Combined cycle fatigue test technology for composite materials

-

摘要:

为了研究复合材料的高低周复合疲劳特性,本文综合分析了现有的高低周复合疲劳试验平台设计思路及研究进展,以搭建适用于复合材料的复合疲劳试验平台。结合复合材料疲劳失效特性,设计了非对称哑铃型的2维编织复合材料试件用于复合疲劳试验。试验结果显示:试件在特殊设计的疲劳考核区发生断裂失效。失效部位的应变曲线既展现了受低周疲劳载荷作用时低频高幅值的变化特征,也具有受高周疲劳载荷作用时高频低幅值的变化特征,证明失效部位在试验中受到非干涉高低周复合疲劳载荷的持续作用。疲劳试验的顺利开展表明该研究为复合材料的复合疲劳试验研究提出一种试验方法。

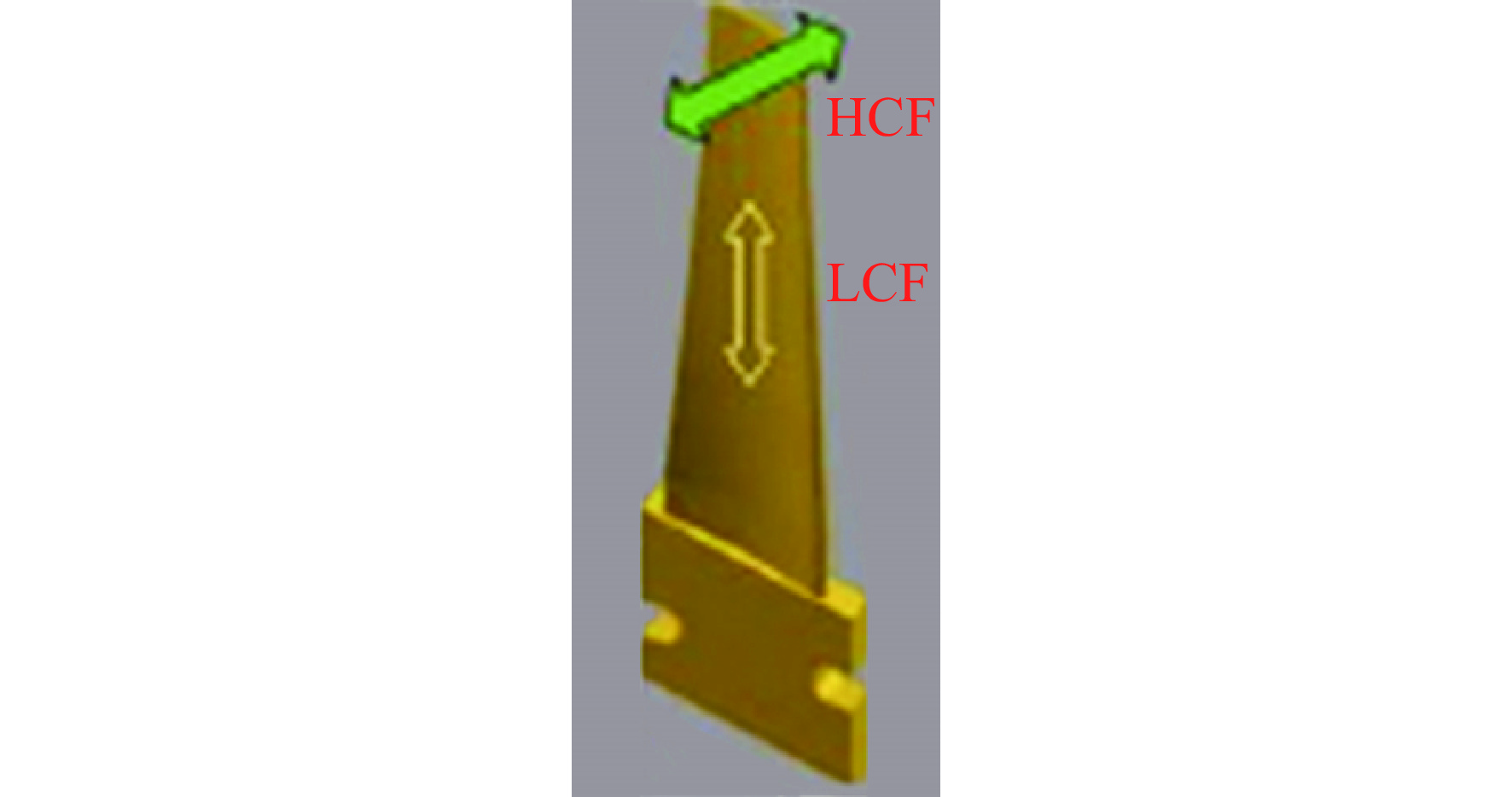

Abstract:In order to research the combined cycle fatigue properties of composite, the design ideas and research progress of existing combined cycle fatigue test platforms were comprehensively analyzed, contributing to building a combined cycle fatigue test platform for composite materials. Based on the fatigue failure mode of composite, the 2D braided composite specimen was designed as the asymmetric dumbbell shape for the fatigue test. The test result showed that failure occurred in the fatigue assessment area of the specimen. The strain curve of the failure site showed the characteristics of low frequency and high amplitude caused by low cycle fatigue load, and also the characteristics of high frequency and low amplitude caused by high cycle fatigue load. The completion of fatigue test demonstrated a test method for the research of combined cycle fatigue test of composite materials.

-

表 1 试验系统对比分析

Table 1. Comparison and analysis of test systems

表 2 应变片测量结果

Table 2. Stain gauge measurement result

应变片 低周疲劳应力峰值/MPa 弯曲应力峰值(谷值)/MPa ① 447.8 37.8(-25.0) ② 526.0 24.7(-18.0) ③ 586.8 5.4(-4.1) -

[1] LUO Shuai,WU Sujun. Fatigue failure analysis of rotor compressor blades concerning the effect of rotating stall and surge[J]. Engineering Failure Analysis,2016,68: 1-9. doi: 10.1016/j.engfailanal.2016.05.021 [2] WESER S,GAMPE U,RADDATZ M,et al. Advanced experimental and analytical investigations on combined cycle fatigue (CCF) of conventional cast and single-crystal gas turbine blades[C]//Proceedings of ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition. Vancouver,Canada: ASME,2012: 19-28. [3] Australian Transport Safety Bureau. Examination of a failed fan blade Rolls-Royce RB211 Trent 892 Turbofan Engine[R]. Canberra,Australian: Australian Transport Safety Bureau,2001. [4] NICHOLAS T. Critical issues in high cycle fatigue[J]. International Journal of Fatigue,1999,21: 221-231. doi: 10.1016/S0142-1123(99)00074-2 [5] MEISCHEL M,STANZL-TSCHEGG S E,ARCARI A,et al. Influence of corrosive NaCl solution on life times of 7075 aluminum alloy under combined fatigue loading in the VHCF regime[J]. Procedia Structural Integrity,2016,2: 1077-1084. doi: 10.1016/j.prostr.2016.06.138 [6] 徐浩,李振磊,石多奇,等. 叶根缘板过渡处特征模拟件双轴弯曲振动疲劳试验研究[J]. 推进技术,2022,43(1): 254-260. XU Hao,LI Zhenlei,SHI Duoqi,et al. Experimental investigation on biaxial bending vibration fatigue of blade-like specimen for fillet between airfoil and platform[J]. Journal of Propulsion Technology,2022,43(1): 254-260. (in ChineseXU Hao, LI Zhenlei, SHI Duoqi, et al. Experimental investigation on biaxial bending vibration fatigue of blade-like specimen for fillet between airfoil and platform[J]. Journal of Propulsion Technology, 2022, 43(1): 254-260. (in Chinese) [7] 闫晓军,孙瑞杰,邓瑛,等. 涡轮叶片复合疲劳特性曲线及其规律的试验[J]. 航空动力学报,2011,26(8): 1824-1829. YAN Xiaojun,SUN Ruijie,DENG Ying,et al. Experimental study on fatigue curve law of turbine blade under combined high and low cycle loading[J]. Journal of Aerospace Power,2011,26(8): 1824-1829. (in ChineseYAN Xiaojun, SUN Ruijie, DENG Ying, et al. Experimental study on fatigue curve law of turbine blade under combined high and low cycle loading[J]. Journal of Aerospace Power, 2011, 26(8): 1824-1829. (in Chinese) [8] 李杰. GE公司复合材料风扇叶片的发展和工艺[J]. 航空发动机,2008,34(4): 54-55. LI Jie. Development and technology for complex material fan blade of GE[J]. Aeroengine,2008,34(4): 54-55. (in Chinese doi: 10.3969/j.issn.1672-3147.2008.04.015LI Jie. Development and technology for complex material fan blade of GE[J]. Aeroengine, 2008, 34(4): 54-55. (in Chinese) doi: 10.3969/j.issn.1672-3147.2008.04.015 [9] European Commission. Predictive methods for combined cycle fatigue in gas turbine blades[R]. Brussels,Belgium: European Commission,2012. [10] XIE Ming,SOMR S,CHARLES J,et al. Multiaxial high cycle fatigue test system: US 2002/0162400 A1[S]. [S. l. ]: Patent Application Publication,2002: 1-67. [11] KRUCKENBERG T,PATON R. 航空航天复合材料结构件树脂传递模塑成形技术[M]. 李宏运,译. 北京: 航空工业出版社,2009. KRUCKENBERG T,PATON R. Resin transfer moulding for aerospace structures[M]. Translated by Li Hongyun. Beijing: Aviation Industry Press,2009. (in ChineseKRUCKENBERG T, PATON R. Resin transfer moulding for aerospace structures[M]. Translated by Li Hongyun. Beijing: Aviation Industry Press, 2009. (in Chinese) [12] American Society for Testing and Materials(ASTM). Standard test method for tension-tension fatigue of polymer matrix composite materials: ASTM D3479/D3479M-19 (2023) [S]. Philadelphia,US: ASTM,2023: 1-6. [13] 国家质量监督检验检疫总局,中国国家标准化管理委员会. 聚合物基复合材料疲劳性能测试方法: 第3部分拉-拉疲劳: GB/T 35465.3-2017[S]. 北京: 中国标准出版社,2017: 1-12. General Administration of Quality Supervision,Inspection and Quarantine of the People’s Republic of China,Standardization Administration of the People’s Republic of China. Test method for fatigue properties of polymer matrix composite materials: Part 3: Tension-tension fatigue: GB/T 35465.3-2017[S]. Beijing: Standards Press of China,2018: 1-12. (in ChineseGeneral Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Test method for fatigue properties of polymer matrix composite materials: Part 3: Tension-tension fatigue: GB/T 35465.3-2017[S]. Beijing: Standards Press of China, 2018: 1-12. (in Chinese) [14] 李丹卉. 拉-拉循环载荷下复合材料固有频率疲劳衰减规律研究[D]南京: 南京航空航天大学,2019. Li Danhui. Research on Natural Frequency Fatigue Degradation Law of composites under Tension-Tension Cyclic Loading [D]. Nanjing: Nanjing University of Aeronautics and Astronautics University,2019. (in ChineseLi Danhui. Research on Natural Frequency Fatigue Degradation Law of composites under Tension-Tension Cyclic Loading [D]. Nanjing: Nanjing University of Aeronautics and Astronautics University, 2019. (in Chinese) [15] 贾西文. 三维正交机织复合材料准静态/低周疲劳多尺度力学响应与损伤分析[D]. 上海: 东华大学,2013. JIA Xiwen. Multi-scale mechanical response and damage analysis of 3-D orthogonal woven composite under quasi-static/low cyclic fatigue loadings[D]. Shanghai: Donghua University,2013. (in ChineseJIA Xiwen. Multi-scale mechanical response and damage analysis of 3-D orthogonal woven composite under quasi-static/low cyclic fatigue loadings[D]. Shanghai: Donghua University, 2013. (in Chinese) [16] LEE C S,KIM H J,AMANOV A,et al. Investigation on very high cycle fatigue of PA66-GF30 GFRP based on fiber orientation[J]. Composites Science and Technology,2019,180: 94-100. doi: 10.1016/j.compscitech.2019.05.021 [17] FLORE D,WEGENER K,MAYER H,et al. Investigation of the high and very high cycle fatigue behaviour of continuous fibre reinforced plastics by conventional and ultrasonic fatigue testing[J]. Composites Science and Technology,2017,141: 130-136. doi: 10.1016/j.compscitech.2017.01.018 [18] SHABANI P,TAHERI-BEHROOZ F,SAMAREH-MOUSAVI S S,et al. Very high cycle and gigacycle fatigue of fiber-reinforced composites: a review on experimental approaches and fatigue damage mechanisms[J]. Progress in Materials Science,2021,118: 100762. doi: 10.1016/j.pmatsci.2020.100762 [19] 刘存,赵卫民,信若飞,等. 悬臂梁往复弯曲腐蚀疲劳试验机的设计[J]. 腐蚀科学与防护技术,2010,22(3): 238-242. LIU Cun,ZHAO Weimin,XIN Ruofei,et al. Design of a canrilever beam reversed bending and corrosion fatigue testing machine[J]. Corrosion Science and Protection Technology,2010,22(3): 238-242. (in ChineseLIU Cun, ZHAO Weimin, XIN Ruofei, et al. Design of a canrilever beam reversed bending and corrosion fatigue testing machine[J]. Corrosion Science and Protection Technology, 2010, 22(3): 238-242. (in Chinese) -

下载:

下载: