Structural parameters of pintle on transcritical combustion efficiency of liquid oxygen/methane engine

-

摘要:

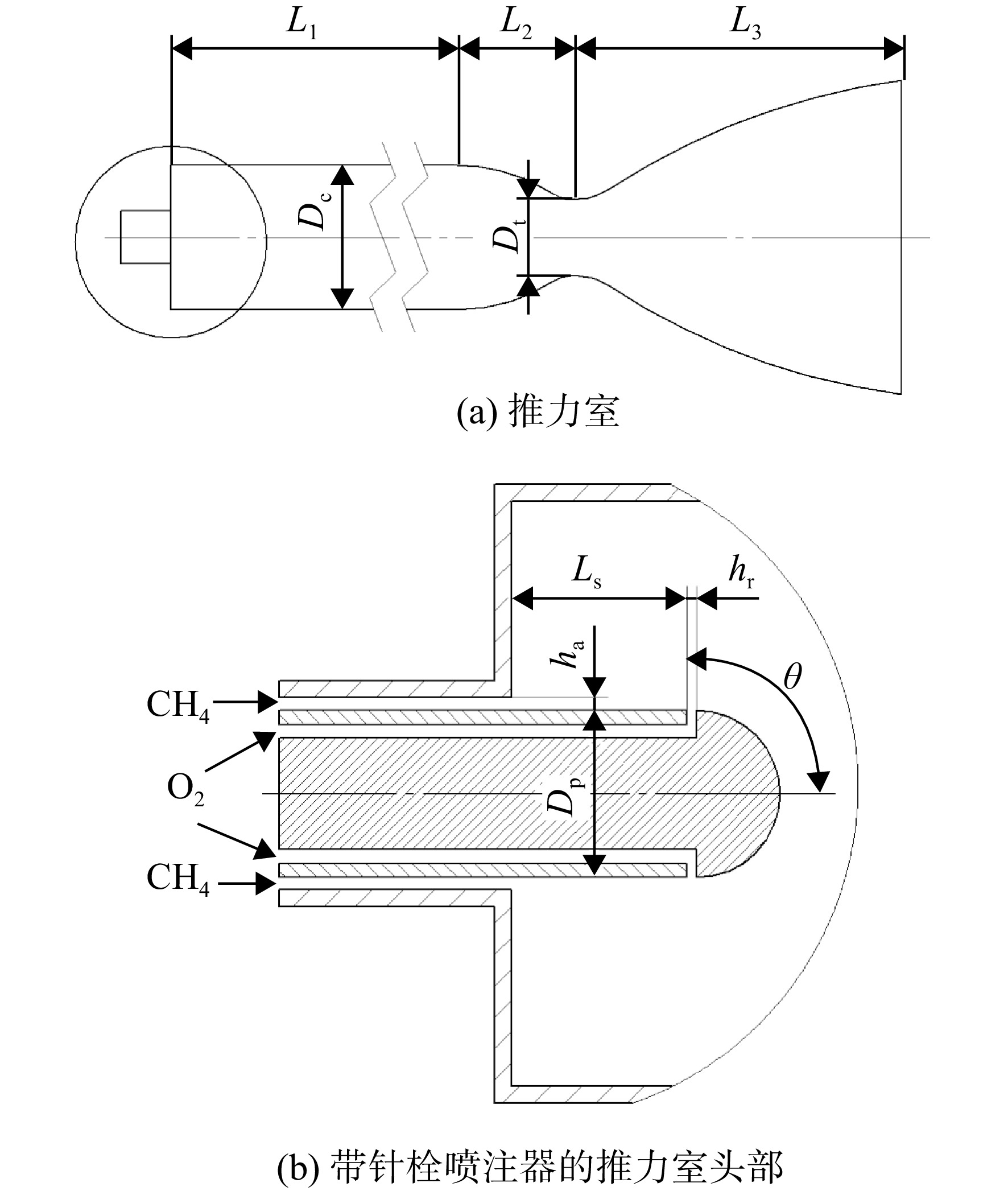

为了研究跨临界燃烧下针栓结构参数对燃烧效率的影响,采用标准

k-ε 湍流模型、非绝热稳态扩散火焰面模型,同时考虑流体真实物性,对液氧/甲烷针栓式发动机跨临界燃烧进行数值研究。分析不同物性计算方法对推力室内流场影响,并分析针栓喷注器径向环缝宽度、轴向环缝宽度对发动机燃烧效率的影响。结果表明:考虑跨临界效应时,形成的中心回流区和高温区域均较小。在一定范围内,径向环缝增大,燃烧效率先减小后增大,轴向环缝宽度增大,燃烧效率降低,轴向环缝宽度取较小值而径向环缝宽度取较大值时,可获得较高的燃烧效率。动量比小于1时,增大轴向动量可有效改善混合;动量比大于1时,增大轴向动量对改善混合的作用减弱。燃烧效率随动量比增大而降低,当不同工况的动量比值接近时,总动量较大工况的燃烧效率更高。-

关键词:

- 液氧/甲烷火箭发动机 /

- 针栓式喷注器 /

- 跨临界燃烧 /

- 结构参数 /

- 燃烧效率

Abstract:To study the effects of pintle structural parameters on the combustion efficiency in transcritical combustion, a standard

k-ε turbulence model and a non-adiabatic stable diffusion flamelet model were utilized to numerically study the transcritical combustion of an LOX/CH4 pintle engine considering the real gas properties of fluid. The study analyzed the impact of various methods for calculating physical properties on the flow field within the thrust chamber, and the effects of radial and axial annular seam width of pintle injector on engine combustion efficiency were analyzed. The results showed that the size of both the central recirculation zone and the high temperature zone was reduced when considering the transcritical effect. Within a certain range, as the radial annular seam width increased, the combustion efficiency initially decreased and then increased, as the axial annular seam width increased, the combustion efficiency decreased. A greater combustion efficiency can be achieved by reducing the axial annular seam width and increasing the radial annular seam width. When the total momentum ratio was less than 1, increasing axial momentum can effectively improve mixing. However, if the total momentum ratio was greater than 1, increasing axial momentum can hinder the improvement of mixing. The combustion efficiency decreased with the increase of the total momentum ratio. When the total momentum ratio for different operating conditions was similar, the operating condition with a higher momentum ratio exhibited a higher combustion efficiency. -

表 1 G2案例测试条件

Table 1. Test condition for the G2 case

压力/MPa 组分 温度/K 质量流量/(kg/s) 5.6 CH4 288 0.1431 O2 85 0.0444 表 2 不同网格数时压力和温度

Table 2. Pressure and temperature of different grids

网格数/104 参数 X/mm 50 100 150 200 5 T/K 1450.58 1707.49 2022.02 2392.32 σT/% 1.734 0.745 0.724 1.425 p/MPa 6.946 6.919 6.880 6.843 σp/% 0.872 0.847 0.811 0.803 10 T/K 1403.28 1706.19 2022.08 2375.68 σT/% −1.583 0.668 0.728 0.720 p/MPa 6.912 6.885 6.849 6.812 σp/% 0.375 0.359 0.353 0.357 15 T/K 1425.85 1694.87 2007.47 2358.70 p/MPa 6.886 6.861 6.824 6.788 -

[1] 张小平,严伟. 蓝箭航天液氧甲烷发动机研制进展[J]. 上海航天,2019,36(6): 83-87. ZHANG Xiaoping,YAN Wei. The development of land space liquid oxygen/methane rocket engine[J]. Aerospace Shanghai,2019,36(6): 83-87. (in ChineseZHANG Xiaoping, YAN Wei. The development of land space liquid oxygen/methane rocket engine[J]. Aerospace Shanghai, 2019, 36(6): 83-87. (in Chinese) [2] 姚照辉,范家璇. 变推力液体火箭发动机推力调节技术研究综述及发展趋势[J]. 推进技术,2022,43(9): 6-19. YAO Zhaohui,FAN Jiaxuan. Review and trend for thrust regulation technology of variable-thrust liquid rocket engine[J]. Journal of Propulsion Technology,2022,43(9): 6-19. (in ChineseYAO Zhaohui, FAN Jiaxuan. Review and trend for thrust regulation technology of variable-thrust liquid rocket engine[J]. Journal of Propulsion Technology, 2022, 43(9): 6-19. (in Chinese) [3] 高朝辉,刘宇,肖肖,等. 垂直着陆重复使用运载火箭对动力技术的挑战[J]. 火箭推进,2015,41(3): 1-6,45. GAO Zhaohui,LIU Yu,XIAO Xiao,et al. Challenge to propulsion technology for vertical landing reusable launch vehicle[J]. Journal of Rocket Propulsion,2015,41(3): 1-6,45. (in ChineseGAO Zhaohui, LIU Yu, XIAO Xiao, et al. Challenge to propulsion technology for vertical landing reusable launch vehicle[J]. Journal of Rocket Propulsion, 2015, 41(3): 1-6, 45. (in Chinese) [4] 岳春国,李进贤,冯喜平,等. 针栓式变推力火箭发动机技术现状与发展探索[J]. 世界科技研究与发展,2008,30(5): 609-612. YUE Chunguo,LI Jinxian,FENG Xiping,et al. The research on technology actuality and development of pintle injector variable thrust rocket engine[J]. World Sci-Tech R & D,2008,30(5): 609-612. (in ChineseYUE Chunguo, LI Jinxian, FENG Xiping, et al. The research on technology actuality and development of pintle injector variable thrust rocket engine[J]. World Sci-Tech R & D, 2008, 30(5): 609-612. (in Chinese) [5] GILROY R,SACKHEIM R. The lunar module descent engine: a historical summary[R]. AIAA 1989-2385,1989. [6] 雷娟萍,兰晓辉,章荣军,等. 嫦娥三号探测器7 500 N变推力发动机研制[J]. 中国科学: 技术科学,2014,44(6): 569-575. LEI Juanping,LAN Xiaohui,ZHANG Rongjun,et al. The development of 7 500 N variable thrust engine for Chang’E-3[J]. Scientia Sinica (Technologica),2014,44(6): 569-575. (in Chinese doi: 10.1360/092014-52LEI Juanping, LAN Xiaohui, ZHANG Rongjun, et al. The development of 7 500 N variable thrust engine for Chang’E-3[J]. Scientia Sinica (Technologica), 2014, 44(6): 569-575. (in Chinese) doi: 10.1360/092014-52 [7] 张雪松. 猎鹰火箭的基础: 不断升级的梅林发动机[J]. 卫星与网络,2017(6): 40-41. ZHANG Xuesong. The foundation of Falcon rocket: the ever-upgrading Merlin engine[J]. Satellite & Network,2017(6): 40-41. (in ChineseZHANG Xuesong. The foundation of Falcon rocket: the ever-upgrading Merlin engine[J]. Satellite & Network, 2017(6): 40-41. (in Chinese) [8] 王凯,雷凡培,张波涛,等. 针栓式喷注单元雾化角模型分析[J]. 航空学报,2020,41(10): 123622. WANG Kai,LEI Fanpei,ZHANG Botao,et al. Analysis on spray angle model for pintle injector element[J]. Acta Aeronautica et Astronautica Sinica,2020,41(10): 123622. (in ChineseWANG Kai, LEI Fanpei, ZHANG Botao, et al. Analysis on spray angle model for pintle injector element[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(10): 123622. (in Chinese) [9] 王凯,雷凡培,杨岸龙,等. 针栓式喷注单元膜束撞击雾化混合过程数值模拟[J]. 航空学报,2020,41(9): 123802. WANG Kai,LEI Fanpei,YANG Anlong,et al. Numerical simulation of spray and mixing process of impingement between sheet and jet in pintle injector element[J]. Acta Aeronautica et Astronautica Sinica,2020,41(9): 123802. (in ChineseWANG Kai, LEI Fanpei, YANG Anlong, et al. Numerical simulation of spray and mixing process of impingement between sheet and jet in pintle injector element[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(9): 123802. (in Chinese) [10] 方昕昕,沈赤兵,康忠涛. 无旋锥形液膜表面波不稳定性试验研究[J]. 推进技术,2016,37(10): 1893-1899. FANG Xinxin,SHEN Chibing,KANG Zhongtao. Experimental research of instability of surface wave on irrotational conical sheets[J]. Journal of Propulsion Technology,2016,37(10): 1893-1899. (in ChineseFANG Xinxin, SHEN Chibing, KANG Zhongtao. Experimental research of instability of surface wave on irrotational conical sheets[J]. Journal of Propulsion Technology, 2016, 37(10): 1893-1899. (in Chinese) [11] 方昕昕,沈赤兵,成鹏,等. 针栓式喷注器雾化特性试验[J]. 航空动力学报,2017,32(8): 1853-1860. FANG Xinxin,SHEN Chibing,CHENG Peng,et al. Experiment on atomization characteristics of pintle injectors[J]. Journal of Aerospace Power,2017,32(8): 1853-1860. (in ChineseFANG Xinxin, SHEN Chibing, CHENG Peng, et al. Experiment on atomization characteristics of pintle injectors[J]. Journal of Aerospace Power, 2017, 32(8): 1853-1860. (in Chinese) [12] SON M,YU K,KOO J,et al. Effects of momentum ratio and Weber number on spray half angles of liquid controlled pintle injector[J]. Journal of Thermal Science,2015,24(1): 37-43. doi: 10.1007/s11630-015-0753-7 [13] SAKAKI K,CHOI M,NAKAYA S,et al. Fundamental combustion characteristics of ethanol/liquid oxygen rocket engine combustor with planar pintle-type injector[J]. Transactions of the Japan Society for Aeronautical and Space Sciences,2015,58(1): 15-22. doi: 10.2322/tjsass.58.15 [14] SAKAKI K,KAKUDO H,NAKAYA S,et al. Combustion characteristics of ethanol/liquid-oxygen rocket-engine combustor with planar pintle injector[J]. Journal of Propulsion and Power,2017,33(2): 514-521. doi: 10.2514/1.B36144 [15] SAKAKI K,FUNAHASHI T,NAKAYA S,et al. Longitudinal combustion instability of a pintle injector for a liquid rocket engine combustor[J]. Combustion and Flame,2018,194: 115-127. doi: 10.1016/j.combustflame.2018.04.017 [16] SON M,RADHAKRISHNAN K,YOON Y,et al. Numerical study on the combustion characteristics of a fuel-centered pintle injector for methane rocket engines[J]. Acta Astronautica,2017,135: 139-149. doi: 10.1016/j.actaastro.2017.02.005 [17] FANG Xinxin,SHEN Chibing. Study on atomization and combustion characteristics of LOX/methane pintle injectors[J]. Acta Astronautica,2017,136: 369-379. doi: 10.1016/j.actaastro.2017.03.025 [18] 方昕昕. 液氧/甲烷针栓式喷注器雾化及燃烧特性研究[D]. 长沙: 国防科技大学,2015: 98-101. FANG Xinxin. Study on the atomization and combustion characteristics of LOX/methane pintle injectors[D]. Changsha: National University of Defense Technology,2015: 98-101. (in ChineseFANG Xinxin. Study on the atomization and combustion characteristics of LOX/methane pintle injectors[D]. Changsha: National University of Defense Technology, 2015: 98-101. (in Chinese) [19] 咸裕丰,孙冰. 针栓式喷注器液氧/甲烷发动机燃烧特性数值仿真[J]. 推进技术,2021,42(7): 1561-1569. XIAN Yufeng,SUN Bing. Numerical simulation of combustion characteristics of LOX/CH4 engine with pintle injector[J]. Journal of Propulsion Technology,2021,42(7): 1561-1569. (in ChineseXIAN Yufeng, SUN Bing. Numerical simulation of combustion characteristics of LOX/CH4 engine with pintle injector[J]. Journal of Propulsion Technology, 2021, 42(7): 1561-1569. (in Chinese) [20] SEEBALD P,SOJKA P E. Supercritical and transcritical injection[M]//ASHGRIZ N. Handbook of Atomization and Sprays. Boston,MA: Springer,2011: 255-261. [21] 谢远,聂万胜,姜传金,等. 针栓式喷嘴喷雾燃烧特性研究进展[J]. 推进技术,2022,43(7): 47-65. XIE Yuan,NIE Wansheng,JIANG Chuanjin,et al. Research progress on spray combustion characteristics of pintle injector[J]. Journal of Propulsion Technology,2022,43(7): 47-65. (in ChineseXIE Yuan, NIE Wansheng, JIANG Chuanjin, et al. Research progress on spray combustion characteristics of pintle injector[J]. Journal of Propulsion Technology, 2022, 43(7): 47-65. (in Chinese) [22] 蔡国飙,李家文,田爱梅,等. 液体火箭发动机设计[M]. 北京: 北京航空航天大学出版社,2011: 80-111. [23] 安鹏,姚世强,王京丽,等. 针栓式喷注器的特点及设计方法[J]. 导弹与航天运载技术,2016(3): 50-54. AN Peng,YAO Shiqiang,WANG Jingli,et al. Characteristics and design of pintle injector[J]. Missiles and Space Vehicles,2016(3): 50-54. (in ChineseAN Peng, YAO Shiqiang, WANG Jingli, et al. Characteristics and design of pintle injector[J]. Missiles and Space Vehicles, 2016(3): 50-54. (in Chinese) [24] POLING B E,PRAUSNITZ J M,O’CONNELL J P. 气液物性估算手册[M]. 赵红玲,王凤坤,陈圣坤,译. 第5版. 北京: 化学工业出版社,2006: 73-411. [25] MENG Hua,YANG V. A unified treatment of general fluid thermodynamics and its application to a preconditioning scheme[J]. Journal of Computational Physics,2003,189(1): 277-304. doi: 10.1016/S0021-9991(03)00211-0 [26] 向纪鑫,张萌,李志强,等. 液氧/甲烷液体火箭发动机推力室跨临界液膜冷却数值模拟[J]. 推进技术,2022,43(11): 291-302. XIANG Jixin,ZHANG Meng,LI Zhiqiang,et al. Numerical simulation of transcritical liquid film cooling in LOX/methane liquid rocket engine thrust chambers[J]. Journal of Propulsion Technology,2022,43(11): 291-302. (in ChineseXIANG Jixin, ZHANG Meng, LI Zhiqiang, et al. Numerical simulation of transcritical liquid film cooling in LOX/methane liquid rocket engine thrust chambers[J]. Journal of Propulsion Technology, 2022, 43(11): 291-302. (in Chinese) [27] KIM T,KIM Y,KIM S K. Effects of pressure and inlet temperature on coaxial gaseous methane/liquid oxygen turbulent jet flame under transcritical conditions[J]. The Journal of Supercritical Fluids,2013,81: 164-174. doi: 10.1016/j.supflu.2013.05.011 [28] SINGLA G,SCOUFLAIRE P,ROLON C,et al. Transcritical oxygen/transcritical or supercritical methane combustion[J]. Proceedings of the Combustion Institute,2005,30(2): 2921-2928. doi: 10.1016/j.proci.2004.08.063 -

下载:

下载: