Effect of reaction progress on temperature measurement system error of gas analysis method

-

摘要:

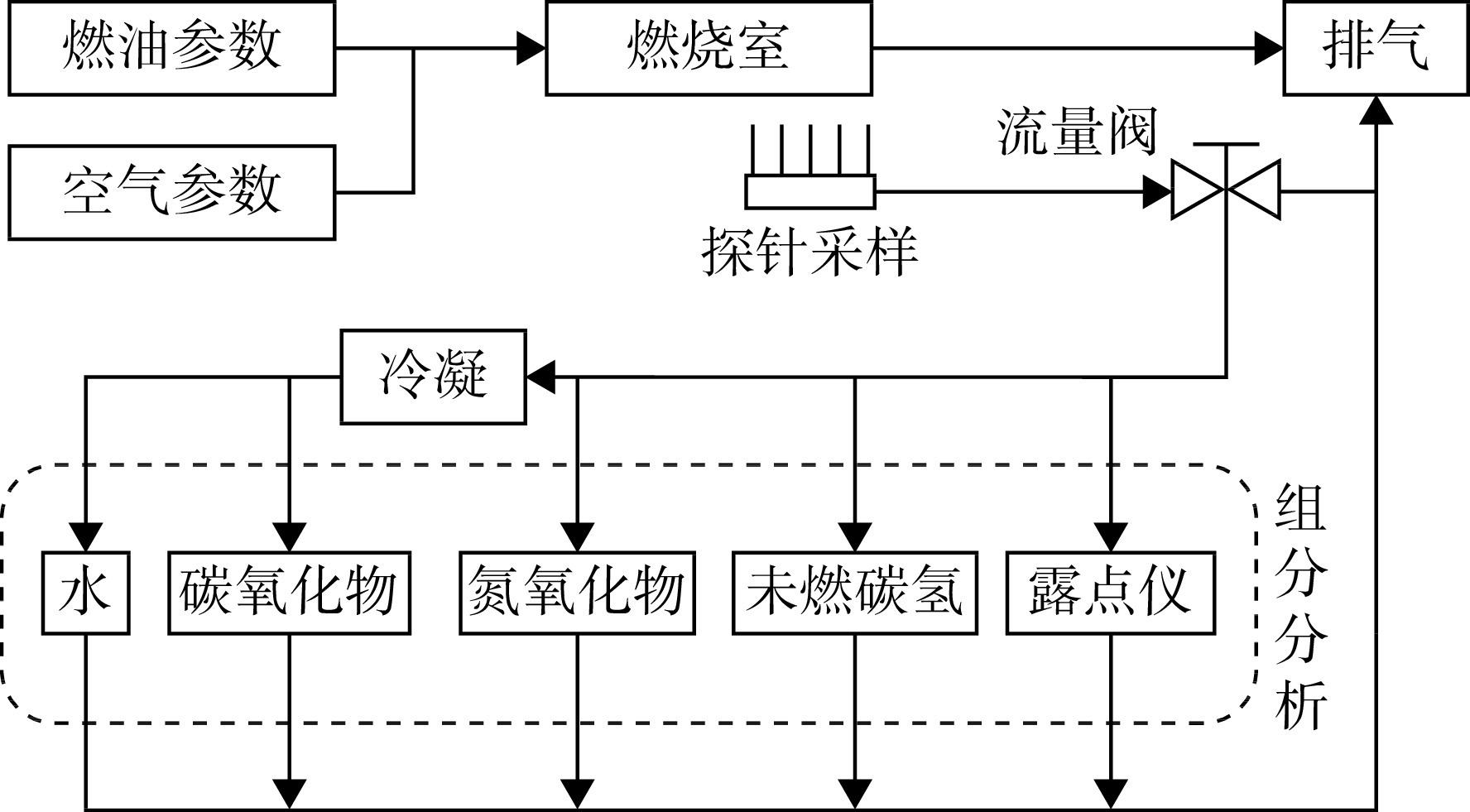

基于焓值守恒法计算燃气温度的误差通常认为来源于直接测量和高温分解的影响,在某型高温升燃烧室的测试中发现:高温环境下以热电偶测量结果作为参考标准来评价燃气分析法的性能会引入较大响应误差,因此采用Sandia实验室的湍流火焰数据作为参考标准对各测点温度进行对比分析。结果显示焓值守恒法计算的温度与实验中测量的温度整体平均误差较小,但是在反应初始区域以及燃烧区域出现较大误差。进一步研究发现:燃气分析法测温不确定度主要来源于反应进度,采用反应进度变量能够对温度计算结果的不确定度进行量化,进而对燃气分析测温法的适用范围进行判断和限定,为进一步研究焓值守恒测温法在湍流火焰和发动机燃烧室测温中的应用以及不确定度评估提供了参考依据。

Abstract:It is generally believed that the error of gas temperature calculation based on enthalpy conservation method is caused by the error of direct measurement and the influence of high temperature decomposition. However, in the test of a certain high temperature combustion chamber, it was found that, taking thermocouple measurement results as the reference standard to evaluate the performance of gas analysis method under high temperature environment may introduce a large response error, so the turbulent flame experimental data of Sandia laboratory were used as reference standard to compare and analyze the temperature of each measuring point. The results showed that the overall average error of the temperature calculated by the enthalpy conservation method was small compared with the temperature measured in the experiment, but there were large errors in the initial reaction region and the combustion region. Further research found that: the uncertainty of temperature measurement in gas analysis was mainly derived from reaction progress. The uncertainty of temperature calculation results can be quantified by using reaction progress variable, and the applicable range of gas analysis method can be judged and limited, providing a reference for further research on the application of the enthalpy conservation temperature measurement method in the temperature measurement of turbulent flame and engine combustion chamber and the evaluation of uncertainty.

-

表 1 某型高温升燃烧室测试工况

Table 1. Test condition of a type of high temperature combustion chamber

工况 燃料 摩尔浓度/% 当量比 N2 O2 H2O A 航空煤油

(C12H24)76.7 20.5 2.8 0.34 B 0.42 C 0.49 D 0.57 表 2 实验测量数据不确定度

Table 2. Uncertainty of experimental measurement data

编号 不确定度/K 编号 不确定度/K A-1 1.35 C-1 2.18 A-2 1.41 C-2 2.88 A-3 1.83 C-3 3.12 A-4 1.76 C-4 5.25 A-5 1.39 C-5 2.84 B-1 1.36 D-1 2.61 B-2 1.67 D-2 3.16 B-3 2.63 D-3 5.03 B-4 4.06 D-4 10.29 B-5 2.19 D-5 4.70 表 3 Sandia D火焰实验喷嘴参数

Table 3. Nozzle parameters of Sandia D flame experiment

流道 流速/(m/s) 组分(体积分数) 空气流道(Coflow) 0.9 100%Air 值班级流道(Pilot) 11.4 100%$ {\mathrm{C}\mathrm{H}}_{4} $ 主燃级流道(Main-Jet) 49.6 25%$ {\mathrm{C}\mathrm{H}}_{4} $、75%Air -

[1] 王海青,林伟,仝毅恒,等. 基于激光的燃烧场温度诊断方法综述[J]. 气体物理,2020,5(1): 42-55. WANG Haiqing,LIN Wei,TONG Yiheng,et al. Review of laser-based temperature diagnosis methods for combustion field[J]. Physics of Gases,2020,5(1): 42-55. (in ChineseWANG Haiqing, LIN Wei, TONG Yiheng, et al. Review of laser-based temperature diagnosis methods for combustion field[J]. Physics of Gases, 2020, 5(1): 42-55. (in Chinese) [2] BIDEAU R J. The development of a computer code for the estimation of combustor exhaust temperature using simple gas analysis measurements[J]. Journal of Engineering for Gas Turbines and Power,1999,121(1): 80-88. doi: 10.1115/1.2816317 [3] WILLIAMSON R C,STANFORTH C M. Measurement of jet engine combustion temperature by the use of thermocouples and gas analysis[R]. SAE Technical Paper,690433,1969. [4] 王明瑞,王振华,韩冰,等. 航空发动机主燃烧室高温测试技术[J]. 航空发动机,2016,42(5): 87-93. WANG Mingrui,WANG Zhenhua,HAN Bing,et al. High temperature measurement technology for main combustion chamber of aeroengine[J]. Aeroengine,2016,42(5): 87-93. (in ChineseWANG Mingrui, WANG Zhenhua, HAN Bing, et al. High temperature measurement technology for main combustion chamber of aeroengine[J]. Aeroengine, 2016, 42(5): 87-93. (in Chinese) [5] 王明瑞,肖阳,韩冰,等. 燃气分析法测量航空发动机五头部燃烧室温度场[J]. 航空动力学报,2016,31(9): 2049-2054. WANG Mingrui,XIAO Yang,HAN Bing,et al. Temperature field test for aeroengine combustor with five nozzles based on gas analysis[J]. Journal of Aerospace Power,2016,31(9): 2049-2054. (in ChineseWANG Mingrui, XIAO Yang, HAN Bing, et al. Temperature field test for aeroengine combustor with five nozzles based on gas analysis[J]. Journal of Aerospace Power, 2016, 31(9): 2049-2054. (in Chinese) [6] SAE. Procedure for the analysis and evaluation of gaseous Emissions from aircraft engines: ARP1533C[S]. SAE,2016. [7] HIBBARD R,EVANS A. Application of gas analysis to combustor research[R]. NASA Memo,1-26-59E,1959. [8] 钟华贵,吉洪湖,李继保. 燃气分析测量高温燃气温度的方法[J]. 航空动力学报,2005,20(3): 460-466. ZHONG Huagui,JI Honghu,LI Jibao. Methods for gas temperature measurement by gas analysis[J]. Journal of Aerospace Power,2005,20(3): 460-466. (in Chinese doi: 10.3969/j.issn.1000-8055.2005.03.023ZHONG Huagui, JI Honghu, LI Jibao. Methods for gas temperature measurement by gas analysis[J]. Journal of Aerospace Power, 2005, 20(3): 460-466. (in Chinese) doi: 10.3969/j.issn.1000-8055.2005.03.023 [9] 韩冰,王明瑞,李亚娟,等. 基于成分的燃烧室出口燃气温度计算方法[J]. 航空动力学报,2018,33(11): 2687-2693. HAN Bing,WANG Mingrui,LI Yajuan,et al. Calculation method for gas temperature from combustor outlet based on gas composition[J]. Journal of Aerospace Power,2018,33(11): 2687-2693. (in ChineseHAN Bing, WANG Mingrui, LI Yajuan, et al. Calculation method for gas temperature from combustor outlet based on gas composition[J]. Journal of Aerospace Power, 2018, 33(11): 2687-2693. (in Chinese) [10] 韩冰,王明瑞,李亚娟,等. 燃气分析法在高温升全环燃烧室出口温度场试验中的应用[J]. 航空发动机,2017,43(5): 79-84. HAN Bing,WANG Mingrui,LI Yajuan,et al. Application of gas analysis method on high temperature rise full annular combustor outlet temperature field test[J]. Aeroengine,2017,43(5): 79-84. (in ChineseHAN Bing, WANG Mingrui, LI Yajuan, et al. Application of gas analysis method on high temperature rise full annular combustor outlet temperature field test[J]. Aeroengine, 2017, 43(5): 79-84. (in Chinese) [11] WALKER P H. Temperature measurement by gas analysis[J]. High Temperature Technology,1983,1(6): 327-332. doi: 10.1080/02619180.1983.11753229 [12] BLUST J,GETZ M,ZABARNICK S,et al. Probe design optimization for the well stirred reactor[R]. AIAA 1997-907,1997. [13] 徐雪睿,仲峰泉. 解离效应对超燃冲压发动机燃烧与传热的影响特性研究[J]. 推进技术,2022,43(5): 239-245. XU Xuerui,ZHONG Fengquan. Effects of dissociation on combustion and heat transfer of scramjet[J]. Journal of Propulsion Technology,2022,43(5): 239-245. (in ChineseXU Xuerui, ZHONG Fengquan. Effects of dissociation on combustion and heat transfer of scramjet[J]. Journal of Propulsion Technology, 2022, 43(5): 239-245. (in Chinese) [14] 李卫东. 一种根据燃气成分计算燃气温度的方法[J]. 中国民航学院学报,2006,24(4): 23-26. LI Weidong. Method of calculating gas temperature based on gas composition[J]. Journal of Civel Aviation University of China,2006,24(4): 23-26. (in ChineseLI Weidong. Method of calculating gas temperature based on gas composition[J]. Journal of Civel Aviation University of China, 2006, 24(4): 23-26. (in Chinese) [15] 王明瑞,肖阳,韩冰,等. 航空燃气涡轮发动机燃气分析测试及计算方法[J]. 航空动力学报,2015,30(11): 2568-2574. WANG Mingrui,XIAO Yang,HAN Bing,et al. Gas analysis test and calculation method of aeroengine[J]. Journal of Aerospace Power,2015,30(11): 2568-2574. (in ChineseWANG Mingrui, XIAO Yang, HAN Bing, et al. Gas analysis test and calculation method of aeroengine[J]. Journal of Aerospace Power, 2015, 30(11): 2568-2574. (in Chinese) [16] 李乐,索建秦,于涵,等. 燃气分析系统优化设计及应用研究[J]. 西北工业大学学报,2020,38(1): 104-113. LI Le,SUO Jianqin,YU Han,et al. Optimal design and application of gas analysis system[J]. Journal of Northwestern Polytechnical University,2020,38(1): 104-113. (in Chinese doi: 10.3969/j.issn.1000-2758.2020.01.013LI Le, SUO Jianqin, YU Han, et al. Optimal design and application of gas analysis system[J]. Journal of Northwestern Polytechnical University, 2020, 38(1): 104-113. (in Chinese) doi: 10.3969/j.issn.1000-2758.2020.01.013 [17] IHME M,SHUNN L,ZHANG Jian. Regularization of reaction progress variable for application to flamelet-based combustion models[J]. Journal of Computational Physics,2012,231(23): 7715-7721. doi: 10.1016/j.jcp.2012.06.029 [18] BRAY K,DOMINGO P,VERVISCH L. Role of the progress variable in models for partially premixed turbulent combustion[J]. Combustion and Flame,2005,141(4): 431-437. doi: 10.1016/j.combustflame.2005.01.017 [19] DUAN Yifan,XIA Zhixun,MA Likun,et al. Numerical simulation of the Sandia Flame D using the ESF method coupled with FGM model[J]. Cluster Computing,2019,22(6): 15103-15110. [20] Sandia National Laboratories. International workshop on measurement and computation of turbulent flames [EB/OL]. [2022-12-07]. http://www.ca.sandia.gov/TNF. -

下载:

下载: