Flow loss mechanism of high subsonic compressor blade vibration under low Reynolds number conditions

-

摘要:

为了探索低雷诺数

Re 下高亚声速压气机叶片振动对附面层流动状态的影响,利用数值模拟手段分析了压气机叶片在不同振动频率下叶片表面附面层分离、再附及转捩的变化规律和流动损失的变化规律。研究表明,在Re =1.5×105条件下,叶片振动引起附面层垂直壁面法向的相对速度增加,使得分离后的附面层提前与主流发生掺混,促使转捩提前,此时壁面附近法向位置处的法向速度型更饱满,这提升了附面层抗分离的能力,限制了分离泡的发展。此外,叶片振动造成附面层和分离泡厚度变“薄”,这使得尾缘堆积的低能流体减少,削弱了尾缘附近流动堵塞和尾迹掺混,进而减少流动损失,改善了低Re 条件下高亚声速压气机叶型的气动性能。Abstract:In order to investigate the influence of high subsonic compressor blade vibration on the flow state of the surface layer under low Reynolds number (

Re ) conditions, numerical simulations were conducted to analyze the rule of separation, re-attachment, transition and flow loss of compressor blade surface boundary layer under different vibration frequencies. According to the simulation results, under the condition ofRe =1.5×105, the increase in the normal relative velocity of the vertical wall of the surface layer caused by blade vibration could trigger the mixing of the separated surface layer with the mainstream in advance, which promoted the advance of transition. In this case, the normal velocity pattern at normal position near the wall was fuller, which improved the ability of the boundary layer to resist separation and limited the development of the separation bubble. In addition, the boundary layer and separation bubble thickness became "thin" due to blade vibration, which reduced the accumulation of low-energy fluid at the trailing edge, and weakened flow blockage near the trailing edge and wakes mixing, thereby reducing flow loss and improving the aerodynamic performance of the high subsonic compressor blade under low Re conditions.-

Key words:

- low Reynolds number /

- compressor blade /

- blade vibration /

- boundary layer separation /

- transition

-

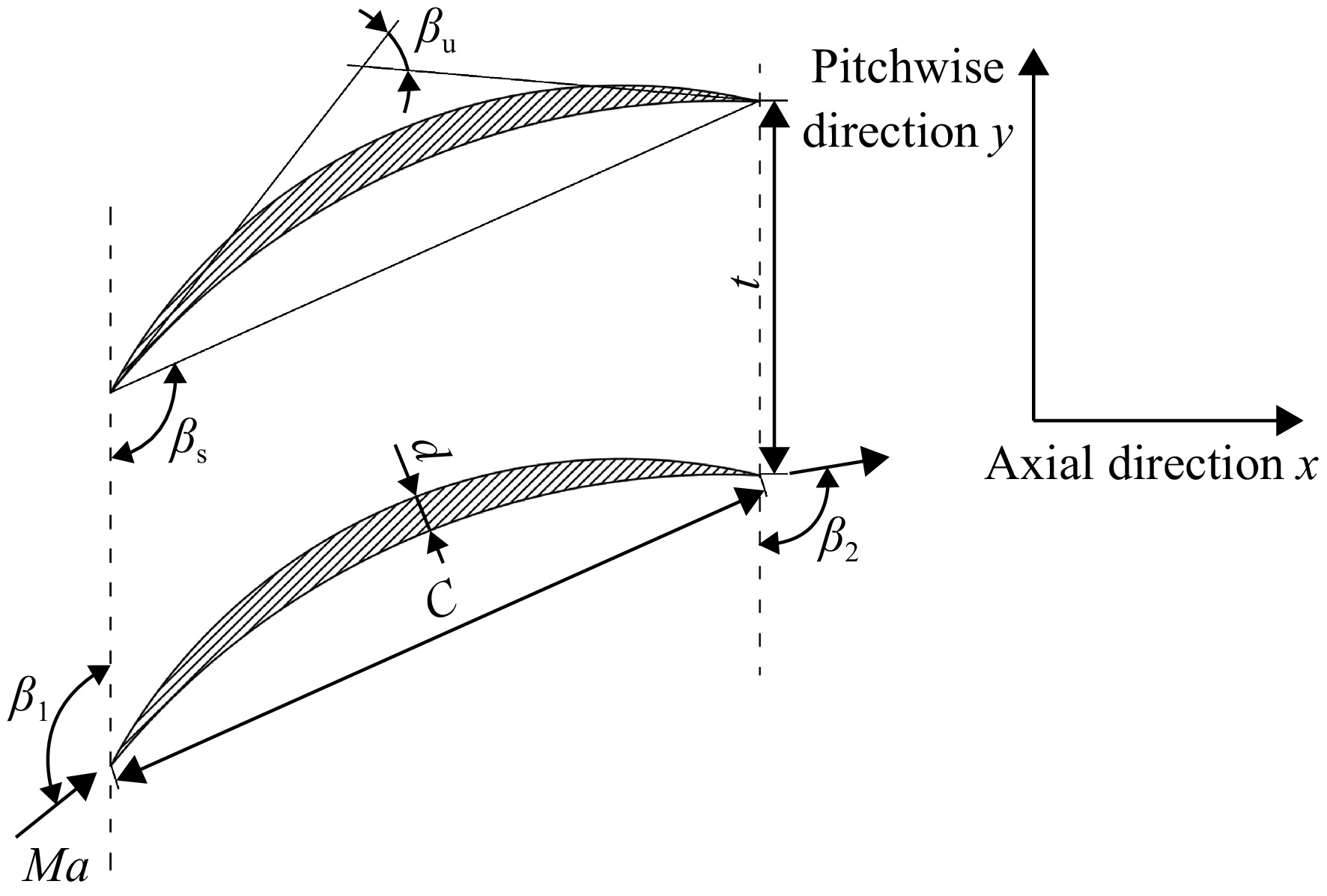

表 1 V103几何及气动参数

Table 1. V103 Geometric and aerodynamic parameters

参数 数值 C/mm 180 t/s 0.55 $d'_{\mathrm{max}} $/C 0.055 βu/(°) 48 βs/(°) 112.5 Ma 0.67 Re 150000 β1/(°) 132 β2/(°) 96 表 2 不同拓扑结构的性能参数对比

Table 2. Comparison of performance parameters of different grid topology

方案 网格

数量/105展向网格

层数单层网格

数量/105总压损失

系数ω0 7.6 2 3.8 0.0499 1 28.6 3 9.53 0.0472 2 33.4 3 11.1 0.0471 3 52.4 4 13.1 0.0470 表 3 V103工况点参数

Table 3. V103 operating condition point parameters

计算工况参数 数值 进口总压p01/Pa 5090.0 进口总温T01/K 236.1 进口气流角β1/° 132 进口马赫数Ma 0.67 进口雷诺数Re 150000 进口湍流度Tu 3.5% 出口静压p2/Pa 4373.76 表 4 V103不同工况参数

Table 4. V103 parameters under different operating conditions

方案 振动幅度/mm 振动频率/Hz 折合频率 1 0 0 k0=0 2 0.25%C 1400 k1=1.275 3 0.25%C 1500 k2=1.366 -

[1] SUN Haiou,WANG Meng,WANG Zhongyi,et al. Numerical investigation of surge prediction in a transonic axial compressor with a hybrid BDF/Harmonic Balance Method[J]. Aerospace Science and Technology,2019,90: 401-409. doi: 10.1016/j.ast.2019.05.006 [2] ISHII H,KASHIWABARA Y. Surge and rotating stall in axial compressors[R]. AIAA 1989-2683,1989. [3] BRAHIMI F,OUIBRAHIM A. Blade dynamical response based on aeroelastic analysis of fluid structure interaction in turbomachinery[J]. Energy,2016,115: 986-995. doi: 10.1016/j.energy.2016.09.071 [4] NAKHCHI M E,NAUNG S W,RAHMATI M. Influence of blade vibrations on aerodynamic performance of axial compressor in gas turbine: direct numerical simulation[J]. Energy,2022,242: 122988. doi: 10.1016/j.energy.2021.122988 [5] 于贤君,徐语航,安广丰,等. 粗糙度对压气机叶型性能影响的数值模拟方法研究[J]. 工程热物理学报,2021,42(7): 1712-1718. YU Xianjun,XU Yuhang,AN Guangfeng,et al. Investigation of the numerical method for the influence of the surface roughness on the performance of compressor blade airfoils[J]. Journal of Engineering Thermophysics,2021,42(7): 1712-1718. (in ChineseYU Xianjun, XU Yuhang, AN Guangfeng, et al. Investigation of the numerical method for the influence of the surface roughness on the performance of compressor blade airfoils[J]. Journal of Engineering Thermophysics, 2021, 42(7): 1712-1718. (in Chinese) [6] LEIPOLD R,BOESE M,FOTTNER L. The influence of technical surface roughness on the flow around a highly loaded compressor cascade[R]. ASME Paper GT-366,1999. [7] SCHA¨FFLER A. Experimental and analytical investigation of the effects of Reynolds number and blade surface roughness on multistage axial flow compressors[J]. Journal of Engineering for Power,1980,102(1): 5-12. doi: 10.1115/1.3230232 [8] ROBERTS W B. The effect of Reynolds number and laminar separation on axial cascade performance[J]. Journal of Engineering for Power,1975,97(2): 261-273. doi: 10.1115/1.3445978 [9] 王文涛,王子楠,张宏武,等. 压气机静叶栅层流分离泡转捩与角区分离数值模拟与实验[J]. 航空动力学报,2017,32(9): 2273-2282. WANG Wentao,WANG Zinan,ZHANG Hongwu,et al. Numerical simulation and experiment of laminar separation bubble transition and corner separation of compressor stator cascade[J]. Journal of Aerospace Power,2017,32(9): 2273-2282. (in ChineseWANG Wentao, WANG Zinan, ZHANG Hongwu, et al. Numerical simulation and experiment of laminar separation bubble transition and corner separation of compressor stator cascade[J]. Journal of Aerospace Power, 2017, 32(9): 2273-2282. (in Chinese) [10] WANG Mingyang,LI Ziliang,YANG Chengwu,et al. Numerical investigations of the separated transitional flow over compressor blades with different loading distributions[J]. Aerospace Science and Technology,2020,106: 106113. doi: 10.1016/j.ast.2020.106113 [11] HILGENFELD L,PFITZNER M. Experimental investigation of wake-induced transition in a highly loaded linear compressor cascade[M]. Dordrecht,the Netherlands: Springer,2006. [12] DONG Y,CUMPSTY N A. Compressor blade boundary layers: Part 2 measurements with incident wakes[J]. Journal of Turbomachinery,1990,112(2): 231-240. doi: 10.1115/1.2927637 [13] SATTA F,SIMONI D,UBALDI M,et al. Loading distribution effects on separated flow transition of ultra-high-lift turbine blades[J]. Journal of Propulsion and Power,2014,30(3): 845-856. doi: 10.2514/1.B34968 [14] 王名扬,李紫良,卢新根,等. 低雷诺数下粗糙度对高亚声速压气机叶型气动性能的影响[J]. 推进技术,2020,41(7): 1510-1519. WANG Mingyang,LI Ziliang,LU Xingen,et al. Effects of surface roughness on aerodynamic performance of a high subsonic compressor airfoil under low Reynolds number conditions[J]. Journal of Propulsion Technology,2020,41(7): 1510-1519. (in ChineseWANG Mingyang, LI Ziliang, LU Xingen, et al. Effects of surface roughness on aerodynamic performance of a high subsonic compressor airfoil under low Reynolds number conditions[J]. Journal of Propulsion Technology, 2020, 41(7): 1510-1519. (in Chinese) [15] 王名扬,赵胜丰,李紫良,等. 低雷诺数下高亚声速压气机叶型流动损失机理研究[J]. 推进技术,2020,41(5): 1046-1054. WANG Mingyang,ZHAO Shengfeng,LI Ziliang,et al. Flow and loss mechanism of high subsonic compressor airfoil under low Reynolds number conditions[J]. Journal of Propulsion Technology,2020,41(5): 1046-1054. (in ChineseWANG Mingyang, ZHAO Shengfeng, LI Ziliang, et al. Flow and loss mechanism of high subsonic compressor airfoil under low Reynolds number conditions[J]. Journal of Propulsion Technology, 2020, 41(5): 1046-1054. (in Chinese) [16] 雷志军,王明杰,朱俊强. 低速压气机叶栅附面层分离的实验研究[J]. 工程热物理学报,2008,29(11): 1839-1843. LEI Zhijun,WANG Mingjie,ZHU Junqiang. Experimental investigation on the suction surface boundary layer separation of a low-speed compressor cascade[J]. Journal of Engineering Thermophysics,2008,29(11): 1839-1843. (in ChineseLEI Zhijun, WANG Mingjie, ZHU Junqiang. Experimental investigation on the suction surface boundary layer separation of a low-speed compressor cascade[J]. Journal of Engineering Thermophysics, 2008, 29(11): 1839-1843. (in Chinese) [17] 刘美茹,朱靖,梁恩波,等. 基于叶尖定时的航空发动机压气机叶片振动测量[J]. 航空动力学报,2019,34(9): 1895-1904. LIU Meiru,ZHU Jing,LIANG Enbo,et al. Vibration measurement on compressor rotor blades of aero-engine based on tip-timing[J]. Journal of Aerospace Power,2019,34(9): 1895-1904. (in ChineseLIU Meiru, ZHU Jing, LIANG Enbo, et al. Vibration measurement on compressor rotor blades of aero-engine based on tip-timing[J]. Journal of Aerospace Power, 2019, 34(9): 1895-1904. (in Chinese) [18] 马明. 低雷诺数环境下民机RAT叶片振动失效机理分析[J]. 环境技术,2020,38(4): 65-70. MA Ming. Vibration failure mechanism analysis of civil aircraft RAT blades under low Reynolds number environment[J]. Environmental Technology,2020,38(4): 65-70. (in ChineseMA Ming. Vibration failure mechanism analysis of civil aircraft RAT blades under low Reynolds number environment[J]. Environmental Technology, 2020, 38(4): 65-70. (in Chinese) [19] 董旭. 跨音风扇颤振及非定常流致振动机理研究[D]. 北京: 中国科学院大学,2021. DONG Xu. Study on flutter and unsteady flow-induced vibration mechanism of transonic fan[D]. Beijing: University of Chinese Academy of Sciences,2021. (in ChineseDONG Xu. Study on flutter and unsteady flow-induced vibration mechanism of transonic fan[D]. Beijing: University of Chinese Academy of Sciences, 2021. (in Chinese) [20] 龙伦,袁巍,成晓鸣,等. 航空发动机带冠涡轮叶片振动特性分析及验证[J]. 机械强度,2021,43(4): 960-965. LONG Lun,YUAN Wei,CHENG Xiaoming,et al. Research and verification on vibration characteristics of the shrouded turbine blade[J]. Journal of Mechanical Strength,2021,43(4): 960-965. (in ChineseLONG Lun, YUAN Wei, CHENG Xiaoming, et al. Research and verification on vibration characteristics of the shrouded turbine blade[J]. Journal of Mechanical Strength, 2021, 43(4): 960-965. (in Chinese) [21] 徐涛,王强,唐洪飞. 气冷涡轮叶片振动特性分析[J]. 机械设计与制造工程,2022,51(3): 63-66. XU Tao,WANG Qiang,TANG Hongfei. Vibration characteristics analysis of air-cooled turbine blades[J]. Machine Design and Manufacturing Engineering,2022,51(3): 63-66. (in ChineseXU Tao, WANG Qiang, TANG Hongfei. Vibration characteristics analysis of air-cooled turbine blades[J]. Machine Design and Manufacturing Engineering, 2022, 51(3): 63-66. (in Chinese) [22] 王增增,马宏伟. 航空发动机轴流压气机非整阶振动实验研究进展[J]. 航空动力学报,2022,37(11): 2416-2429. WANG Zengzeng,MA Hongwei. Overview of experimental research on non-synchronous vibration in aero-engine axial compressor[J]. Journal of Aerospace Power,2022,37(11): 2416-2429. (in ChineseWANG Zengzeng, MA Hongwei. Overview of experimental research on non-synchronous vibration in aero-engine axial compressor[J]. Journal of Aerospace Power, 2022, 37(11): 2416-2429. (in Chinese) [23] HUANG W,XIAO Dandan,REN Jie,et al. Bypass transition in flow over a vibrating flat plate[J]. Journal of Fluid Mechanics,2021,909: A15. doi: 10.1017/jfm.2020.923 [24] HACK M J P,ZAKI T A. Modal and non-modal stability of boundary layers forced by spanwise wall oscillations[J]. Journal of Fluid Mechanics,2015,778: 389-427. doi: 10.1017/jfm.2015.387 [25] SENGUPTA A,TUCKER P. Effects of forced frequency oscillations and free stream turbulence on the separation-induced transition in pressure gradient dominated flows[J]. Physics of Fluids,2020,32(10): 104105. doi: 10.1063/5.0022865 [26] 张英强,张燕峰,朱淼怡,等. 低雷诺数下低压涡轮叶片振动对分离及转捩的影响机制[J]. 航空动力学报,2022: 1-9. ZHANG Yingqiang,ZHANG Yanfeng,ZHU Miaoyi,et al. Influence mechanism of high load low pressure turbine blade vibration on separation and transition[J]. Journal of Aerospace Power,2022,1-9. (in ChineseZHANG Yingqiang, ZHANG Yanfeng, ZHU Miaoyi, et al. Influence mechanism of high load low pressure turbine blade vibration on separation and transition[J]. Journal of Aerospace Power, 2022, 1-9. (in Chinese) [27] WISSINK J,RODI W. DNS of a laminar separation bubble affected by free-stream disturbances[M]//FRIEDRICH R,GEURTS BJ,MÉTAIS O. Direct and Large-Eddy Simulation V. Dordrecht,the Netherlands: Springer,2004: 213-220. [28] YANG H,HE Li. Experimental study on linear compressor cascade with three-dimensional blade oscillation[J]. Journal of Propulsion and Power,2004,20: 180-188. doi: 10.2514/1.1280 [29] HOLZINGER F,WARTZEK F,SCHIFFER H P,et al. Self-excited blade vibration experimentally investigated in transonic compressors: acoustic resonance[J]. Journal of Turbomachinery,2016,138(4): 041001. doi: 10.1115/1.4032042 [30] BOESE M,FOTTNER L. Effects of riblets on the loss behavior of a highly loaded compressor cascade[R]. ASME Paper 2002-GT-30438. [31] 原泽,郑群,岳国强,等. 低负荷和高负荷压气机叶栅气动性能的实验和数值模拟[J]. 航空动力学报,2021,36(4): 724-733. YUAN Ze,ZHENG Qun,YUE Guoqiang,et al. Experiment and numerical simulation on aerodynamic performance of low-loaded and highly-loaded compressor cascades[J]. Journal of Aerospace Power,2021,36(4): 724-733. (in ChineseYUAN Ze, ZHENG Qun, YUE Guoqiang, et al. Experiment and numerical simulation on aerodynamic performance of low-loaded and highly-loaded compressor cascades[J]. Journal of Aerospace Power, 2021, 36(4): 724-733. (in Chinese) [32] WIN NAUNG S,NAKHCHI M E,RAHMATI M. Prediction of flutter effects on transient flow structure and aeroelasticity of low-pressure turbine cascade using direct numerical simulations[J]. Aerospace Science and Technology,2021,119: 107151. doi: 10.1016/j.ast.2021.107151 [33] JIANG Siya,FU Song. Numerical investigation of separation-induced transition in a low-pressure turbine cascade in a low-disturbance environment[J]. Science China Physics,Mechanics & Astronomy,2020,63(6): 264711. [34] RIST U,MAUCHER U. Investigations of time-growing instabilities in laminar separation bubbles[J]. European Journal of Mechanics - B,2002,21(5): 495-509. doi: 10.1016/S0997-7546(02)01205-0 [35] 李伟,张波,周敏,等. 尾迹扫掠下超高负荷低压涡轮叶片附面层特性[J]. 航空动力学报,2012,27(1): 176-182. LI Wei,ZHANG Bo,ZHOU Min,et al. Boundary layer behaviors on an ultra-high-lift low-pressure turbine profile under unsteady wakes[J]. Journal of Aerospace Power,2012,27(1): 176-182. (in ChineseLI Wei, ZHANG Bo, ZHOU Min, et al. Boundary layer behaviors on an ultra-high-lift low-pressure turbine profile under unsteady wakes[J]. Journal of Aerospace Power, 2012, 27(1): 176-182. (in Chinese) [36] THWAITES B. Approximate calculation of the laminar boundary layer[J]. Aeronautical Quarterly,1949,1(3): 245-280. doi: 10.1017/S0001925900000184 -

下载:

下载: