Comparative analysis on aircraft and engine integration performance of RBCC engines with different fuels

-

摘要:

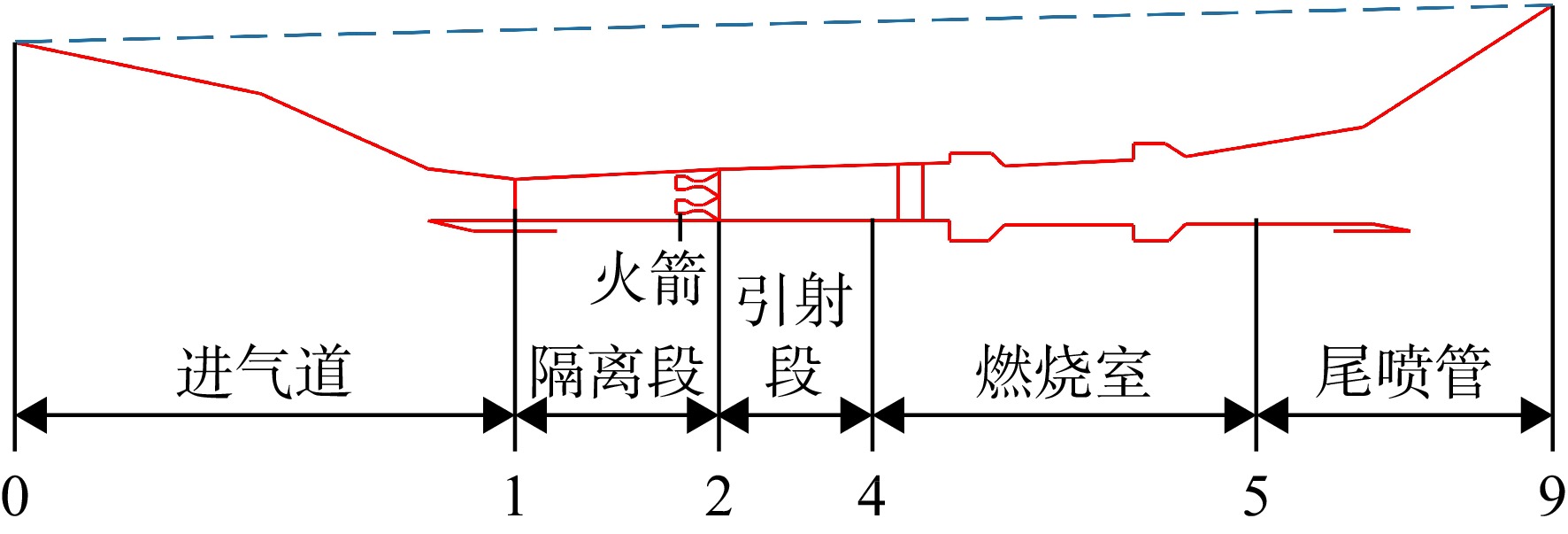

为了研究不同燃料火箭基组合循环(rocket based combined cycle,RBCC)发动机总体性能的影响,建立了RBCC发动机准一维总体性能仿真模型,分别研究了以液氧煤油、过氧化氢煤油、液氧甲烷和液氧液氢为燃料的RBCC发动机推力和比冲性能。结合飞/发一体化性能分析模型,研究了不同燃料发动机性能对完成飞行任务能力的影响。结果表明:氢燃料RBCC发动机引射模态推力是煤油燃料RBCC发动机的1.3倍;氢燃料RBCC动力飞行器巡航距离最远,为4470 km;相同的飞行器参数下,过氧化氢煤油燃料RBCC动力飞行器机动性最大。本方法可为RBCC发动机总体性能方案设计和燃料选取提供参考。

Abstract:In order to study the impact of different fuels on the overall performance of rocket based combined cycle (RBCC) engines, a quasi-one-dimensional overall performance simulation model of RBCC engines was built. The thrust and specific impulse performance of RBCC engines fueled with liquid oxygen kerosene, hydrogen peroxide kerosene, liquid oxygen methane, and liquid oxygen liquid hydrogen were studied. Combined with the integrated aircraft engine performance analysis model, the effects of different fuel engine performance on flight mission capability were studied. The results showed that at ejector mode, the thrust of hydrogen fuel was 1.3 times greater than kerosene fuel; the hydrogen fueled RBCC engine had the farthest cruising distance of 4470 km; under the same aircraft parameters, hydrogen peroxide kerosene fuel RBCC powered aircraft had the highest maneuverability. This method can provide a reference for the overall performance scheme design and fuel selection of RBCC engines.

-

Key words:

- RBCC engine /

- aircraft and engine integration /

- kerosene /

- methane /

- hydrogen /

- engine performance

-

表 1 发动机设计点参数

Table 1. Engine design point parameters

参 数 数值 整机参数 空气流量Wa0/(kg/s) 2.0 整机宽度/m 0.12 飞行条件 飞行高度H/km 26.5 飞行马赫数Ma0 6.0 进气道 出口马赫数Ma2 3.0 修正马赫数 4.0 隔离段 高度His/m 0.044 长度/m 0.30 火箭 流量/(kg/s) 1 火箭室压/MPa 3 燃烧室 扩张段扩张比 1.5/2.0 当量油气比Φ 1.0 燃烧效率ηb 0.85 两段供油比例Φ1/Φ2 1∶4 尾喷管 底板长度 1.0 A9/A0 1.5 扩张角/(°) 15 表 2 不同燃料燃烧特性

Table 2. Combustion characteristics of different fuels

燃料 空燃比 燃烧热/

(MJ/kg)燃烧单位质量

空气放热/MJ甲烷 17.16 50.02 2.91 煤油 14.70 43.11 2.93 氢 34.48 143.0 3.13 表 3 约束条件

Table 3. Constraint conditions

航段 航段 马赫数Ma 质量比 1 起飞 0~0.3 0.9 2 加速爬升 0.3~0.8 0.7 3 等动压爬升 1.5~6 0.4 4 巡航 6 0.4 5 降落 0~0.3 0.3 表 4 高超声速飞行器参数

Table 4. Hypersonic vehicle parameters

参数 ABLV-GT Argus Lazarus GTX RBCC 起飞质量/t 613.3 270.9 81.6 108.2 325 结构质量/t 104.4 34.2 18.9 23.4 76.48 推进剂质量/t 481 223.69 57.6 84.67 248.5 有效载荷/t 11.34 5.03 2.27 0.136 空重比 0.197 0.156 0.266 0.216 0.235 表 5 不同RBCC发动机飞/发一体化分析结果

Table 5. Analysis results of flight/engine integration for different RBCC engines

火箭燃料/

冲压燃料煤油+O2/

煤油煤油+H2O2/

煤油CH4+O2/

CH4H2+O2/

H2起飞总重/t 80 80 80 80 推质比 0.65 0.65 0.65 0.65 翼载/(N/m2) 5000 5000 5000 5000 机翼面积/m2 156.96 156.96 156.96 156.96 空重比 0.25 0.25 0.25 0.25 转场距离/km 1401.58 1936.51 2096.02 5698.68 总转场时间/min 23.50 27.63 30.08 63.36 爬升段时间/min 11.55 9.20 12.05 11.92 总耗油量/t 57.01 57.00 57.00 57.03 燃料体积/m3 61.51 56.52 95.70 492.40 巡航距离/km 200 900 860 4470.0 -

[1] 曾家,黄辉,朱平平,等. 火箭基组合动力研究进展与关键技术[J]. 宇航总体技术,2022,6(3): 49-57. ZENG Jia,HUANG Hui,ZHU Pingping,et al. Research progress and key technology analysis of rocket based combined cycle engines[J]. Astronautical Systems Engineering Technology,2022,6(3): 49-57. (in ChineseZENG Jia, HUANG Hui, ZHU Pingping, et al. Research progress and key technology analysis of rocket based combined cycle engines[J]. Astronautical Systems Engineering Technology, 2022, 6(3): 49-57. (in Chinese) [2] 王亚军,何国强,秦飞,等. 火箭冲压组合动力研究进展[J]. 宇航学报,2019,40(10): 1125-1133. WANG Yajun,HE Guoqiang,QIN Fei,et al. Research progress of rocket based combined cycle engines[J]. Journal of Astronautics,2019,40(10): 1125-1133. (in Chinese doi: 10.3873/j.issn.1000-1328.2019.10.003WANG Yajun, HE Guoqiang, QIN Fei, et al. Research progress of rocket based combined cycle engines[J]. Journal of Astronautics, 2019, 40(10): 1125-1133. (in Chinese) doi: 10.3873/j.issn.1000-1328.2019.10.003 [3] 姚卫,张政,赵伟,等. 高超声速飞/发一体化进展与趋势[J]. 推进技术,2023,44(8): 6-21. YAO Wei,ZHANG Zheng,ZHAO Wei,et al. Advances and trends in airframe/engine integration of hypersonic vehicles[J]. Journal of Propulsion Technology,2023,44(8): 6-21. (in ChineseYAO Wei, ZHANG Zheng, ZHAO Wei, et al. Advances and trends in airframe/engine integration of hypersonic vehicles[J]. Journal of Propulsion Technology, 2023, 44(8): 6-21. (in Chinese) [4] 陈宣亮,曾军,李刚团,等. 高马赫数飞行器飞/发性能一体化评估方法初步研究[J]. 燃气涡轮试验与研究,2022,35(1): 16-22. CHEN Xuanliang,ZENG Jun,LI Gangtuan,et al. Performance evaluation method of high Mach number aircraft/engine integration design[J]. Gas Turbine Experiment and Research,2022,35(1): 16-22. (in Chinese doi: 10.3969/j.issn.1672-2620.2022.01.004CHEN Xuanliang, ZENG Jun, LI Gangtuan, et al. Performance evaluation method of high Mach number aircraft/engine integration design[J]. Gas Turbine Experiment and Research, 2022, 35(1): 16-22. (in Chinese) doi: 10.3969/j.issn.1672-2620.2022.01.004 [5] BRADFORD J,OLDS J,BECHTEL R,et al. Exploration of the design space for the ABLV-GT SSTO reusable launch vehicle: AIAA 2000-5136[R]. Reston,Virigina: AIAA,2000. [6] KIM H S,OH S,CHOI J Y. Quasi-1D analysis and performance estimation of a sub-scale RBCC engine with chemical equilibrium[J]. Aerospace Science and Technology,2017,69: 39-47. doi: 10.1016/j.ast.2017.06.019 [7] CHOI Y,DRISCOLL J F. Thrust optimization of the computed flowpath of scramjet engines fueled by JP-7: AIAA 2021-4097[R]. Reston,Virginia: AIAA,2021. [8] LASTIWKA D,KOROBENKO A,JOHANSEN C T. Validation and verification of pimpleCentralFOAM and a 1D-ERAM solver for analysis of an ejector-ramjet: AIAA 2022-3347[R]. Reston,Virginia: AIAA,2022. [9] LASTIWKA D,KOROBENKO A,JOHANSEN C T. Analysis and Optimisation of an Ejector Ramjet using CFD and a 1D Control Volume Solver: AIAA 2023-3302[R]. Reston,Virginia: AIAA,2023. [10] VU L N,WILSON D. Quasi-one-dimensional scramjet combustor flow solver using the numerical propulsion system simulation: AIAA 2018-4843[R]. Reston,Virginia: AIAA,2018. [11] 张时空,刘佩进,吕翔,等. RBCC发动机性能快速分析方法改进和验证[J]. 固体火箭技术,2013,36(4): 468-473. ZHANG Shikong,LIU Peijin,LYU Xiang,et al. Improvement and validation of rapid prediction method for RBCC engine performance[J]. Journal of Solid Rocket Technology,2013,36(4): 468-473. (in ChineseZHANG Shikong, LIU Peijin, LYU Xiang, et al. Improvement and validation of rapid prediction method for RBCC engine performance[J]. Journal of Solid Rocket Technology, 2013, 36(4): 468-473. (in Chinese) [12] 董泽宇,李大鹏,王振国. 基于分析法的RBCC引射模态能量利用规律[J]. 航空动力学报,2018,33(7): 1787-1792. DONG Zeyu,LI Dapeng,WANG Zhenguo. RBCC energy utilization rule during ejector mode based on exergy analysis method[J]. Journal of Aerospace Power,2018,33(7): 1787-1792. (in ChineseDONG Zeyu, LI Dapeng, WANG Zhenguo. RBCC energy utilization rule during ejector mode based on exergy analysis method[J]. Journal of Aerospace Power, 2018, 33(7): 1787-1792. (in Chinese) [13] 陈玉春,刘小勇,黄兴,等. 基于集总参数方程的超燃冲压发动机性能计算模型[J]. 推进技术,2012,33(6): 840-846. CHEN Yuchun,LIU Xiaoyong,HUANG Xing,et al. A model based on lumped parameter method for scramjet performance computation[J]. Journal of Propulsion Technology,2012,33(6): 840-846. (in ChineseCHEN Yuchun, LIU Xiaoyong, HUANG Xing, et al. A model based on lumped parameter method for scramjet performance computation[J]. Journal of Propulsion Technology, 2012, 33(6): 840-846. (in Chinese) [14] 陈军,白菡尘,万冰. 火箭基组合循环发动机引射过程准一维分析方法研究[J]. 推进技术,2022,43(8): 53-61. CHEN Jun,BAI Hanchen,WAN Bing. Quasi-one-dimensional method for ejecting process in RBCC engine[J]. Journal of Propulsion Technology,2022,43(8): 53-61. (in ChineseCHEN Jun, BAI Hanchen, WAN Bing. Quasi-one-dimensional method for ejecting process in RBCC engine[J]. Journal of Propulsion Technology, 2022, 43(8): 53-61. (in Chinese) [15] 南向军,李斌,何国强,等. RBCC发动机冲压模态热力循环分析[J]. 火箭推进,2022,48(6): 17-25. NAN Xiangjun,LI Bin,HE Guoqiang,et al. Analysis on thermodynamic cycle of scramjet mode for RBCC engine[J]. Journal of Rocket Propulsion,2022,48(6): 17-25. (in Chinese doi: 10.3969/j.issn.1672-9374.2022.06.003NAN Xiangjun, LI Bin, HE Guoqiang, et al. Analysis on thermodynamic cycle of scramjet mode for RBCC engine[J]. Journal of Rocket Propulsion, 2022, 48(6): 17-25. (in Chinese) doi: 10.3969/j.issn.1672-9374.2022.06.003 [16] 张留欢,杜泉,张蒙正. RBCC发动机火箭-冲压模态理想热力循环优化分析[J]. 火箭推进,2016,42(3): 21-25,32. ZHANG Liuhuan,DU Quan,ZHANG Mengzheng. Optimum analysis on ideal thermodynamic cycle of RBCC engine at special rocket-ramjet mode[J]. Journal of Rocket Propulsion,2016,42(3): 21-25,32. (in Chinese doi: 10.3969/j.issn.1672-9374.2016.03.004ZHANG Liuhuan, DU Quan, ZHANG Mengzheng. Optimum analysis on ideal thermodynamic cycle of RBCC engine at special rocket-ramjet mode[J]. Journal of Rocket Propulsion, 2016, 42(3): 21-25, 32. (in Chinese) doi: 10.3969/j.issn.1672-9374.2016.03.004 [17] 刘昊,王春民. 不同燃料RBCC发动机性能分析[J]. 火箭推进,2021,47(6): 33-38,54. LIU Hao,WANG Chunmin. Analysis of RBCC engine performance with different fuel[J]. Journal of Rocket Propulsion,2021,47(6): 33-38,54. (in Chinese doi: 10.3969/j.issn.1672-9374.2021.06.004LIU Hao, WANG Chunmin. Analysis of RBCC engine performance with different fuel[J]. Journal of Rocket Propulsion, 2021, 47(6): 33-38, 54. (in Chinese) doi: 10.3969/j.issn.1672-9374.2021.06.004 [18] MATTINGLY J D,HEISER W H,PRATT D T. Aircraft Engine Design,Second Edition[M]. Reston,US: AIAA,2002. [19] RAMUNNO M A,BOYD I M,GRANDHI R V,et al. Integrated hypersonic aero-propulsion model for multidisciplinary vehicle analysis and optimization: AIAA 2021-2440[R]. Reston,Virginia: AIAA,2021. [20] 徐思远,刘振德,王永文,等. 基于飞/发一体化的涡轮冲压组合发动机概念方案设计[J]. 燃气涡轮试验与研究,2013,26(6): 46-52. XU Siyuan,LIU Zhende,WANG Yongwen,et al. Conceptual design of TBCC based on airframe and engine integration[J]. Gas Turbine Experiment and Research,2013,26(6): 46-52. (in ChineseXU Siyuan, LIU Zhende, WANG Yongwen, et al. Conceptual design of TBCC based on airframe and engine integration[J]. Gas Turbine Experiment and Research, 2013, 26(6): 46-52. (in Chinese) [21] 张冬青,李正洲,邓维鑫,等. 基于飞/发一体化的Ma=8~10飞行器任务性能快速评估与分析[J]. 航空动力学报,2022,37(5): 1054-1063. ZHANG Dongqing,LI Zhengzhou,DENG Weixin,et al. Fast evaluation and analysis of Ma=8-10 vehicle mission performance based on vehicle and engine integration[J]. Journal of Aerospace Power,2022,37(5): 1054-1063. (in ChineseZHANG Dongqing, LI Zhengzhou, DENG Weixin, et al. Fast evaluation and analysis of Ma=8-10 vehicle mission performance based on vehicle and engine integration[J]. Journal of Aerospace Power, 2022, 37(5): 1054-1063. (in Chinese) [22] GORDON S,MCBRIDE B. Computer program for calculation of complex chemical equilibrium compositions and applications. Part 1: Analysis [R]. Houston: NASA Reference Publication 1311,1994. [23] BILLIG F S. Supersonic combustion ramjet missile[J]. Journal of Propulsion and Power,1995,11(6): 1139-1146. doi: 10.2514/3.23952 [24] BILLIG F S,SULLINS G A. Optimization of combustor-isolator in dual-mode scramjets: AIAA 93-515[R]. Reston,Virginia: AIAA,1993. [25] Kyle Charles Markell. Exergy methods for the generic analysis and optimization of hypersonic vehicle concepts[D]. Reston: Virginia Polytechnic Institute and State University,2005. [26] 黄兴. 超燃冲压发动机特性计算与一体化设计技术研究[D]. 西安: 西北工业大学,2014. HUANG Xing. The characteristic simulation of scramjet and the integration design research[D]. Xi’an: Northwestern Polytechnical University,2014. (in ChineseHUANG Xing. The characteristic simulation of scramjet and the integration design research[D]. Xi’an: Northwestern Polytechnical University, 2014. (in Chinese) [27] Tokudome S,Kobayashi K. Experimental study on rocket-ejector systems: AIAA 2006-7977 [R]. Reston,Virigina: AIAA,2006. [28] 吕翔,郑思行,何国强,等. 火箭引射模态下主火箭总压与RBCC发动机的匹配性[J]. 固体火箭技术,2015,38(2): 179-184,197. LV Xiang,ZHENG Sihang,HE Guoqiang,et al. Operation match between primary rocket and RBCC engine during rocket ejector mode[J]. Journal of Solid Rocket Technology,2015,38(2): 179-184,197. (in ChineseLV Xiang, ZHENG Sihang, HE Guoqiang, et al. Operation match between primary rocket and RBCC engine during rocket ejector mode[J]. Journal of Solid Rocket Technology, 2015, 38(2): 179-184, 197. (in Chinese) [29] HOLLINGSWORTH P,DE BAETS,IGNACIO E,et al. Peregrine hypersonic strike fighter weapons system[R]. Reston: The 1999/2000 AIAA Foundation Graduate Team Aircraft Design Competition,2000. [30] SMART M. Scramjets[J]. The Aeronautical Journal,2007,111(1124): 605-619. doi: 10.1017/S0001924000004796 [31] 秦云鹏,杨旸,郑思行,等. 地面辅助发射RBCC动力单级入轨飞行器参数敏感性分析[J]. 火箭推进,2022,48(6): 9-16. QIN Yunpeng,YANG Yang,ZHENG Sihang,et al. Parameter sensitivity analysis of RBCC powered SSTO vehicle with an auxiliary launch system[J]. Journal of Rocket Propulsion,2022,48(6): 9-16. (in Chinese doi: 10.3969/j.issn.1672-9374.2022.06.002QIN Yunpeng, YANG Yang, ZHENG Sihang, et al. Parameter sensitivity analysis of RBCC powered SSTO vehicle with an auxiliary launch system[J]. Journal of Rocket Propulsion, 2022, 48(6): 9-16. (in Chinese) doi: 10.3969/j.issn.1672-9374.2022.06.002 [32] OLDS J,BELLINI P. Argus,a highly reusable SSTO rocket-based combined cycle launch vehicle with Maglifter launch assist: AIAA 1998-1557 [R]. Reston,Virigina: AIAA,1998. [33] YOUNG D,KOKAN T,TANNER C,et al. Lazarus: a SSTO hypersonic vehicle concept utilizing RBCC and HEDM propulsion technologies: AIAA 2006-8099[R]. Reston,Virigina: AIAA,2006. [34] TREFNY C,ROCHE J M. Performance validation approach for the GTX air-breathing launch vehicle[R]. Houston: NASA Reference Publication,2002. [35] 杜文豪,邓新宇,马英,等. RBCC单级入轨运载器总体方案设计[J]. 战术导弹技术,2019(6): 60-66. DU Wenhao,DENG Xinyu,MA Ying,et al. System design for single-stage-to-orbit launch vehicle utilizing RBCC propulsion[J]. Tactical Missile Technology,2019(6): 60-66. (in ChineseDU Wenhao, DENG Xinyu, MA Ying, et al. System design for single-stage-to-orbit launch vehicle utilizing RBCC propulsion[J]. Tactical Missile Technology, 2019(6): 60-66. (in Chinese) -

下载:

下载: