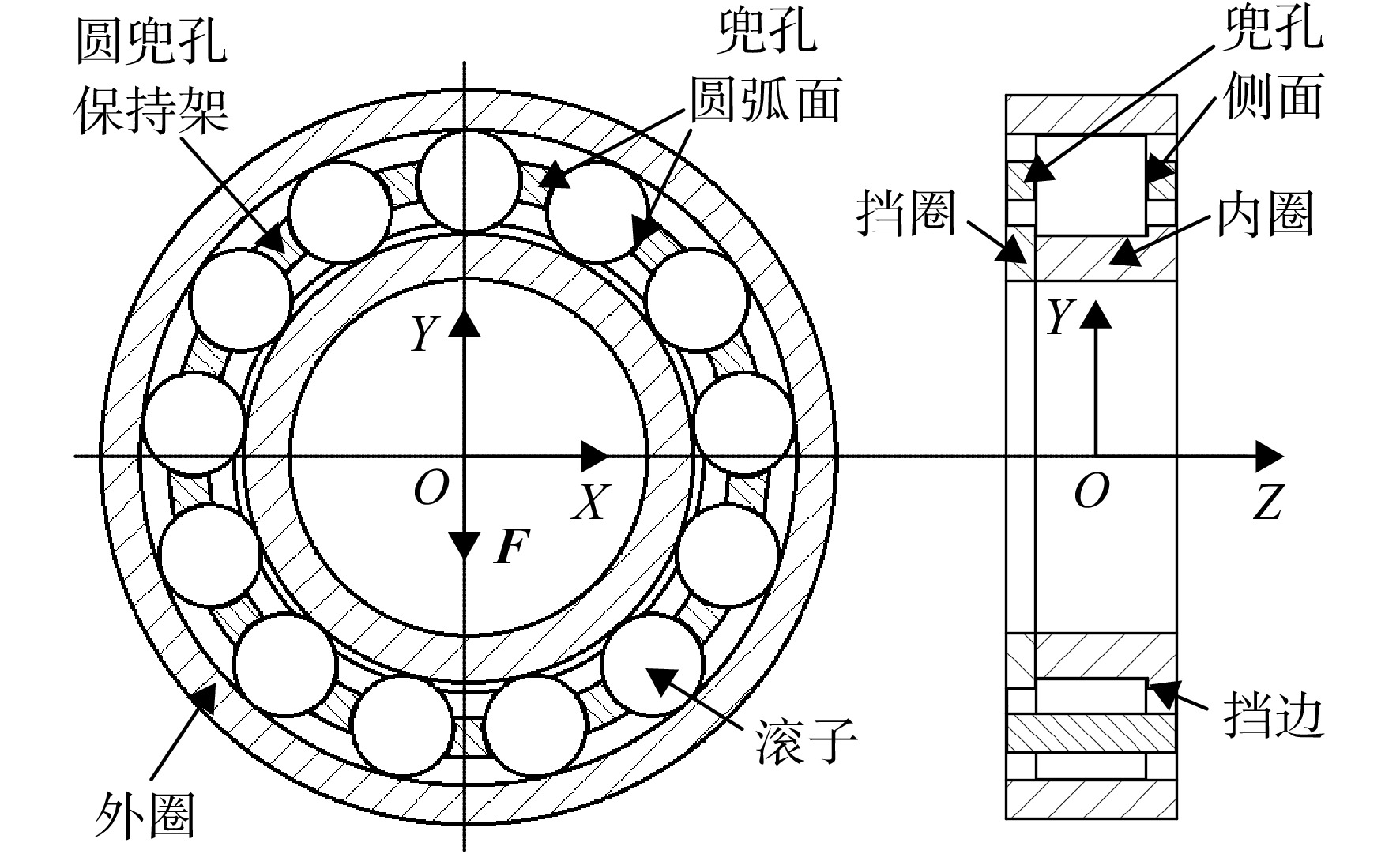

Research on dynamics of cylindrical roller bearing with circular pockets considering conformal contact

-

摘要:

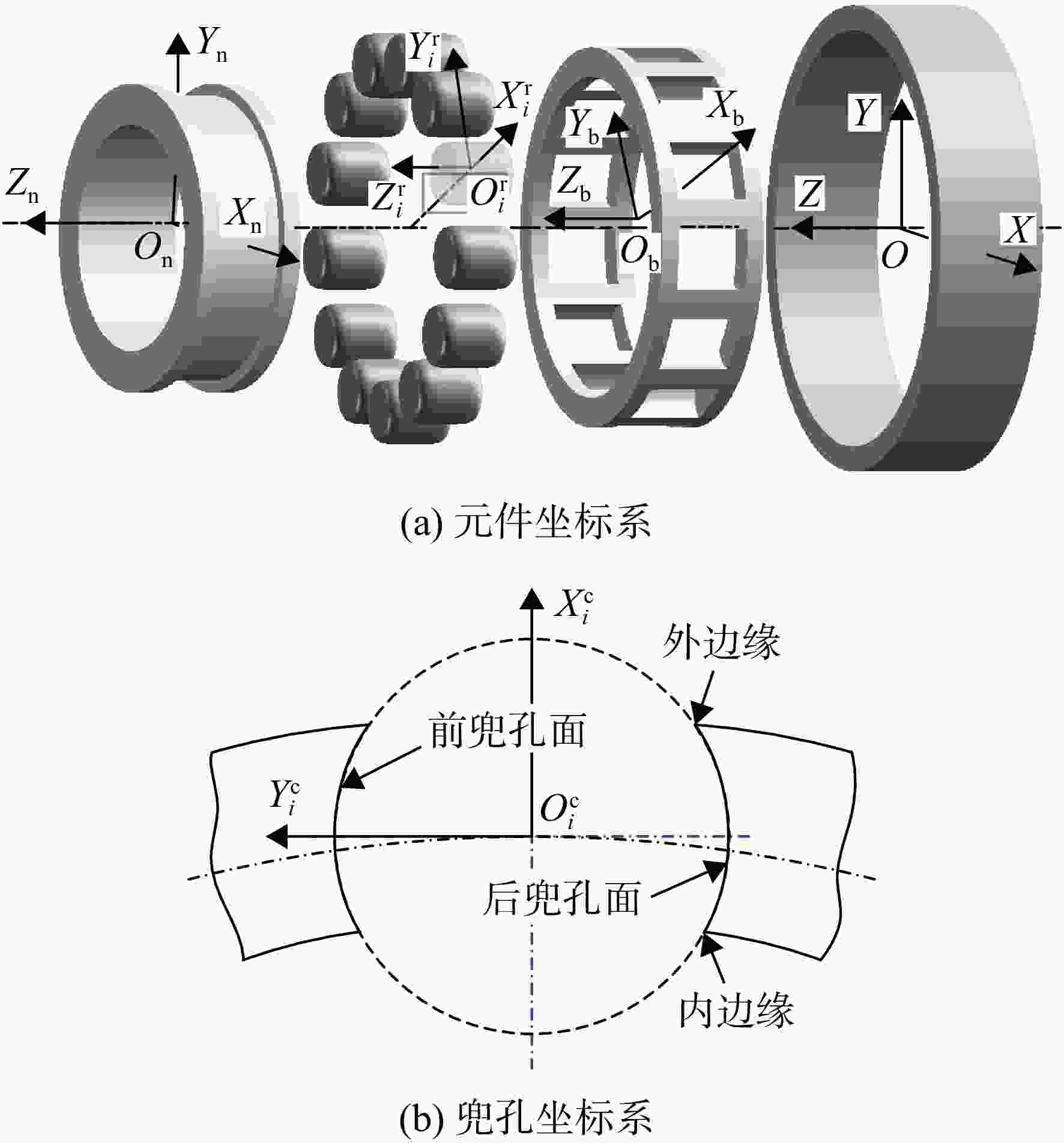

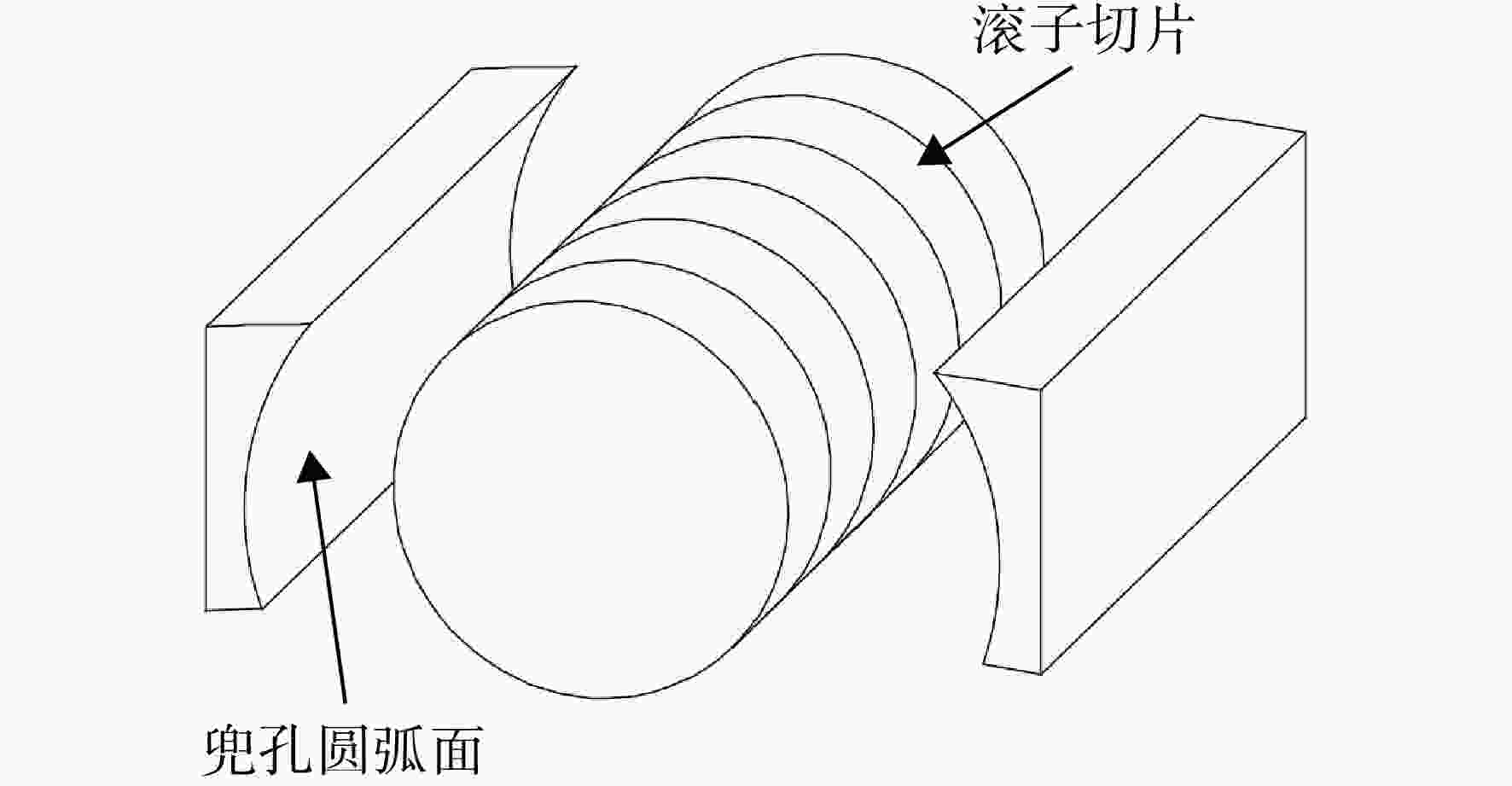

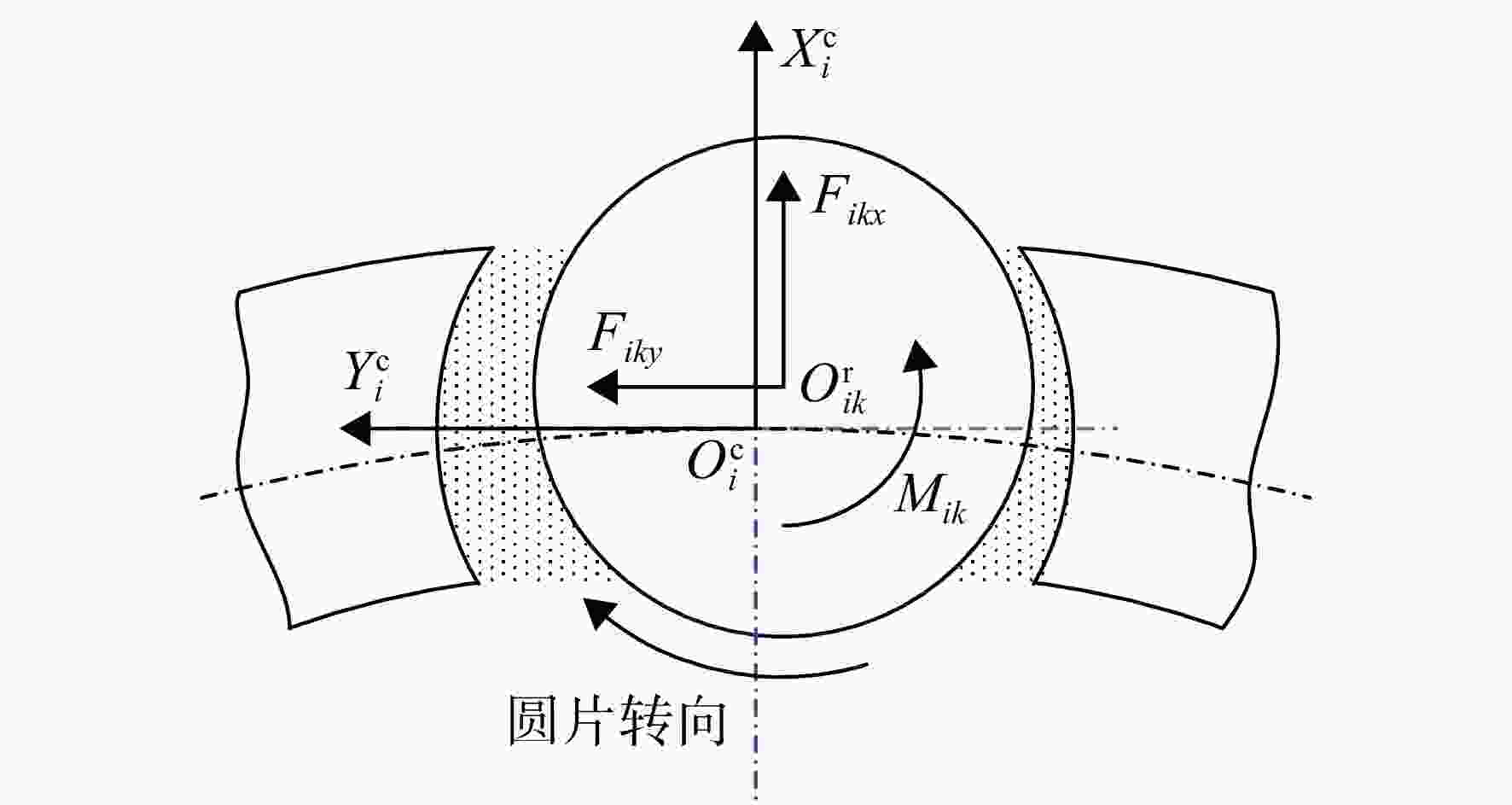

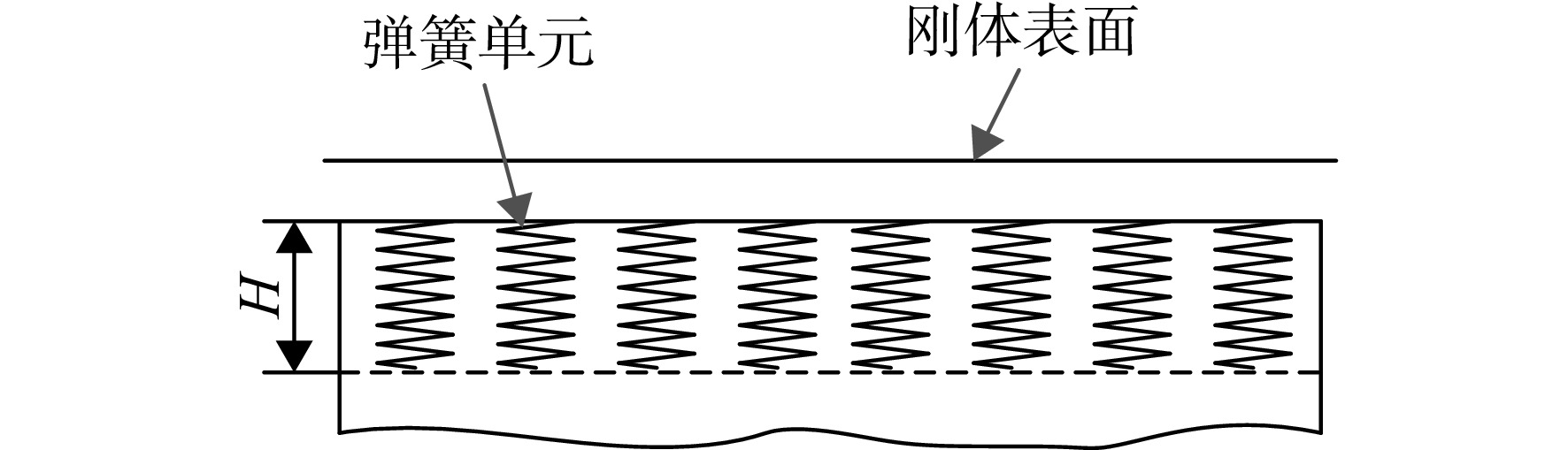

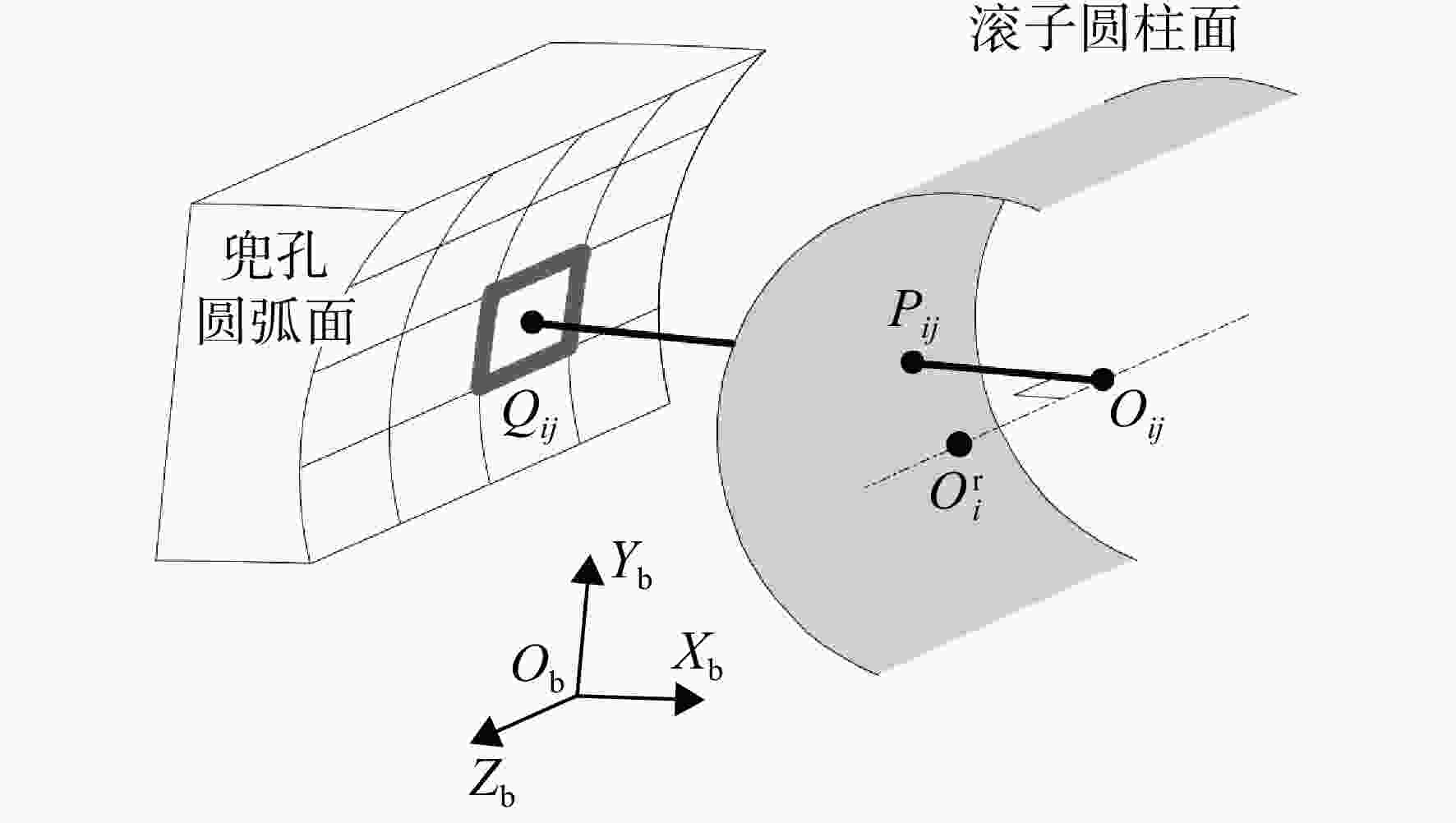

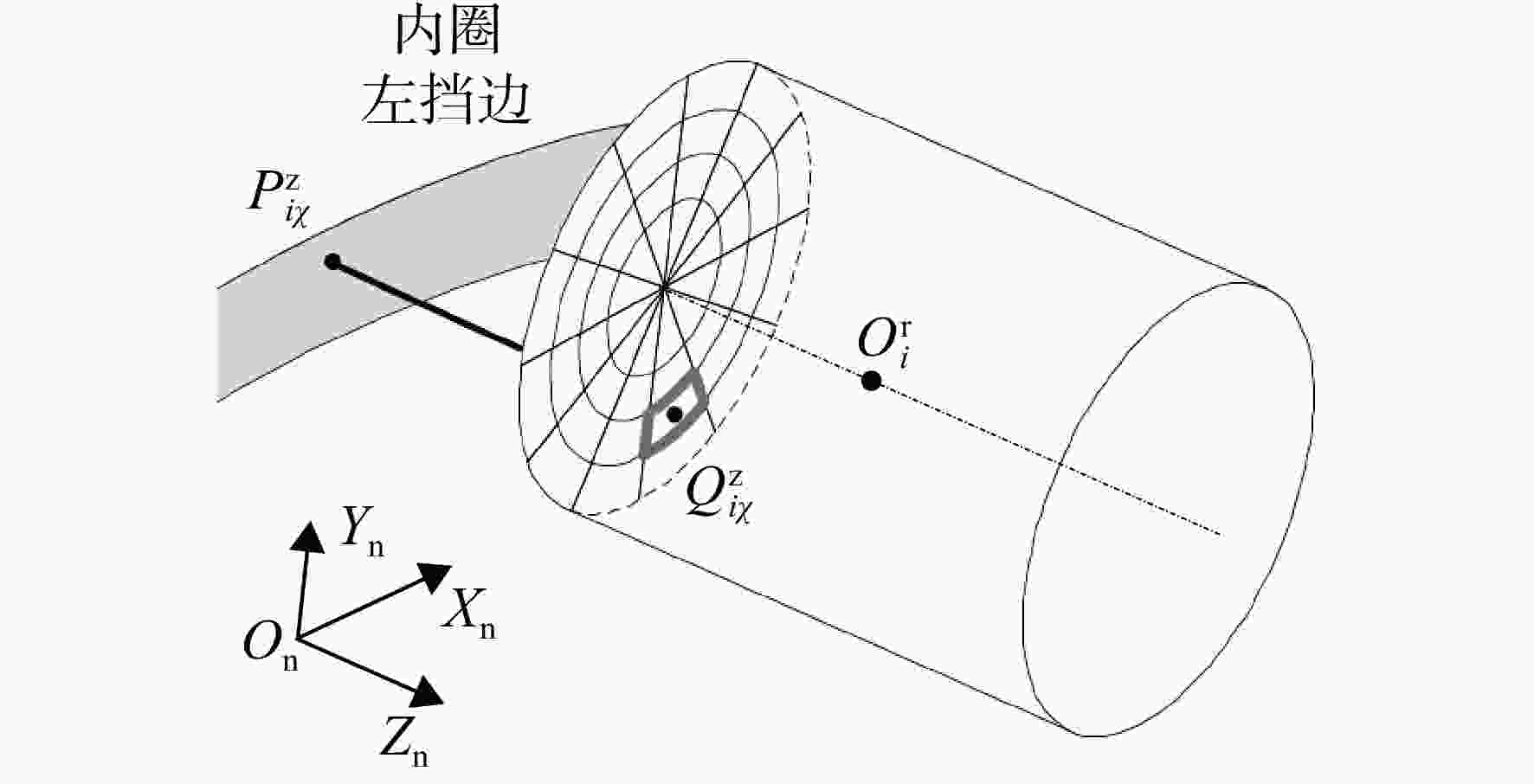

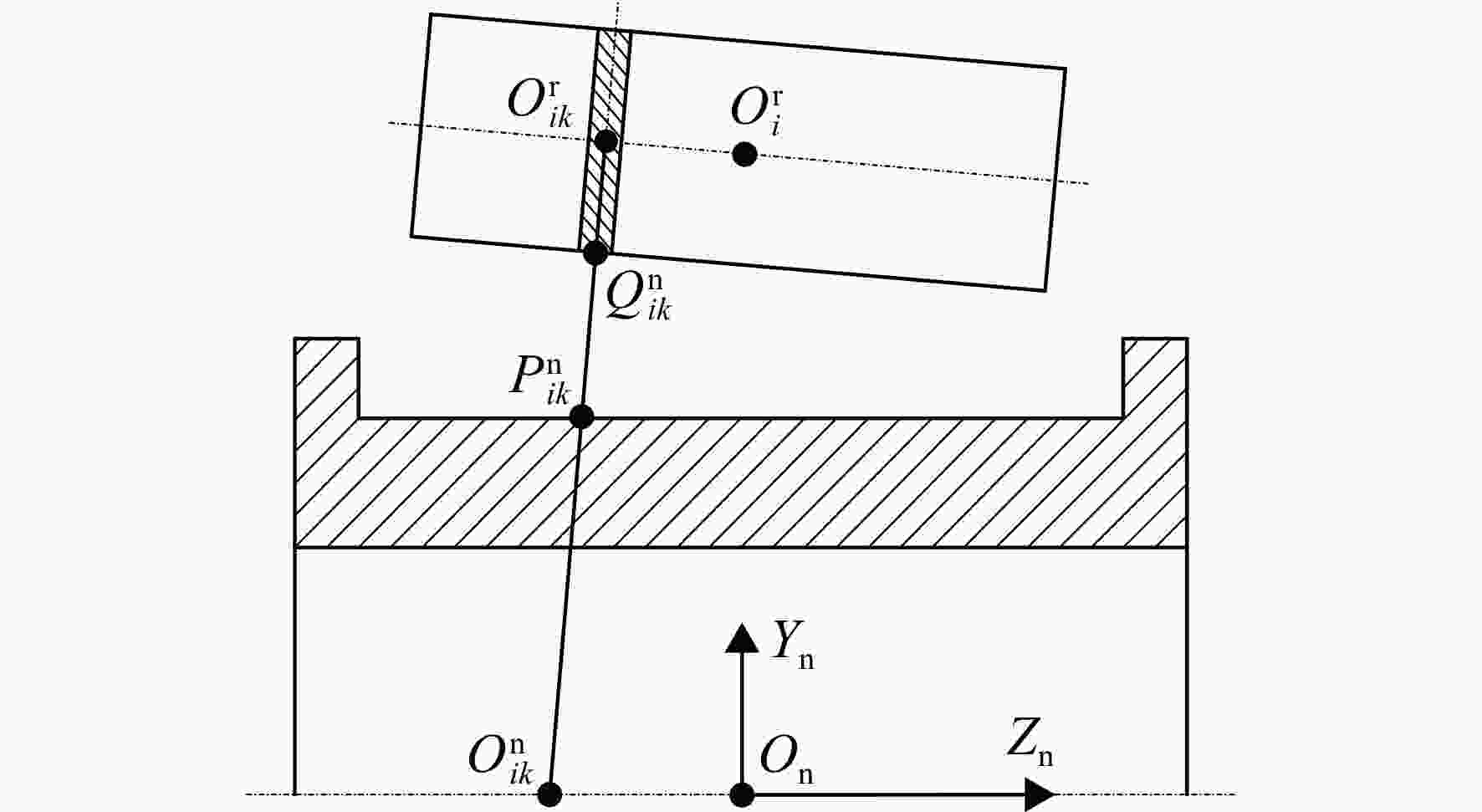

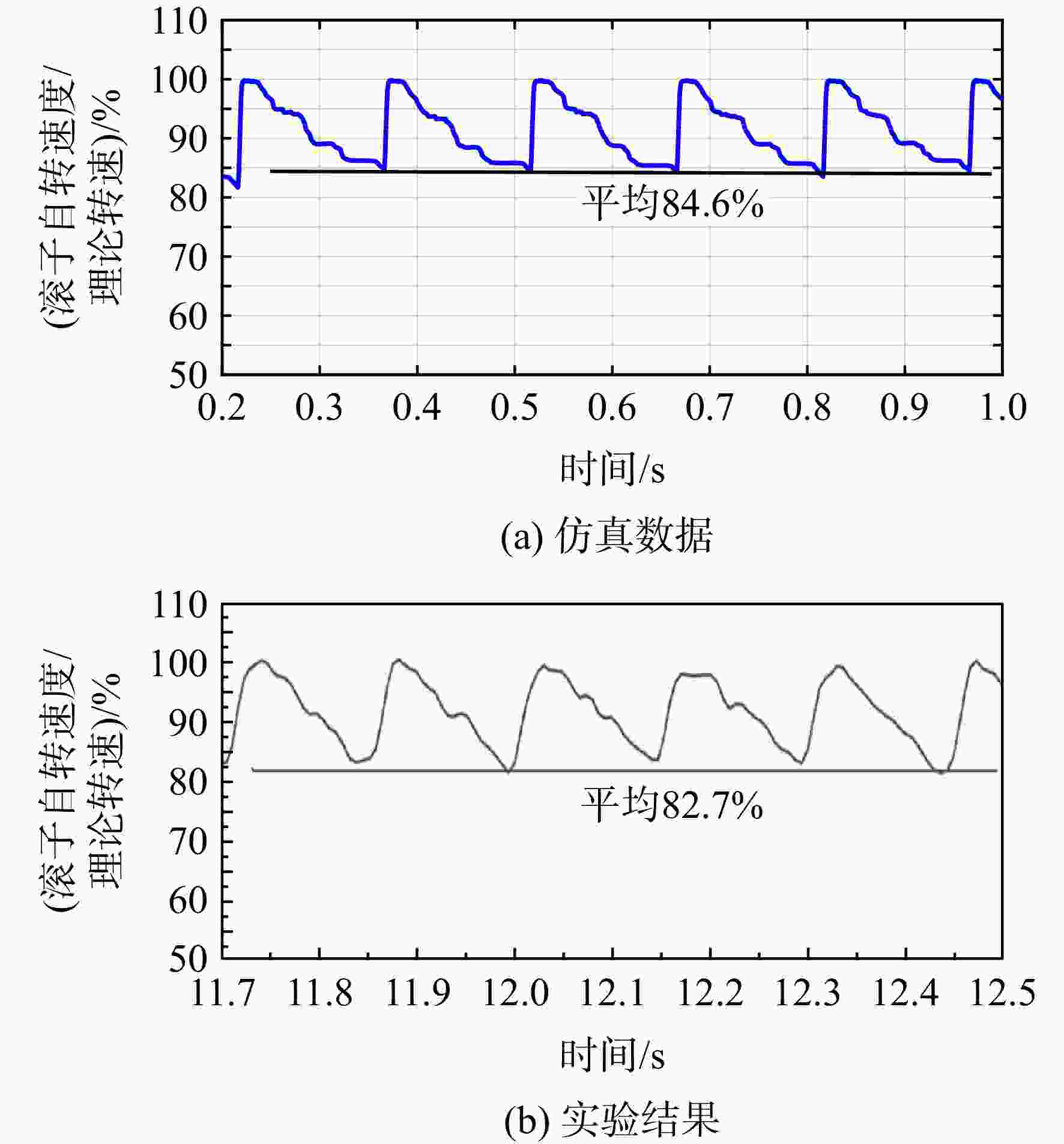

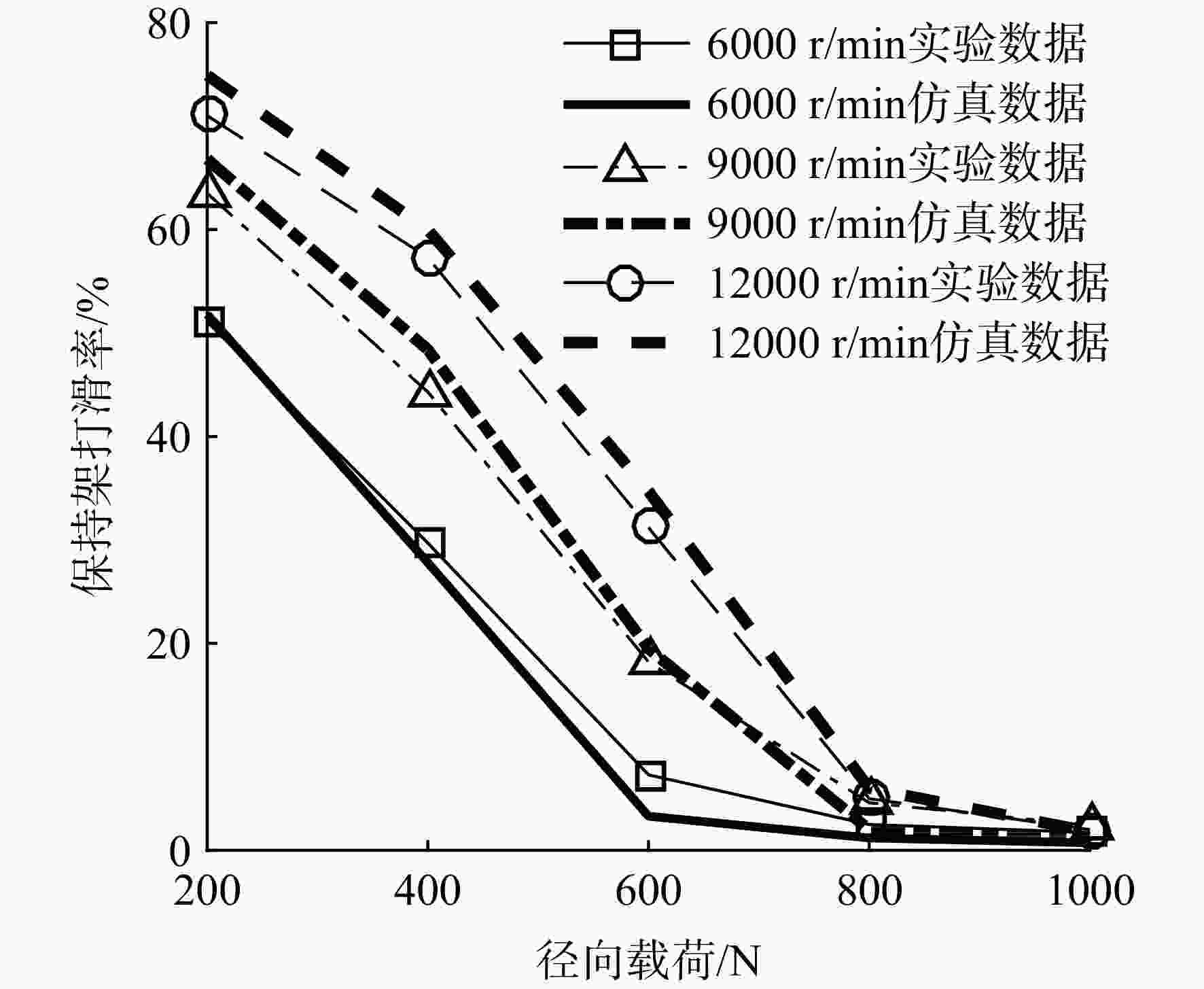

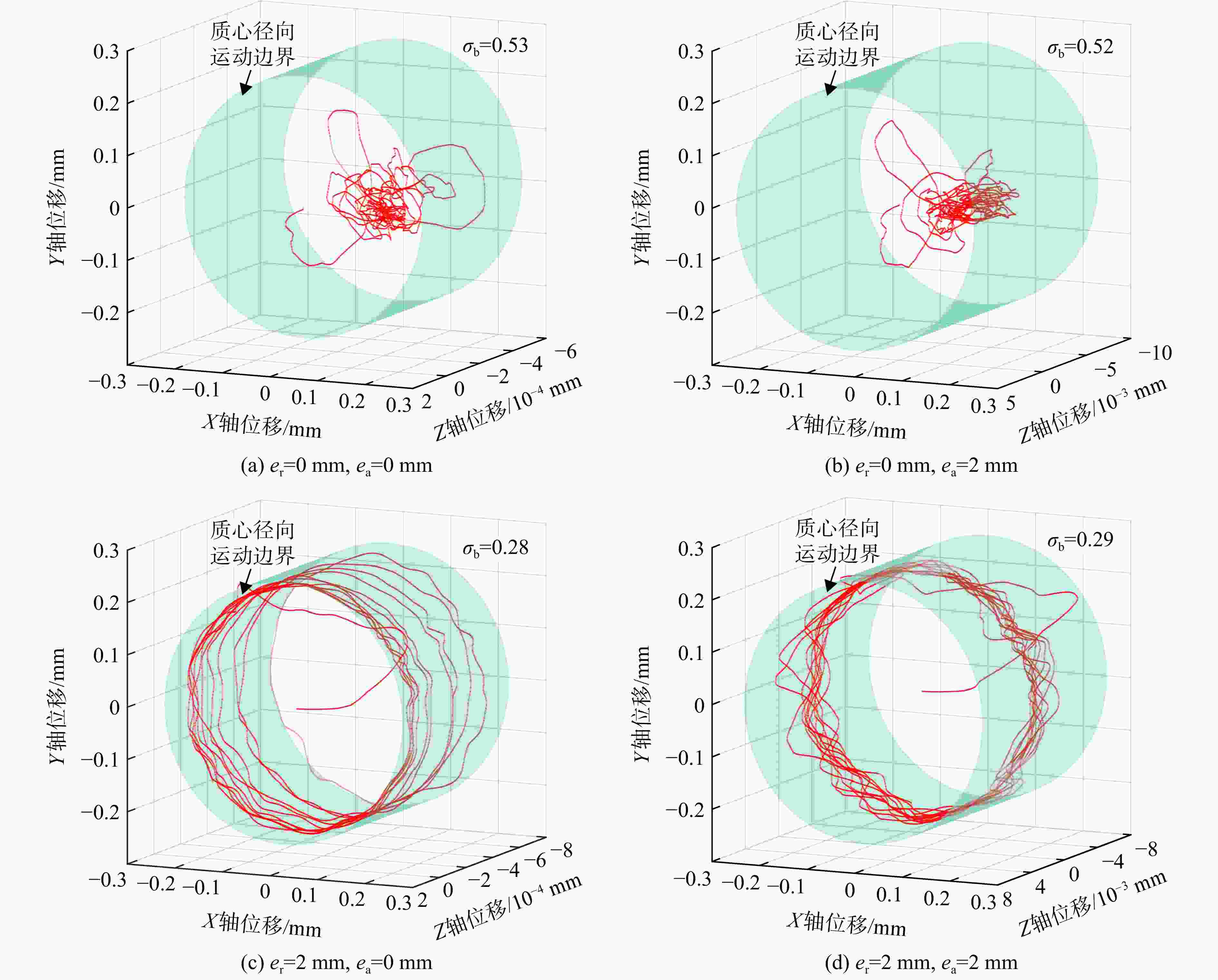

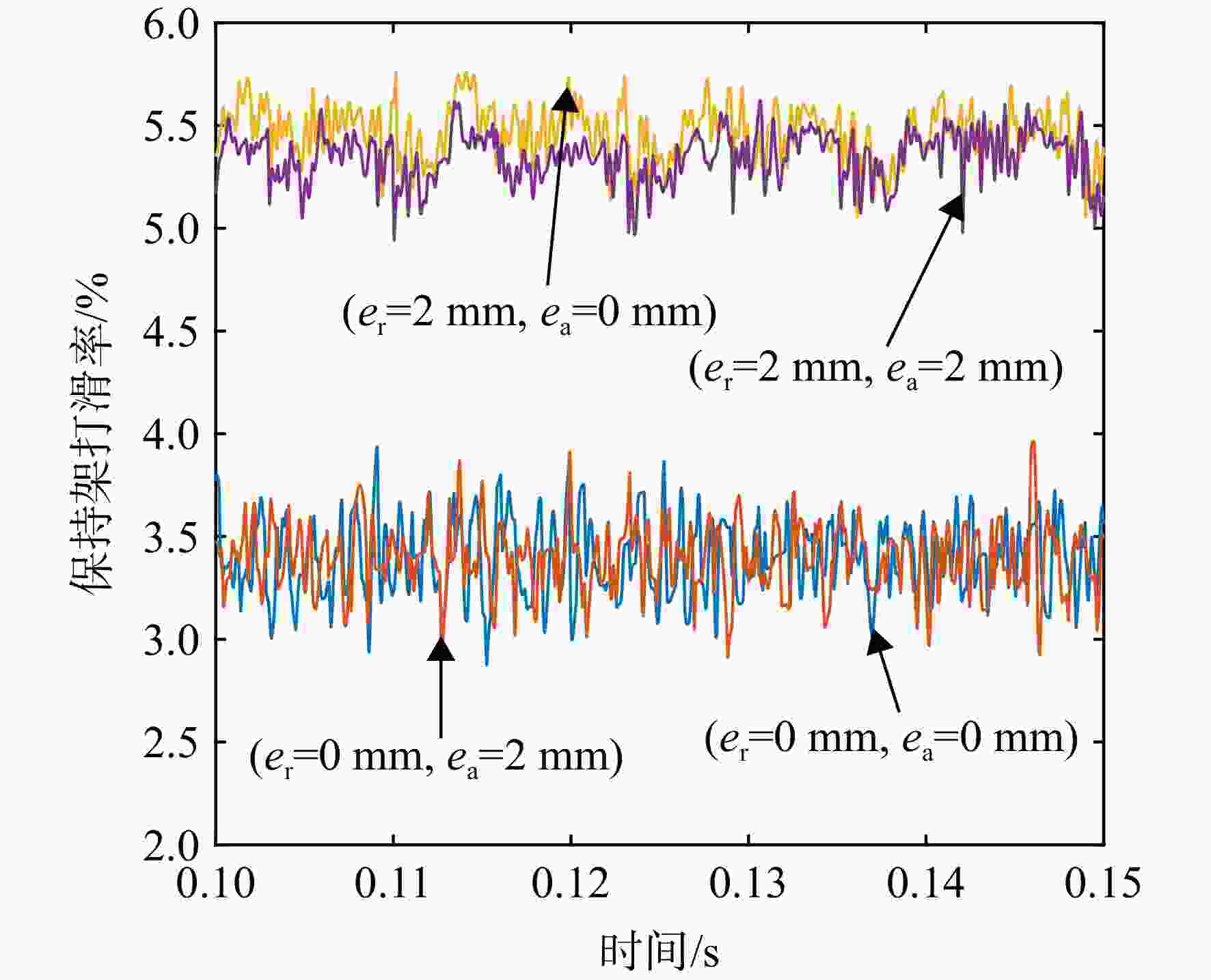

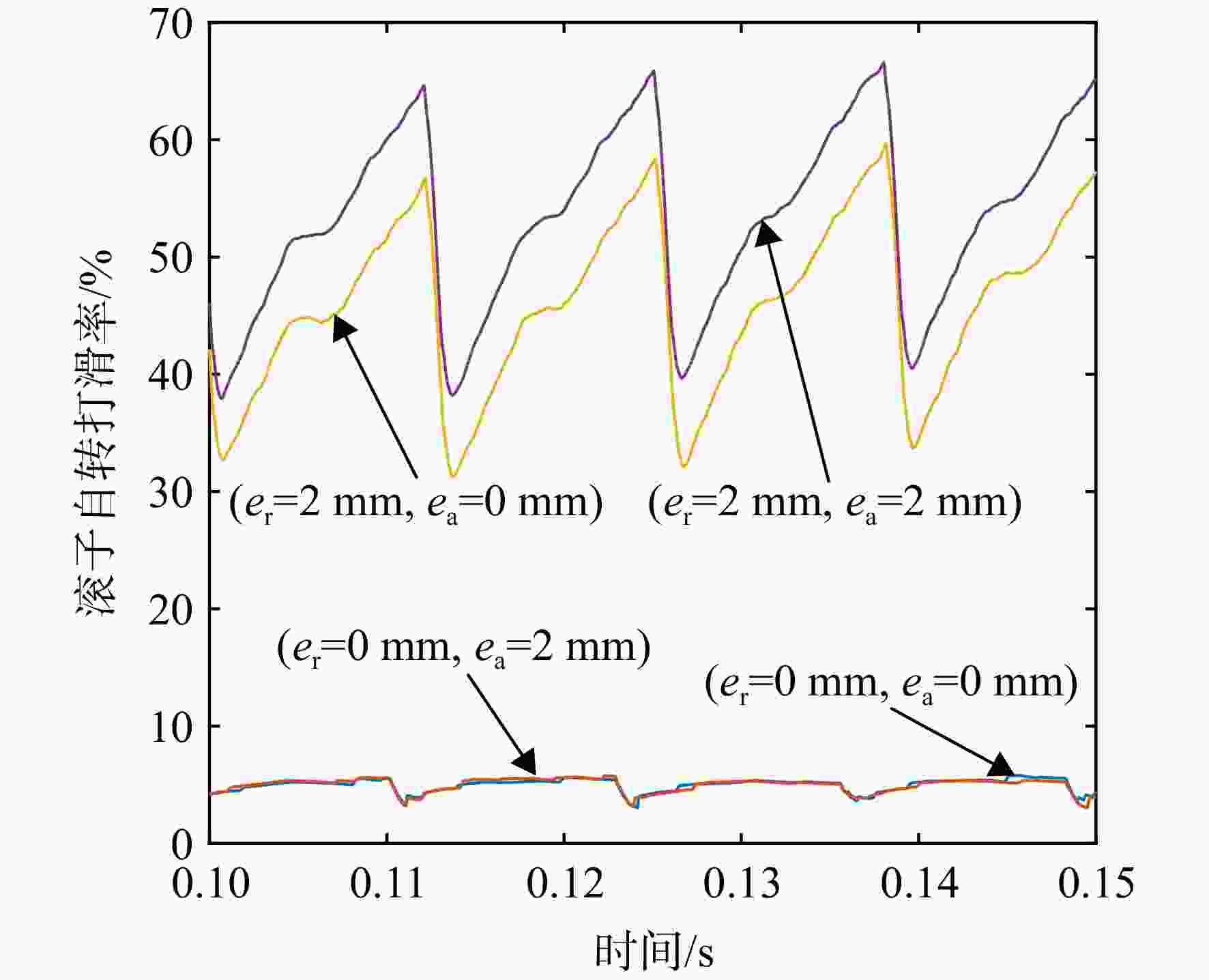

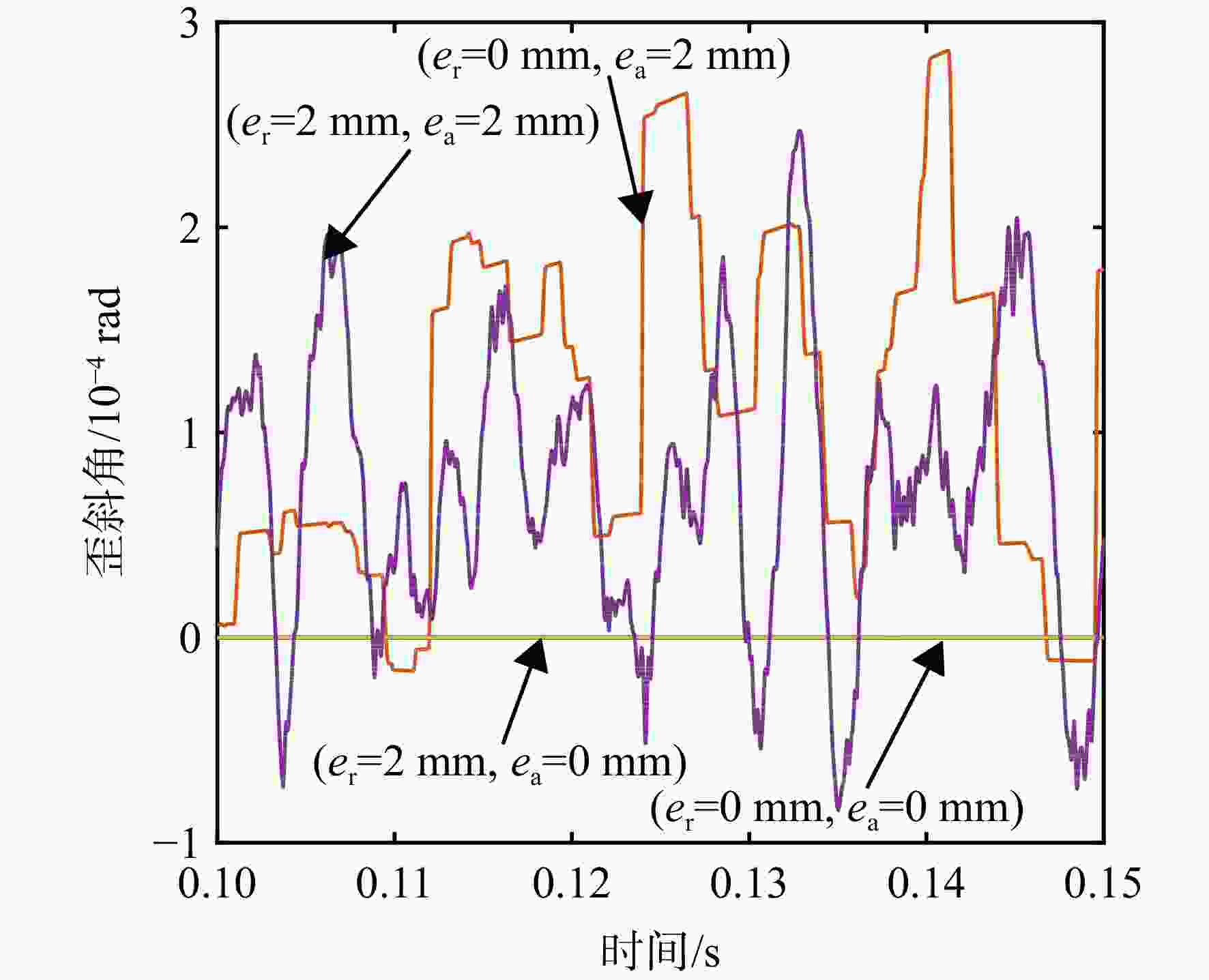

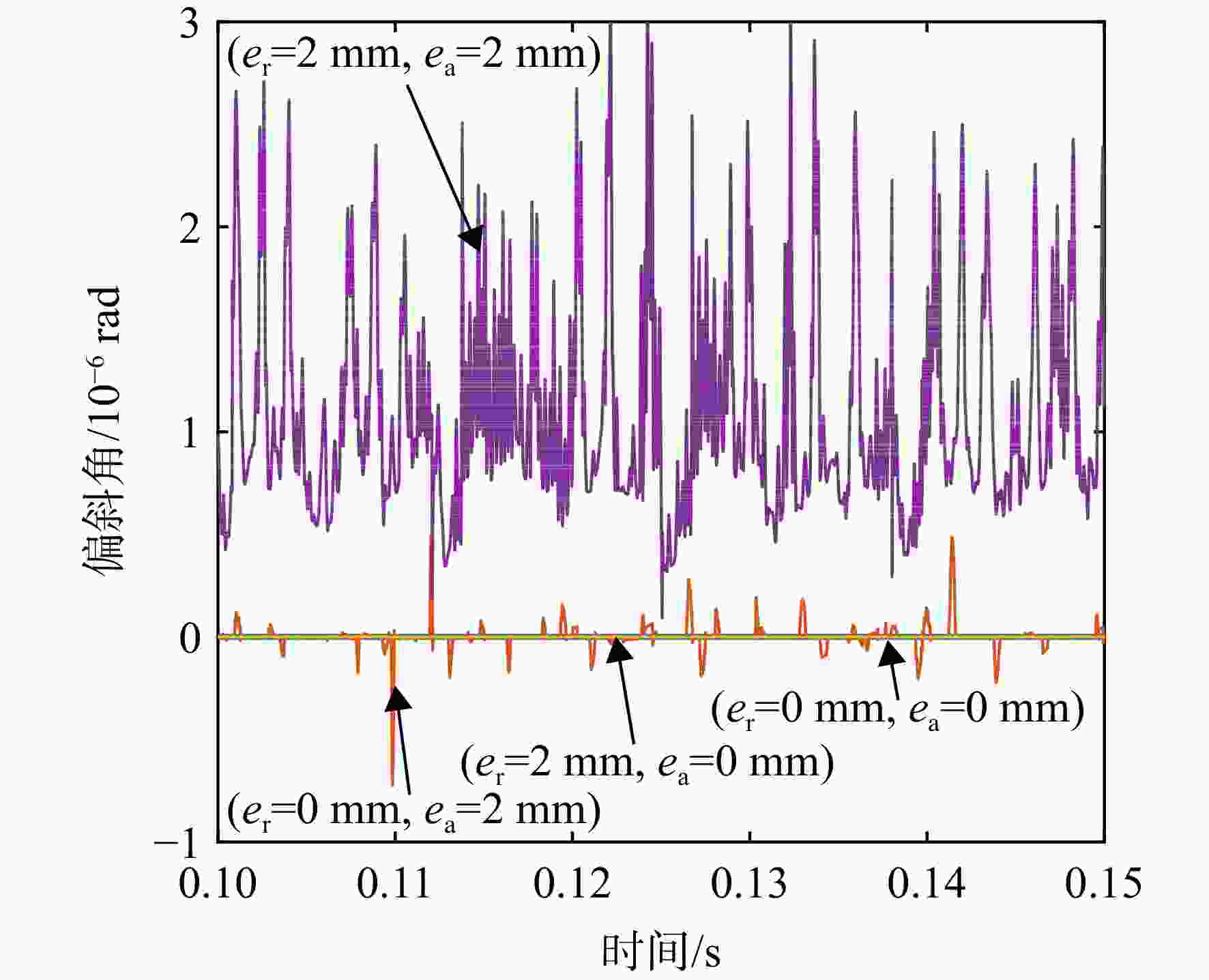

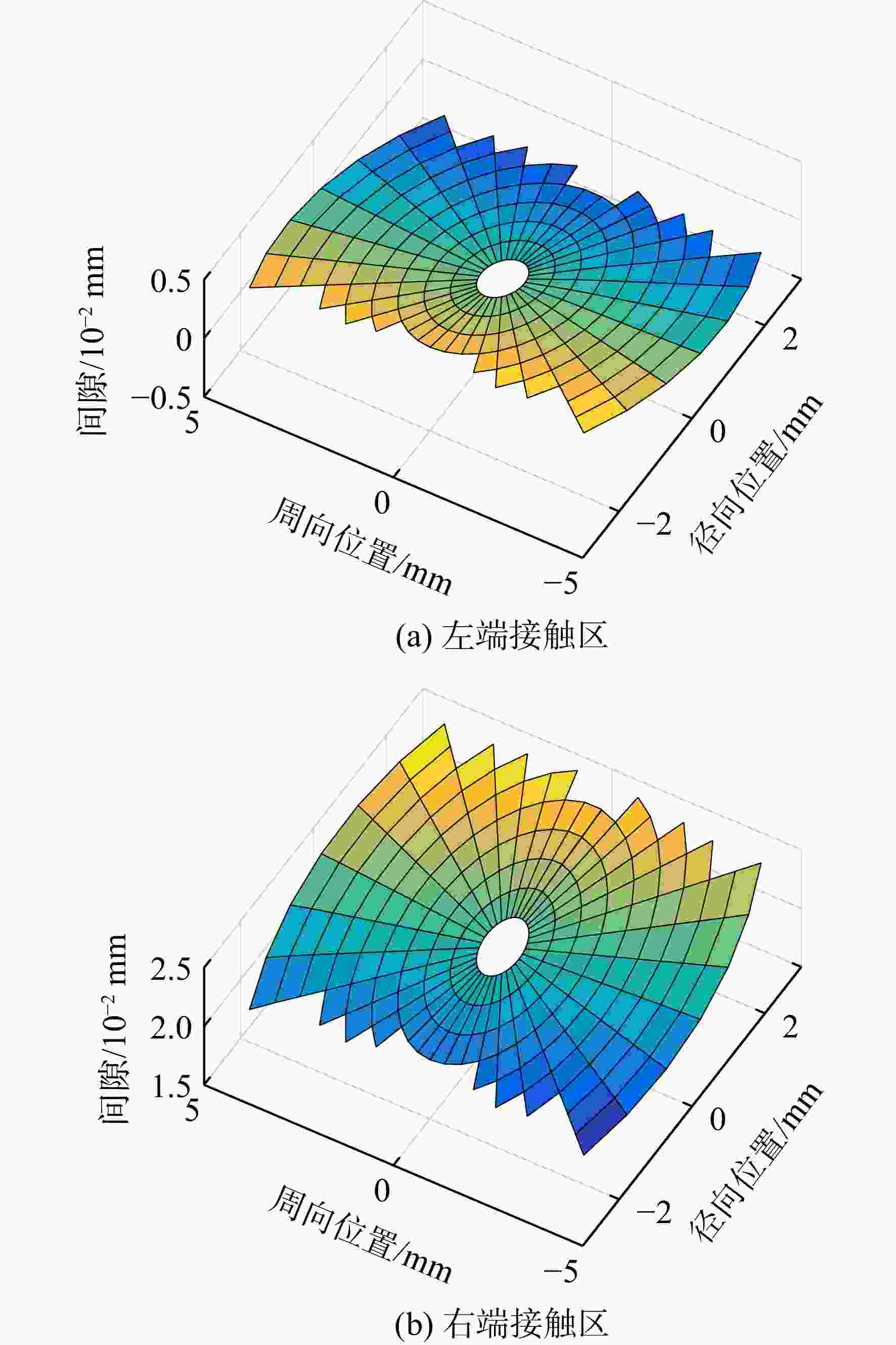

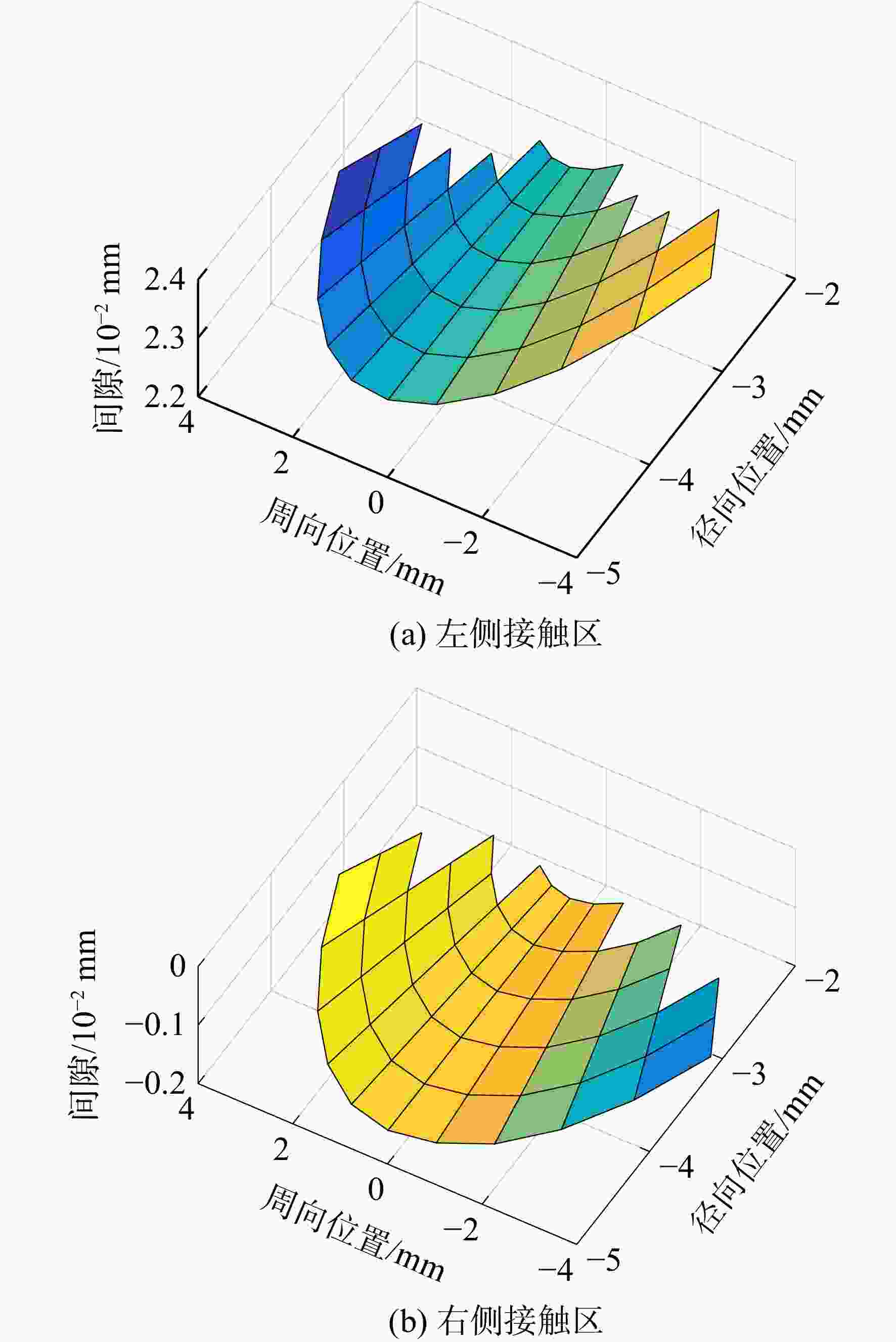

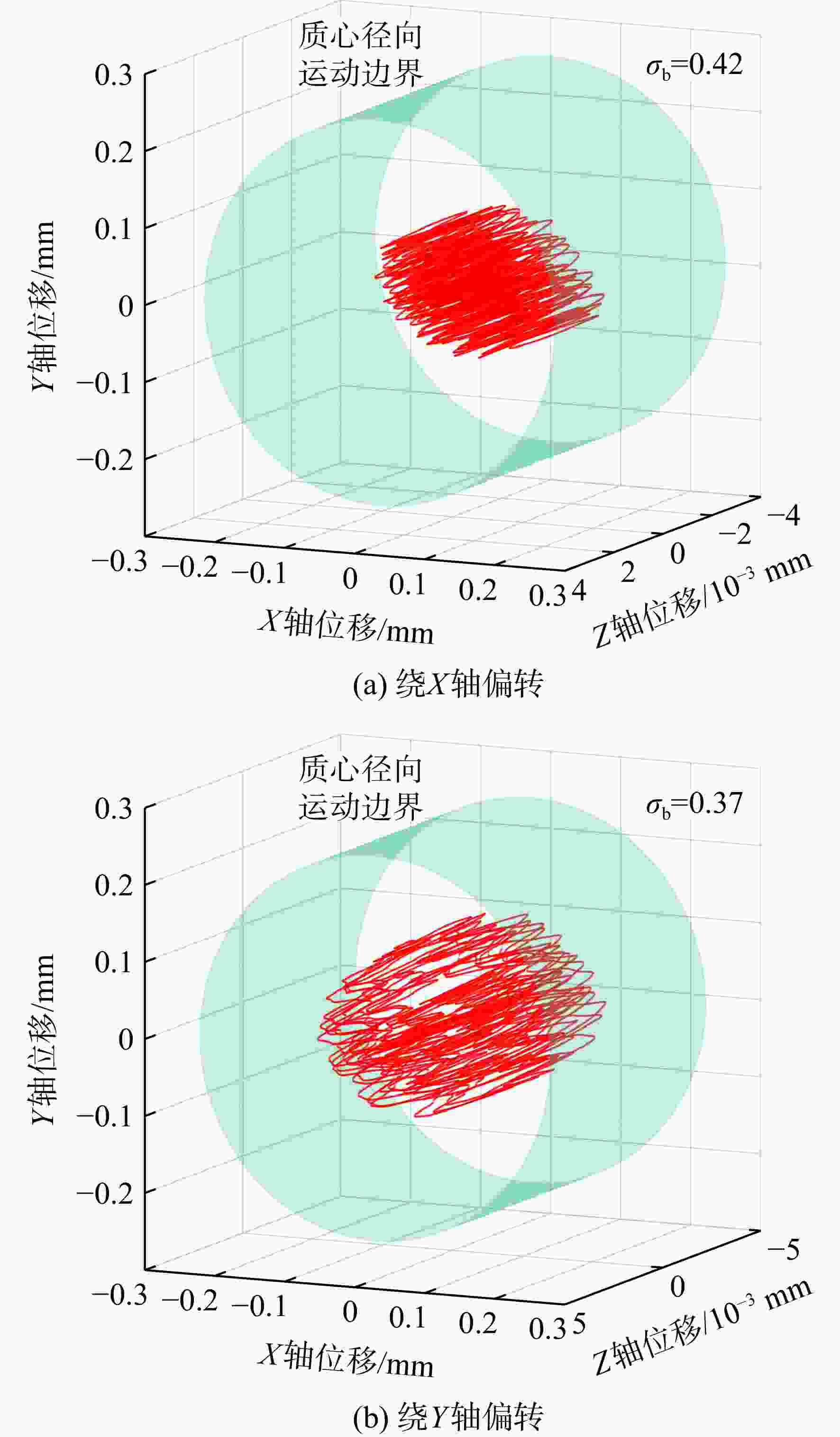

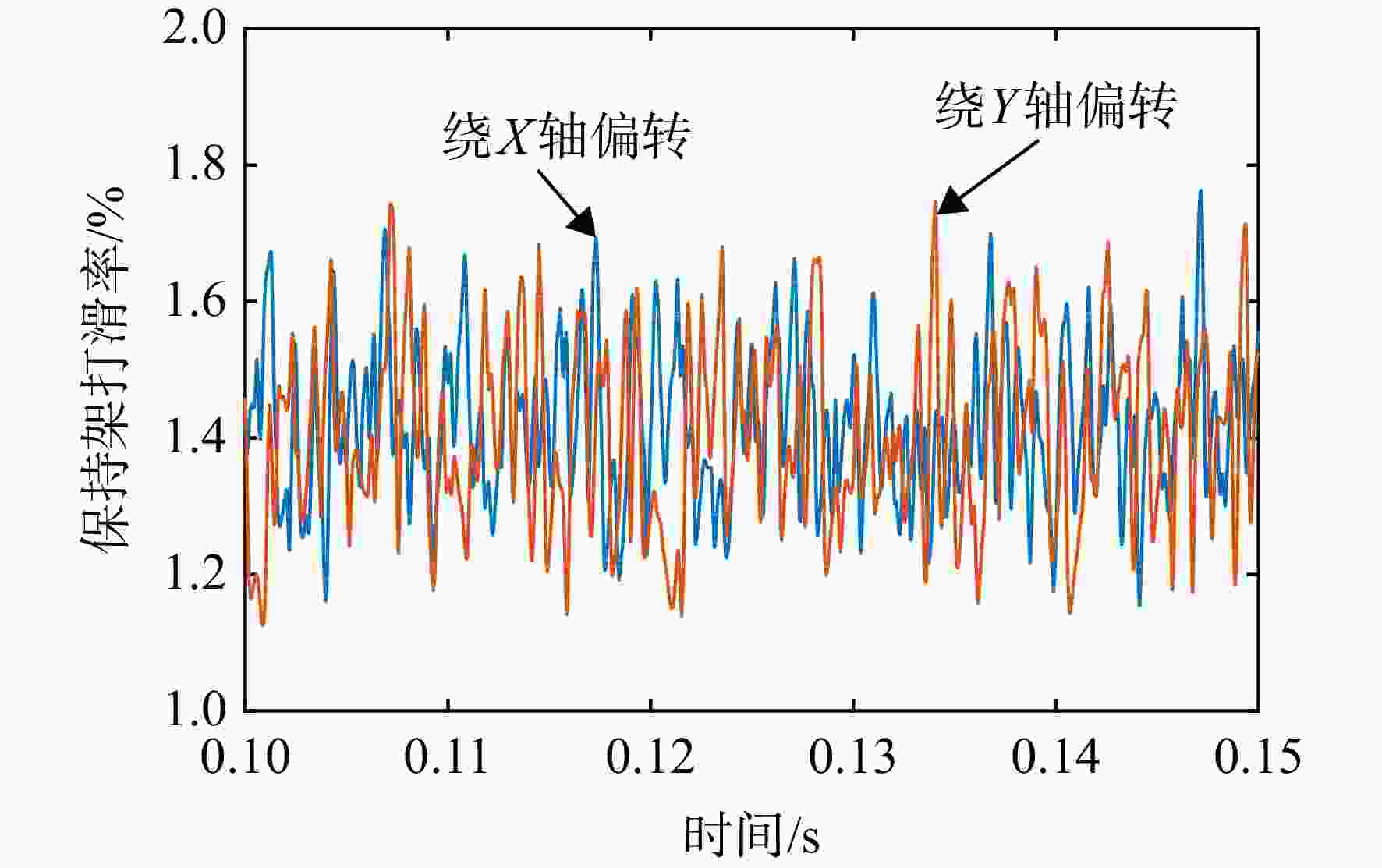

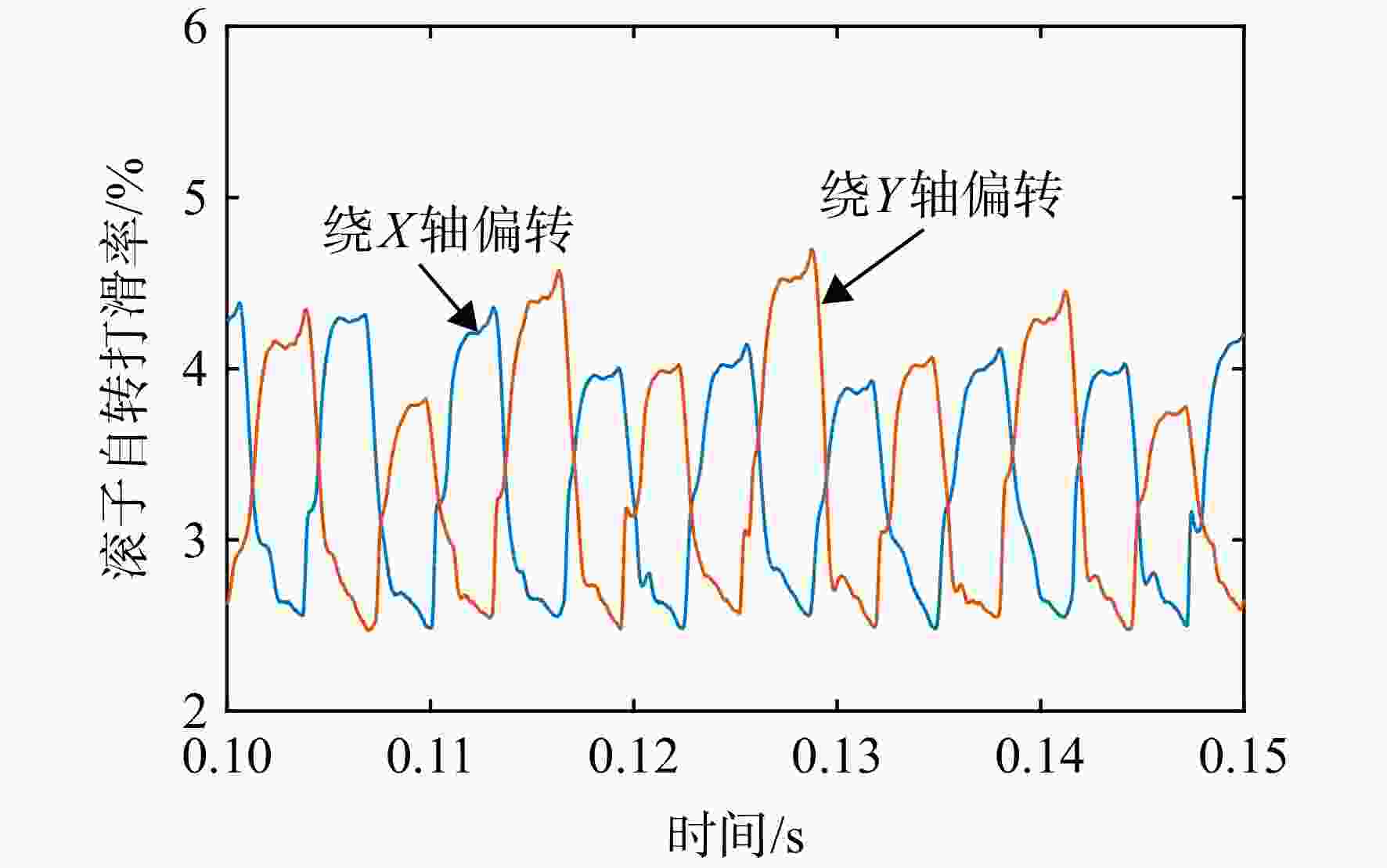

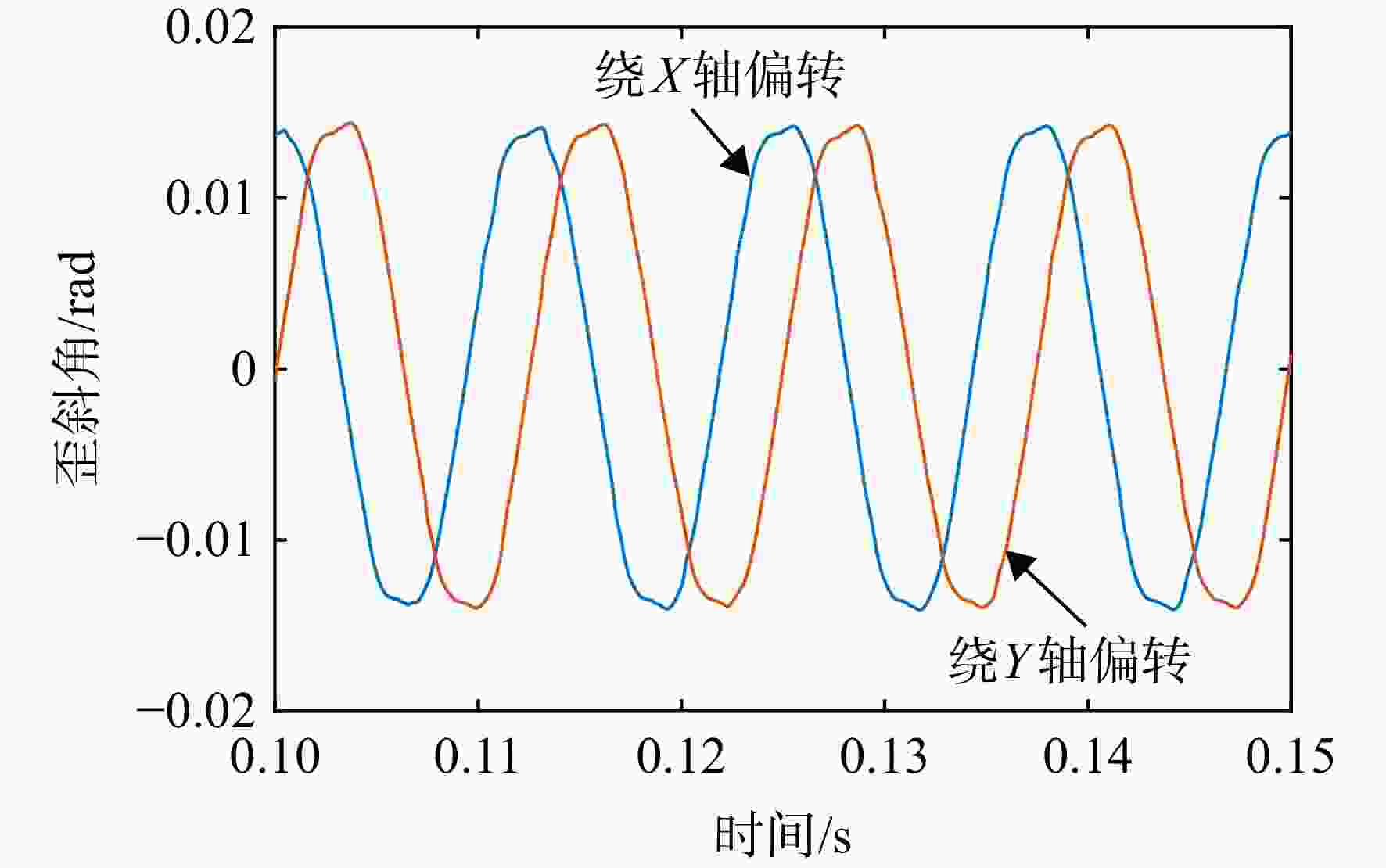

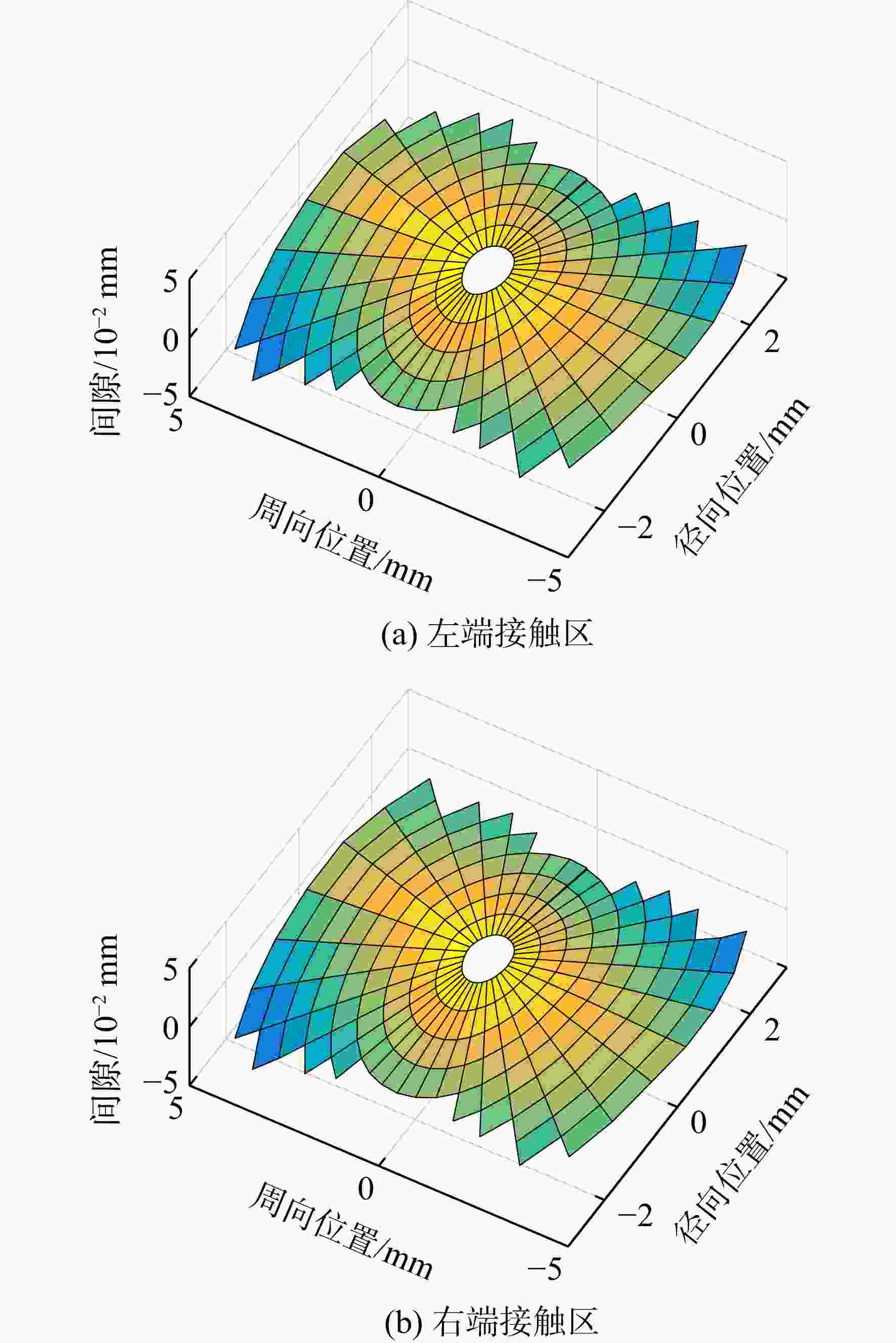

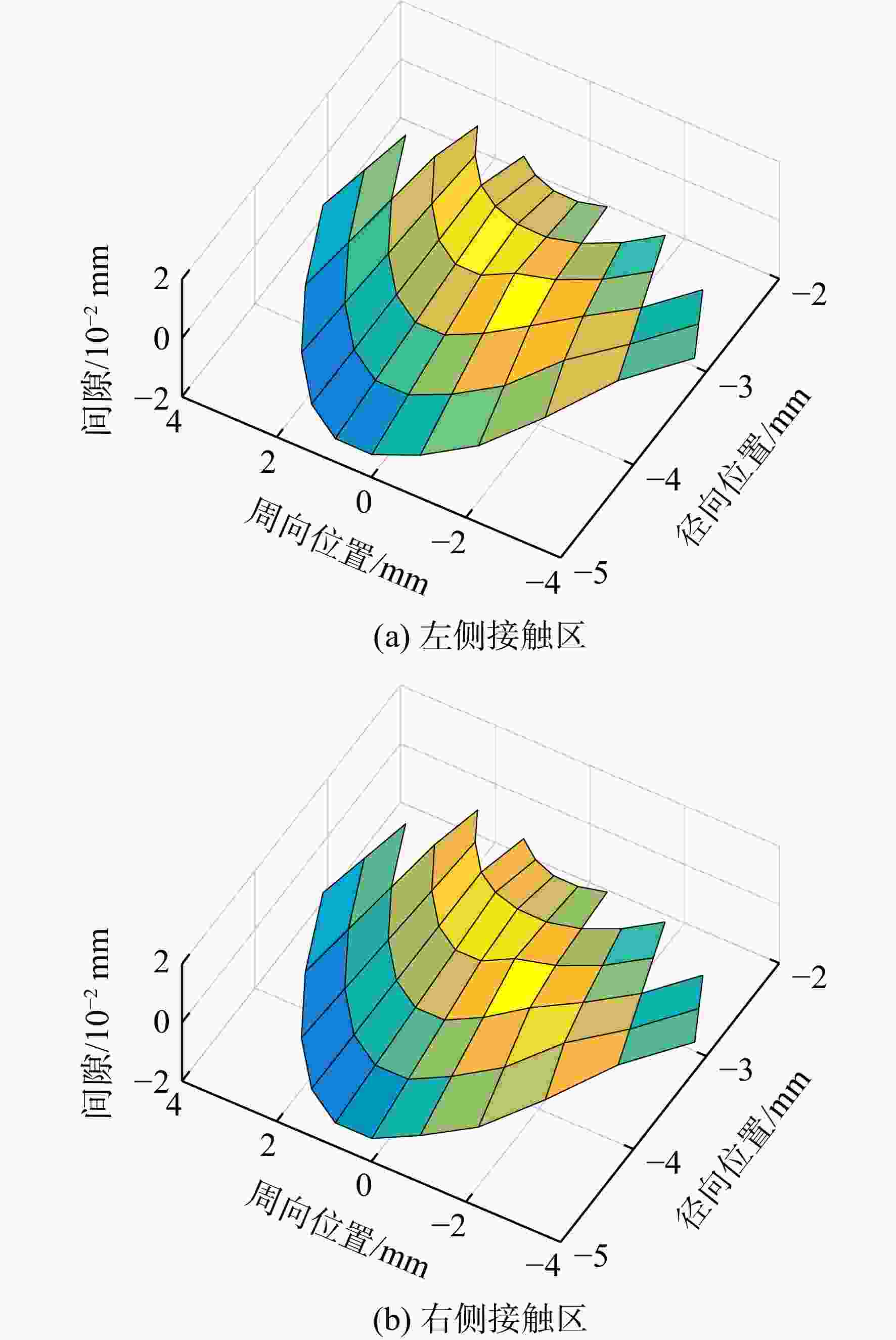

针对接触廓形高度密合的滚子-兜孔圆弧面、滚子-兜孔端面、滚子-挡边等协调接触副,基于Winkler弹性基础模型,提出一种协调接触建模方法,然后结合牛顿-欧拉动力学理论,提出考虑协调接触的圆兜孔圆柱滚子轴承的六自由度动力学建模方法,通过与文献结果和实验数据对比,验证了建模方法的有效性,在此基础上仿真研究了保持架质量偏心和内外圈角度不对中对保持架打滑/涡动、滚子打滑/偏歪斜、滚子-兜孔碰撞以及滚子-挡边碰撞的影响,结果表明:保持架质量径向偏心会加剧保持架和滚子的打滑,但有助于提高保持架涡动的稳定性,而轴向偏心会引起滚子的偏歪斜,当轴向偏心与径向偏心叠加时,滚子与兜孔、挡边更易产生边缘碰撞;内外圈角度不对中也容易引起滚子的偏歪斜,以及滚子与兜孔、挡边的边缘碰撞,但可明显降低保持架和滚子的打滑。

Abstract:For the conformal contact pairs such as the roller-circular surface of the pocket, the roller-end face of the pocket, and the roller-rib with highly close contact profiles, based on the Winkler's elastic foundation model, a conformal contact modeling method was proposed; by combining the conformal contact modeling method with the Newton-Euler's dynamics theory, the six degree-of-freedom dynamics modeling method of the bearing with circular pockets considering conformal contact was proposed; and by comparing with both the reference results and the experiment data, the proposed dynamics modeling method was validated. On this basis, influences of both the mass eccentricity of the cage and the angle misalignment of the inner and outer rings on the cage slip/whirl, the roller slip/skew/tilt, the roller-cage collision and the roller-rib collision were studied by use of dynamics simulation. The results showed that the radial mass eccentricity of the cage could aggravate the cage slip and the roller slip, but contributed to improve the cage whirl stability, and the axial mass eccentricity may cause the roller skew/tilt; when the axial mass eccentricity was combined with the radial mass eccentricity, the roller-pocket peripheral collision and the roller-rib peripheral collision easily appeared. Secondly, the angle misalignment of the inner and outer rings was more likely to cause the roller skew/tilt, and the roller-pocket peripheral collision and the roller-rib peripheral collision, but it can significantly reduce the cage slip and the roller slip.

-

表 1 轴承几何参数、材料及工况

Table 1. Bearing geometry, material and operating conditions

参数 数值及说明 几何参数 轴承型号 NU2330EM1 轴承内径/mm 165 几何 滚子数 14 参数 滚子长度/mm 74.6 滚子半径/mm 22.5 径向游隙/mm 0.08 兜孔间隙/mm 0.36/滚子引导 挡边轴向侧隙/mm 0.015 材料 滚子及套圈 钢 保持架 黄铜 工况 内圈转速/(r/min) 1000 径向载荷/kN 50 表 2 轴承几何参数

Table 2. Bearing geometry

参数 数值 滚子数 13 轴承内径/mm 35 轴承外径/mm 72 内滚道直径/mm 44 外滚道直径/mm 63.82 径向游隙/mm 0.02 挡边轴向侧隙/mm 0.015 保持架内径/mm 48.5 保持架外径/mm 59 兜孔间隙/mm 0.1 兜孔轴向侧隙/mm 0.015 滚子直径/mm 10 滚子长度/有效长度/mm 11/7.2 表 3 轴承材料

Table 3. Bearing material

元件 材料 材料特性 密度/ (kg/m3) 弹性模量/GPa 泊松比 滚子 钢 7820 207 0.28 套圈 钢 7820 207 0.28 保持架 黄铜 8600 106 0.32 -

[1] 方明伟,谢向宇,罗军,等. 航空发动机主轴后轴承打滑损伤失效分析[J]. 润滑与密封,2016,41(10): 98-102. FANG Mingwei,XIE Xiangyu,LUO Jun,et al. Failure analysis of skidding damage of rear bearing aero-engine main shaft[J]. Lubrication Engineering,2016,41(10): 98-102. (in Chinese FANG Mingwei, XIE Xiangyu, LUO Jun, et al . Failure analysis of skidding damage of rear bearing aero-engine main shaft[J]. Lubrication Engineering,2016 ,41 (10 ):98 -102 . (in Chinese)[2] 赵燕,毕明龙,石东丹. 基于抑制滚子歪斜的高速圆柱滚子轴承设计[J]. 轴承,2018(12): 14-16. ZHAO Yan,BI Minglong,SHI Dongdan. Design of high speed cylindrical roller bearings based on control of roller skew[J]. Bearing,2018(12): 14-16. (in Chinese ZHAO Yan, BI Minglong, SHI Dongdan . Design of high speed cylindrical roller bearings based on control of roller skew[J]. Bearing,2018 (12 ):14 -16 . (in Chinese)[3] GUPTA P K. Cage unbalance and wear in roller bearings[J]. Wear,1991,147(1): 105-118. doi: 10.1016/0043-1648(91)90122-B [4] 陈国定,李建华,徐建东,等. 高速滚动轴承弹性流体动力润滑分析[J]. 航空学报,1994,15(12): 1475-1477. CHEN Guoding,LI Jianhua,XU Jiandong,et al. Elastohydrodynamic lubrication analysis for the high-speed roller bearing[J]. Acta Aeronautica et Astronautica Sinica,1994,15(12): 1475-1477. (in Chinese CHEN Guoding, LI Jianhua, XU Jiandong, et al . Elastohydrodynamic lubrication analysis for the high-speed roller bearing[J]. Acta Aeronautica et Astronautica Sinica,1994 ,15 (12 ):1475 -1477 . (in Chinese)[5] KANG Y S,EVANS R D,DOLL G L. Roller-raceway slip simulations of wind turbine gearbox bearings using dynamic bearing model[C]//Proceedings of STLE/ASME 2010 International Joint Tribology Conference. San Francisco,US: ASME,2010: 407-409. [6] SELVARAJ A,MARAPPAN R. Experimental analysis of factors influencing the cage slip in cylindrical roller bearing[J]. The International Journal of Advanced Manufacturing Technology,2011,53(5/6/7/8): 635-644. [7] 陈渭,李军宁,张立波,等. 考虑涡动工况的高速滚动轴承打滑失效分析[J]. 机械工程学报,2013,49(6): 38-43. CHEN Wei,LI Junning,ZHANG Libo,et al. Skidding analysis of high speed rolling bearing considering whirling of bearing[J]. Journal of Mechanical Engineering,2013,49(6): 38-43. (in Chinese doi: 10.3901/JME.2013.06.038 CHEN Wei, LI Junning, ZHANG Libo, et al . Skidding analysis of high speed rolling bearing considering whirling of bearing[J]. Journal of Mechanical Engineering,2013 ,49 (6 ):38 -43 . (in Chinese) doi: 10.3901/JME.2013.06.038[8] 韩勤锴,李兴林,闫国斌,等. 变载偏斜圆柱滚子轴承打滑动力学分析[J]. 机械工程学报,2017,53(9): 58-65. HAN Qinkai,LI Xinglin,YAN Guobin,et al. Dynamic skidding behavior of skew cylindrical roller bearings under time-variable loads[J]. Journal of Mechanical Engineering,2017,53(9): 58-65. (in Chinese doi: 10.3901/JME.2017.09.058 HAN Qinkai, LI Xinglin, YAN Guobin, et al . Dynamic skidding behavior of skew cylindrical roller bearings under time-variable loads[J]. Journal of Mechanical Engineering,2017 ,53 (9 ):58 -65 . (in Chinese) doi: 10.3901/JME.2017.09.058[9] 孙雪,邓四二,陈国定,等. 弹性支承下圆柱滚子轴承保持架稳定性分析[J]. 航空动力学报,2018,33(2): 487-496. SUN Xue,DENG Sier,CHEN Guoding,et al. Analysis of cage’s stability in a cylindrical roller bearing with elastic support[J]. Journal of Aerospace Power,2018,33(2): 487-496. (in Chinese SUN Xue, DENG Sier, CHEN Guoding, et al . Analysis of cage’s stability in a cylindrical roller bearing with elastic support[J]. Journal of Aerospace Power,2018 ,33 (2 ):487 -496 . (in Chinese)[10] 曹伟,王家序,蒲伟,等. 加速工况下圆柱滚子轴承运动特性[J]. 中南大学学报(自然科学版),2018,49(3): 583-591. CAO Wei,WANG Jiaxu,PU Wei,et al. Kinetic characteristics of cylindrical roller bearing during acceleration[J]. Journal of Central South University (Science and Technology),2018,49(3): 583-591. (in Chinese CAO Wei, WANG Jiaxu, PU Wei, et al . Kinetic characteristics of cylindrical roller bearing during acceleration[J]. Journal of Central South University (Science and Technology),2018 ,49 (3 ):583 -591 . (in Chinese)[11] DENG Sier,LU Yujia,ZHANG Wenhu,et al. Cage slip characteristics of a cylindrical roller bearing with a trilobe-raceway[J]. Chinese Journal of Aeronautics,2018,31(2): 351-362. doi: 10.1016/j.cja.2017.07.001 [12] 龚岸琦,姚廷强,咸利国. 中大型圆柱滚子轴承柔性保持架动力学分析[J]. 轴承,2019(2): 6-11. GONG Anqi,YAO Tingqiang,XIAN Liguo. Dynamics analysis on flexible cages of medium and large scale cylindrical roller bearings[J]. Bearing,2019(2): 6-11. (in Chinese GONG Anqi, YAO Tingqiang, XIAN Liguo . Dynamics analysis on flexible cages of medium and large scale cylindrical roller bearings[J]. Bearing,2019 (2 ):6 -11 . (in Chinese)[13] 涂文兵,杨锦雯,罗丫,等. 高速列车轴箱圆柱滚子轴承启动过程的打滑动力学特性[J]. 振动与冲击,2020,39(10): 127-132. TU Wenbing,YANG Jinwen,LUO Ya,et al. Skidding dynamic characteristics of axle box roller bearing of high-speed trains during start-up[J]. Journal of Vibration and Shock,2020,39(10): 127-132. (in Chinese TU Wenbing, YANG Jinwen, LUO Ya, et al . Skidding dynamic characteristics of axle box roller bearing of high-speed trains during start-up[J]. Journal of Vibration and Shock,2020 ,39 (10 ):127 -132 . (in Chinese)[14] GUO Yi,KELLER J. Validation of combined analytical methods to predict slip in cylindrical roller bearings[J]. Tribology International,2020,148: 106347. doi: 10.1016/j.triboint.2020.106347 [15] WANG Zhijian,SONG Jiawei,LI Xinglin,et al. Modeling and dynamic analysis of cylindrical roller bearings under combined radial and axial loads[J]. Journal of Tribology,2022,144(12): 121203. doi: 10.1115/1.4055406 [16] 刘秀海. 高速滚动轴承动力学分析模型与保持架动态性能研究[D]. 大连: 大连理工大学,2011. LIU Xiuhai. Dynamics analysis model of high-speed rolling bearings and dynamic performance of cages[D]. Dalian: Dalian University of Technology,2011. (in ChineseLIU Xiuhai. Dynamics analysis model of high-speed rolling bearings and dynamic performance of cages[D]. Dalian: Dalian University of Technology, 2011. (in Chinese) [17] JOHNSON K L. Contact mechanics[M]. Cambridge: Cambridge University Press,1987. [18] HUNT K H,CROSSLEY F R E. Coefficient of restitution interpreted as damping in vibroimpact[J]. Journal of Applied Mechanics,1975,42(2): 440-445. doi: 10.1115/1.3423596 [19] 秦志英,陆启韶. 基于恢复系数的碰撞过程模型分析[J]. 动力学与控制学报,2006,4(4): 294-298. QIN Zhiying,LU Qishao. Analysis of impact process model based on restitution coefficien[J]. Journal of Dynamics and Control,2006,4(4): 294-298. (in Chinese QIN Zhiying, LU Qishao . Analysis of impact process model based on restitution coefficien[J]. Journal of Dynamics and Control,2006 ,4 (4 ):294 -298 . (in Chinese)[20] QIAN W H. Dynamic simulation of cylindrical roller bearing[D]. Aachen,Germany: RWTH Aachen University,2014. [21] GHAISAS N,WASSGREN C R,SADEGHI F. Cage instabilities in cylindrical roller bearings[J]. Journal of Tribology,2004,126(4): 681-689. doi: 10.1115/1.1792674 -

下载:

下载: