Parametric modeling method and mechanical behavior of 3D woven composites with warp insertion

-

摘要:

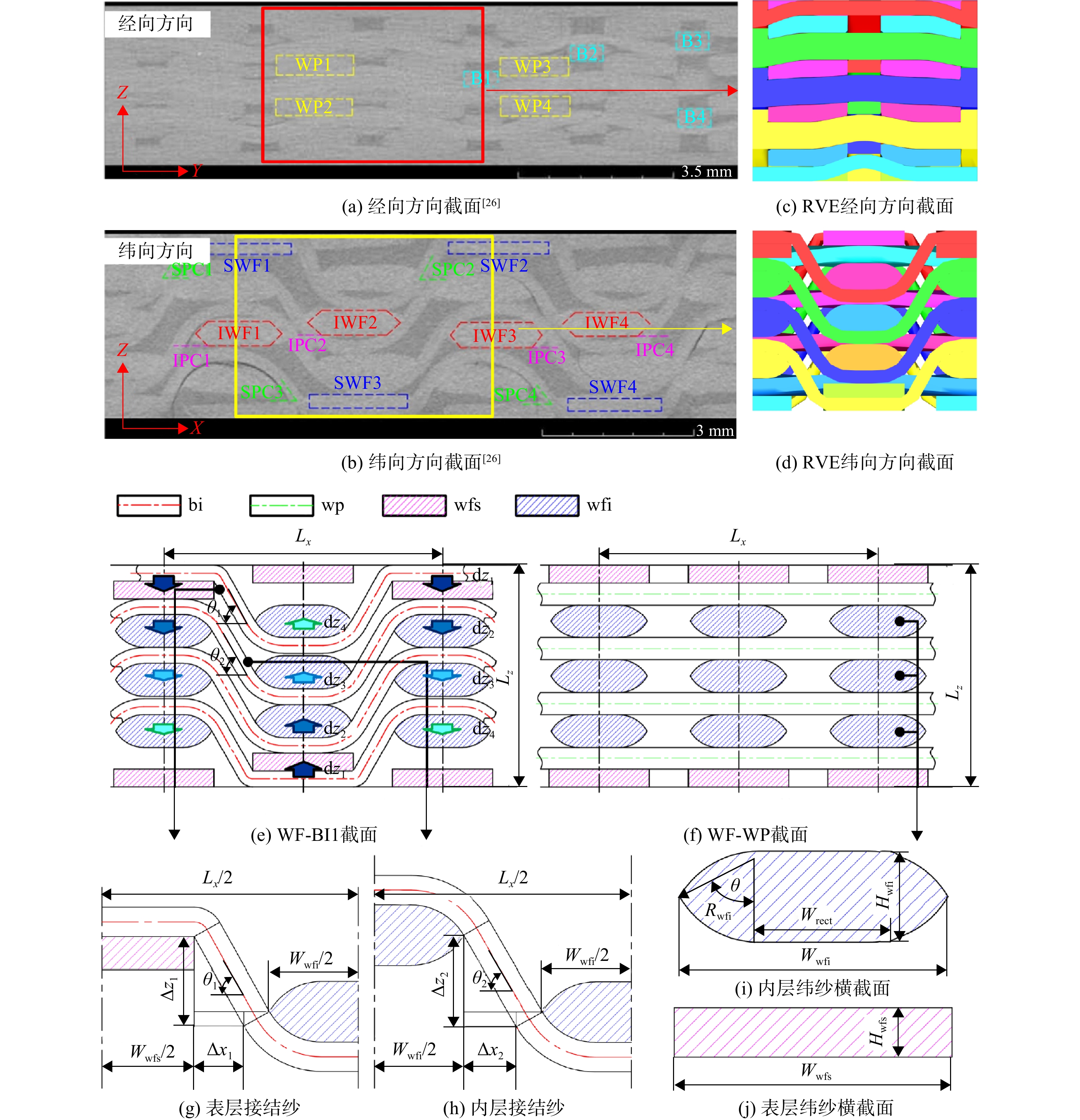

为了能够更为准确地描述机织复合材料的细观结构和力学行为,建立了一种适用于含衬经的三维机织复合材料的参数化模型构建方法,讨论了几何模型内部各参数之间的等式约束关系,并以此建立了几何约束模型以实现对几何模型的参数化描述。在几何约束模型的基础上,重点讨论了参数化模型的建立方法,以输入参数建立了几何模型与实际结构的映射关系,提高了几何模型对实际结构的还原程度,对材料的分析与设计具有指导意义。采用渐进损伤模型预测了三维机织复合材料的经向强度,并与试验结果进行对比。在拉伸载荷作用下,经纱和接结纱以纵向断裂失效为主,纬纱以横向开裂失效为主,富树脂区的失效模式为拉伸断裂,经向强度预测值为853.6 MPa,相对误差为2.3%,与试验结果基本吻合。

Abstract:To describe the microstructure and mechanical behavior of woven composites more accurately, a parametric model construction method for 3D woven composites with warp insertion was established. The equality constraints among the parameters in the geometric model were investigated, and the geometric constraint model was developed to realize the parametric description of the geometric model. Based on the geometric constraint model, the construction method of the parametric model was discussed, and the mapping relationship between the geometric model and the actual structure was established by input parameters, which not only improves the reduction degree of the geometric model to the actual structure but also provides guidance for material analysis and design. The progressive damage model was applied to predict the strength of 3D woven composites in the warp direction, and the prediction results were compared with the experimental results. Under the tensile load, the failure mode of the warp and binder yarn is mainly longitudinal fracture, the failure mode of the weft yarn is transverse fracture, and the failure mode of the resin-rich region is tensile fracture. The predicted strength of the material in the warp direction is 853.6 MPa, with a relative error of 2.3%, which is basically consistent with the experimental results.

-

纱线 材料 纱线纤度/(g/km) 接结纱 TG800HXC-6K 250 经纱 TG800X-12K×2 1000 纬纱 TG800X-12K×2 1000 材料 参数 数值 T800碳纤维 纵向模量Ef11/GPa 294.0 横向模量Ef22/GPa 19.3 剪切模量Gf12/GPa 43.5 泊松比νf12 0.29 纵向拉伸强度Xft/MPa 5500 纵向拉伸失效应变$\varepsilon _{{\text{lt}}}^{{\mathrm{final}}}$ 0.0232 密度ρ/(g/cm3) 1.8 TDE-86树脂 树脂模量Em/GPa 3.55 树脂泊松比νm 0.33 拉伸强度Xmt/MPa 80.0 压缩强度Xmc/MPa 241.0 参数 数值 纬纱机织密度Mwf/(根/cm) 4.0 经纱机织密度Mwp/(根/cm) 4.0 接结纱机织密度Mbi/(根/cm) 4.0 机织复合材料平均厚度T/mm 4.0 纬纱总层数Nwf/层 5 经纱总层数Nwp/层 4 接结纱总层数Nbi/层 4 表层纬纱横截面平均面积Awfs/mm2 0.551 内层纬纱横截面平均面积Awfi/mm2 0.852 经纱横截面平均面积Awp/mm2 0.760 接结纱横截面平均面积Abi/mm2 0.230 表层纬纱平均厚度Hwfs/mm 1.78 接结纱平均宽度Wbi/mm 0.81 表 4 三维机织复合材料RVE模型参数

Table 4. Parameters of 3D woven composites RVE model

参数 数值 RVE长度/mm 5.0 RVE宽度/mm 5.0 RVE厚度/mm 4.0 表层纬纱宽度/mm 1.820 表层纬纱厚度/mm 0.303 内层纬纱宽度/mm 1.784 内层纬纱厚度/mm 0.559 经纱宽度/mm 1.767 经纱厚度/mm 0.430 接结纱宽度/mm 0.733 接结纱厚度/mm 0.314 表层接结纱倾斜角度/rad 1.109 内层接结纱倾斜角度/rad 1.056 表 5 纱线路径曲线及横截面方向

Table 5. The yarn path curve and cross-section direction

纱线 Fi(t) Vi(t) Ni(t) 接结纱 $ {{\boldsymbol{F}}_i} (t) = \left\{ \begin{gathered} x{\boldsymbol{i}} + 0{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (y = 0) \\ x{\boldsymbol{i}} + ({{{L_{{y}}}} / 2) }{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (y = {{{L_{{y}}}} /2) } \\ x{\boldsymbol{i}} + {L_{{y}}}{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (y = {L_{{y}}}) \\ \end{gathered} \right. $ $ {{\boldsymbol{V}}_i} (t) = u{\boldsymbol{i}} + 0{\boldsymbol{j}} + w{\boldsymbol{k}} (y = 0,{{{L_{{y}}}} /2},{L_{{y}}}) $ $ {{\boldsymbol{N}}_i} (t) = - w{\boldsymbol{i}} + 0{\boldsymbol{j}} + u{\boldsymbol{k}} (y = 0,{{{L_{{y}}}} /2},{L_{{y}}}) $ 经纱 $ {{\boldsymbol{F}}_i} (t) = \left\{ \begin{gathered} x{\boldsymbol{i}} + {{{L_{{y}}}} /4}{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (y = {{{L_{{y}}}}/4}) \\ x{\boldsymbol{i}} + ({{3{L_{{y}}}} / 4}) {\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (y = {{3{L_{{y}}}} / 4) } \\ \end{gathered} \right. $ $ {{\boldsymbol{V}}_i} (t) = 1{\boldsymbol{i}} + 0{\boldsymbol{j}} + 0{\boldsymbol{k}} (y = {{{L_{{y}}}} / 4},{{3{L_{{y}}}} / 4}) $ $ {{\boldsymbol{N}}_i} (t) = 0{\boldsymbol{i}} + 0{\boldsymbol{j}} + 1{\boldsymbol{k}} (y = {{{L_{{y}}}} /4},{{3{L_{{y}}}}/ 4}) $ 纬纱 $ {{\boldsymbol{F}}_i} (t) = \left\{ \begin{gathered} 0{\boldsymbol{i}} + y{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (x = 0) \\ ({{{L_{{x}}}}/2}) {\boldsymbol{i}} + y{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (x = {{{L_{{x}}}} /2) } \\ {L_{{x}}}{\boldsymbol{i}} + y{\boldsymbol{j}} + {\textit{z}}{\boldsymbol{k}} (x = {L_{{x}}}) \\ \end{gathered} \right. $ $ {{\boldsymbol{V}}_i} (t) = 0{\boldsymbol{i}} + 1{\boldsymbol{j}} + 0{\boldsymbol{k}} (x = 0,{{{L_{{x}}}} / 2},{L_{{x}}}) $ $ {{\boldsymbol{N}}_i} (t) = 0{\boldsymbol{i}} + 0{\boldsymbol{j}} + 1{\boldsymbol{k}} (x = 0,{{{L_{{x}}}} /2},{L_{{x}}}) $ 表 6 几何模型输入参数

Table 6. Input parameters of the geometric model

模型 细观结构输入参数 宏观结构输入参数 几何模型[26] ①表层纬纱宽度、②表层纬纱厚度、③内层纬纱宽度、④内层纬纱厚度、

⑤经纱厚度、⑥经纱宽度、⑦接结纱宽度、⑧接结纱厚度、

⑨表层接结纱倾斜角度、⑩内层接结纱倾斜角度参数化模型 ①表层纬纱面积、②内层纬纱面积、③经纱横截面面积、

④接结纱横截面面积、⑤接结纱宽度、⑥纬纱机织密度、⑦经纱机织密度、

⑧接结纱(经纱)层数、⑨材料厚度损伤模式 判定准则 纱线纵向拉伸损伤 ${\varphi _{{\text{lt}}}} = { ( {{{{\sigma _{11}}} / {{X_{\text{t}}}}}} ) ^2} + {{ ( {\tau _{12}^2 + \tau _{13}^2} ) } /{S_{{\text{lt}}}^2}} \geqslant 1$ 纱线纵向压缩损伤 ${\varphi _{{\text{lc}}}} = { ( {{{{\sigma _{11}}} \mathord{\left/ {\vphantom {{{\sigma _{11}}} {{X_{\text{c}}}}}} \right. } {{X_{\text{c}}}}}} ) ^2} \geqslant 1{\text{ }}$ 纱线横向拉伸损伤 $ {\varphi _{{\text{tt}}}} = {[ {{{ ( {{\sigma _{22}} + {\sigma _{33}}} ) } / {{Y_{\text{t}}}}}} ]^2} + {{ ( {\tau _{23}^2 - {\sigma _{22}}{\sigma _{33}}} ) } /{S_{{\text{tz}}}^2}} + {{ ( {\tau _{12}^2 + \tau _{13}^2} ) } /{S_{{\text{lt}}}^2}} \geqslant 1 $ 纱线横向压缩损伤 $ {\varphi _{{\text{tc}}}} =[{{{Y_{\text{c}}^2}/ {{{ ( {2{S_{{\text{tz}}}}} ) }^2}}} - 1} ]{{ ( {{\sigma _{22}} + {\sigma _{33}}} ) }/ {{Y_{\text{c}}}}} + {{{{ ( {{\sigma _{22}} + {\sigma _{33}}} ) }^2}}/ {{{ ( {2{S_{{\text{tz}}}}} ) }^2}}} + {{ ( {\tau _{23}^2 - {\sigma _{22}}{\sigma _{33}}} ) } / {S_{{\text{tz}}}^2}} + {{ ( {\tau _{12}^2 + \tau _{13}^2} ) } /{S_{{\text{lt}}}^2}} \geqslant 1{\text{ }} $ 树脂基体拉伸损伤 $ {\varphi _{{\text{mt}}}} = {{\left[ {3{J_2} + {I_1} ( {{X_{{\text{mc}}}} - {X_{{\text{mt }}}}} ) } \right]}/ { ( {{X_{{\text{mc}}}}{X_{{\text{mt}}}}} ) }} \geqslant 1 $ 树脂基体压缩损伤 $ {\varphi _{{\text{mc}}}} = {{\left[ {3{J_2} + {I_1} ( {{X_{{\text{mc}}}} - {X_{{\text{mt }}}}} ) } \right]} / { ( {{X_{{\text{mc}}}}{X_{{\text{mt}}}}} ) }} \geqslant 1 $ 注:σii和τij (i, j = 1, 2, 3)为正应力与切应力分量,I1为应力第一不变量,J2为应力偏量第二不变量;Xt和Xc为纱线纵向拉伸和压缩强度,Yt和Yc为纱线横向拉伸和压缩强度,Slt、Stz为纱线剪切强度,Xmt和Xmc为树脂基体的拉伸和压缩强度。 表 8 不同损伤模式的等价位移和等价应力[34]

Table 8. Equivalent displacement and equivalent stress for different damage modes[34]

损伤模式 等价位移 等价应力 纱线纵向拉伸损伤 $\chi _{{\text{eq}}}^{{\text{lt}}} = \sqrt {\varepsilon _{11}^2 + \varepsilon _{12}^2 + \varepsilon _{13}^2} {l_{{\text{eq}}}}$ $\sigma _{{\text{eq}}}^{{\text{lt}}} = {{\left( {{\sigma _{11}}{\varepsilon _{11}} + {\tau _{12}}{\varepsilon _{12}} + {\tau _{13}}{\varepsilon _{13}}} \right){l_{{\text{eq}}}}} \mathord{\left/ {\vphantom {{\left( {{\sigma _{11}}{\varepsilon _{11}} + {\tau _{12}}{\varepsilon _{12}} + {\tau _{13}}{\varepsilon _{13}}} \right){l_{{\text{eq}}}}} {\chi _{{\text{eq}}}^{{\text{lt}}}}}} \right. } {\chi _{{\text{eq}}}^{{\text{lt}}}}}$ 纱线纵向压缩损伤 $\chi _{{\text{eq}}}^{{\text{lc}}} = \left\langle { - {\varepsilon _{11}}} \right\rangle {l_{{\text{eq}}}}$ $ \sigma _{{\text{eq}}}^{{\text{lc}}} = {{\left\langle { - {\sigma _{11}}} \right\rangle \left\langle { - {\varepsilon _{11}}} \right\rangle {l_{{\text{eq}}}}} \mathord{\left/ {\vphantom {{\left\langle { - {\sigma _{11}}} \right\rangle \left\langle { - {\varepsilon _{11}}} \right\rangle {l_{{\text{eq}}}}} {\chi _{{\text{eq}}}^{{\text{lc}}}}}} \right. } {\chi _{{\text{eq}}}^{{\text{lc}}}}} $ 纱线横向拉伸损伤 $\chi _{{\text{eq}}}^{{\text{tt}}} = \sqrt {\varepsilon _{22}^2 + \varepsilon _{12}^2 + \varepsilon _{23}^2} {l_{{\text{eq}}}}$ $\sigma _{{\text{eq}}}^{{\text{tt}}} = {{\left( {{\sigma _{22}}{\varepsilon _{22}} + {\tau _{12}}{\varepsilon _{12}} + {\tau _{23}}{\varepsilon _{23}}} \right){l_{{\text{eq}}}}} \mathord{\left/ {\vphantom {{\left( {{\sigma _{22}}{\varepsilon _{22}} + {\tau _{12}}{\varepsilon _{12}} + {\tau _{23}}{\varepsilon _{23}}} \right){l_{{\text{eq}}}}} {\chi _{{\text{eq}}}^{{\text{tt}}}}}} \right. } {\chi _{{\text{eq}}}^{{\text{tt}}}}}$ 纱线横向压缩损伤 $\chi _{{\text{eq}}}^{{\text{tc}}} = \left\langle { - {\varepsilon _{22}}} \right\rangle {l_{{\text{eq}}}}$ $ \sigma _{{\text{eq}}}^{{\text{tc}}} = {{\left\langle { - {\sigma _{22}}} \right\rangle \left\langle { - {\varepsilon _{22}}} \right\rangle {l_{{\text{eq}}}}} \mathord{\left/ {\vphantom {{\left\langle { - {\sigma _{22}}} \right\rangle \left\langle { - {\varepsilon _{22}}} \right\rangle {l_{{\text{eq}}}}} {\chi _{{\text{eq}}}^{{\text{tc}}}}}} \right. } {\chi _{{\text{eq}}}^{{\text{tc}}}}} $ 树脂基体拉伸损伤 $\chi _{{\text{eq}}}^{{\text{mt}}} = \left| {{\varepsilon _1}} \right|{l_{{\text{eq}}}}$ $ \sigma _{{\text{eq}}}^{{\text{mt}}} = {{\left| {{\sigma _1}{\varepsilon _1}} \right|{l_{{\text{eq}}}}} \mathord{\left/ {\vphantom {{\left| {{\sigma _1}{\varepsilon _1}} \right|{l_{{\text{eq}}}}} {\chi _{{\text{eq}}}^{{\text{mt}}}}}} \right. } {\chi _{{\text{eq}}}^{{\text{mt}}}}} $ 树脂基体压缩损伤 $\chi _{{\text{eq}}}^{{\text{mc}}} = \left| {{\varepsilon _3}} \right|{l_{{\text{eq}}}}$ $ \sigma _{{\text{eq}}}^{{\text{mc}}} = {{\left| {{\sigma _3}{\varepsilon _3}} \right|{l_{{\text{eq}}}}} \mathord{\left/ {\vphantom {{\left| {{\sigma _3}{\varepsilon _3}} \right|{l_{{\text{eq}}}}} {\chi _{{\text{eq}}}^{{\text{mc}}}}}} \right. } {\chi _{{\text{eq}}}^{{\text{mc}}}}} $ 注:leq为单元特征长度,六面体单元特征长度为单元体积的立方根。 表 9 三维机织复合材料参数化模型特征参数

Table 9. Characteristic parameters of the parametric model for 3D woven composites

特征参数 参数化模型预测值 测量值[26] 相对误差/% 三维机织复合材料RVE厚度/mm 4.0 4.0 0 表层接结纱倾斜角度/rad 1.109 1.134 −2.2 内层接结纱倾斜角度/rad 1.056 1.065 −0.8 经纱宽度/mm 1.767 1.70 3.9 经纱厚度/mm 0.430 0.45 −4.4 表层纬纱宽度/mm 1.820 1.78 2.2 表层纬纱厚度/mm 0.303 0.28 8.2 -

[1] LIU Gang,ZHANG Li,GUO Licheng,et al. Multi-scale progressive failure simulation of 3D woven composites under uniaxial tension[J]. Composite Structures,2019,208: 233-243. doi: 10.1016/j.compstruct.2018.09.081 [2] MOUNTASIR A,HOFFMANN G,CHERIF C,et al. Competitive manufacturing of 3D thermoplastic composite panels based on multi-layered woven structures for lightweight engineering[J]. Composite Structures,2015,133: 415-424. doi: 10.1016/j.compstruct.2015.07.071 [3] HUANG Tao,WANG Yanling,WANG Gang. Review of the mechanical properties of a 3D woven composite and its applications[J]. Polymer-Plastics Technology and Engineering,2018,57(8): 740-756. doi: 10.1080/03602559.2017.1344857 [4] MARSH G. Aero engines lose weight thanks to composites[J]. Reinforced Plastics,2012,56(6): 32-35. doi: 10.1016/S0034-3617(12)70146-7 [5] ISART N,EL SAID B,IVANOV D S,et al. Internal geometric modelling of 3D woven composites: a comparison between different approaches[J]. Composite Structures,2015,132: 1219-1230. doi: 10.1016/j.compstruct.2015.07.007 [6] LI Haolin,BACARREZA O,KHODAEI Z S,et al. Probabilistic multi-scale design of 2D plain woven composites considering meso-scale uncertainties[J]. Composite Structures,2022,300: 116099. doi: 10.1016/j.compstruct.2022.116099 [7] ZHANG Yuyang,LI Huimin,GAO Yihang,et al. Multi-scale modeling and elastic properties prediction of 3D four-directional tubular braided composites[J]. Composite Structures,2022,292: 115632. doi: 10.1016/j.compstruct.2022.115632 [8] YANG Xue,AI Jing,ZHU Hao,et al. Multi-directional compression behaviors and failure mechanisms of 3D orthogonal woven composites: Parametric modeling and strength prediction[J]. Materials & Design,2022,222: 111108. [9] GUO Junhua,WEN Weidong,ZHANG Hongjian,et al. Investigation of mechanical properties for 2.5D woven composites with different weft-layer-numbers by a triple-cell model system[J]. Journal of Industrial Textiles,2022,51(3_suppl): 5243S-5285S. doi: 10.1177/1528083720958046 [10] GUO Junhua,WEN Weidong,ZHANG Hongjian,et al. Mechanical properties prediction of 2.5D woven composites via voxel-mesh full-cell model[J]. Fibers and Polymers,2021,22(7): 1899-1914. doi: 10.1007/s12221-021-0153-4 [11] GUO Junhua,WEN Weidong,ZHANG Hongjian,et al. Representative cell modeling strategy of 2.5D woven composites considering the randomness of weft cross-section for mechanical properties prediction[J]. Engineering Fracture Mechanics,2020,237: 107255. doi: 10.1016/j.engfracmech.2020.107255 [12] WARREN K C,LOPEZ-ANIDO R A,GOERING J. Experimental investigation of three-dimensional woven composites[J]. Composites Part A: Applied Science and Manufacturing,2015,73: 242-259. doi: 10.1016/j.compositesa.2015.03.011 [13] DAI S,CUNNINGHAM P R. Multi-scale damage modelling of 3D woven composites under uni-axial tension[J]. Composite Structures,2016,142: 298-312. doi: 10.1016/j.compstruct.2016.01.103 [14] LU Zixing,ZHOU Yuan,YANG Zhenyu,et al. Multi-scale finite element analysis of 2.5D woven fabric composites under on-axis and off-axis tension[J]. Computational Materials Science,2013,79: 485-494. doi: 10.1016/j.commatsci.2013.07.003 [15] LU Huaiyu,GUO Licheng,LIU Gang,et al. Progressive damage investigation of 2.5D woven composites under quasi-static tension[J]. Acta Mechanica,2019,230(4): 1323-1336. doi: 10.1007/s00707-017-2024-z [16] SONG Jian,WEN Weidong,CUI Haitao. Experimental and numerical investigation of mechanical behaviors of 2.5D woven composites at ambient and un-ambient temperatures[J]. Composite Structures,2018,201: 699-720. doi: 10.1016/j.compstruct.2018.06.054 [17] SONG Jian,LIU Lu,LI Lixiao,et al. Thermo-mechanical responses of notched layer-to-layer 3D angle-interlock woven composites[J]. Composites Part B: Engineering,2019,176: 107262. doi: 10.1016/j.compositesb.2019.107262 [18] ZHONG Suyang,GUO Licheng,LIU Gang,et al. A continuum damage model for three-dimensional woven composites and finite element implementation[J]. Composite Structures,2015,128: 1-9. doi: 10.1016/j.compstruct.2015.03.030 [19] ZHENG Tao,GUO Licheng,SUN Ruijian,et al. Investigation on the compressive damage mechanisms of 3D woven composites considering stochastic fiber initial misalignment[J]. Composites Part A: Applied Science and Manufacturing,2021,143: 106295. doi: 10.1016/j.compositesa.2021.106295 [20] ZHENG Tao,GUO Licheng,HUANG Jinzhao,et al. A novel mesoscopic progressive damage model for 3D angle-interlock woven composites[J]. Composites Science and Technology,2020,185: 107894. doi: 10.1016/j.compscitech.2019.107894 [21] ZHENG Tao,GUO Licheng,DING Junfeng,et al. An innovative micromechanics-based multiscale damage model of 3D woven composites incorporating probabilistic fiber strength distribution[J]. Composite Structures,2022,287: 115345. doi: 10.1016/j.compstruct.2022.115345 [22] ZHENG Tao,GUO Licheng,BENEDICTUS R,et al. Micromechanics-based multiscale progressive failure simulation of 3D woven composites under compressive loading with minimal material parameters[J]. Composites Science and Technology,2022,219: 109227. doi: 10.1016/j.compscitech.2021.109227 [23] ZHANG Yifan,GUO Qiwei,CHEN Xiaoming,et al. Effect of apertures on tensile property of warp-reinforced 2.5D woven composites notched plates[J]. Composite Structures,2020,252: 112693. doi: 10.1016/j.compstruct.2020.112693 [24] GUO Qiwei,ZHANG Yifan,LI Diansen,et al. Experimental and numerical investigation of open-hole tensile properties and damage mechanisms of 3D woven composites under weft-loading[J]. Thin-Walled Structures,2021,161: 107455. doi: 10.1016/j.tws.2021.107455 [25] ZHANG Yifan,LI Mohan,GUO Qiwei,et al. Tensile failure of multiaxial 3D woven composites with an open-hole: an experimental and numerical study[J]. Composite Structures,2022,279: 114746. doi: 10.1016/j.compstruct.2021.114746 [26] GUO Qiwei,ZHANG Yifan,LI Diansen,et al. Tensile properties and failure mechanism of 3D woven composites containing holes of different geometries[J]. Thin-Walled Structures,2021,166: 108115. doi: 10.1016/j.tws.2021.108115 [27] GUO Licheng,HUANG Jinzhao,ZHANG Li,et al. Damage evolution of 3D woven carbon/epoxy composites under tension-tension fatigue loading based on synchrotron radiation computed tomography (SRCT)[J]. International Journal of Fatigue,2021,142: 105913. doi: 10.1016/j.ijfatigue.2020.105913 [28] LIN Hua,BROWN L P,LONG A C. Modelling and simulating textile structures using TexGen[J]. Advanced Materials Research,2011,331: 44-47. doi: 10.4028/www.scientific.net/AMR.331.44 [29] HASHIN Z. Failure criteria for unidirectional fiber composites[J]. Journal of Applied Mechanics,1980,47(2): 329-334. doi: 10.1115/1.3153664 [30] TSCHOEGL N W. Failure surfaces in principal stress space[J]. Journal of Polymer Science Part C: Polymer Symposia,1971,32(1): 239-267. doi: 10.1002/polc.5070320113 [31] SENDECKYJ G P,WANG S S,STEVEN JOHNSON W,et al. Mechanics of composite materials: past,present,and future[J]. Journal of Composites Technology and Research,1989,11(1): 3. doi: 10.1520/CTR10143J [32] ZAKO M,UETSUJI Y,KURASHIKI T. Finite element analysis of damaged woven fabric composite materials[J]. Composites Science and Technology,2003,63(3/4): 507-516. [33] BAŽANT Z P,OH B H. Crack band theory for fracture of concrete[J]. Matériaux et Construction,1983,16(3): 155-177. [34] FANG Guodong,LIANG Jun,LU Qi,et al. Investigation on the compressive properties of the three dimensional four-directional braided composites[J]. Composite Structures,2011,93(2): 392-405. doi: 10.1016/j.compstruct.2010.09.002 -

下载:

下载: