Heat transfer characteristics of wettability gradient surfaces in spray cooling

-

摘要:

采用组分输运模型discrete phase model(DPM)和欧拉壁面液膜模型对加热条件下圆环形化学图案改性表面上的喷雾冷却流动换热特性进行了数值模拟。通过对比四种改性表面的液膜厚度、液膜流速、表面温度不均匀性和平均表面传热系数的变化研究了润湿性梯度对表面流动换热特性的影响。结果表明:润湿性梯度表面的换热性能优于均匀润湿性表面,可以促进排液,优化液体管理。润湿性梯度大的表面,液膜流速快、液膜厚度小,疏水表面的排液效果可能优于亲-疏水混合表面,但通过疏水促进成核和亲水延缓干涸的良好设计,亲-疏水混合表面的换热性能最好,并且能够改善表面温度不均匀性。增加润湿性数量和增大梯度,可强化换热。

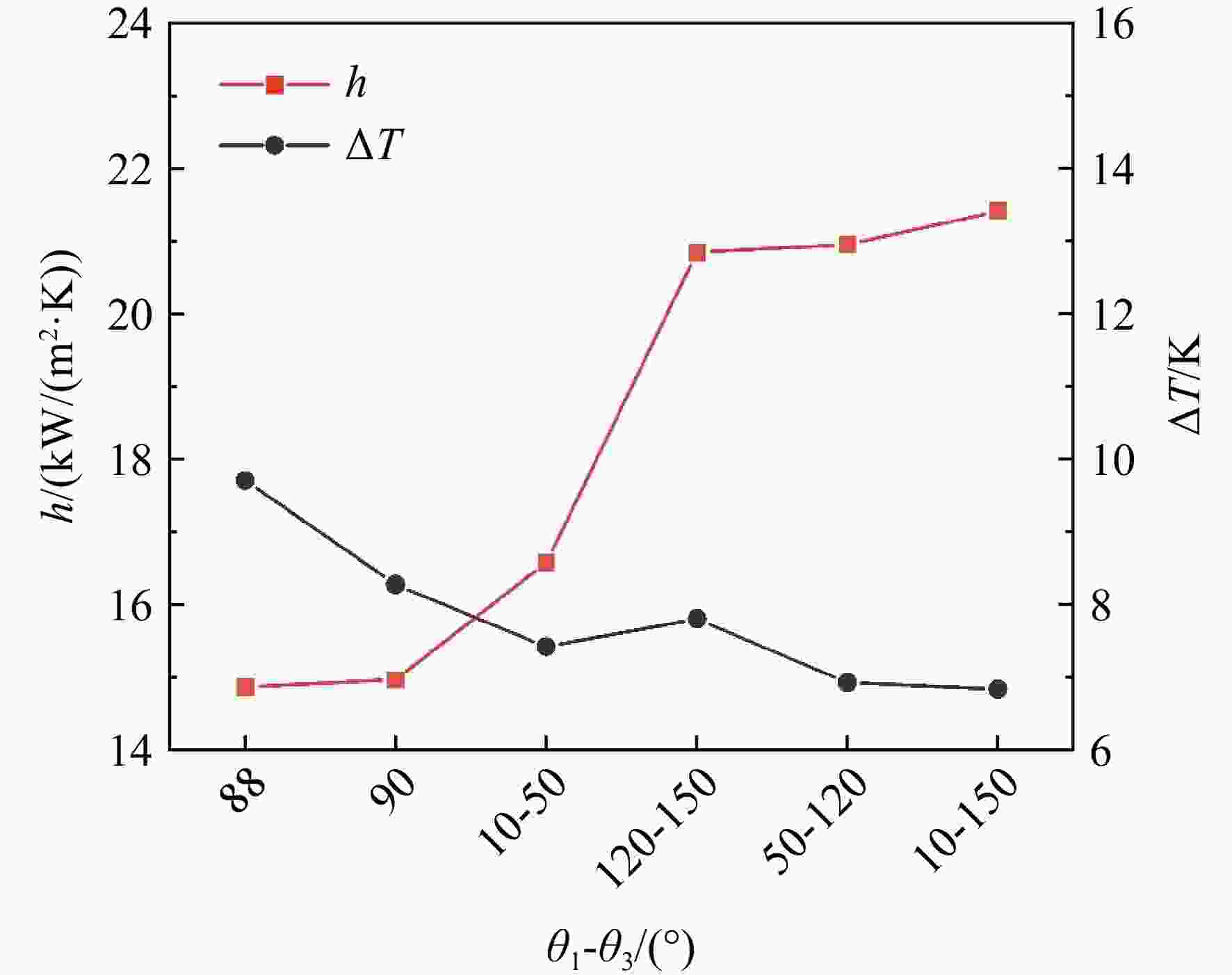

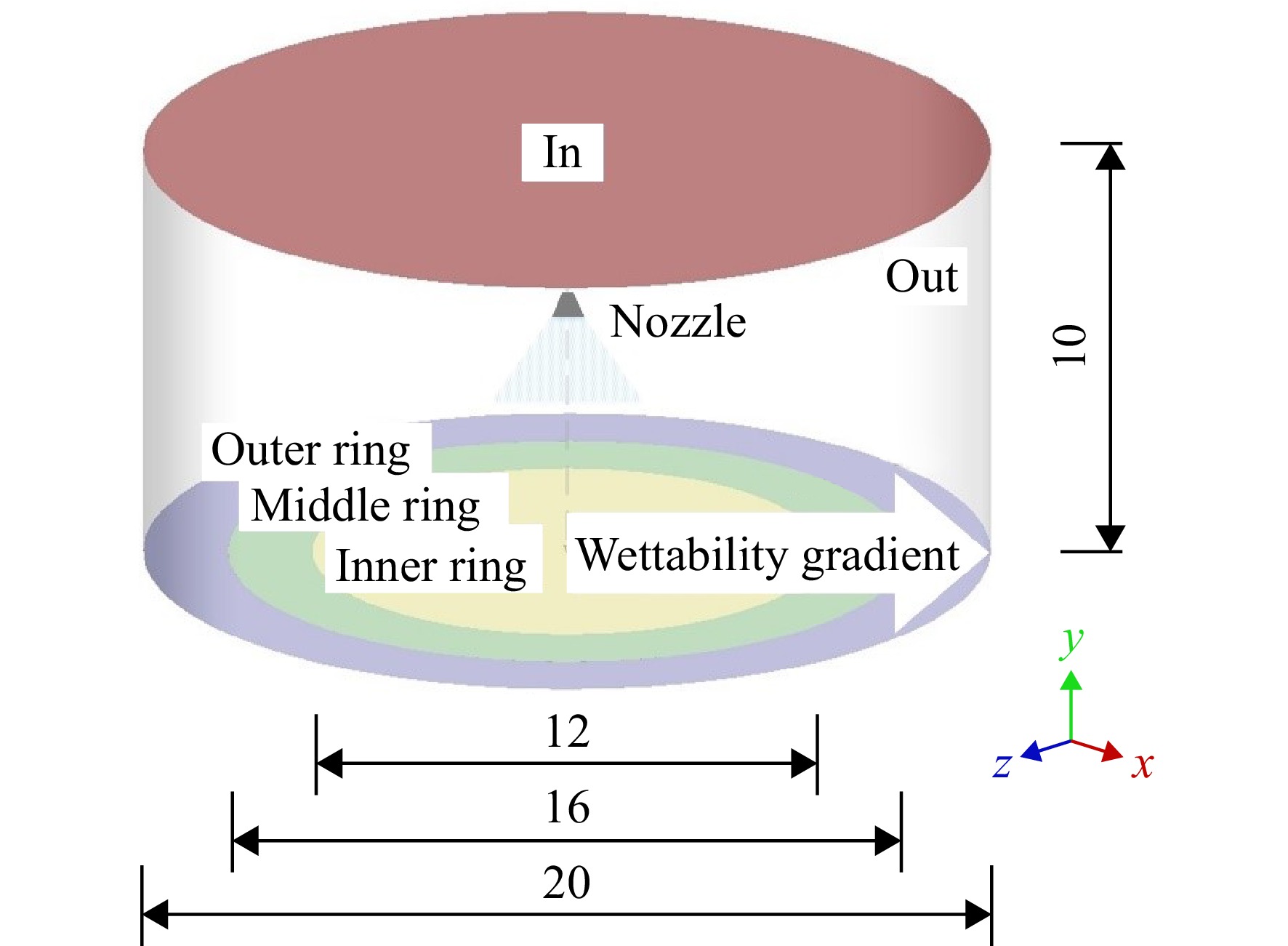

Abstract:The Species Transport model, Discrete Phase Model (DPM) and Eulerian wall film model were used to simulate the heat transfer characteristics of the spray cooling on circular chemically patterned modified surfaces under uniform heating conditions. The effect of wettability gradient on heat transfer performance on surfaces was studied by comparing four modified surfaces’ liquid film thickness, liquid film flow rate, surface temperature inhomogeneity and average surface heat transfer coefficient. The results showed that the heat transfer performance of the wettability gradient surfaces was better than that of uniformly wet table surfaces, which can promote the liquid drainage and optimize the liquid management. Surfaces with large wettability gradients had faster liquid film flow rate and smaller liquid film thickness, and hydrophobic surfaces may have better liquid drainage than hydrophilic-hydrophobic hybrid surfaces, yet hydrophilic-hydrophobic hybrid surfaces had the best heat transfer performance through a good hydrophobic design to promote nucleation and hydrophilic performance to retard drying, and can improve surface temperature inhomogeneity. Increasing the number of wettability and increasing the gradient can enhance the heat transfer.

-

Key words:

- spray cooling /

- modified surfaces /

- wettability gradient /

- liquid drainage /

- heat transfer

-

表 1 不同模拟工况的边界条件

Table 1. Boundary conditions for different simulation conditions

喷雾

压力/Pa喷雾

高度/mm热流密度/

(W/cm2)数量/个 表面类型 接触角 外圆环$ {\theta }_{1} $/ (°) 中圆环$ {\theta }_{2} $/ (°) 内圆环$ {\theta }_{3} $/ (°) 1000000 10 100 1 超亲水[18] 10 10 10 亲水 50 50 50 铜基[19] 88 88 88 分界[18] 90 90 90 疏水 120 120 120 超疏水[18] 150 150 150 2 亲水 10 10 50 疏水 120 120 150 亲-疏水混合 50 50 120 10 10 150 3 亲水 10 50 90 疏水 90 120 150 亲-疏水混合 50 90 120 10 90 150 表 2 模拟参数

Table 2. simulation parameters

工质 质量流量/ (L/min) 喷射半锥角/ (°) 喷嘴直径/ mm 初始液膜厚度/ mm 水 0.52 30 0.56 0.03 -

[1] ZHOU Nianyong,FENG Hao,GUO Yixing,et al. Experimental study on the spray cooling heat transfer performance and dimensionless correlations for ethylene glycol water solution[J]. Applied Thermal Engineering,2022,214: 118824. doi: 10.1016/j.applthermaleng.2022.118824 [2] XU Xinjie,WANG Yu,JIANG Yanlong,et al. Recent advances in closed loop spray cooling and its application in airborne systems[J]. Journal of Thermal Science,2021,30(1): 32-50. doi: 10.1007/s11630-020-1395-y [3] SOMASUNDARAM S,TAY A A O. A study of the effect of exit boundary conditions on the performance of a spray cooling system[C]//2010 12th Electronics Packaging Technology Conference. Singapore: IEEE,2010: 620-625. [4] XIE J L,RANJITH K,WONG T N,et al. Comparative study on the heat transfer characteristics of spray cooling in confined spray chambers[J]. Applied Thermal Engineering,2020,164: 114463. doi: 10.1016/j.applthermaleng.2019.114463 [5] SILK E A,KIM J,KIGER K. Spray cooling of enhanced surfaces: impact of structured surface geometry and spray axis inclination[J]. International Journal of Heat and Mass Transfer,2006,49(25/26): 4910-4920. [6] RAVIKUMAR BANDARU S V,VILLANUEVA W,THAKRE S,et al. Multi-nozzle spray cooling of a reactor pressure vessel steel plate for the application of ex-vessel cooling[J]. Nuclear Engineering and Design,2021,375: 111101. doi: 10.1016/j.nucengdes.2021.111101 [7] LOWREY S,MISIIUK K,BLAIKIE R,et al. Survey of micro/nanofabricated chemical,topographical,and compound passive wetting gradient surfaces[J]. Langmuir: the ACS Journal of Surfaces and Colloids,2022,38(2): 605-619. doi: 10.1021/acs.langmuir.1c00612 [8] SHCHEDRINA N N,KUDRYASHOV S I,MOSKVIN M K,et al. Elementary autonomous surface microfluidic devices based on laser-fabricated wetting gradient microtextures that drive directional water flows[J]. Optics Express,2021,29(8): 12616-12624. doi: 10.1364/OE.418173 [9] ITO Y. Surface micropatterning to regulate cell functions[J]. Biomaterials,1999,20(23/24): 2333-2342. [10] HUANG Z,WANG P C,FENG J,et al. Selective deposition of films of polypyrrole,polyaniline and nickel on hydrophobic/hydrophilic patterned surfaces and applications[J]. Synthetic Metals,1997,85(1/2/3): 1375-1376. [11] WEN Liping,TIAN Ye,JIANG Lei. Bioinspired super-wettability from fundamental research to practical applications[J]. Angewandte Chemie International Edition,2015,54(11): 3387-3399. doi: 10.1002/anie.201409911 [12] WOJTYK J T C,TOMIETTO M,BOUKHERROUB R,et al. “reagentless” micropatterning of organics on silicon surfaces: control of hydrophobic/hydrophilic Domains1[J]. Journal of the American Chemical Society,2001,123(7): 1535-1536. doi: 10.1021/ja005741e [13] JANSEN H P,BLIZNYUK O,KOOIJ E S,et al. Simulating anisotropic droplet shapes on chemically striped patterned surfaces[J]. Langmuir: the ACS Journal of Surfaces and Colloids,2012,28(1): 499-505. doi: 10.1021/la2039625 [14] GUO Yunhe,SONG Dong,SONG Baowei,et al. Manipulating dynamic drops using a hybrid superhydrophobic/hydrophilic surface[J]. Applied Surface Science,2016,387: 1225-1229. doi: 10.1016/j.apsusc.2016.07.008 [15] NAKAJIMA A,NAKAGAWA Y,FURUTA T,et al. Sliding of water droplets on smooth hydrophobic silane coatings with regular triangle hydrophilic regions[J]. Langmuir: the ACS Journal of Surfaces and Colloids,2013,29(29): 9269-9275. doi: 10.1021/la401517v [16] BETZ A R,XU Jie,QIU Huihe,et al. Do surfaces with mixed hydrophilic and hydrophobic areas enhance pool boiling?[J]. Applied Physics Letters,2010,97(14): 141909. doi: 10.1063/1.3485057 [17] LIN C W,LIN Yuchen,HUNG T C,et al. A numerical investigation of the superbiphilic surface on the boiling curve using the volume of fluid method[J]. International Journal of Heat and Mass Transfer,2021,171: 121058. doi: 10.1016/j.ijheatmasstransfer.2021.121058 [18] 赵鑫. 超亲水/超疏水图案化组合表面及电场作用强化滴状冷凝特性研究[D]. 江苏 镇江: 江苏大学,2022. ZHAO Xin. Investigation of enhanced dropwise condensation on superhydrophilic and superhydrophobic hybrid patterned surface and by electric field[D]. Zhenjiang,Jiangsu: Jiangsu University,2022. (in ChineseZHAO Xin. Investigation of enhanced dropwise condensation on superhydrophilic and superhydrophobic hybrid patterned surface and by electric field[D]. Zhenjiang, Jiangsu: Jiangsu University, 2022. (in Chinese) [19] 刘井坤. 纯铜的腐蚀过程及其基于超疏水涂层的防腐蚀研究[D]. 青岛: 青岛科技大学,2020. LIU Jingkun. Study on corrosion process of pure copper and its anti-corrosion based by superhydrophobic coatings[D]. Qingdao: Qingdao University of Science & Technology,2020. (in ChineseLIU Jingkun. Study on corrosion process of pure copper and its anti-corrosion based by superhydrophobic coatings[D]. Qingdao: Qingdao University of Science & Technology, 2020. (in Chinese) [20] 文华. 基于CFD的柴油机喷雾混合过程的多维数值模拟[D]. 武汉: 华中科技大学,2004. WEN Hua. Multi-dimensional numerical modeling of spray mixing process in diesel engines based on CFD[D]. Wuhan: Huazhong University of Science and Technology,2004. (in ChineseWEN Hua. Multi-dimensional numerical modeling of spray mixing process in diesel engines based on CFD[D]. Wuhan: Huazhong University of Science and Technology, 2004. (in Chinese) [21] 吴正人,甄猛,刘梅,等. 雾化压力对喷雾冷却效果影响的数值模拟[J]. 中国科技论文,2018,13(11): 1309-1314. WU Zhengren,ZHEN Meng,LIU Mei,et al. Numerical simulation of the effect of pressure on the heat transfer characteristics of nozzles[J]. China Sciencepaper,2018,13(11): 1309-1314. (in Chinese doi: 10.3969/j.issn.2095-2783.2018.11.019WU Zhengren, ZHEN Meng, LIU Mei, et al. Numerical simulation of the effect of pressure on the heat transfer characteristics of nozzles[J]. China Sciencepaper, 2018, 13(11): 1309-1314. (in Chinese) doi: 10.3969/j.issn.2095-2783.2018.11.019 [22] 张振豪. 基于多介质比较的机载条件下喷雾冷却特性模拟研究[D]. 南京: 南京航空航天大学,2020. ZHANG Zhenhao. Simulation study on spray cooling characteristics under airborne conditions based on multi-media comparison[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2020. (in ChineseZHANG Zhenhao. Simulation study on spray cooling characteristics under airborne conditions based on multi-media comparison[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020. (in Chinese) [23] 张亚萌. 喷嘴组液滴雾化特性对强化换热的影响[D]. 北京: 华北电力大学,2021. ZHANG Yameng. Influence of droplet atomization characteristics on enhanced heat transfer in nozzle group[D]. Beijing: North China Electric Power University,2021. (in ChineseZHANG Yameng. Influence of droplet atomization characteristics on enhanced heat transfer in nozzle group[D]. Beijing: North China Electric Power University, 2021. (in Chinese) [24] TU Zecan,MAO Junkui,HAN Xingsi. Numerical study of film cooling over a flat plate with anisotropic thermal conductivity[J]. Applied Thermal Engineering,2017,111: 968-980. doi: 10.1016/j.applthermaleng.2016.09.170 [25] SINGH K,PREMACHANDRAN B,RAVI M R. Experimental and numerical studies on film cooling with reverse/backward coolant injection[J]. International Journal of Thermal Sciences,2017,111: 390-408. doi: 10.1016/j.ijthermalsci.2016.09.027 [26] 颜培亮. 乙醇水喷雾冷却换热数值研究[D]. 辽宁 大连: 大连理工大学,2018. YAN Peiliang. Numerical study on spray cooling heat transfer of ethanol water[D]. Dalian,Liaoning: Dalian University of Technology,2018. (in ChineseYAN Peiliang. Numerical study on spray cooling heat transfer of ethanol water[D]. Dalian, Liaoning: Dalian University of Technology, 2018. (in Chinese) [27] 高明,孔鹏,章立新. 恒热流条件下亲疏水表面液滴蒸发特性[J]. 化工学报,2018,69(7): 2979-2984. GAO Ming,KONG Peng,ZHANG Lixin. Character of sessile droplets evaporation on hydrophilic and hydrophobic heating surface with constant heat fluxes[J]. CIESC Journal,2018,69(7): 2979-2984. (in ChineseGAO Ming, KONG Peng, ZHANG Lixin. Character of sessile droplets evaporation on hydrophilic and hydrophobic heating surface with constant heat fluxes[J]. CIESC Journal, 2018, 69(7): 2979-2984. (in Chinese) [28] 任辉,王宏,朱恂,等. 润湿性图案表面上的液滴侧向弹跳行为[J]. 化工学报,2021,72(8): 4255-4266. REN Hui,WANG Hong,ZHU Xun,et al. Lateral bouncing behavior of droplets on the wettability-patterned surface[J]. CIESC Journal,2021,72(8): 4255-4266. (in ChineseREN Hui, WANG Hong, ZHU Xun, et al. Lateral bouncing behavior of droplets on the wettability-patterned surface[J]. CIESC Journal, 2021, 72(8): 4255-4266. (in Chinese) [29] 李昀. 液滴撞击超亲水表面薄液膜的波动特性和温度演化规律[D]. 大连: 大连理工大学,2018. LI Yun. Fluctuation characteristics and temperature evolution for droplet impact on a thin liquid film at superhydrophilic surfaces[D]. Dalian: Dalian University of Technology,2018. (in ChineseLI Yun. Fluctuation characteristics and temperature evolution for droplet impact on a thin liquid film at superhydrophilic surfaces[D]. Dalian: Dalian University of Technology, 2018. (in Chinese) [30] 郭永献. 喷雾液膜流动理论及电子器件喷雾冷却实验研究[D]. 西安: 西安电子科技大学,2009. GUO Yongxian. Flow theory of spray liquid film and experimental study on spray cooling of electronic devices[D]. Xi’an: Xidian University,2009. (in ChineseGUO Yongxian. Flow theory of spray liquid film and experimental study on spray cooling of electronic devices[D]. Xi’an: Xidian University, 2009. (in Chinese) -

下载:

下载: