Aerodynamic design and axial force analysis of partial admission radial turbine with cracked fuel vapor

-

摘要:

从涡轮结构形式的角度探究了油气涡轮轴向力平衡问题。建立了半开式、开式与闭式3种局部进气裂解油气向心涡轮,通过数值仿真对比分析了设计工况下3种油气涡轮的气动性能与轴向力,并归纳总结了非设计工况下总轴向力随压比的变化规律。仿真结果表明:半开式、开式与闭式油气涡轮的总体气动性能相近但轴向力表现有明显的差别。当涡轮压比发生变化时,开式油气涡轮轴向力稳定性最好,半开式油气涡轮轴向力稳定性最差,闭式油气涡轮轴向力始终是3种油气涡轮中最小的。由结果分析可知,当涡轮压比低于3时,应避免选用半开式油气涡轮,而涡轮压比变化较大时,则宜采用开式油气涡轮,此外,在采用闭式油气涡轮时需要轴承预留足够的轴向载荷裕度。

Abstract:Axial-force balance of the cracked fuel vapor turbine was studied from the perspective of turbine structure. Partial admission cracked fuel vapor turbines with unshrouded, open, and enclosed impellers were established respectively, and the aerodynamic performance and axial force of turbines under the design condition were compared and analyzed by numerical simulation. Meanwhile, the variation law of the total axial force with pressure ratio under off-design conditions was summarized, which provided guidance and suggestions for the selection of cracked fuel vapor turbine structure forms. The simulation results showed that the aerodynamic performance of unshrouded, open, and enclosed turbines was similar, but the axial force performance was distinctive. When the pressure ratio changed, the axial force stability of the open turbine was the best, the unshrouded one was the worst, and the enclosed turbine axial force was the smallest among the three kinds of cracked fuel vapor turbines. The result analysis showed that when the turbine pressure ratio was lower than 3, the unshrouded turbine should be discarded; if the turbine pressure ratio changed greatly, the open turbine should be adopted. In addition, axial load of bearings should be sufficient when enclosed cracked fuel vapor turbines were exploited.

-

Key words:

- partial admission /

- fuel vapor turbine /

- radial turbine /

- axial force /

- turbine power generation

-

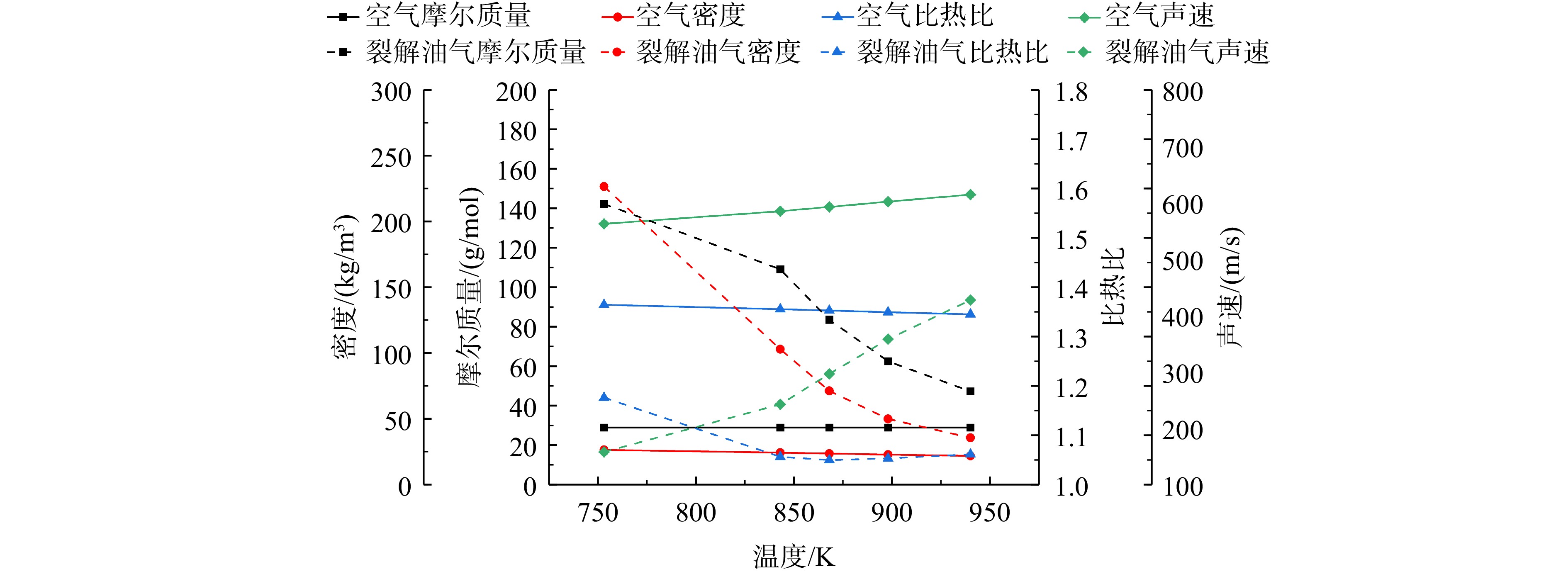

表 1 裂解油气工质的温度与压力

Table 1. Temperature and pressure of cracked fuel vapor

裂解度/% 压力/MPa 温度/K 0 6 753 17.8 6 843 39.3 6 868 62.2 6 898 80 6 940 表 2 油气涡轮设计工况

Table 2. Design conditions of fuel vapor turbine

参数 数值 入口压力/MPa 6 入口温度/K 940 出口压力/MPa 3 转速/(r/min) 60000 表 3 3种油气涡轮的几何尺寸

Table 3. Geometric dimensions of three fuel vapor turbines

参数 数值 蜗壳入口半径/mm 12 导叶入口半径/mm 47.8 导叶出口半径/mm 42 导叶喉口面积/mm2 9.3 导叶通道数 5 转子入口半径/mm 41.3 转子入口叶高/mm 2.7 转子叶顶间隙/mm 0.5 转子出口叶尖半径/mm 22.9 转子出口叶根半径/mm 14.3 转子叶片数 14 开式涡轮盘缘半径/mm 33.6 闭式涡轮轮盖间隙/mm 0.5 轮盖篦齿数 5 表 4 3种油气涡轮关键气动参数对比

Table 4. Comparison of key aerodynamic parameters of three fuel vapor turbines

参数 半开式涡轮 开式涡轮 闭式涡轮 数值 数值 偏差/% 数值 偏差/% 质量流量/(kg/s) 0.505 0.502 −0.594 0.503 −0.396 功率/kW 39.749 39.473 −0.694 41.113 3.433 等熵效率/% 69.098 69.029 −0.100 71.755 3.844 转子入口压力/kPa 395.025 405.273 2.594 394.718 −0.078 转子入口绝对速度/(m/s) 333.664 327.868 −1.737 338.078 1.323 转子入口绝对气流角/(°) 15.931 16.057 0.788 15.826 −0.657 转子入口相对速度/(m/s) 108.519 104.755 −3.469 111.459 2.709 转子入口相对气流角/(°) 57.560 59.960 4.170 55.815 −3.031 转子出口绝对速度/(m/s) 96.478 93.388 −3.203 86.744 −0.101 转子出口绝对气流角/(°) 73.101 76.679 4.895 88.799 0.215 转子出口相对气流角/(°) 134.298 136.751 1.826 143.289 0.067 表 5 3种油气涡轮各受力面轴向力对比

Table 5. Comparison of axial force on each surface of three fuel vapor turbines

受力面 轴向力/N 半开式 开式 闭式 前盘 −1375.2 −1374.3 −1378 叶片 −2089.3 −2089.4 −550.2 轮毂 −13895.8 −8155.3 −13872.3 背盘 18649.7 12443.2 18588.9 轮盖内侧 11174.2 轮盖外侧 −13428 总计 1289.4 824.2 534.6 -

[1] CURRAN E T. Scramjet engines: the first forty years[J]. Journal of Propulsion and Power,2001,17(6): 1138-1148. doi: 10.2514/2.5875 [2] FIDAN B,MIRMIRANI M,IOANNOU P. Flight dynamics and control of air-breathing hypersonic vehicles: review and new directions[R]. AIAA2003-7081,2003. [3] 蔡国飙,徐大军. 高超声速飞行器技术[M]. 北京: 科学出版社,2012. [4] 焦子涵,邓帆,范宇,等. 吸气式高超声速飞行器前体/进气道一体化设计与试验[J]. 航空动力学报,2017,32(1): 168-176. JIAO Zihan,DENG Fan,FAN Yu,et al. Integrated design and test of forebody/inlet for air-breathing hypersonic vehicle[J]. Journal of Aerospace Power,2017,32(1): 168-176. (in Chinese doi: 10.13224/j.cnki.jasp.2017.01.023 JIAO Zihan, DENG Fan, FAN Yu, et al . Integrated design and test of forebody/inlet for air-breathing hypersonic vehicle[J]. Journal of Aerospace Power,2017 ,32 (1 ):168 -176 . (in Chinese) doi: 10.13224/j.cnki.jasp.2017.01.023[5] SFORZA P. Electric power generation onboard hypersonic aircraft[R]. AIAA2009-5119,2009. [6] MADONNA V,GIANGRANDE P,GALEA M. Electrical power generation in aircraft: review,challenges,and opportunities[J]. IEEE Transactions on Transportation Electrification,2018,4(3): 646-659. doi: 10.1109/TTE.2018.2834142 [7] 张铎. 碳氢燃料超燃冲压发动机油气涡轮发电系统研究[D]. 哈尔滨: 哈尔滨工业大学,2016. ZHANG Duo. Investigation of power generation system driven by fuel vapor turbine on a hydrocarbon scramjet[D]. Harbin: Harbin Institute of Technology,2016. (in ChineseZHANG Duo. Investigation of power generation system driven by fuel vapor turbine on a hydrocarbon scramjet[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [8] BAO Wen,ZHANG Duo,QIN Jiang,et al. Performance analysis on fuel turbo-pump and motor system of scramjet engine[R]. AIAA2012-4159,2012. [9] 李鹏. 有机朗肯循环与向心透平性能优化及实验研究[D]. 北京: 华北电力大学,2020. LI Peng. Performance optimization and experimental study of organic Rankine cycle and radial inflow turbine[D]. Beijing: North China Electric Power University,2020. (in ChineseLI Peng. Performance optimization and experimental study of organic Rankine cycle and radial inflow turbine[D]. Beijing: North China Electric Power University, 2020. (in Chinese) [10] FIASCHI D,INNOCENTI G,MANFRIDA G,et al. Design of micro radial turboexpanders for ORC power cycles: from 0D to 3D[J]. Applied Thermal Engineering,2016,99: 402-410. doi: 10.1016/j.applthermaleng.2015.11.087 [11] RAHBAR K,MAHMOUD S,AL-DADAH R K,et al. One-dimensional and three-dimensional numerical optimization and comparison of single-stage supersonic and dual-stage transonic radial inflow turbines for the ORC[R]. Charlotte,US: ASME 2016 Power Conference,2016. [12] BOZZI L,MALAVASI F,GAROTTA V. Heavy-duty gas turbines axial thrust calculation in different operating conditions[R]. Vancouver,Canada: ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition,2011. [13] TIAINEN J,JAATINEN-VÄRRI A,GRÖNMAN A,et al. Validation of the axial thrust estimation method for radial turbomachines[J]. International Journal of Rotating Machinery,2021,2021: 1-18. [14] HUO Changjiang,SUN Jinju,SONG Peng,et al. Investigating the influence of impeller axial thrust balance holes on the flow and overall performance of a cryogenic liquid turbine expander[J]. Journal of Engineering for Gas Turbines and Power,2021,143(10): 101014. doi: 10.1115/1.4051501 [15] 何嘉伟,王强,李书奇,等. 涡轮增压器转子涡轮级气动轴向力数值计算[J]. 机械设计与制造,2019(4): 196-199,203. HE Jiawei,WANG Qiang,LI Shuqi,et al. Numerical calculation of aerodynamic axial force of turbine rotor[J]. Machinery Design & Manufacture,2019(4): 196-199,203. (in Chinese doi: 10.3969/j.issn.1001-3997.2019.04.049 HE Jiawei, WANG Qiang, LI Shuqi, et al . Numerical calculation of aerodynamic axial force of turbine rotor[J]. Machinery Design & Manufacture,2019 (4 ):196 -199, 203 . (in Chinese) doi: 10.3969/j.issn.1001-3997.2019.04.049[16] 蔡毅,朱惠人,张丽,等. 影响某型燃机转子轴向力关键因素分析[J]. 航空工程进展,2013,4(1): 66-70. CAI Yi,ZHU Huiren,ZHANG Li,et al. Key factors investigation on the rotors axial thrust of a gas turbine[J]. Advances in Aeronautical Science and Engineering,2013,4(1): 66-70. (in Chinese doi: 10.16615/j.cnki.1674-8190.2013.01.023 CAI Yi, ZHU Huiren, ZHANG Li, et al . Key factors investigation on the rotors axial thrust of a gas turbine[J]. Advances in Aeronautical Science and Engineering,2013 ,4 (1 ):66 -70 . (in Chinese) doi: 10.16615/j.cnki.1674-8190.2013.01.023[17] 邵冬,孙志刚,谭春青,等. 闭式叶轮轮盖空腔流场的数值研究[J]. 推进技术,2017,38(6): 1241-1248. SHAO Dong,SUN Zhigang,TAN Chunqing,et al. Numerical investigation on flow field of impeller front-side cavity for shrouded impeller[J]. Journal of Propulsion Technology,2017,38(6): 1241-1248. (in Chinese doi: 10.13675/j.cnki.tjjs.2017.06.006 SHAO Dong, SUN Zhigang, TAN Chunqing, et al . Numerical investigation on flow field of impeller front-side cavity for shrouded impeller[J]. Journal of Propulsion Technology,2017 ,38 (6 ):1241 -1248 . (in Chinese) doi: 10.13675/j.cnki.tjjs.2017.06.006[18] ZHOU Weixing,JIA Zhenjian,QIN Jiang,et al. Experimental study on effect of pressure on heat sink of n-decane[J]. Chemical Engineering Journal,2014,243: 127-136. doi: 10.1016/j.cej.2013.12.081 [19] WARD T A,ERVIN J S,STRIEBICH R C,et al. Simulations of flowing mildly-cracked normal alkanes incorporating proportional product distributions[J]. Journal of Propulsion and Power,2004,20(3): 394-402. doi: 10.2514/1.10380 [20] 禹进,龚相奎,张俊良. RP-3航空煤油模型燃料及其骨架机理构建新方法研究[J/OL]. 航空动力学报,[2023-12-18]. https://kns-cnki-net-s.vpn.buaa.edu.cn: 8118/kcms2/article/abstract?v=p7sfyaWOx3N_k6ItXtI5H0iEMysAGi1TCDwtrtDz3vQ9dwOQ9yn_xhOZpAUpY2hIj77zzCEk3ids0Ikal8IamEt2C-LNoRnIPY52T7JNkqmq996ILhXLaS71cWOMPOESH2hjPSa9WvU=&uniplatform=NZKPT&language=CHS. YU Jin,GONG Xiangkui,ZHANG Junliang. Study on a surrogate fuel model and a now methodology for developing skeletal mechanism for RP-3 aviation kerosene [J/OL]. Journal of Aerospace Power,[2023-12-18]. https://kns-cnki-net-s.vpn.buaa.edu.cn:8118/kcms2/article/abstract?v=p7sfyaWOx3N_k6ItXtI5H0iEMysAGi1TCDwtrtDz3vQ9dwOQ9yn_xhOZpAUpY2hIj77zzCEk3ids0Ikal8IamEt2C-LNoRnIPY52T7JNkqmq996ILhXLaS71cWOMPOESH2hjPSa9WvU=&uniplatform=NZKPT&language=CHS. (in ChineseYU Jin, GONG Xiangkui, ZHANG Junliang. Study on a surrogate fuel model and a now methodology for developing skeletal mechanism for RP-3 aviation kerosene [J/OL]. Journal of Aerospace Power, [2023-12-18]. https://kns-cnki-net-s.vpn.buaa.edu.cn:8118/kcms2/article/abstract?v=p7sfyaWOx3N_k6ItXtI5H0iEMysAGi1TCDwtrtDz3vQ9dwOQ9yn_xhOZpAUpY2hIj77zzCEk3ids0Ikal8IamEt2C-LNoRnIPY52T7JNkqmq996ILhXLaS71cWOMPOESH2hjPSa9WvU=&uniplatform=NZKPT&language=CHS. (in Chinese) [21] LI Haowei,QIN Jiang,JIANG Yuguang,et al. Experimental study on the thermodynamic characteristics of the high temperature hydrocarbon fuel in the cooling channel of the hypersonic vehicle[J]. Acta Astronautica,2019,155: 63-79. doi: 10.1016/j.actaastro.2018.11.021 [22] WANG Hanwei,LUO Kai,HUANG Chuang,et al. Numerical investigation of partial admission losses in radial inflow turbines[J]. Energy,2022,239: 121870. doi: 10.1016/j.energy.2021.121870 [23] WANG Hanwei,CHAO Yue,TANG Tian,et al. A comparison of partial admission axial and radial inflow turbines for underwater vehicles[J]. Energies,2021,14(5): 1514. doi: 10.3390/en14051514 [24] 孙冠珂,李文,张雪辉,等. 向心涡轮进气结构的气动性能及损失机理[J]. 航空动力学报,2015,30(8): 1926-1935. SUN Guanke,LI Wen,ZHANG Xuehui,et al. Aerodynamic performance and losses mechanism of radial turbine intake components[J]. Journal of Aerospace Power,2015,30(8): 1926-1935. (in Chinese doi: 10.13224/j.cnki.jasp.2015.08.016 SUN Guanke, LI Wen, ZHANG Xuehui, et al . Aerodynamic performance and losses mechanism of radial turbine intake components[J]. Journal of Aerospace Power,2015 ,30 (8 ):1926 -1935 . (in Chinese) doi: 10.13224/j.cnki.jasp.2015.08.016[25] 冯涛,周颖,邹正平,等. 向心涡轮内部流动数值模拟分析[J]. 航空动力学报,2006,21(3): 448-454. FENG Tao,ZHOU Ying,ZOU Zhengping,et al. Numerical simulation of the flow inside radial inflow turbine[J]. Journal of Aerospace Power,2006,21(3): 448-454. (in Chinese doi: 10.13224/j.cnki.jasp.2006.03.003 FENG Tao, ZHOU Ying, ZOU Zhengping, et al . Numerical simulation of the flow inside radial inflow turbine[J]. Journal of Aerospace Power,2006 ,21 (3 ):448 -454 . (in Chinese) doi: 10.13224/j.cnki.jasp.2006.03.003[26] 欧阳玉清,李维,曾飞,等. 向心涡轮跨声速导向叶片叶型设计及验证[J]. 航空动力学报,2023,38(5): 1217-1225. OUYANG Yuqing,LI Wei,ZENG Fei,et al. Design and validation of transonic nozzle guide vane profile of radial-inflow turbine[J]. Journal of Aerospace Power,2023,38(5): 1217-1225. (in Chinese doi: 10.13224/j.cnki.jasp.20220820 OUYANG Yuqing, LI Wei, ZENG Fei, et al . Design and validation of transonic nozzle guide vane profile of radial-inflow turbine[J]. Journal of Aerospace Power,2023 ,38 (5 ):1217 -1225 . (in Chinese) doi: 10.13224/j.cnki.jasp.20220820[27] MENTER F,KUNTZ M,LANGTRY R. Ten years of industrial experience with the SST turbulence mode[J]. Heat and Mass Transfer,2003,4: 625-632. [28] BONCINELLI P,RUBECHINI F,ARNONE A,et al. Real gas effects in turbomachinery flows: a computational fluid dynamics model for fast computations[J]. Journal of Turbomachinery,2004,126(2): 268-276. doi: 10.1115/1.1738121 [29] WAKEHAM W A. Transport properties of fluids: their correlation,prediction and estimation[M]. Cambridge,US: Cambridge University Press,1996. [30] 张程,夏智勋,马超,等. 基于 k- ω SST模型的同心筒发射装置流场数值模拟[J]. 航空动力学报,2019,34(11): 2331-2338. ZHANG Cheng,XIA Zhixun,MA Chao,et al. Numerical simulation of flow field of concentric canister launcher based on k- ω SST turbulence model[J]. Journal of Aerospace Power,2019,34(11): 2331-2338. (in Chinese ZHANG Cheng, XIA Zhixun, MA Chao, et al . Numerical simulation of flow field of concentric canister launcher based on k-ω SST turbulence model[J]. Journal of Aerospace Power,2019 ,34 (11 ):2331 -2338 . (in Chinese)[31] DONG Bensi,XU Guoqiang,LUO Xiang,et al. Analysis of the supercritical organic Rankine cycle and the radial turbine design for high temperature applications[J]. Applied Thermal Engineering,2017,123: 1523-1530. doi: 10.1016/j.applthermaleng.2016.12.123 [32] 孙大伟,乔渭阳,许开富,等. 不同攻角对涡轮叶栅损失的影响[J]. 航空动力学报,2008,23(7): 1232-1239. SUN Dawei,QIAO Weiyang,XU Kaifu,et al. Influence of different incidences on loss in turbine cascade[J]. Journal of Aerospace Power,2008,23(7): 1232-1239. (in Chinese doi: 10.13224/j.cnki.jasp.2008.07.026 SUN Dawei, QIAO Weiyang, XU Kaifu, et al . Influence of different incidences on loss in turbine cascade[J]. Journal of Aerospace Power,2008 ,23 (7 ):1232 -1239 . (in Chinese) doi: 10.13224/j.cnki.jasp.2008.07.026 -

下载:

下载: