Review of composite-steel hybrid gear:application technology and future directions

-

摘要:

综述了复合材料-钢混合齿轮应用技术研究现状。简述开展复合材料-钢混合齿轮应用技术研究的军事需求以及对于提高直升机传动系统功率密度的重要研究意义;从齿轮辐板用复合材料力学性能表征、混合齿轮结构强度分析、构型设计、制备工艺和试验验证五个方面,详细阐述国外复合材料-钢混合齿轮应用技术研究现状和发展趋势;通过对国外复合材料-钢混合齿轮应用技术研究现状进行总结,论述我国在复合材料-钢混合齿轮应用技术研究方面的不足之处,从材料力学性能表征、强度分析技术、构型设计及优化、制备工艺及试验验证四个方面,全面展望我国在复合材料-钢混合齿轮应用技术研究方面亟需开展的研究方向。

Abstract:The research status of composite-steel hybrid gears is reviewed. First of all, this paper briefly describes the military requirements for the research of composite-steel hybrid gears and the important research significance for improving the power density of helicopter transmission system. Secondly, the research status and development trends of composite-steel hybrid gears are described in detail from five aspects: mechanical properties characterization of composite materials for gear spokes, structural strength analysis of hybrid gears, configuration design, manufacturing and experimental verification technology. Finally, the research status of composite-steel hybrid gear application technology is summarized. The shortcomings of the application technology of composite-steel hybrid gears in China and the future directions that need to be carried out urgently are pointed out.

-

Key words:

- hybrid gear /

- composite material /

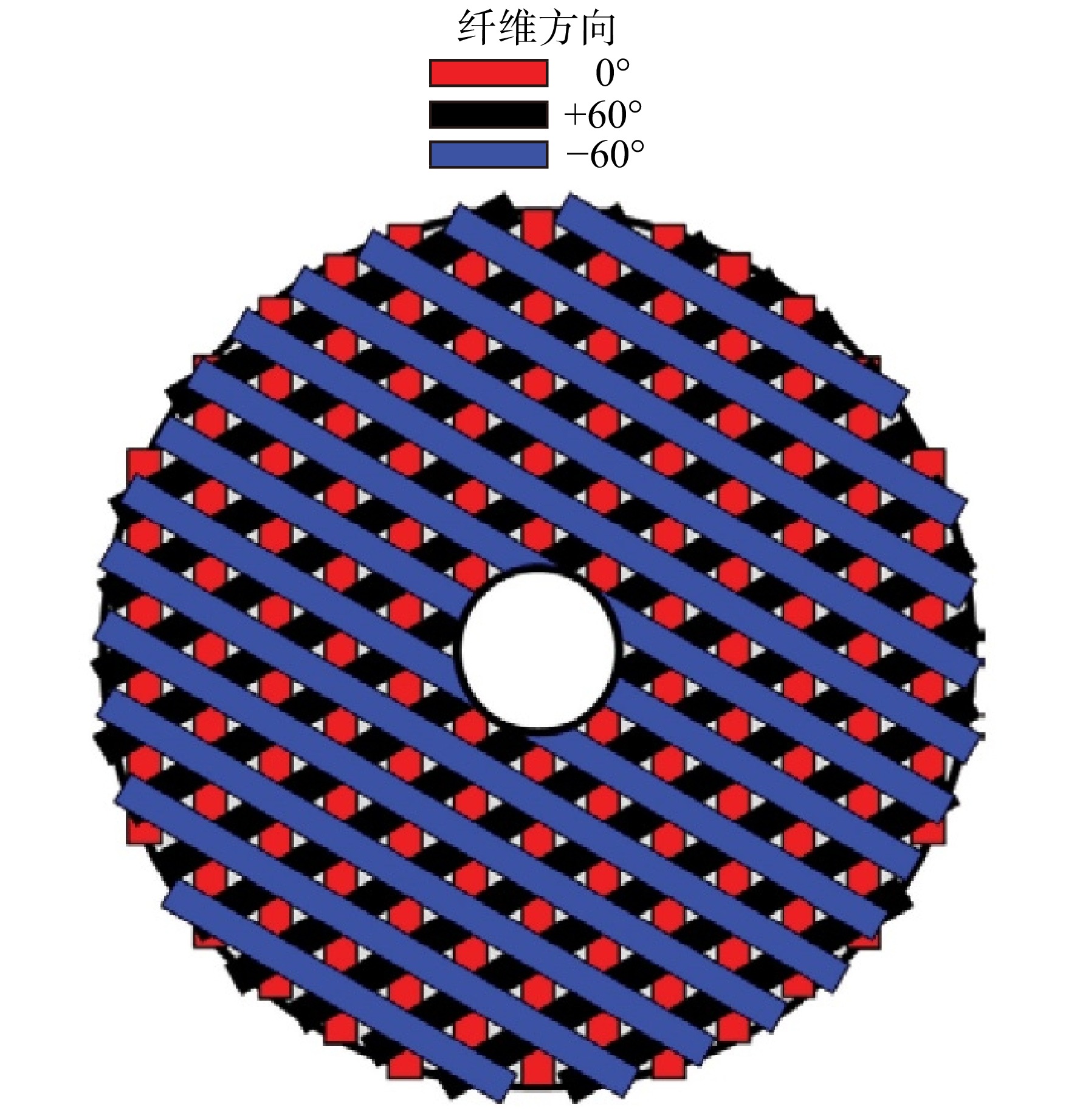

- helicopter transmission /

- strength analysis /

- configuration design

-

-

[1] 符长青,符晓勤,马宇平. 旋翼飞行器动力装置[M]. 北京: 清华大学出版社,2017. FU Changqing,FU Xiaoqin,MA Yuping. Rotorcraft power plant[M]. Beijing: Tsinghua University Press,2017. (in ChineseFU Changqing, FU Xiaoqin, MA Yuping. Rotorcraft power plant[M]. Beijing: Tsinghua University Press, 2017. (in Chinese) [2] 倪德,朱如鹏,陆凤霞,等. 考虑空间机动飞行的直升机尾传动轴建模与临界转速分析[J]. 航空动力学报,2015,30(6): 1520-1528. NI De,ZHU Rupeng,LU Fengxia,et al. Modeling and analysis of critical speed for tail drive shaft of helicopter considering space maneuvering flight[J]. Journal of Aerospace Power,2015,30(6): 1520-1528. (in ChineseNI De, ZHU Rupeng, LU Fengxia, et al. Modeling and analysis of critical speed for tail drive shaft of helicopter considering space maneuvering flight[J]. Journal of Aerospace Power, 2015, 30(6): 1520-1528. (in Chinese) [3] 佘亦曦,康丽霞,唐朋. 直升机传动系统的现状与发展研究[J]. 航空科学技术,2021,32(1): 78-82. SHE Yixi,KANG Lixia,TANG Peng. Development status and future trend of helicopter transmission system[J]. Aeronautical Science & Technology,2021,32(1): 78-82. (in ChineseSHE Yixi, KANG Lixia, TANG Peng. Development status and future trend of helicopter transmission system[J]. Aeronautical Science & Technology, 2021, 32(1): 78-82. (in Chinese) [4] SHOAIB NADEEM S K,GIRIDHARA G,RANGAVITTAL H K. A Review on the design and analysis of composite drive shaft[J]. Materials Today: Proceedings,2018,5(1): 2738-2741. doi: 10.1016/j.matpr.2018.01.058 [5] 常燕,朱涛,孙士祥,等. 复合材料传动轴的应用及技术研究进展[J]. 工程塑料应用,2020,48(7): 154-157. CHANG Yan,ZHU Tao,SUN Shixiang,et al. Application and advance in technology research of composite drive shaft[J]. Engineering Plastics Application,2020,48(7): 154-157. (in Chinese doi: 10.3969/j.issn.1001-3539.2020.07.029CHANG Yan, ZHU Tao, SUN Shixiang, et al. Application and advance in technology research of composite drive shaft[J]. Engineering Plastics Application, 2020, 48(7): 154-157. (in Chinese) doi: 10.3969/j.issn.1001-3539.2020.07.029 [6] Cecil,Timothy,Ehinger,et al. Application and configurationssues of resin transfer molded composite transmission housings: a program overview[C]//Annual Forum Proceedings-American Helicopter Society. Virginia: American Helicopter Society,2007: 1544-1552. [7] LIN S,POSTER S. Development of a braided-composite drive shaft with captured end fittings[C]//60th annual forum of the American Helicopter Society International. Baltimore: American Helicopter Society International,2004: 673-687. [8] HANDSCHUH R F,SINNAMON R,STRINGER D B,et al. Hybrid gear preliminary results-application of composites to dynamic mechanical components[C]//68th American Helicopter Society (AHS) Annual forum and Technology Display. Fort Worth: American Helicopter Society,2012: 72-79. [9] GOLDBERG R K,BLINZLER B J,BINIENDA W K. Investigation of a macromechanical approach to analyzing triaxially-braided polymer composites[J]. AIAA Journal,2011,49(1): 205-215. doi: 10.2514/1.J050675 [10] MASTERS J E,PORTANOVA M A. Standard test methods for textile composites: NASA-CR-4751[R]. Washington,DC: National Aeronautics and Space Administration,1996. [11] FALZON P J,HERSZBERG I. Mechanical performance of 2-D braided carbon/epoxy composites[J]. Composites Science and Technology,1998,58(2): 253-265. doi: 10.1016/S0266-3538(97)00133-4 [12] LITTELL J. The experimental and analytical characterization of the macromechanical response for triaxial braided composite materials[M]. Akron: The University of Akron,2008. [13] 赵振强. 二维三轴编织复合材料的动态力学行为与失效机理[D]. 西安: 西北工业大学,2019. ZHAO Zhenqiang. Dynamic mechanical behavior and failure mechanism of two-dimensional triaxially braided composites[D]. Xi’an: Northwestern Polytechnical University,2019. (in ChineseZHAO Zhenqiang. Dynamic mechanical behavior and failure mechanism of two-dimensional triaxially braided composites[D]. Xi’an: Northwestern Polytechnical University, 2019. (in Chinese) [14] CATERA P G,GAGLIARDI F,MUNDO D,et al. Multi-scale modeling of triaxial braided composites for FE-based modal analysis of hybrid metal-composite gears[J]. Composite Structures,2017,182: 116-123. doi: 10.1016/j.compstruct.2017.09.017 [15] GAUNTT S M,CAMPBELL R L. Characterization of a hybrid (steel-composite) gear with various composite materials and layups[R]. AIAA-2019-0146,2019. [16] WALLER M,KOUDELA K,MCINTYRE S. Design of composite materials for improved loss-of-lubrication survivability of hybrid rotorcraft gears[C]//Proceedings of the 75th Annual VFS Forum. Philadelphia: American Helicopter Society,2019: 3046-3057. [17] WALLER M D,MCINTYRE S M,KOUDELA K L. Composite materials for hybrid aerospace gears[J]. Journal of the American Helicopter Society,2020,65(4): 1-11. [18] CATERA P G,MUNDO D,TREVISO A,et al. On the design and simulation of hybrid metal-composite gears[J]. Applied Composite Materials,2019,26(3): 817-833. doi: 10.1007/s10443-018-9753-6 [19] HANDSCHUH R F,LABERGE K E,DELUCA S,et al. Vibration and operational characteristics of a composite-steel (hybrid) gear[R]. Cleveland: NASA Glenn Research Center,2014. [20] LABERGE K E,JOHNSTON J P,HANDSCHUH R F,et al. Evaluation of a variable thickness hybrid composite bull gear[C]//Annual Forum of the American Helicopter Society. Phoenix: American Helicopter Society,2018: 1778-1784. [21] KARPAT F,YILMAZ T G,DOĞAN O,et al. Stress and mesh stiffness evaluation of bimaterial spur gears[C]//ASME International Mechanical Engineering Congress and Exposition. Salt Lake City: American Society of Mechanical Engineers,2019,59384: V02BT02A025. [22] YıLMAZ TUFAN G,OĞUZ D,FATIH K. A numerical investigation on the hybrid spur gears: stress and dynamic analysis[J]. Proceedings of the Institution of Mechanical Engineers,Part C: Journal of Mechanical Engineering Science,2022,236(1): 354-369. [23] YıLMAZ TUFAN G,GÜLTEKIN K,FATIH K. A numerical analysis of hybrid spur gears with asymmetric teeth: stress and dynamic behavior[J]. Machines,2022,10(11): 1056. doi: 10.3390/machines10111056 [24] LABERGE K E,HANDSCHUH R F,ROBERTS G,et al. Performance investigation of a full-scale hybrid composite bull gear[C]//American Helicopter Society Annual Forum. Florida: American Helicopter Society,2016: 2591-2597. [25] LABERGE K E,BERKEBILE S P,HANDSCHUH R F,et al. Hybrid gear performance under loss-of-lubrication conditions[C]//American Helicopter Society Annual Forum. Fort Worth: American Helicopter Society,2017: 2250-2256. [26] JOHNSTON J P,ROBERTS G D,MILLER S G. A Design Methodology for Optimizing and Integrating Composite Materials in Gear Structures[R]. Washington,DC: NASA Center for Aerospace Information,2019. [27] DARMSTADT P R,ROBUCK M J,MOORE Ⅲ R F,et al. Composites for Advanced Drive Systems,A Systems Analysis-Revolutionary Vertical Lift Technology (RVLT)[R]. Washington,DC: NASA Center for Aerospace Information,2019. [28] ANDERSON C,MORALES G. Composites for Advanced Drive Systems[R]. Washington,DC: NASA Center for Aerospace Information,2019. [29] GAUNTT S,UNIVERSITY P S,CAMPBELL R,et al. Design optimization of a hybrid spur gear[C]//Proceedings of the Vertical Flight Society 75th Annual Forum. Philadelphia: The Vertical Flight Society,2019: 2939-2948. [30] HADKA D,REED P. Borg: an auto-adaptive many-objective evolutionary computing framework[J]. Evolutionary Computation,2013,21(2): 231-259. doi: 10.1162/EVCO_a_00075 [31] GAUNTT S,MCINTYRE S,CAMPBELL R. Static transmission error analysis of a hybrid spur gear drivetrain[C]//Vertical Flight Society’s 76th Annual Forum and Technology Display. Fairfax: Vertical Flight Society,2020: 827-843. [32] GAUNTT S,MCINTYRE S,CAMPBELL R. Design Optimization of a Hybrid Spur Gear Including Tooth Bending Effects[J]. Journal of the American Helicopter Society,2022,67(4): 1-15. [33] ALI R,CATERA PIERVINCENZO G,CRISTIAN C,et al. Numerical and experimental analysis of the transmission error in hybrid metal-composite gears[J]. Composite Structures,2022,298: 116012. doi: 10.1016/j.compstruct.2022.116012 [34] KIM H,KIM C,KIM S,et al. Novel steel and aramid/phenol composite gear for a transmission with optimum design and FEM vibration analysis[J]. International Journal of Automotive Technology,2019,20(4): 749-754. doi: 10.1007/s12239-019-0070-3 [35] SIM E,KIM C,KWAK K S,et al. Optimum interface shape and vibration test for a new transmission helical gear composed of steel and aramid/phenol composite[J]. Journal of Mechanical Science and Technology,2020,34(4): 1629-1634. doi: 10.1007/s12206-020-0325-y [36] FURROW K W. Material property evaluation of braided and braided/woven wing skin blade stiffeners[R]. Washington,DC: NASA contractor report,1996. [37] CATERA P G,MUNDO D,GAGLIARDI F,et al. A comparative analysis of adhesive bonding and interference fitting as joining technologies for hybrid metal-composite gear manufacturing[J]. International Journal on Interactive Design and Manufacturing (IJIDeM),2020,14(2): 535-550. doi: 10.1007/s12008-020-00647-y [38] JOHNSTON J P,ALLEN A R,LABERGE K E,et al. Static torsion testing and modeling of a variable thickness hybrid composite bull gear[R]. Washington DC: NASA Center for Aerospace Information,2019. [39] KOHLMAN L W. Evaluation of test methods for triaxial braid composites and the development of a large multiaxial test frame for validation using braided tube specimens[M]. Akron: The University of Akron,2012. [40] 王旦,林瑶洁,陈蔚芳,等. 一种基于智能复合材料的复合型齿轮: CN113007310A[P]. 2021-06-22. WANG Dan,LIN Yaojie,CHEN Weifang,et al. Composite gear based on intelligent composite material: CN113007310A[P]. 2021-06-22. (in Chinese).WANG Dan, LIN Yaojie, CHEN Weifang, et al. Composite gear based on intelligent composite material: CN113007310A[P]. 2021-06-22. (in Chinese). [41] 王振. 基于接触力学的高分子复合材料齿轮磨损寿命模型及实验研究[D]. 济南: 济南大学,2018. WANG Zhen. Wear mechanical life model and experimental study on polymer composite material based on contact mechanics[D]. Jinan: University of Jinan,2018. (in ChineseWANG Zhen. Wear mechanical life model and experimental study on polymer composite material based on contact mechanics[D]. Jinan: University of Jinan, 2018. (in Chinese) [42] 苗天峰,王砚军,赵中轩,等. 高分子材料齿轮的热力耦合模型及接触界面瞬态温度场数值分析[J]. 机械传动,2019,43(2): 94-99. MIAO Tianfeng,WANG Yanjun,ZHAO Zhongxuan,et al. Thermal-mechanical coupling model of polymer gear and numerical analysis of transient temperature field at its contact interface[J]. Journal of Mechanical Transmission,2019,43(2): 94-99. (in ChineseMIAO Tianfeng, WANG Yanjun, ZHAO Zhongxuan, et al. Thermal-mechanical coupling model of polymer gear and numerical analysis of transient temperature field at its contact interface[J]. Journal of Mechanical Transmission, 2019, 43(2): 94-99. (in Chinese) [43] LU Zehua,LIU Huaiju,ZHU Caichao,et al. Identification of failure modes of a PEEK-steel gear pair under lubrication[J]. International Journal of Fatigue,2019,125: 342-348. doi: 10.1016/j.ijfatigue.2019.04.004 [44] 卢泽华. 塑料齿轮接触疲劳寿命预测与试验研究[D]. 重庆: 重庆大学,2021. LU Zehua. Prediction and experiment of plastic gear contact fatigue life[D]. Chongqing: Chongqing University,2021. (in ChineseLU Zehua. Prediction and experiment of plastic gear contact fatigue life[D]. Chongqing: Chongqing University, 2021. (in Chinese) [45] 汪志鹏,戴宁,雷鹏福. 齿轮轻量化设计[J]. 机械设计与制造工程,2022,51(7): 9-13. WANG Zhipeng,DAI Ning,LEI Pengfu. Lightweight design of gears[J]. Machine Design and Manufacturing Engineering,2022,51(7): 9-13. (in Chinese doi: 10.3969/j.issn.2095-509X.2022.07.002WANG Zhipeng, DAI Ning, LEI Pengfu. Lightweight design of gears[J]. Machine Design and Manufacturing Engineering, 2022, 51(7): 9-13. (in Chinese) doi: 10.3969/j.issn.2095-509X.2022.07.002 [46] 李术龙. PEEK基高温自润滑复合材料的设计制备及其摩擦学性能研究[D]. 济南: 济南大学,2017. LI Shulong. Study on design,preparation and tribological properties of peek based high temperature self-lubrication composites[D]. Jinan: University of Jinan,2017. (in ChineseLI Shulong. Study on design, preparation and tribological properties of peek based high temperature self-lubrication composites[D]. Jinan: University of Jinan, 2017. (in Chinese) [47] 常亮亮. 三维编织复合材料直齿圆柱齿轮的动力学分析[D]. 西安: 西安理工大学,2021. CHANG Liangliang. Dynamic anaysis of three-dimensional braided composite spur gear[D]. Xi’an: Xi’an University of Technology,2021. (in ChineseCHANG Liangliang. Dynamic anaysis of three-dimensional braided composite spur gear[D]. Xi’an: Xi’an University of Technology, 2021. (in Chinese) [48] 刘峰峰,王旭鹏,刘舒伟,等. 复合材料齿轮的接触和弯曲应力分析[J]. 机械科学与技术,2022,41(5): 681-687. LIU Fengfeng,WANG Xupeng,LIU Shuwei,et al. Contact and bending stress analysis of composite gear[J]. Mechanical Science and Technology for Aerospace Engineering,2022,41(5): 681-687. (in ChineseLIU Fengfeng, WANG Xupeng, LIU Shuwei, et al. Contact and bending stress analysis of composite gear[J]. Mechanical Science and Technology for Aerospace Engineering, 2022, 41(5): 681-687. (in Chinese) [49] 刘舒伟,王旭鹏,刘峰峰,等. 2.5D编织复合材料齿轮性能仿真分析[J]. 重庆理工大学学报(自然科学),2023,37(1): 337-344. LIU Shuwei,WANG Xupeng,LIU Fengfeng,et al. Performance simulation analysis of 2.5D braided composite gears[J]. Journal of Chongqing University of Technology (Natural Science),2023,37(1): 337-344. (in ChineseLIU Shuwei, WANG Xupeng, LIU Fengfeng, et al. Performance simulation analysis of 2.5D braided composite gears[J]. Journal of Chongqing University of Technology (Natural Science), 2023, 37(1): 337-344. (in Chinese) -

下载:

下载: