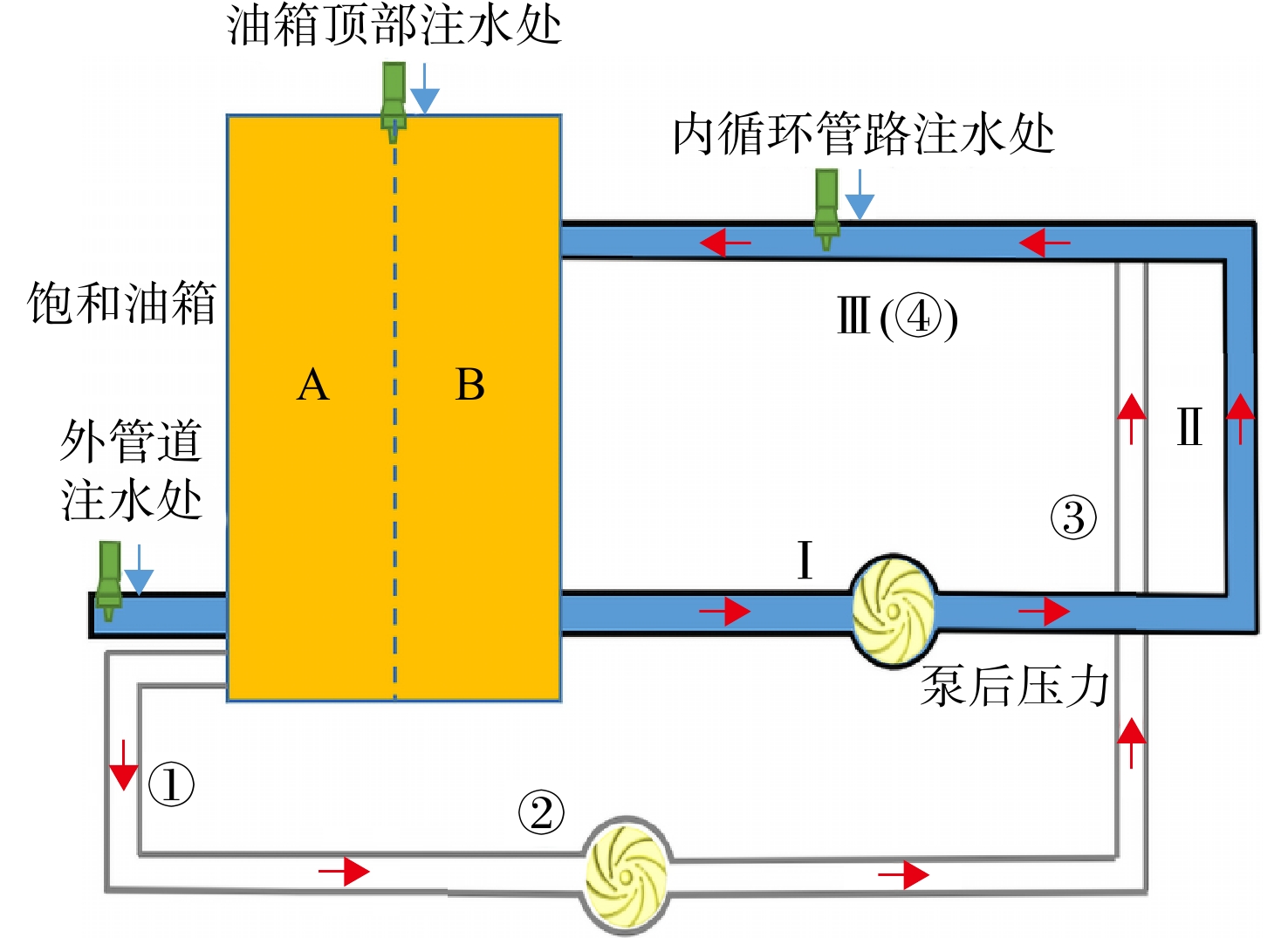

为研究燃油结冰试验中饱和燃油含水量的影响规律,以达到适航标准要求的油水均匀度,提出对配水循环系统进行数值模拟。运用欧拉-拉格朗日法分别表示连续项与离散项,用离散相模型(discrete phase model,DPM)模拟水粒子的碰撞、融合和破碎。对液滴喷射与水-燃油两相流循环进行仿真计算,研究注水位置、循环泵后压力及液流进出排布对燃油含水量的影响规律。基于循环系统内不同区域离散项质量浓度的取样统计,分析适航标准规定时间内水与燃油混合情况。利用燃油配水装置进行了泵压式循环注水试验,实测不通过油水分离器循环的泵后燃油含水量。结果表明:测量结果与数值模拟基本吻合,液流进出口设于油箱同侧且在泵后管路注水时循环掺混效果好。0.2 MPa泵后压力时油水混合均匀,且含水量可保持在适航标准规定的90×10−6~130×10−6范围内。

Abstract:In order to study the influence rules of water content in saturated fuel for fuel icing tests, and find the way to meet airworthiness requirement on fuel-water homogeneity, numerical simulation of water injection and circulation system was proposed. Euler-Lagrange algorithm represented continuous and discrete terms respectively, and discrete phase model (DPM) simulated the collision, fusion and fragmentation of water particles. Water droplet spray and water-fuel two-phase flow cycle was simulated, to examine effects of injection position, pressure of the pump outlet and in/out arrangement of fluid on the water content in the fuel. Based on statistical sampling on the mass concentration of the discrete terms for different regions in the cycle system, water-fuel mixing within the prescribed time by the airworthiness standard was analyzed. Water injection experiment for the fuel cycle was conducted by using water distribution apparatus, and the water content in the cycle fuel without passing through the fuel-water separator was measured. The results showed that, the measured results were in good agreement with the numerical simulation. The circulating mixing exhibited excellent effect when the inlet and the outlet of the liquid flow were on the same side of the tank or water was injected into the downstream pipe of the pump. Moreover, fuel-water mixing was uniform at 0.2MPa pump outlet pressure, and stable water content was kept within the range of 90×10-6 to 130×10-6 specified by the airworthiness standard.

-

Key words:

- fuel icing /

- water content /

- discrete items /

- piping layout /

- pump-outlet pressure

-

表 1 油箱横向分区离散项质量浓度

Table 1. Mass concentration of discrete term in lateral region of fuel tank

横向

分区/mm统计数量 离散项质量浓度/(kg/m3) 网格尺寸

为4 mm网格尺寸

为2 mm网格尺寸为

4 mm网格尺寸

为2 mm0~13 85 370 0.986 4.366 13~16 66 360 0.911 5.292 26~39 78 429 0.998 5.663 39~52 98 354 1.205 4.567 52~65 102 449 1.091 5.164 表 2 泵后某截面燃油含水量

Table 2. Water content in fuel at a pump outlet section

时间/min 试验含水量 仿真含水量 误差/% 时间/min 试验含水量 仿真含水量 误差 5 73.85 66.71 9.67 20 127.36 132.08 3.71 6 78.21 70.49 9.87 22 128.57 131.55 2.32 7 84.61 80.15 5.27 24 126.43 121.99 3.51 8 90.15 88.30 2.05 26 131.69 127.36 3.33 9 95.76 93.01 2.87 28 128.81 131.21 1.86 10 98.33 95.59 2.79 30 127.94 122.84 3.99 -

[1] 韩斌,张志强. 飞机燃油结冰试验用油的制备技术[J]. 中国科技信息,2017(22): 94-95. HAN Bin,ZHANG Zhiqiang. Preparation technology of aircraft fuel icing test oil[J]. China Science and Technology Information,2017(22): 94-95. (in Chinese doi: 10.3969/j.issn.1001-8972.2017.22.035HAN Bin, ZHANG Zhiqiang. Preparation technology of aircraft fuel icing test oil[J]. China Science and Technology Information, 2017(22): 94-95. (in Chinese) doi: 10.3969/j.issn.1001-8972.2017.22.035 [2] LAM J K W,WOODS R D. Ice accretion and release in fuel systems[J]. The Aeronautical Journal,2018,122(1253): 1051-1082. doi: 10.1017/aer.2018.50 [3] LEONARD R S. Above and beyond: fire and ice[J]. Air and Space,2010(5): 25. [4] 李洁,马文孝. 民用飞机辅助动力装置燃油结冰验证方法研究[J]. 科技视界,2017(7): 24-25. LI Jie,MA Wenxiao. Research on auxiliary power unit fuel system icing qualification method on civil aircraft[J]. Science & Technology Vision,2017(7): 24-25. (in ChineseLI Jie, MA Wenxiao. Research on auxiliary power unit fuel system icing qualification method on civil aircraft[J]. Science & Technology Vision, 2017(7): 24-25. (in Chinese) [5] 章涛. 油水两相流中液滴运动的直接数值模拟研究[D]. 北京: 中国石油大学(北京),2016. ZHANG Tao. Study on the Direct Numerical Simulation of Droplet Motion in Oil-water Two Phase Flow[D]. Beijing: China University of Petroleum (Beijing),2016. (in ChineseZHANG Tao. Study on the Direct Numerical Simulation of Droplet Motion in Oil-water Two Phase Flow[D]. Beijing: China University of Petroleum (Beijing), 2016. (in Chinese) [6] 刘志权,荣峰,佟仕忠. 倾斜管内高黏油水两相流的数值模拟[J]. 石油化工,2020,49(3): 269-278. LIU Zhiquan,RONG Feng,TONG Shizhong. Numerical simulation of high-viscosity oil-water two-phase flow in inclined pipe[J]. Petrochemical Technology,2020,49(3): 269-278. (in Chinese doi: 10.3969/j.issn.1000-8144.2020.03.011LIU Zhiquan, RONG Feng, TONG Shizhong. Numerical simulation of high-viscosity oil-water two-phase flow in inclined pipe[J]. Petrochemical Technology, 2020, 49(3): 269-278. (in Chinese) doi: 10.3969/j.issn.1000-8144.2020.03.011 [7] 张亚辉,米智楠,吴仁智,等. 管径大小对水平圆管油水两相流的影响[J]. 流体传动与控制,2017(2): 18-21. ZHANG Yahui,MI Zhinan,WU Renzhi,et al. Oil-water two-phase flows in horizontal pipes of different diameters[J]. Fluid Power Transmission & Control,2017(2): 18-21. (in Chinese doi: 10.3969/j.issn.1672-8904.2017.02.006ZHANG Yahui, MI Zhinan, WU Renzhi, et al. Oil-water two-phase flows in horizontal pipes of different diameters[J]. Fluid Power Transmission & Control, 2017(2): 18-21. (in Chinese) doi: 10.3969/j.issn.1672-8904.2017.02.006 [8] 中国民用航空局. 飞机燃油系统和部件结冰试验: MH/T 9004—2013[S]. 北京: 中国民航出版社,2013. [9] AE-5A Aerospace Fuel,Inerting and Lubrication Sys Committee. Aircraft fuel system and component icing test: ARP1401B-2012[S]. Warrendale,US: SAE International,2012: 5-9. [10] 罗天培,刘瑞敏,李茂,等. 基于DPM的试验台导流槽喷水冷却数值研究[J]. 航空动力学报,2018,33(2): 497-507. LUO Tianpei,LIU Ruimin,LI Mao,et al. Numerical investigations of water-spray cooling effect on test stand’s deflector based on DPM[J]. Journal of Aerospace Power,2018,33(2): 497-507. (in ChineseLUO Tianpei, LIU Ruimin, LI Mao, et al. Numerical investigations of water-spray cooling effect on test stand’s deflector based on DPM[J]. Journal of Aerospace Power, 2018, 33(2): 497-507. (in Chinese) [11] LIU Jie,KE Peng. Modelling and analysis of initial icing roughness with fixed-grid enthalpy method based on DPM-VOF algorithm[J]. Chinese Journal of Aeronautics,2022,35(7): 168-178. doi: 10.1016/j.cja.2021.07.028 [12] YIN Pengbo,LI Tingting,CAO Xuewen,et al. Condensation properties of water vapor under different back pressures in nozzle[J]. Case Studies in Thermal Engineering,2022,31: 101783. doi: 10.1016/j.csite.2022.101783 [13] 吕美茜,任伟. 燃油结冰试验用油的配制方法研究[J]. 工程与试验,2010,50(2): 29-32. LV Meiqian,REN Wei. Study on the method for setting specific fuel used in fuel system icing test[J]. Engineering & Test,2010,50(2): 29-32. (in Chinese doi: 10.3969/j.issn.1674-3407.2010.02.010LV Meiqian, REN Wei. Study on the method for setting specific fuel used in fuel system icing test[J]. Engineering & Test, 2010, 50(2): 29-32. (in Chinese) doi: 10.3969/j.issn.1674-3407.2010.02.010 [14] 吕宇玲,何利民,程浩,等. 油水两相分散流液滴粒径预测模型[J]. 化工学报,2012,63(7): 2059-2063. LÜ Yuling,HE Limin,CHENG Hao,et al. Drop size model in oil-water dispersed flows[J]. CIESC Journal,2012,63(7): 2059-2063. (in ChineseLÜ Yuling, HE Limin, CHENG Hao, et al. Drop size model in oil-water dispersed flows[J]. CIESC Journal, 2012, 63(7): 2059-2063. (in Chinese) [15] HADI NAJAFABADI H,KESHAVARZ MORAVEJI M. CFD investigation of local properties of Al2O3/water nanofluid in a converging microchannel under imposed pressure difference[J]. Advanced Powder Technology,2017,28(3): 763-774. doi: 10.1016/j.apt.2016.11.024 [16] 李浩,程嘉辉,孙春亚,等. 基于CFD-DPM的大规模颗粒-流体系统数值仿真与分析[J]. 机械工程学报,2022,58(22): 450-461. LI Hao,CHENG Jiahui,SUN Chunya,et al. Numerical simulation and analysis of large-scale particle fluid system based on CFD-DPM method[J]. Journal of Mechanical Engineering,2022,58(22): 450-461. (in Chinese doi: 10.3901/JME.2022.22.450LI Hao, CHENG Jiahui, SUN Chunya, et al. Numerical simulation and analysis of large-scale particle fluid system based on CFD-DPM method[J]. Journal of Mechanical Engineering, 2022, 58(22): 450-461. (in Chinese) doi: 10.3901/JME.2022.22.450 [17] SOMWANGTHANAROJ S,FUKUDA S. CFD modeling of biomass grate combustion using a steady-state discrete particle model (DPM) approach[J]. Renewable Energy,2020,148: 363-373. doi: 10.1016/j.renene.2019.10.042 [18] PETIT H A,PAULO C I,CABRERA O A,et al. Modelling and optimization of an inclined plane classifier using CFD-DPM and the Taguchi method[J]. Applied Mathematical Modelling,2020,77: 617-634. doi: 10.1016/j.apm.2019.07.059 [19] 龙绍桥,娄安刚,谭海涛,等. 海上溢油粒子追踪预测模型中的两种数值方法比较[J]. 中国海洋大学学报(自然科学版),2006,36(增刊1): 157-162. LONG Shaoqiao,LOU Angang,TAN Haitao,et al. Comparision of two numerical methods for solving the model for oil spill particle trajectory on the sea[J]. Periodical of Ocean University of China,2006,36(Sup 1): 157-162. (in ChineseLONG Shaoqiao, LOU Angang, TAN Haitao, et al. Comparision of two numerical methods for solving the model for oil spill particle trajectory on the sea[J]. Periodical of Ocean University of China, 2006, 36(Sup 1): 157-162. (in Chinese) [20] 张江华,史琼艳. 考虑汽化的喷嘴高温气流注水两相流动规律[J]. 航空动力学报,2017,32(7): 1545-1553. ZHANG Jianghua,SHI Qiongyan. Regularity of two-phase flow with vaporization produced by injecting water to the high temperature airflow for nozzle[J]. Journal of Aerospace Power,2017,32(7): 1545-1553. (in ChineseZHANG Jianghua, SHI Qiongyan. Regularity of two-phase flow with vaporization produced by injecting water to the high temperature airflow for nozzle[J]. Journal of Aerospace Power, 2017, 32(7): 1545-1553. (in Chinese) [21] 张淑荣,尹洪超. 空气雾化燃油喷嘴的喷雾数值模拟[J]. 能源技术,2007,28(1): 14-16. ZHANG Shurong,YIN Hongchao. Spray numerical simulation of air blast fuel-oil atomizer[J]. Energy Technology,2007,28(1): 14-16. (in Chinese doi: 10.3969/j.issn.1005-7439.2007.01.004ZHANG Shurong, YIN Hongchao. Spray numerical simulation of air blast fuel-oil atomizer[J]. Energy Technology, 2007, 28(1): 14-16. (in Chinese) doi: 10.3969/j.issn.1005-7439.2007.01.004 -

下载:

下载: