Robust optimization in aero-engine design considering uncertainty of high-pressure turbine performance

-

摘要:

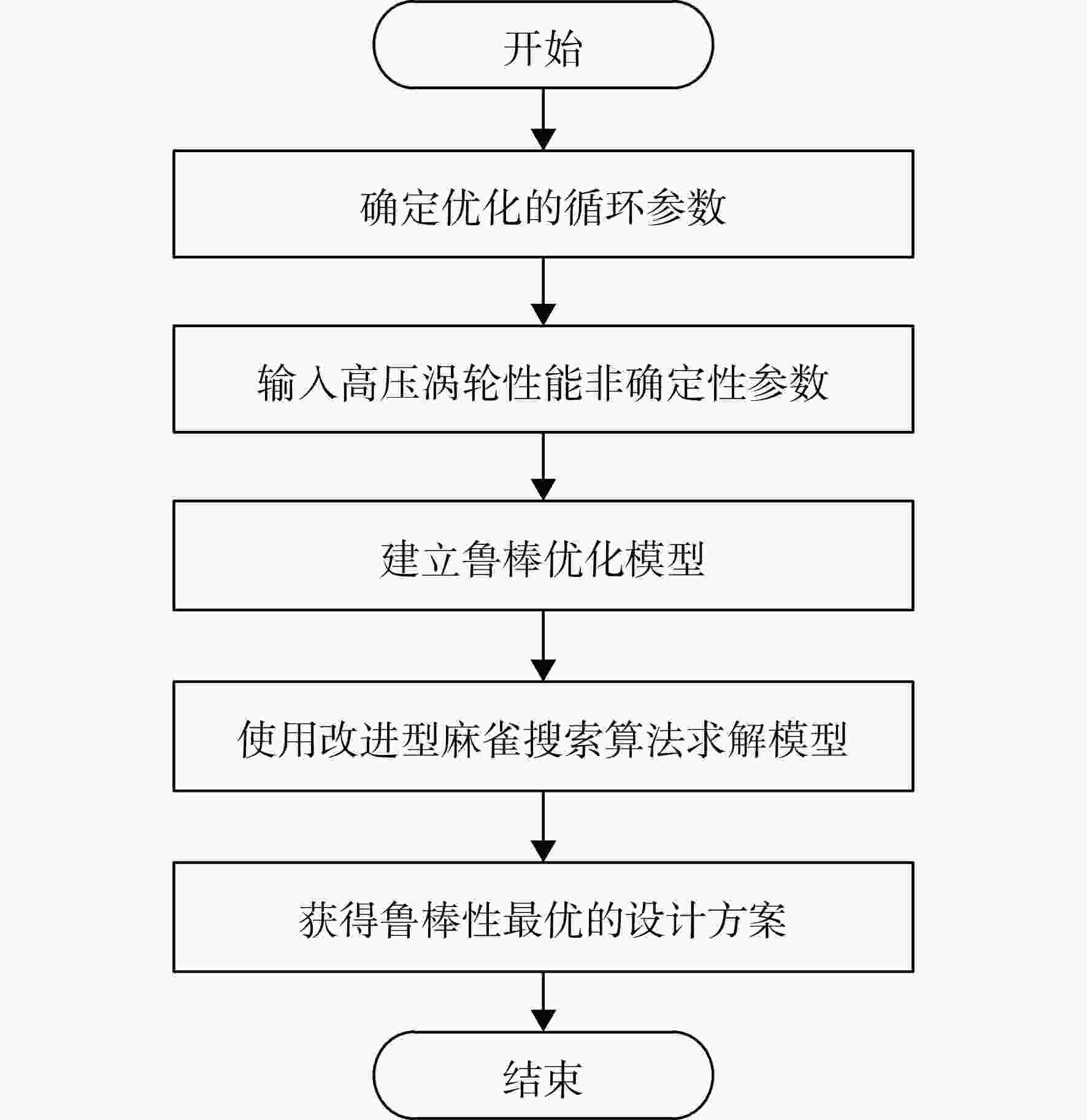

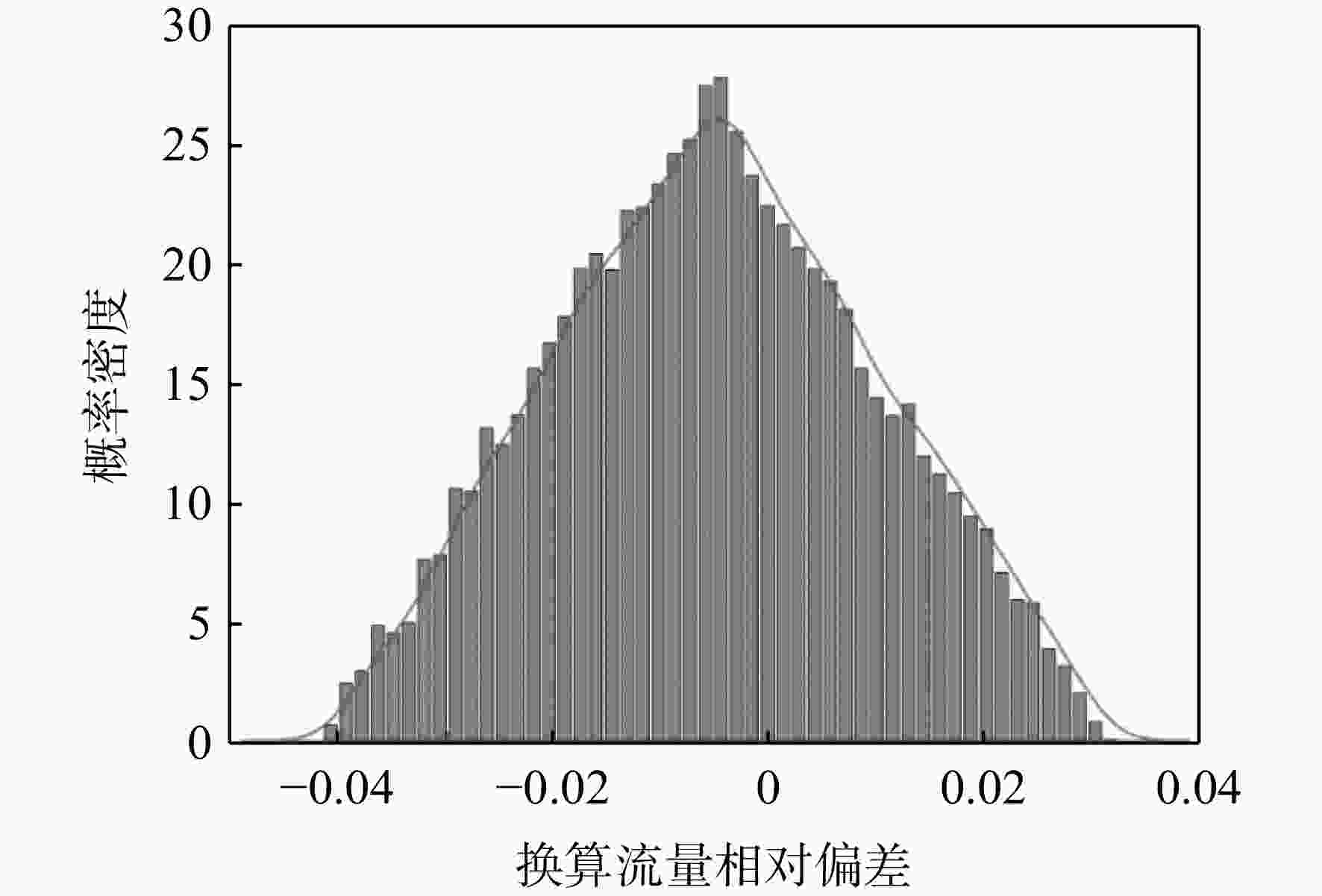

为了降低制造过程中非确定性因素对航空发动机总体性能的影响,通过在设计阶段考虑高压涡轮性能的非确定性,构建鲁棒优化设计模型来优化总体性能的设计方案,使用蒙特卡洛仿真量化非确定性的影响,并开发了相应的全局优化算法进行求解。数值实验的结果验证了鲁棒设计模型的优势,与传统确定性设计方法相比,在高压涡轮性能非确定的情况下,鲁棒设计模型获得的方案能平均减少15.97%的总体性能离散程度,具有较优鲁棒性。

Abstract:In order to reduce the impact of uncertain factors in manufacturing on the overall performance of aero-engines, a robust design model was constructed by considering the uncertainty of high-pressure turbine performance in the design stage. Monte Carlo simulation was used in this model to quantify the effect of uncertainty. A global optimization algorithm was developed to solve the robust design model. Numerical results validated the advantages of the robust design model. Its optimal solution can reduce the variability of the engine performance by an average of 15.97%, which showed better robustness in uncertain environment than the solution obtained by generic deterministic design method.

-

Key words:

- engine performance /

- uncertainty /

- robust design /

- Monte Carlo simulation /

- optimization

-

表 1 循环参数设计范围

Table 1. Value range of design parameters

循环参数 下界 上界 $ {\pi }_{\mathrm{O}\mathrm{F}} $ 1 2 $ {\pi }_{\mathrm{H}\mathrm{C}} $ 16 24 $ {T}_{4}/\mathrm{K} $ 1600 2000 $ B $ 6 12 $ {W}_{02}/ (\mathrm{k}\mathrm{g}/\mathrm{s}) $ 150 400 表 2 各典型工况的输入参数与约束

Table 2. Input parameters and constraints for typical working conditions

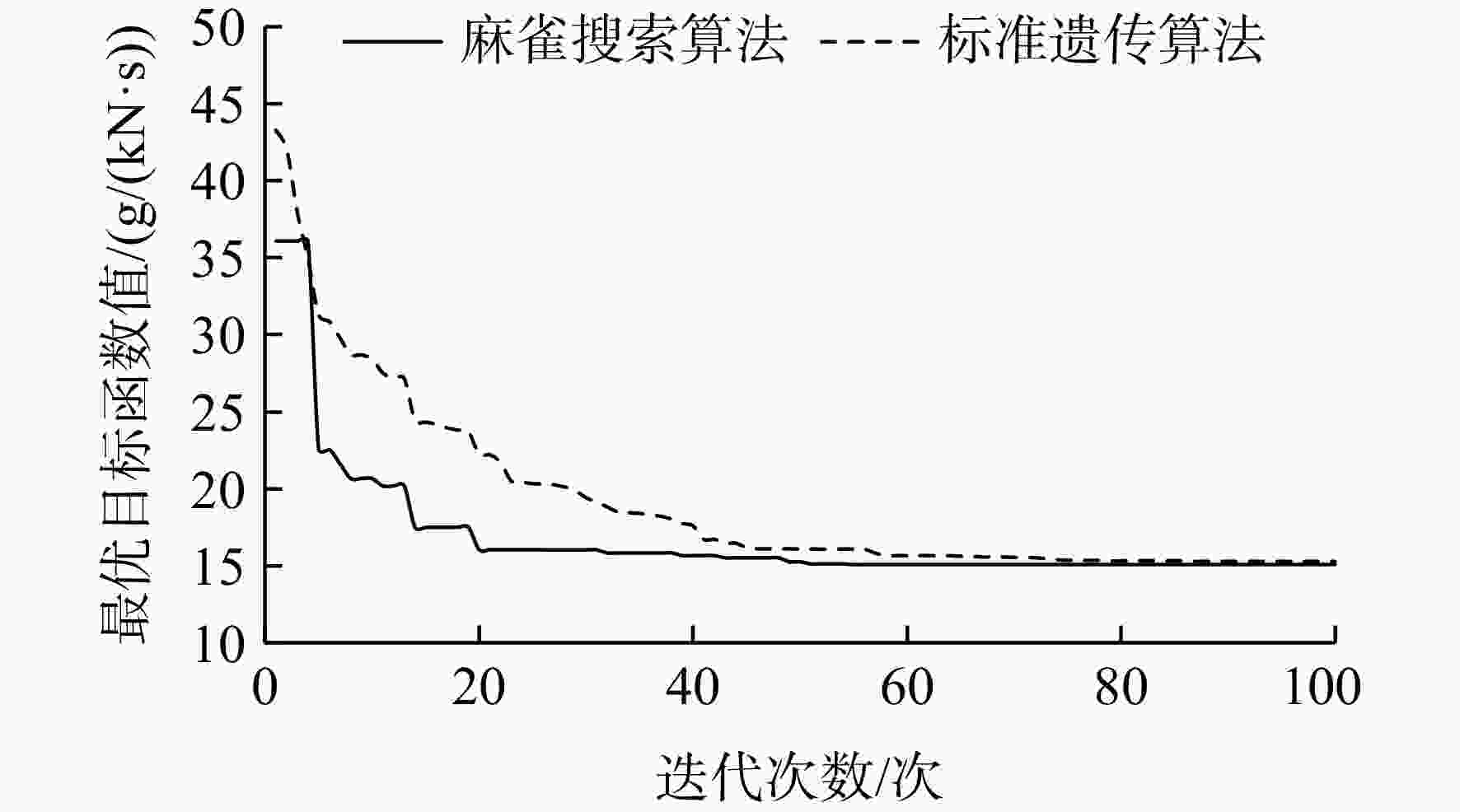

参数 典型工况 经济巡航 高温起飞 最大爬升 高度/m 10668 0 10668 温度/K 0.785 0 0.785 马赫数 0 15 10 相对湿度/% 0 0 0 功率提取/kW 118.49 121.92 103.28 推力要求/kN ≥22.3636 ≥133.3584 ≥27.734 耗油率权重 0.62 0.04 0.34 表 3 改进麻雀搜索算法参数设置

Table 3. Parameters of the proposed algorithm

算法参数 取值 麻雀数量 50 最大迭代次数 100 发现者占比 0.4 预警者占比 0.2 预警值 0.55 $ {w}_{i} $取值范围 1~3 表 4 优化得到的最优设计方案

Table 4. Optimal design results obtained by the algorithm

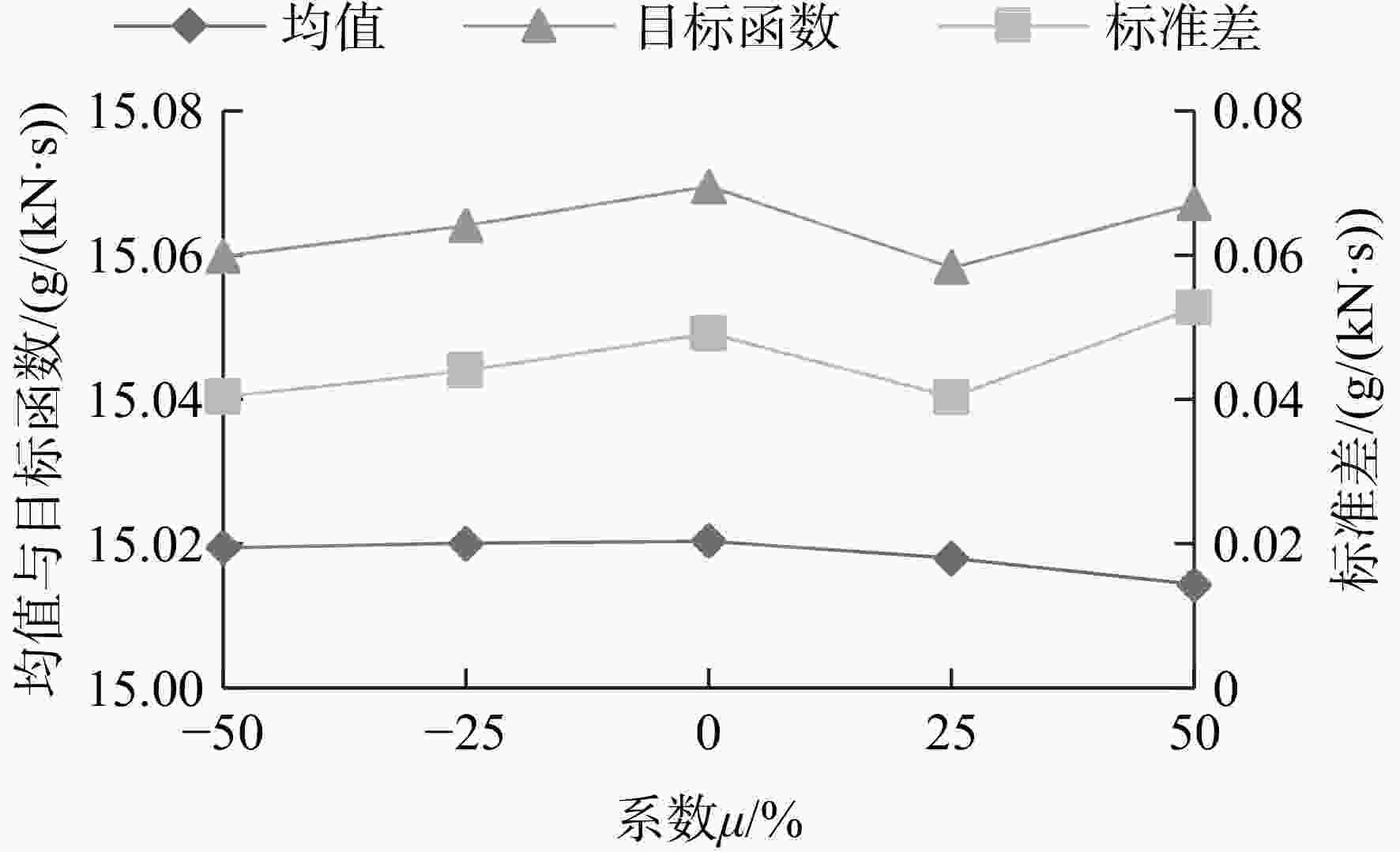

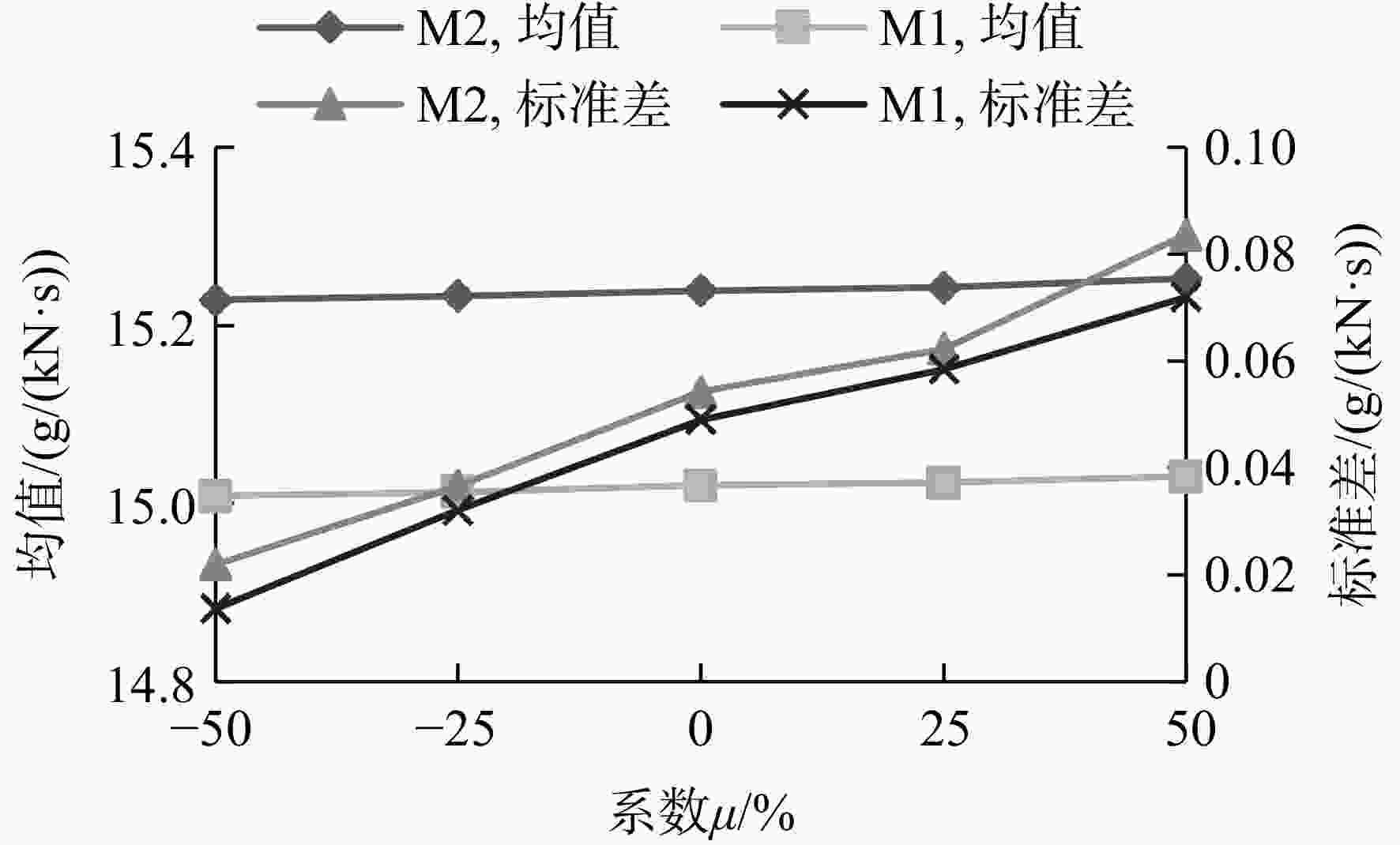

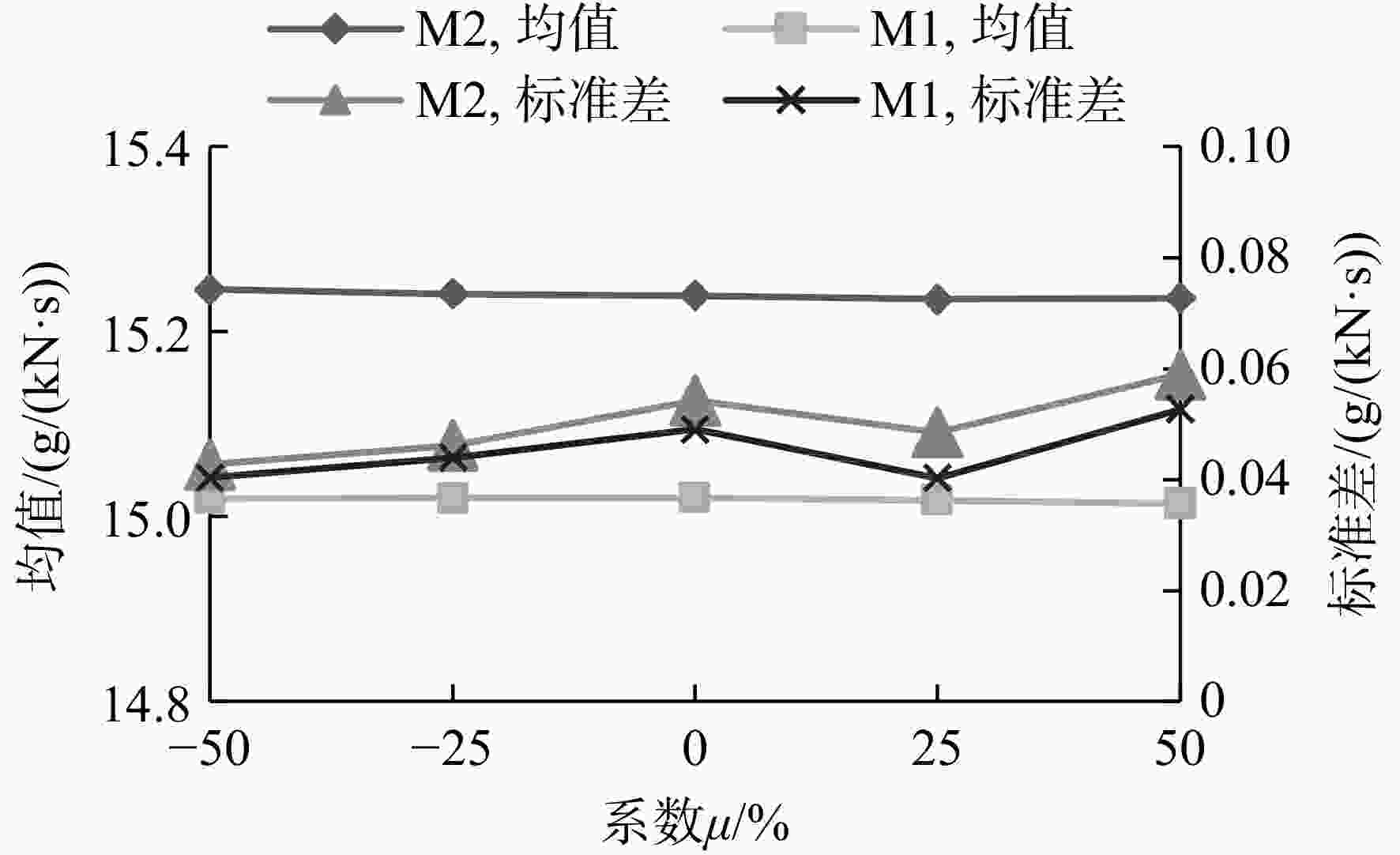

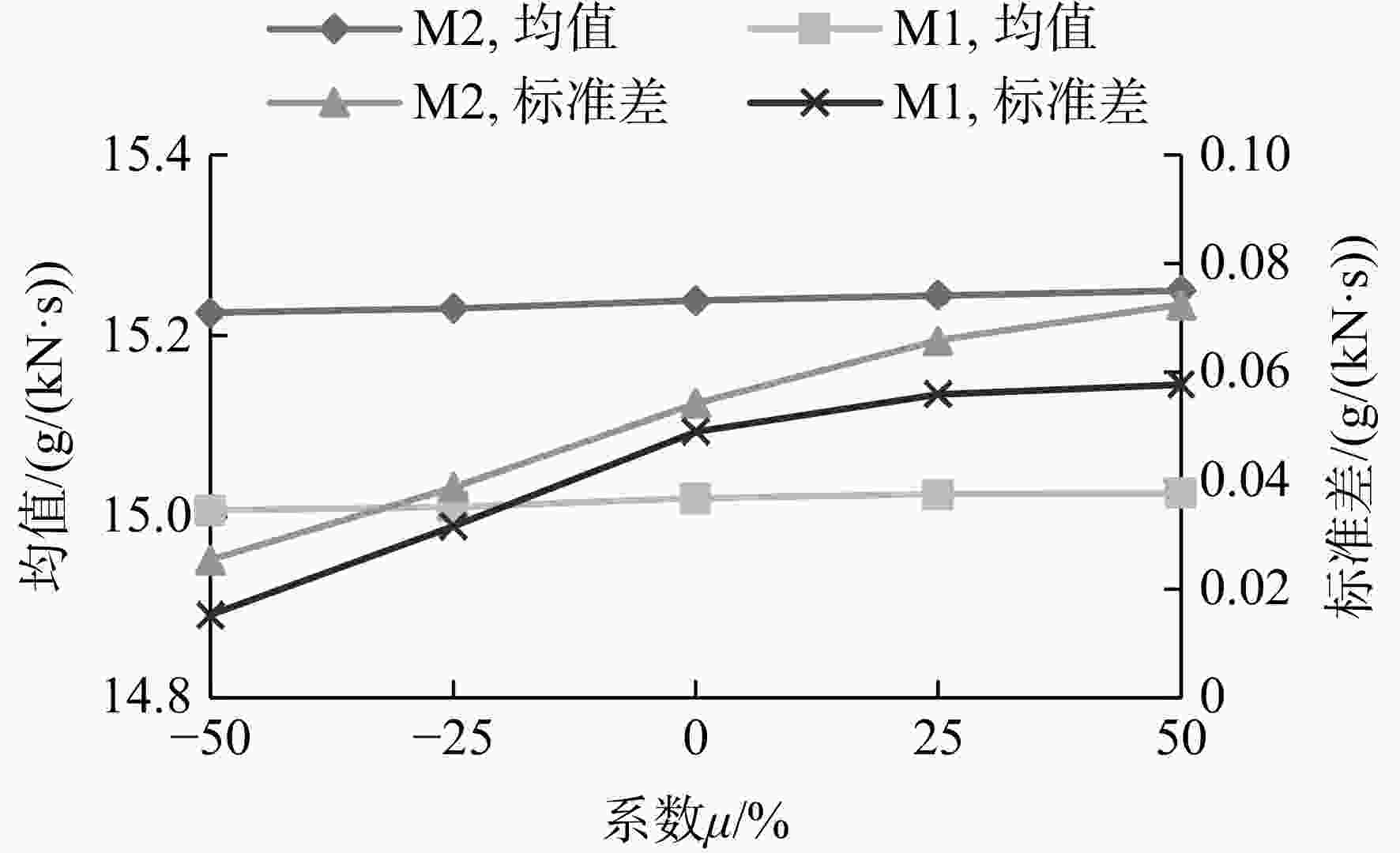

循环参数 最优值 $ {\pi }_{\mathrm{O}\mathrm{F}} $ 1.61047 $ {\pi }_{\mathrm{H}\mathrm{C}} $ 23.7566 $ {T}_{4}/\mathrm{K} $ 1902.76 $ B $ 10.8741 $ {W}_{02}/ (\mathrm{k}\mathrm{g}/\mathrm{s}) $ 212.824 表 5 最优方案的耗油率统计分析

Table 5. Statistical analysis of SFC for the optimal solution

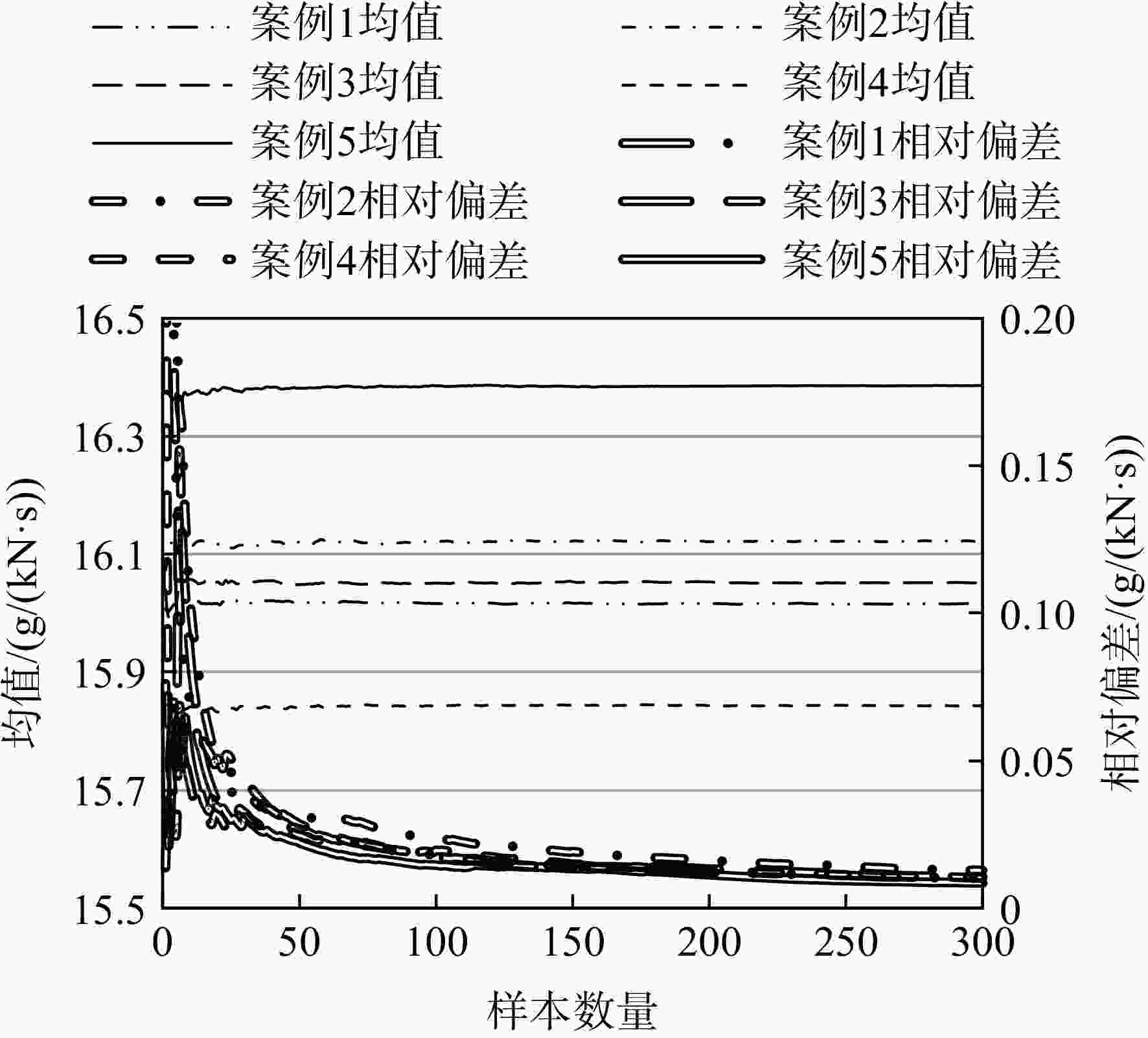

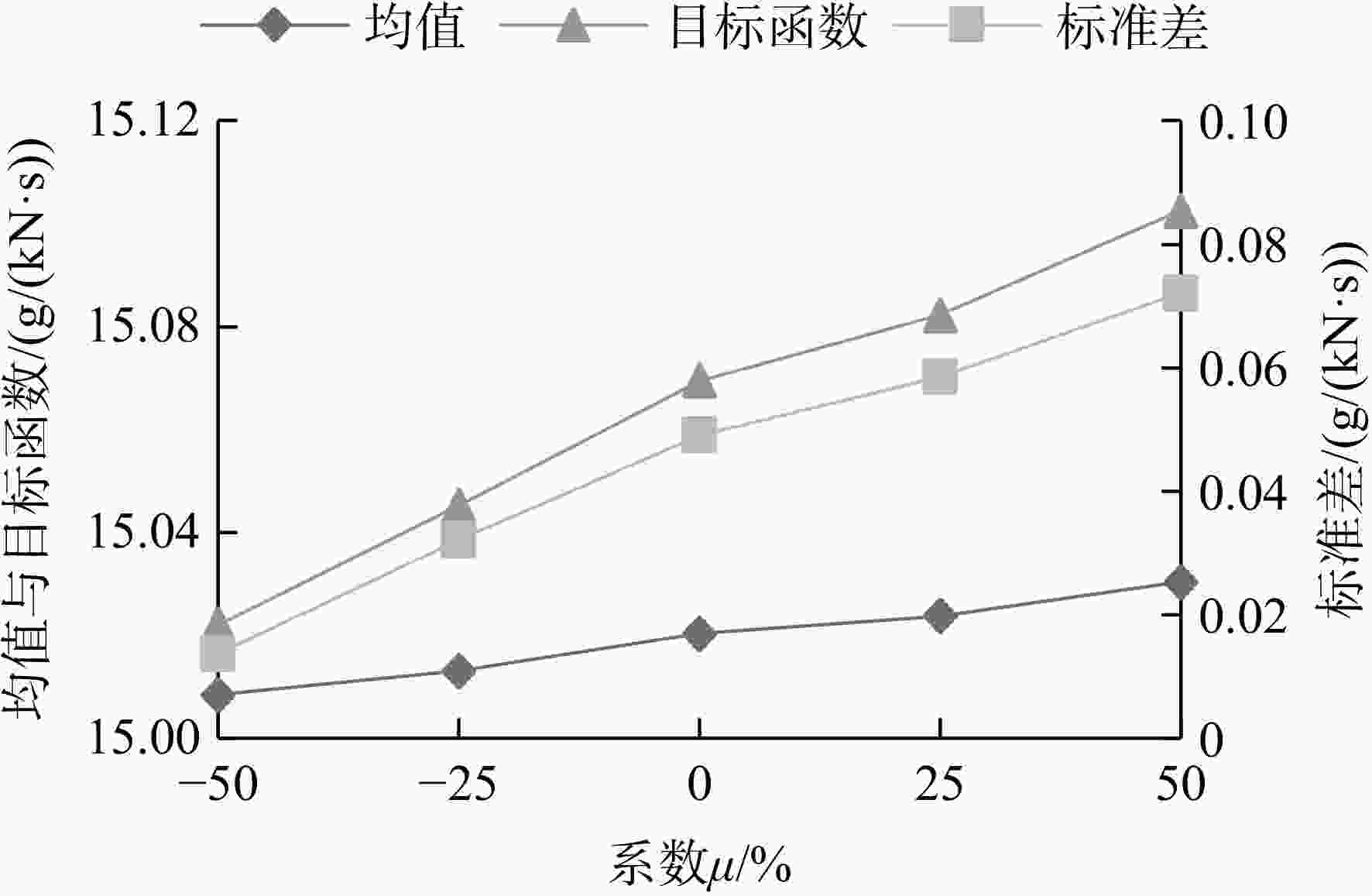

参数 耗油率/(g/(kN·s)) 经济巡航 高温起飞 最大爬升 加权和 均值 15.1350 6.8922 15.4819 15.0204 标准差 0.0428 0.0334 0.0536 0.0491 表 6 高压涡轮性能非确定性参数偏差上下界取值

Table 6. Value range of uncertain parameters deviation

% 参数 案例序号 1 2 3 4 5 系数$ \mu $ −50 −25 0 25 50 效率偏差上界 0.5 0.75 1 1.25 1.5 效率偏差下界 −1 −1.5 −2 −2.5 −3 换算流量偏差上界 1.5 2.25 3 3.75 4.5 换算流量偏差下界 −2 −3 −4 −5 −6 表 7 M2方法得到的最优设计方案

Table 7. Optimal design results obtained by M2

循环参数 最优值 $ {\pi }_{\mathrm{O}\mathrm{F}} $ 1.5995 $ {\pi }_{\mathrm{H}\mathrm{C}} $ 21.4379 $ {T}_{4}/\mathrm{K} $ 1868.95 $ B $ 10.2856 $ {W}_{02}/ (\mathrm{k}\mathrm{g}/\mathrm{s}) $ 209.63 -

[1] 郑新前,王钧莹,黄维娜,等. 航空发动机不确定性设计体系探讨[J]. 航空学报,2023,44(7): 6-23. ZHENG Xinqian,WANG Junying,HUANG Weina,et al. Uncertainty-based design system for aeroengines[J]. Acta Aeronautica et Astronautica Sinica,2023,44(7): 6-23. (in Chinese ZHENG Xinqian, WANG Junying, HUANG Weina, et al . Uncertainty-based design system for aeroengines[J]. Acta Aeronautica et Astronautica Sinica,2023 ,44 (7 ):6 -23 . (in Chinese)[2] 计自飞,韩文俊,李瑞军,等. 考虑部件不确定性的发动机性能裕度设计方法[J]. 航空发动机,2022,48(6): 34-41. JI Zifei,HAN Wenjun,LI Ruijun,et al. Determination of design margins for aeroengine performance targets considering component uncertainties[J]. Aeroengine,2022,48(6): 34-41. (in Chinese JI Zifei, HAN Wenjun, LI Ruijun, et al . Determination of design margins for aeroengine performance targets considering component uncertainties[J]. Aeroengine,2022 ,48 (6 ):34 -41 . (in Chinese)[3] BROWN H,ELGIN J A. Aircraft engine control mode analysis[J]. Journal of Engineering for Gas Turbines and Power,1985,107(4): 838-844. doi: 10.1115/1.3239820 [4] SPIELER S,STAUDACHER S,FIOLA R,et al. Probabilistic engine performance scatter and deterioration modeling[J]. Journal of Engineering for Gas Turbines and Power,2008,130(4): 1073-1082. [5] 唐海龙,张坤,郭昆,等. 部件性能非确定性对涡轴发动机性能影响量化方法研究[J]. 推进技术,2015,36(8): 1143-1150. TANG Hailong,ZHANG Kun,GUO Kun,et al. Quantification method of effects of uncertainty on component performance for turbo-shaft engine performance[J]. Journal of Propulsion Technology,2015,36(8): 1143-1150. (in Chinese doi: 10.13675/j.cnki.tjjs.2015.08.004 TANG Hailong, ZHANG Kun, GUO Kun, et al . Quantification method of effects of uncertainty on component performance for turbo-shaft engine performance[J]. Journal of Propulsion Technology,2015 ,36 (8 ):1143 -1150 . (in Chinese) doi: 10.13675/j.cnki.tjjs.2015.08.004[6] TONG M T,JONES S M,ARCARA P C Jr,et al. A probabilistic assessment of NASA ultra-efficient engine technologies for a large subsonic transport: ASME Paper GT-2004-53485 [R]. Vienna,Austria: ASME,2004. [7] SCHUTTE J,TAI J C,SANDS J S,et al. Cycle design exploration using multi-design point approach: ASME Paper GT2012-69334 [R]. Copenhagen,Denmark: ASME,2012. [8] HUGHES M J,PERULLO C,MAVRIS D N. Common core engine design for multiple applications using a concurrent multi-design point approach: AIAA 2014-3443 [R]. Cleveland,US: AIAA,2014. [9] HENDRICKS E S. Development of an open rotor cycle model in NPSS using a multi-design point approach[R]. NASA/TM-2011-217225,2011. [10] 曹大录,白广忱,吕晶薇,等. 考虑多工况性能可靠性的航空发动机循环设计方法[J]. 航空动力学报,2019,34(1): 217-227. CAO Dalu,BAI Guangchen,LÜ Jingwei,et al. Aero-engine cycle design approach for multiple operating conditions performance reliability[J]. Journal of Aerospace Power,2019,34(1): 217-227. (in Chinese doi: 10.13224/j.cnki.jasp.2019.01.025 CAO Dalu, BAI Guangchen, LÜ Jingwei, et al . Aero-engine cycle design approach for multiple operating conditions performance reliability[J]. Journal of Aerospace Power,2019 ,34 (1 ):217 -227 . (in Chinese) doi: 10.13224/j.cnki.jasp.2019.01.025[11] PARKINSON A. Robust mechanical design using engineering models[J]. Journal of Mechanical Design,1995,117: 48-54. [12] SHOEMAKER A C,TSUI K L,WU C F. Economical experimentation methods for robust design[J]. Technometrics,1991,33(4): 415-427. doi: 10.1080/00401706.1991.10484870 [13] PREGIBON D. Review of generalized linear models[J]. The Annals of Statistics,1984,12(4): 1589-1596. [14] 陈立周,翁海珊. 工程稳健优化设计[J]. 机械设计,1998,15(8): 6-9. CHEN Lizhou,WENG Haishan. Engineering robust optimal design[J]. Machine Design,1998,15(8): 6-9. (in Chinese doi: 10.3969/j.issn.1001-2354.1998.08.002 CHEN Lizhou, WENG Haishan . Engineering robust optimal design[J]. Machine Design,1998 ,15 (8 ):6 -9 . (in Chinese) doi: 10.3969/j.issn.1001-2354.1998.08.002[15] MONTOMOLI F,MASSINI M,SALVADORI S. Geometrical uncertainty in turbomachinery: tip gap and fillet radius[J]. Computers & Fluids,2011,46(1): 362-368. [16] BAMMERT K,SANDSTEDE H. Measurements concerning the influence of surface roughness and profile changes on the performance of gas turbines[J]. Journal of Engineering for Power,1972,94(3): 207-213. doi: 10.1115/1.3445674 [17] DUFFNER J D. The effects of manufacturing variability on turbine vane performance[D]. Cambridge,US: Massachusetts Institute of Technology,2008. [18] 张伟昊,邹正平,李维,等. 叶型偏差对涡轮性能影响的非定常数值模拟研究[J]. 航空学报,2010,31(11): 2130-2138. ZHANG Weihao,ZOU Zhengping,LI Wei,et al. Unsteady numerical simulation investigation of effect of blade profile deviation on turbine performance[J]. Acta Aeronautica et Astronautica Sinica,2010,31(11): 2130-2138. (in Chinese ZHANG Weihao, ZOU Zhengping, LI Wei, et al . Unsteady numerical simulation investigation of effect of blade profile deviation on turbine performance[J]. Acta Aeronautica et Astronautica Sinica,2010 ,31 (11 ):2130 -2138 . (in Chinese)[19] 唐海龙. 面向对象的航空发动机性能仿真系统及其应用[D]. 北京: 北京航空航天大学,2000. TANG Hailong. Object-oriented aeroengine performance simulation system and its application[D]. Beijing: Beijing University of Aeronautics and Astronautics,2000. (in ChineseTANG Hailong. Object-oriented aeroengine performance simulation system and its application[D]. Beijing: Beijing University of Aeronautics and Astronautics, 2000. (in Chinese) [20] CHEN Min,TANG Hailong,ZHANG Kun,et al. Turbine-based combined cycle propulsion system integration concept design[J]. Proceedings of the Institution of Mechanical Engineers: Part G Journal of Aerospace Engineering,2013,227(7): 1068-1089. doi: 10.1177/0954410012449246 [21] 张伟康,刘升,任春慧. 混合策略改进的麻雀搜索算法[J]. 计算机工程与应用,2021,57(24): 74-82. ZHANG Weikang,LIU Sheng,REN Chunhui. Mixed strategy improved sparrow search algorithm[J]. Computer Engineering and Applications,2021,57(24): 74-82. (in Chinese doi: 10.3778/j.issn.1002-8331.2101-0161 ZHANG Weikang, LIU Sheng, REN Chunhui . Mixed strategy improved sparrow search algorithm[J]. Computer Engineering and Applications,2021 ,57 (24 ):74 -82 . (in Chinese) doi: 10.3778/j.issn.1002-8331.2101-0161[22] SCHÖNBRODT F D,PERUGINI M. At what sample size do correlations stabilize?[J]. Journal of Research in Personality,2013,47(5): 609-612. doi: 10.1016/j.jrp.2013.05.009 -

下载:

下载: