Study on aerodynamic characteristics computation method for turbine considering component effects

-

摘要:

为研究现有燃气轮机改烧氢混燃料时的涡轮气动特性变化,推荐了一种涡轮气动特性参数定义方法,其中折合流量和折合转速的定义考虑了燃气工质物性的变化。以LM2500+SAC航改燃气轮机的高压涡轮和动力涡轮为例,其高压涡轮为2级轴流式气冷涡轮,动力涡轮为6级轴流式无冷却涡轮,采用基于单通道RANS(Reynolds averaged Navier-Stokes)方程求解的三维数值模拟方法,分别计算了烧天然气燃料场景下的涡轮气动特性及烧氢混燃料场景下的涡轮气动特性,并对比分析了两者之间的变化关系。结果表明:利用推荐的涡轮气动特性参数定义,可以统一两种燃料的涡轮特性曲线(同一折合转速和膨胀比下的折合流量相差在0.2%以内)。这说明在已知天然气工质的涡轮工作特性时,可以直接换算出氢混燃料涡轮的工作特性,这为涡轮气动特性数据的推广应用提供了方便。

Abstract:In order to study the turbine aerodynamic characteristic variation when the fuel changed from natural gas to mixed-hydrogen fuel, an aerodynamic characteristic definition for turbine was given, in which the definition of corrected mass flow and corrected rotation speed can integrated the gas property variation. The turbine aerodynamic characteristics 2-stage cooled high pressure turbine and 6-stage uncooled power turbine of LM2500+SAC gas turbine was investigated based on the RANS (Reynolds averaged Navier-Stokes) simulation method and the new characteristic definitions. Also, the fuels variations from natural gas fuel to mixed-hydrogen fuel are studied. The results shows that, the two work characteristic curves can be classified using recommended aerodynamic parameters definition (the corrected mass-flow distinction between the two fuels was under 0.2% at the same corrected rotating speed and total pressure ratio conditions), and it was indicated that the real turbine aerodynamic characteristic of mixed-hydrogen fuel could be gotten from the turbine aerodynamic characteristic of original natural gas fuel using the characteristic definition. This provides convenience for the application turbine aerodynamic characteristic data.

-

Key words:

- gas turbine /

- cooled turbine /

- aerodynamic characteristic /

- corrected mass flow /

- turbine efficiency

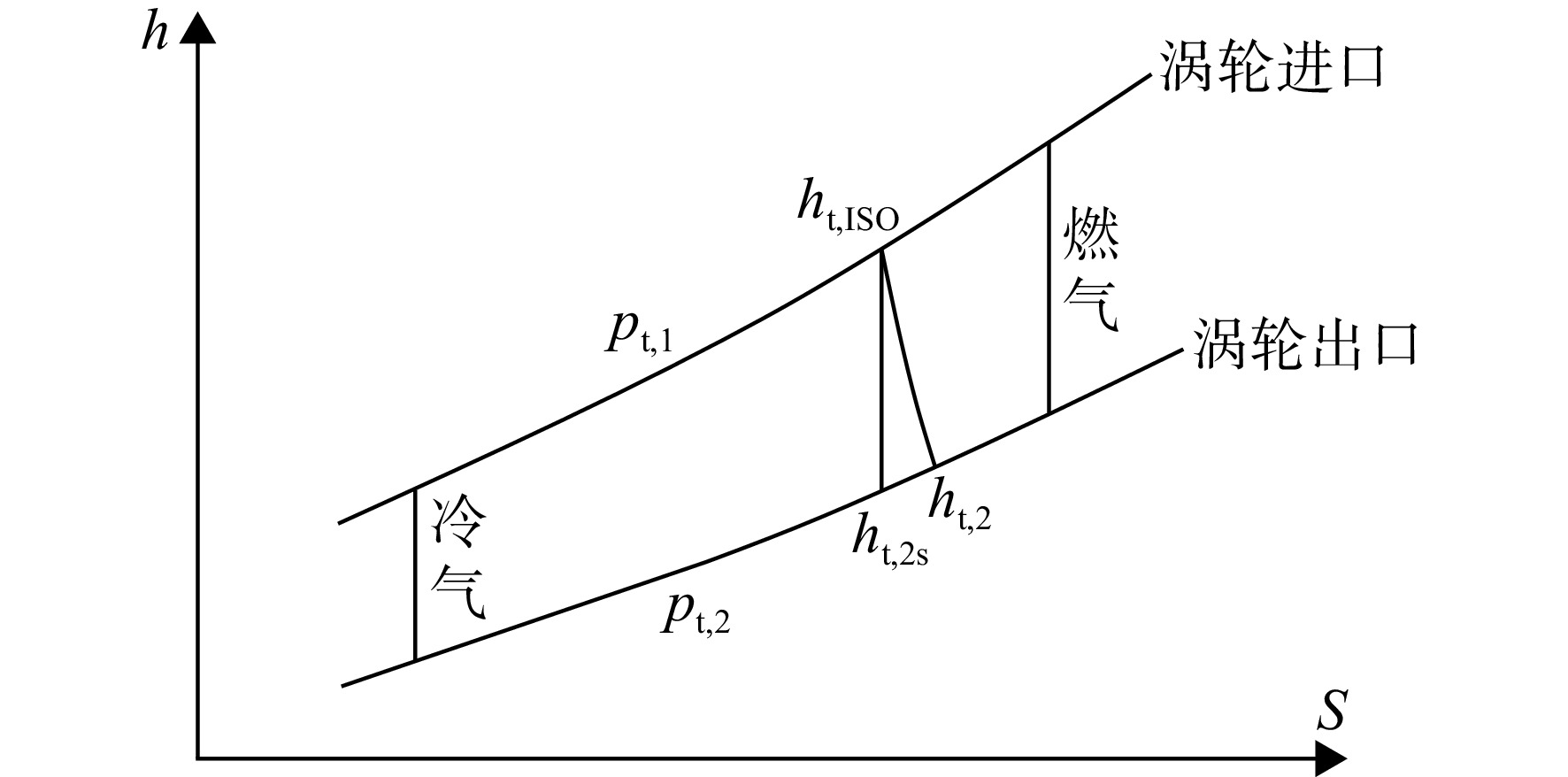

-

表 1 效率计算过程参数

Table 1. Efficiency computation process parameters

引气位置 质量流量/(kg/s) 总温/K 总压/kPa 焓/(kJ/kg) 主流 67.89 1638.0 2191 1927.67 冷气EI1+ EI2 8.27 774.5 2301 836.54 EI3 3.44 774.5 2301 836.54 EI4 1.38 774.5 2301 836.54 冷气EA 2.07 645.4 1512 686.73 ISO 82.67 1487.5 1728.52 实际出口 82.67 1094.9 475 1224.50 理想出口 82.67 1048.0 1166.20 表 2 涡轮特性参数定义

Table 2. Parameter definition for turbine performance

参数 常规定义 推荐定义1

(用于无冷却涡轮)推荐定义2

(用于冷却涡轮)折合流量 $ {G}_{1}^{*}=G\sqrt{{T}_{\mathrm{t},1}}/{p}_{\mathrm{t},1} $ $ {G}_{2}^{*}=G\sqrt{R{T}_{t,1}}/{p}_{\mathrm{t},1} $ $ {G}_{3}^{*}={G}_{2}\sqrt{{R}_{2}{T}_{\mathrm{I}\mathrm{S}\mathrm{O}}}/{p}_{\mathrm{t},1} $ 折合转速 $ {n}_{1}^{*}=n/\sqrt{{T}_{\mathrm{t},1}} $ $ {n}_{2}^{*}=n/\sqrt{R{T}_{\mathrm{t},1}} $ $ {n}_{3}^{*}=n/\sqrt{{R}_{2}{T}_{\mathrm{I}\mathrm{S}\mathrm{O}}} $ 表 3 燃气组分摩尔分数

Table 3. Molar fraction of gas composition

燃料类型 组分摩尔分数/% N2 O2 CO2 H2O AR(氩气) SO2 天燃气(NG) 74.44 10.81 4.65 9.22 0.88 0 氢混燃料

(75%H2+25%NG)72.51 10.90 2.49 13.23 0.86 0 -

[1] 《航空发动机手册》总编委会. 航空发动机设计手册,第10册 涡轮[M]. 北京: 航空工业出版社,2000. Editorial Board of the Aviation Engine Manual. Aircraft engine design manual: Volume 10 turbine [M] Beijing: Aviation Industry Press. 2000. (in ChineseEditorial Board of the Aviation Engine Manual. Aircraft engine design manual: Volume 10 turbine [M] Beijing: Aviation Industry Press. 2000. (in Chinese) [2] 杜莹莹. 中低热值燃料多轴燃气轮机热力性能模拟[D]. 北京: 中国科学院,2013. DU Yingying. Modeling of multi-shaft gas turbine powered by medium and low heating value fuels[D]. Beijing: Chinese Academy of Sciences,2013. (in ChineseDU Yingying. Modeling of multi-shaft gas turbine powered by medium and low heating value fuels[D]. Beijing: Chinese Academy of Sciences, 2013. (in Chinese) [3] CHIESA P,LOZZA G,MAZZOCCHI L. Using hydrogen as gas turbine fuel[J]. Journal of Engineering for Gas Turbines and Power,2005,127(1): 73-80. doi: 10.1115/1.1787513 [4] SHILLING N Z,JONES R M. Gas turbine experience with high hydrogen fuels[C]// Proceedings of the 12th annual Power-Gen Europe conference and exhibition. Barcelona,Spain: Power-Gen Europe,2004: 1-11. [5] 李海波,潘志明,黄耀文. 浅析氢燃料燃气轮机发电的应用前景[J]. 电力设备管理,2020(8): 94-96. LI Haibo,PAN Zhiming,HUANG Yaowen. Analysis on the application prospect of hydrogen fuel gas turbine power generation[J]. Electric Power Equipment Management,2020(8): 94-96. (in ChineseLI Haibo, PAN Zhiming, HUANG Yaowen. Analysis on the application prospect of hydrogen fuel gas turbine power generation[J]. Electric Power Equipment Management, 2020(8): 94-96. (in Chinese) [6] 秦锋,秦亚迪,单彤文. 碳中和背景下氢燃料燃气轮机技术现状及发展前景[J]. 广东电力,2021(10): 10-17. QIN Feng,QIN Yadi,SHAN Tongwen. Technology status and development prospects of hydrogen fuel gas turbine under the background of carbon neutral[J]. Guangdong Electric Power,2021(10): 10-17. (in ChineseQIN Feng, QIN Yadi, SHAN Tongwen. Technology status and development prospects of hydrogen fuel gas turbine under the background of carbon neutral[J]. Guangdong Electric Power, 2021(10): 10-17. (in Chinese) [7] 宫鹏. 中低热值燃料燃气轮机热力性能建模与分析[D]. 北京: 中国科学院大学,2020. GONG Peng. Thermodynamic performance modeling and analysis of low-medium heating value fuel gas turbine[D]. Beijing: University of Chinese Academy of Sciences,2020. (in ChineseGONG Peng. Thermodynamic performance modeling and analysis of low-medium heating value fuel gas turbine[D]. Beijing: University of Chinese Academy of Sciences, 2020. (in Chinese) [8] 马勤勇,钱白云,董利江,等. 掺氢比例对氢混天然气燃气轮机运行特性影响的研究[J]. 热能动力工程,2022,37(9): 41-49. MA Qinyong,QIAN Baiyun,DONG Lijiang,et al. Research on the influence of hydrogen blending ratio on the operation characteristics of hydrogen blended fuel gas turbine[J]. Journal of Engineering for Thermal Energy and Power,2022,37(9): 41-49. (in ChineseMA Qinyong, QIAN Baiyun, DONG Lijiang, et al. Research on the influence of hydrogen blending ratio on the operation characteristics of hydrogen blended fuel gas turbine[J]. Journal of Engineering for Thermal Energy and Power, 2022, 37(9): 41-49. (in Chinese) [9] 李立新,张昭昭. 某型号F级燃气轮机混氢燃烧的性能分析和工程实践[J]. 动力工程学报,2022,42(10): 912-918. LI Lixin,ZHANG Zhaozhao. Combustion performance analysis and engineering practice of a F-class gas turbine with hydrogen addition[J]. Journal of Chinese Society of Power Engineering,2022,42(10): 912-918. (in ChineseLI Lixin, ZHANG Zhaozhao. Combustion performance analysis and engineering practice of a F-class gas turbine with hydrogen addition[J]. Journal of Chinese Society of Power Engineering, 2022, 42(10): 912-918. (in Chinese) [10] LIU Xun,WANG Songtao,ZHAO Yifan,et al. The impact of fuel heat value change on the turbine part of the ground 9FA gas turbine[J]. Science Technology and Engineering,2010,10(19): 4784-4788. [11] 李国强,岳彭,朱凯迪,等. 冷气掺混对涡轮叶栅气动性能影响试验研究[J]. 热能动力工程,2019,34(1): 17-22. LI Guoqiang,YUE Peng,ZHU Kaidi,et al. Study on aerodynamic performance of turbine cascade with cooling-air ejection[J]. Journal of Engineering for Thermal Energy and Power,2019,34(1): 17-22. (in ChineseLI Guoqiang, YUE Peng, ZHU Kaidi, et al. Study on aerodynamic performance of turbine cascade with cooling-air ejection[J]. Journal of Engineering for Thermal Energy and Power, 2019, 34(1): 17-22. (in Chinese) [12] 邱涛. 气冷涡轮效率定义方法探讨[J]. 燃气轮机技术,2013,26(4): 6-9. QIU Tao. Investigation of efficiency definition methods for cooled turbine[J]. Gas Turbine Technology,2013,26(4): 6-9. (in Chinese doi: 10.3969/j.issn.1009-2889.2013.04.002QIU Tao. Investigation of efficiency definition methods for cooled turbine[J]. Gas Turbine Technology, 2013, 26(4): 6-9. (in Chinese) doi: 10.3969/j.issn.1009-2889.2013.04.002 [13] 魏成亮,刘尚明,蒲星星,等. 冷却对燃气透平的熵增及透平效率影响的研究[J]. 热力透平,2012,41(2): 140-146. WEI Chengliang,LIU Shangming,PU Xingxing,et al. Research of impact of cooling on entropy creation and turbine efficiency[J]. Thermal Turbine,2012,41(2): 140-146. (in Chinese doi: 10.3969/j.issn.1672-5549.2012.02.009WEI Chengliang, LIU Shangming, PU Xingxing, et al. Research of impact of cooling on entropy creation and turbine efficiency[J]. Thermal Turbine, 2012, 41(2): 140-146. (in Chinese) doi: 10.3969/j.issn.1672-5549.2012.02.009 [14] 好毕斯嘎拉图,陈仲光,张志舒,等. 航空发动机不同涡轮效率定义及等效应用方法研究[J]. 通信电源技术,2018,35(6): 35-37. HAO Bisigalatu,CHEN Zhongguang,ZHANG Zhishu,et al. To accelerate the process of research on the effect on the stability of the aircraft engine pneumatic analysis[J]. Telecom Power Technology,2018,35(6): 35-37. (in ChineseHAO Bisigalatu, CHEN Zhongguang, ZHANG Zhishu, et al. To accelerate the process of research on the effect on the stability of the aircraft engine pneumatic analysis[J]. Telecom Power Technology, 2018, 35(6): 35-37. (in Chinese) [15] BERDANIER R A. Calculating cooled turbine efficiency with weighted cooling flow distributions: ASME Paper GT2022-82365 [R]. Rotterdam,The Netherlands: ASME,2022. [16] HARTSEL J. Prediction of effects of mass-transfer cooling on the blade-row efficiency of turbine airfoils: [C]//Proceedings of the 10th AIAA Aerospace Sciences Meeting. ,San Diego: AIAA Paper,1972: 17-19. [17] BIGALK J,BIESINGER T,BROEKER M,et al. SGT5-8000H experimental test results and validation of high fidelity 3D CFD[C]//Proceedings of ASME Turbo Expo 2012: Turbine Technical Conference and Exposition. Copenhagen,Denmark: ASME,2013: 993-1002. [18] YOUNG J B,WILCOCK R C. Modeling the air-cooled gas turbine: Part 2 coolant flows and losses[J]. Journal of Turbomachinery,2002,124(2): 214-221. doi: 10.1115/1.1415038 [19] TORBIDONI L,HORLOCK J H. Calculation of the expansion through a cooled gas turbine stage[J]. Journal of Turbomachinery,2006,128(3): 555-563. doi: 10.1115/1.2185123 [20] HORLOCK J H,TORBIDONI L. Calculations of cooled turbine efficiency[J]. Journal of Engineering for Gas Turbines and Power,2008,130(1): 1-5. -

下载:

下载: