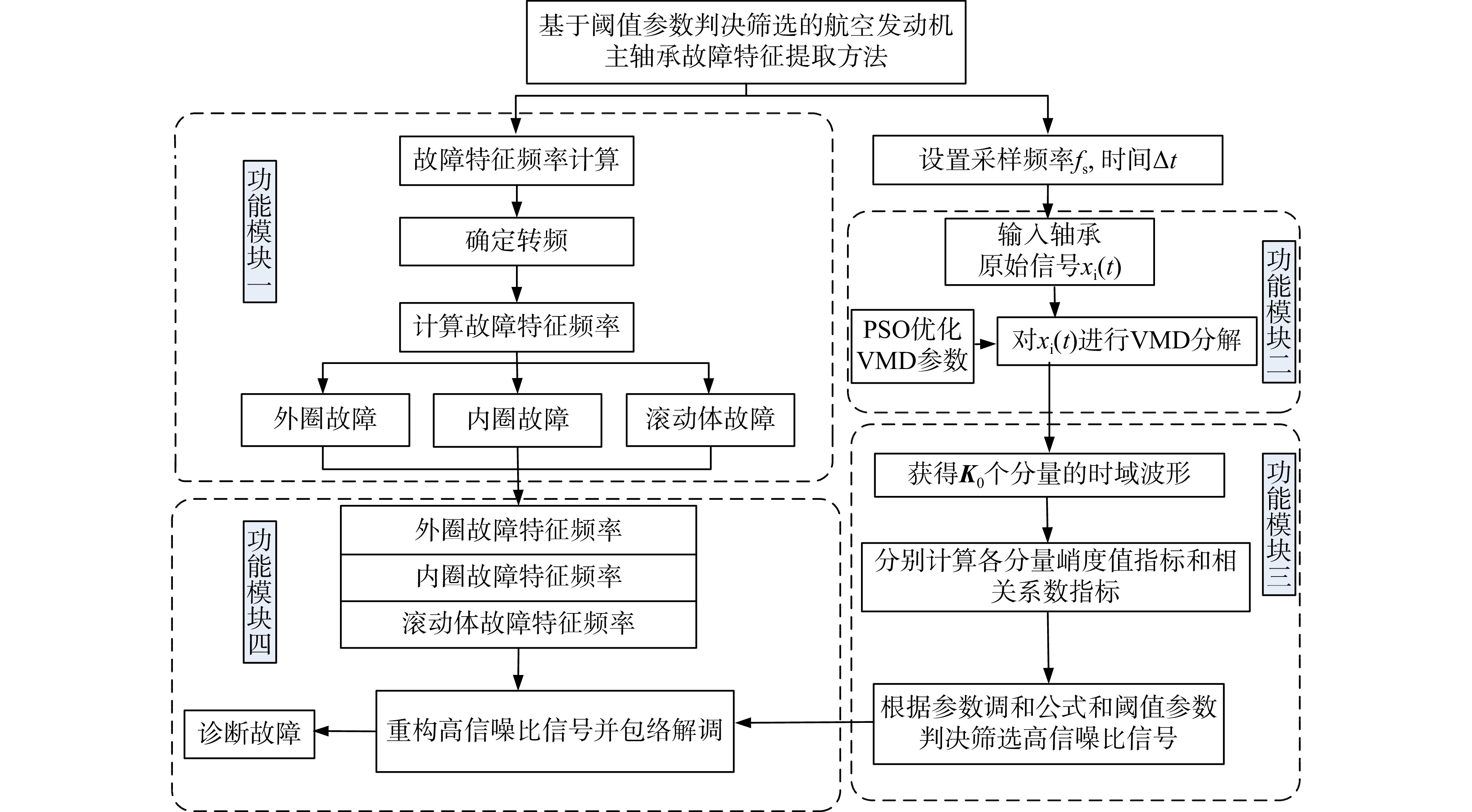

Aircraft engine main bearing fault feature extraction method based on threshold parameter decision screening

-

摘要:

针对航空发动机中滚动轴承微弱故障信号受环境噪声影响提取困难的问题,提出一种基于阈值参数判决筛选的航空发动机主轴承故障特征提取方法。为了自适应选择变分模态分解(variational mode decomposition,VMD)中的参数,采用粒子群算法(PSO)对VMD算法中的参数进行优化,将其作为前置参数来处理传感器收集到的轴承原始振动信号,得到

K 0个模态分量;其次提出一种新的参数调和公式,该公式将峭度和相关系数平衡融合为一个参数P ,然后基于阈值参数准则划分筛选出高信噪比信号,整合高信噪比信号产生新的振动信号;最后通过包络谱提取出轴承微弱故障特征。结果表明:参数调和公式与阈值参数判决方法能平衡峭度和相关系数之间的关系,滤除了峭度值较高但有效信息少的分量,该方法可有效提取滚动轴承简单及复杂传递路径下的故障特征,为航空发动机主轴承故障复杂信号处理和诊断提供了有效手段。Abstract:In view of the difficulty in extracting weak fault signals from rolling bearings in aircraft engines due to the influence of environmental noise, this paper proposes an aircraft engine main bearing fault feature extraction method based on threshold parameter decision screening. To adaptively select the parameters in variational mode decomposition (VMD), the Particle Swarm Optimization (PSO) algorithm is used to optimize the parameters in the VMD algorithm, which are used as pre-parameters to process the raw vibration signals collected by sensors, resulting in K0 modal components. Furthermore, a new parameter harmonization formula is proposed. This formula balances kurtosis and correlation coefficient and combines them into a single parameter P. Then, based on threshold parameter criteria, high signal-to-noise ratio signals are selected and integrated to generate new vibration signals. Finally, weak fault features of the bearing are extracted using envelope spectrum analysis. The results show that Parameter harmonic formula and threshold parameter decision method can balance the relationship between kurtosis and correlation coefficient, and filter out the components with higher kurtosis value but less effective information, the method can effectively extract fault features of rolling bearings in both simple and complex transmission paths, providing an effective means for complex signal processing and diagnosis of main bearing faults of aircraft engines.

-

Key words:

- rolling bearings /

- VMD /

- parameter harmonization formula /

- threshold parameter /

- fault diagnosing /

- aircraft engine

-

表 1 高/低信噪比信号划分

Table 1. High/low SNR signal division

参数对比 高/低信噪比信号划分 P≥M 高信噪比信号 P<M 低信噪比信号 表 2 试验轴承参数

Table 2. Experimental bearing parameter

滚动体个数

Zr/个滚动体节径

Dr/mm滚动体直径

dr/mm接触角

α/(°)11 33.5 7 0 表 3 各分量参数

Table 3. Parameters of each component

IMF P M 1 0.501 1.123 2 0.439 3 0.487 4 0.568 5 3.000 表 4 试验轴承参数

Table 4. Test bearing parameter

类型 滚动体

个数/个外圈直径/

mm内圈直径/

mm接触角/

/(°)滚动体直径/

mm滚棒轴承 34 140 110 0 8 表 5 滚动体故障各分量参数

Table 5. Parameters of rolling element fault components

IMF P M 1 2.102 1.405 2 2.188 3 0.953 4 1.23 5 1.415 6 1.187 7 1.641 -

[1] 尉询楷,冯悦,杨立等. 航空发动机中介主轴承故障预测研究[C]//中国航空学会航空维修工程专业委员会,国防工业出版社,空军安全局,空军装备部外场部,空军工程大学装备管理与安全工程学院. 航空安全与装备维修技术——航空安全与装备维修技术学术研讨会论文集. 北京航空工程技术研究中心,2014: 10. WEI Xunkai,FENG Yue,YANG Li et al. Research on Fault Prediction of Aero-engine Medium Main Bearing [C]// Aviation Maintenance Engineering Committee of China Aeronautical Society,National Defense Industry Press,Air Force Security Bureau,External Field Department of Air Force Equipment Department,Air Force Engineering University Equipment Management and Safety Engineering College. Aviation Safety and Equipment Maintenance Technology - Proceedings of the Symposium on Aviation Safety and Equipment Maintenance Technology. Beijing Aeronautical Engineering Technology Research Center; The 2014-10. (in ChineseWEI Xunkai, FENG Yue, YANG Li et al. Research on Fault Prediction of Aero-engine Medium Main Bearing [C]// Aviation Maintenance Engineering Committee of China Aeronautical Society, National Defense Industry Press, Air Force Security Bureau, External Field Department of Air Force Equipment Department, Air Force Engineering University Equipment Management and Safety Engineering College. Aviation Safety and Equipment Maintenance Technology - Proceedings of the Symposium on Aviation Safety and Equipment Maintenance Technology. Beijing Aeronautical Engineering Technology Research Center; The 2014-10. (in Chinese) [2] 贾艳秋,张兵,陈雪梅. 滚动轴承的故障机理及诊断[J]. 化工装备技术,2011,32(4): 55-57. JIA Yanqiu,ZHANG Bing,CHEN Xuemei. Malfunction mechanism and diagnosis of rolling bearing[J]. Chemical Equipment Technology,2011,32(4): 55-57. (in Chinese doi: 10.3969/j.issn.1007-7251.2011.04.015JIA Yanqiu, ZHANG Bing, CHEN Xuemei. Malfunction mechanism and diagnosis of rolling bearing[J]. Chemical Equipment Technology, 2011, 32(4): 55-57. (in Chinese) doi: 10.3969/j.issn.1007-7251.2011.04.015 [3] OH J W,PARK D,JEONG J. Fault detection for lubricant bearing with CNN[C]//2019 2nd International Conference on Intelligent Autonomous Systems. Piscataway,US: IEEE,2019: 142-145. [4] 杜小磊,陈志刚,王衍学. 基于同步挤压S变换和集成深层脊波自编码器的轴承故障诊断[J]. 振动与冲击,2020,39(14): 59-68. DU Xiaolei,CHEN Zhigang,WANG Yanxue. Bearing fault diagnosis based on the synchrosqueezed S transform and ensemble deep ridgelet auto-encoder[J]. Journal of Vibration and Shock,2020,39(14): 59-68. (in ChineseDU Xiaolei, CHEN Zhigang, WANG Yanxue. Bearing fault diagnosis based on the synchrosqueezed S transform and ensemble deep ridgelet auto-encoder[J]. Journal of Vibration and Shock, 2020, 39(14): 59-68. (in Chinese) [5] 刘敏,范红波,张英堂,等. 机械振动信号自适应多尺度非线性动力学特征提取方法研究[J]. 振动与冲击,2020,39(14): 224-232,250. LIU Min,FAN Hongbo,ZHANG Yingtang,et al. Adaptive multi-scale method for the non-linear dynamic feature extraction of mechanical vibration signals[J]. Journal of Vibration and Shock,2020,39(14): 224-232,250. (in ChineseLIU Min, FAN Hongbo, ZHANG Yingtang, et al. Adaptive multi-scale method for the non-linear dynamic feature extraction of mechanical vibration signals[J]. Journal of Vibration and Shock, 2020, 39(14): 224-232, 250. (in Chinese) [6] 栾孝驰,沙云东,柳贡民,等. 基于WPD-KVI-Hilbert变换相结合的滚动轴承早期故障特征精准识别[J]. 推进技术,2022,43(2): 362-373. LUAN Xiaochi,SHA Yundong,LIU Gongmin,et al. Accurate identification for early fault features of rolling bearings based on WPD-KVI-hilbert transform[J]. Journal of Propulsion Technology,2022,43(2): 362-373. (in ChineseLUAN Xiaochi, SHA Yundong, LIU Gongmin, et al. Accurate identification for early fault features of rolling bearings based on WPD-KVI-hilbert transform[J]. Journal of Propulsion Technology, 2022, 43(2): 362-373. (in Chinese) [7] 沙云东,赵宇,栾孝驰等. 基于多参数信息融合筛选的滚动轴承振动信号特征提取与表征方法[J]. 推进技术,2023,44(7): 243-253. Sha Yundong,Zhao Yu,Luan Xiaochi et al. Feature Extraction and Characterization Method of Rolling Bearing Vibration Signal Based on Multi-parameter Information Fusion Screening[J]. Journal of Advanced Technology,2023,44(7): 243-253. (in ChineseSha Yundong, Zhao Yu, Luan Xiaochi et al. Feature Extraction and Characterization Method of Rolling Bearing Vibration Signal Based on Multi-parameter Information Fusion Screening[J]. Journal of Advanced Technology, 2023, 44(7): 243-253. (in Chinese) [8] HUANG N E,SHEN Zheng,LONG S R,et al. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis[J]. Proceedings of the Royal Society of London Series A: Mathematical,Physical and Engineering Sciences,1998,454(1971): 903-995. [9] SMITH J S. The local mean decomposition and its application to EEG perception data[J]. Journal of the Royal Society,Interface,2005,2(5): 443-454. doi: 10.1098/rsif.2005.0058 [10] DRAGOMIRETSKIY K,ZOSSO D. Variational mode decomposition[J]. IEEE Transactions on Signal Processing,2014,62(3): 531-544. doi: 10.1109/TSP.2013.2288675 [11] CHEN Qiming,LANG Xun,XIE Lei,et al. Detecting nonlinear oscillations in process control loop based on an improved VMD[J]. IEEE Access,1950,7: 91446-91462. [12] 刘尚坤,唐贵基,王晓龙. 基于改进变分模态分解的旋转机械故障时频分析方法[J]. 振动工程学报,2016,29(6): 1119-1126. LIU Shangkun,TANG Guiji,WANG Xiaolong. Time frequency analysis method for rotary mechanical fault based on improved variational mode decomposition[J]. Journal of Vibration Engineering,2016,29(6): 1119-1126. (in ChineseLIU Shangkun, TANG Guiji, WANG Xiaolong. Time frequency analysis method for rotary mechanical fault based on improved variational mode decomposition[J]. Journal of Vibration Engineering, 2016, 29(6): 1119-1126. (in Chinese) [13] MCDONALD G L,ZHAO Qing,ZUO M J. Maximum correlated Kurtosis deconvolution and application on gear tooth chip fault detection[J]. Mechanical Systems and Signal Processing,2012,33: 237-255. doi: 10.1016/j.ymssp.2012.06.010 [14] 郑义,岳建海,焦静,等. 基于参数优化变分模态分解的滚动轴承故障特征提取方法[J]. 振动与冲击,2021,40(1): 86-94. ZHENG Yi,YUE Jianhai,JIAO Jing,et al. Fault feature extraction method of rolling bearing based on parameter optimized VMD[J]. Journal of Vibration and Shock,2021,40(1): 86-94. (in ChineseZHENG Yi, YUE Jianhai, JIAO Jing, et al. Fault feature extraction method of rolling bearing based on parameter optimized VMD[J]. Journal of Vibration and Shock, 2021, 40(1): 86-94. (in Chinese) [15] 姚成玉,来博文,陈东宁,等. 基于最小熵解卷积-变分模态分解和优化支持向量机的滚动轴承故障诊断方法[J]. 中国机械工程,2017,28(24): 3001-3012. YAO Chengyu,LAI Bowen,CHEN Dongning,et al. Fault diagnosis method based on MED-VMD and optimized SVM for rolling bearings[J]. China Mechanical Engineering,2017,28(24): 3001-3012. (in Chinese doi: 10.3969/j.issn.1004-132X.2017.24.017YAO Chengyu, LAI Bowen, CHEN Dongning, et al. Fault diagnosis method based on MED-VMD and optimized SVM for rolling bearings[J]. China Mechanical Engineering, 2017, 28(24): 3001-3012. (in Chinese) doi: 10.3969/j.issn.1004-132X.2017.24.017 [16] 王朝阁,李宏坤,胡少梁,等. 利用参数自适应多点最优最小熵反褶积的行星轮轴承微弱故障特征提取[J]. 振动工程学报,2021,34(3): 633-645. WANG Chaoge,LI Hongkun,HU Shaoliang,et al. Weak fault feature extraction of planetary bearing based on parameter adaptive MOMEDA[J]. Journal of Vibration Engineering,2021,34(3): 633-645. (in ChineseWANG Chaoge, LI Hongkun, HU Shaoliang, et al. Weak fault feature extraction of planetary bearing based on parameter adaptive MOMEDA[J]. Journal of Vibration Engineering, 2021, 34(3): 633-645. (in Chinese) [17] 夏俊,贾民平. 基于共振稀疏分解和松鼠优化算法的滚动轴承故障诊断[J]. 振动与冲击,2021,40(4): 250-254. XIA Jun,JIA Minping. Rolling bearing fault diagnosis with a resonance-based sparse decomposition and squirrel optimization algorithm[J]. Journal of Vibration and Shock,2021,40(4): 250-254. (in ChineseXIA Jun, JIA Minping. Rolling bearing fault diagnosis with a resonance-based sparse decomposition and squirrel optimization algorithm[J]. Journal of Vibration and Shock, 2021, 40(4): 250-254. (in Chinese) [18] HUANG Yan,LIN Jianhui,LIU Zechao,et al. A modified scale-space guiding variational mode decomposition for high-speed railway bearing fault diagnosis[J]. Journal of Sound Vibration,2019,444: 216-234. doi: 10.1016/j.jsv.2018.12.033 [19] 李可,牛园园,宿磊,等. 参数优化VMD的滚动轴承故障诊断方法[J]. 振动工程学报,2023,36(1): 280-287. LI Ke,NIU Yuanyuan,SU Lei,et al. Rolling bearing fault diagnosis method based on parameter optimized VMD[J]. Journal of Vibration Engineering,2023,36(1): 280-287. (in ChineseLI Ke, NIU Yuanyuan, SU Lei, et al. Rolling bearing fault diagnosis method based on parameter optimized VMD[J]. Journal of Vibration Engineering, 2023, 36(1): 280-287. (in Chinese) [20] LI Hua,LIU Tao,WU Xing,et al. An optimized VMD method and its applications in bearing fault diagnosis[J]. Measurement,2020,166: 108185. doi: 10.1016/j.measurement.2020.108185 [21] 张俊,张建群,钟敏,等. 基于PSO-VMD-MCKD方法的风机轴承微弱故障诊断[J]. 振动 测试与诊断,2020,40(2): 287-296,418. ZHANG Jun,ZHANG Jianqun,ZHONG Min,et al. PSO-VMD-MCKD based fault diagnosis for incipient damage in wind turbine rolling bearing[J]. Journal of Vibration,Measurement & Diagnosis,2020,40(2): 287-296,418. (in ChineseZHANG Jun, ZHANG Jianqun, ZHONG Min, et al. PSO-VMD-MCKD based fault diagnosis for incipient damage in wind turbine rolling bearing[J]. Journal of Vibration, Measurement & Diagnosis, 2020, 40(2): 287-296, 418. (in Chinese) [22] 张仲海. 基于随机共振的滚动轴承微弱特征检测技术应用研究[D]. 天津: 天津大学,2012. ZHANG Zhonghai. Research on weak signal detection of rolling bearings based on stochastic resonance[D]. Tianjin: Tianjin University,2012. (in ChineseZHANG Zhonghai. Research on weak signal detection of rolling bearings based on stochastic resonance[D]. Tianjin: Tianjin University, 2012. (in Chinese) [23] 李永琪,彭珍瑞. 参数优化VMD和SVM的滚动轴承故障诊断[J]. 机械科学与技术,2022,41(10): 1509-1514. LI Yongqi,PENG Zhenrui. Rolling bearing fault diagnosis with parameters optimized VMD and SVM[J]. Mechanical Science and Technology for Aerospace Engineering,2022,41(10): 1509-1514. (in ChineseLI Yongqi, PENG Zhenrui. Rolling bearing fault diagnosis with parameters optimized VMD and SVM[J]. Mechanical Science and Technology for Aerospace Engineering, 2022, 41(10): 1509-1514. (in Chinese) -

下载:

下载: