Research on peeling propagation characteristics of outer ring of ball bearings based on wear particles analysis

-

摘要:

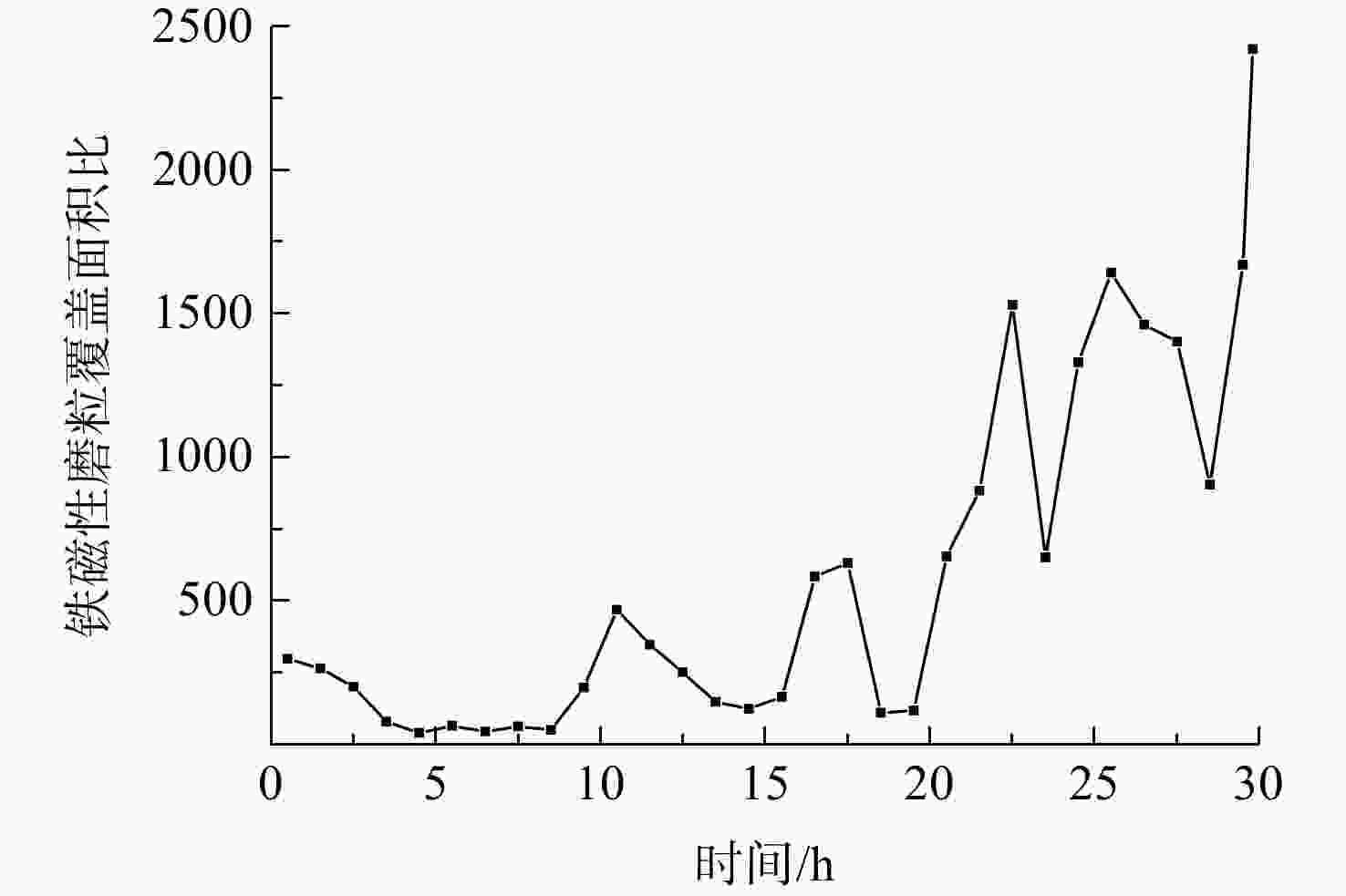

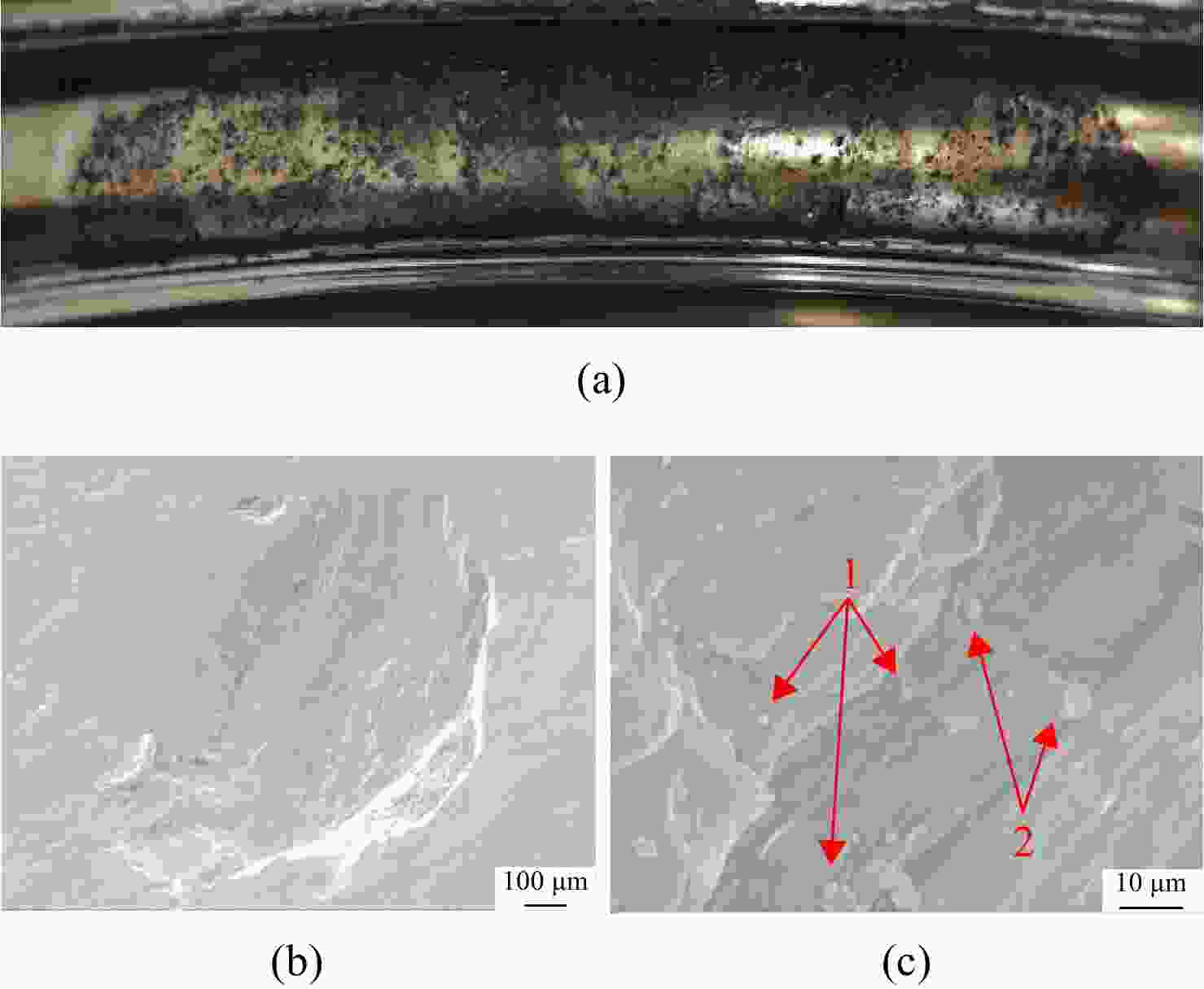

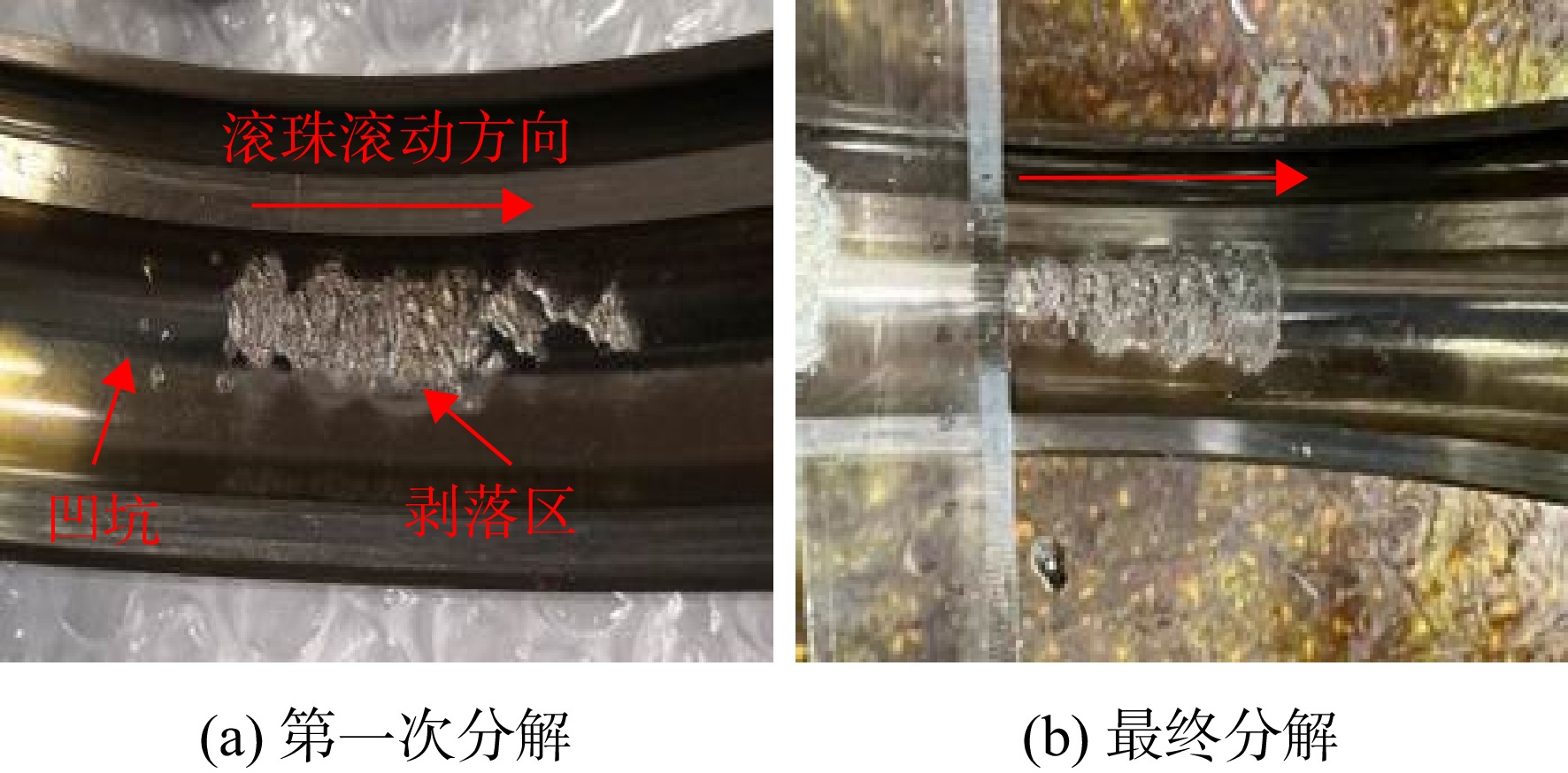

为研究航空发动机球轴承外圈的剥落扩展特性,首先利用外圈含预制缺陷的球轴承开展零部件实验,再选取外圈存在剥落缺陷的球轴承在发动机上开展剥落扩展研究。综合利用滑油光谱、便携式铁谱、分析式铁谱及能谱分析技术对发动机滑油中的磨粒进行分析。结果表明:球轴承外圈的剥落扩展是渐进性的;表面存在沿长轴方向划痕的疲劳磨粒数量及比例随外圈的剥落发展而不断增加;磨粒总量及尺寸在剥落发展期出现明显增长,在快速扩展期急剧增加。结论:外圈的剥落首先出现在距凹坑一定距离的后方位置,沿滚珠的滚动方向扩展;剥落扩展分为4个阶段:裂纹萌生、裂纹扩展、裂纹贯穿及剥落扩展。

Abstract:To study the peeling propagation characteristics of outer ring of aero-engine ball bearings, two experiments were carried out. The former was component experiment, which employed outer rings with prefabricated defects, the latter was aero-engine experiment, which adopted those with peeling defects. Atomic emission spectroscopy, portable ferrography, analytical ferrography and energy-dispersive X-ray spectroscopy analysis were conducted to analyze the wear particles in lubricating oil. The results showed that the peeling of the outer ring was progressive. The fatigue wear particles, with scratches along major dimension, continuously increased in quantity and proportion with the peeling. The total amount and size of abrasive particles showed an obvious increase during the peeling development, and also a sharp increase during the rapid propagation. In short, the peeling first appeared at a certain distance behind pits, and then extended along the rolling direction of balls, which can be divided into four stages: cracks initiation, propagation, coalescing, and peeling propagation.

-

Key words:

- ball bearings /

- peeling of outer ring /

- wear particles /

- prefabricated defects /

- cracks

-

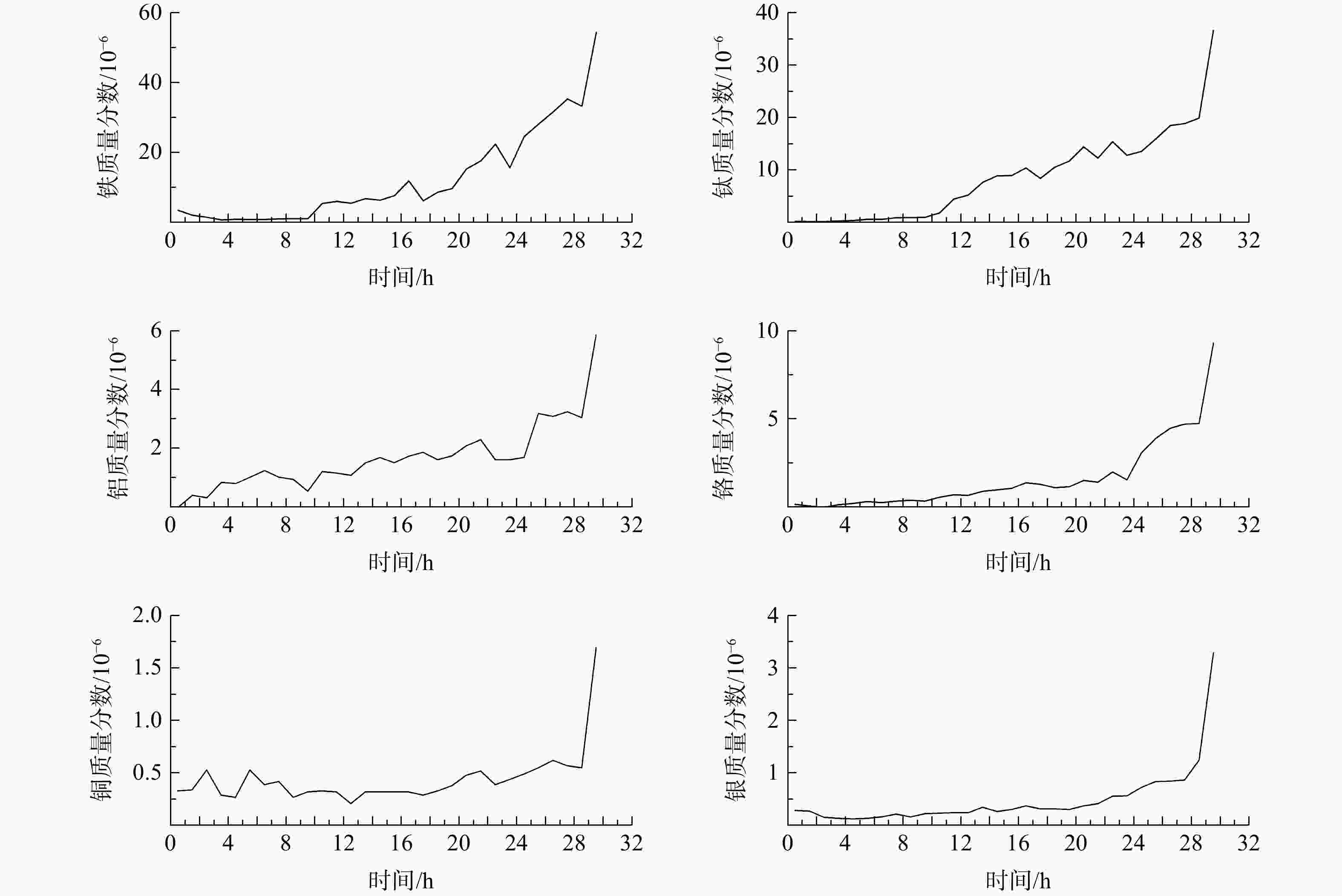

表 1 滑油中主要金属元素质量分数

Table 1. Main metal element mass fraction in lubricating oil

元素 质量分数10−6 Fe 143.75 Ti 57.49 Al 8.83 Cr 10.86 Cu 4.86 Ag 10.56 表 2 0.5 h能谱分析结果

Table 2. Energy spectrum analysis results at 0.5 h

磨粒 质量分数/% Fe Cr Ni Mo Ti V 1 余 4.0 4.3 0.9 2 余 3.9 4.2 1.0 表 3 10.5 h能谱分析结果

Table 3. Energy spectrum analysis results at 10.5 h

磨粒 质量分数/% Fe Cr Mo V Ag 1 余 4.1 4.3 0.9 2 余 4.5 4.0 0.8 3 余 3.9 4.4 1.1 4 余 4.4 4.2 0.7 2.5 5 1.8 余 -

[1] 刘振侠,江平. 航空发动机机械系统设计[M]. 北京: 科学出版社,2022. [2] WANG Liqin,LI Yunfeng. Boundary for aviation bearing accelerated life test based on quasi-dynamic analysis[J]. Tribology International,2017,116: 414-421. doi: 10.1016/j.triboint.2017.06.014 [3] 彭朝林,谢小鹏,陈祯. 润滑因素与滚动轴承失效的关系研究[J]. 润滑与密封,2015,40(8): 26-30. PENG Chaolin,XIE Xiaopeng,CHEN Zhen. Research on relationship between lubrication factors and failure mechanism of rolling bearing[J]. Lubrication Engineering,2015,40(8): 26-30. (in Chinese PENG Chaolin, XIE Xiaopeng, CHEN Zhen . Research on relationship between lubrication factors and failure mechanism of rolling bearing[J]. Lubrication Engineering,2015 ,40 (8 ):26 -30 . (in Chinese)[4] 李青,杨纯辉,佟文伟,等. 航空发动机球轴承外圈剥落机理分析[J]. 航空发动机,2020,46(5): 10-13. LI Qing,YANG Chunhui,TONG Wenwei,et al. Spalling mechanism analysis on outer ring of aeroengine ball bearing[J]. Aeroengine,2020,46(5): 10-13. (in Chinese LI Qing, YANG Chunhui, TONG Wenwei, et al . Spalling mechanism analysis on outer ring of aeroengine ball bearing[J]. Aeroengine,2020 ,46 (5 ):10 -13 . (in Chinese)[5] MILLER G R,KEER L,CHENG H S. On the mechanics of fatigue crack growth due to contact loading[J]. Proceedings of the Royal Society of London A Mathematical and Physical Sciences,1985,397: 197-209. doi: 10.1098/rspa.1985.0011 [6] JOHN G,DARLENE E,SHELTON C. Accurate assessment of partical counts in liquids[J]. Lubrication Engineering,1995,51(3): 205-208. [7] TUNCA N,LAUFER E E. Wear mechanisms and finite element crack propagation analysis of high speed roller bearings[J]. Wear,1987,118(1): 77-97. doi: 10.1016/0043-1648(87)90006-8 [8] 国家市场监督管理总局,国家标准化管理委员会. 滚动轴承损伤和失效术语、特征及原因: GB/T 24611—2020[S]. 北京: 中国标准出版社,2020: 3-6. [9] LEI Yaguo,LIN Jing,HE Zhengjia,et al. A review on empirical mode decomposition in fault diagnosis of rotating machinery[J]. Mechanical Systems and Signal Processing,2013,35(1/2): 108-126. [10] FLANAGAN I M,JORDAN J R,WHITTINGTON H W. Wear-debris detection and analysis techniques for lubricant-based condition monitoring[J]. Journal of Physics E: Scientific Instruments,1988,21(11): 1011-1016. doi: 10.1088/0022-3735/21/11/001 [11] WANG Siyuan,YANG Dingxin,HU H. Evaluation for bearing wear states based on online oil multi-parameters monitoring[J]. Sensors,2018,18(4): 1111.1-1111.22. [12] 陈果,贺志远,尉询楷,等. 基于整机的中介轴承外圈剥落故障振动分析[J]. 航空动力学报,2020,35(3): 658-672. CHEN Guo,HE Zhiyuan,YU Xunkai,et al. Vibration analysis of peeling fault of intermediate bearing outer ring based on whole aero-engine[J]. Journal of Aerospace Power,2020,35(3): 658-672. (in Chinese CHEN Guo, HE Zhiyuan, YU Xunkai, et al . Vibration analysis of peeling fault of intermediate bearing outer ring based on whole aero-engine[J]. Journal of Aerospace Power,2020 ,35 (3 ):658 -672 . (in Chinese)[13] BARBINI L,OMPUSUNGGU A P,HILLIS A J,et al. Phase editing as a signal pre-processing step for automated bearing fault detection[J]. Mechanical Systems and Signal Processing,2017,91: 407-421. doi: 10.1016/j.ymssp.2016.12.004 [14] BARBINI L,ELTABACH M,HILLIS A J,et al. Amplitude-cyclic frequency decomposition of vibration signals for bearing fault diagnosis based on phase editing[J]. Mechanical Systems and Signal Processing,2018,103: 76-88. doi: 10.1016/j.ymssp.2017.09.044 [15] 王洪伟,陈果,陈立波,等. 一种航空发动机滚动轴承磨损故障监测技术[J]. 航空动力学报,2014,29(9): 2256-2263. WANG Hongwei,CHEN Guo,CHEN Libo,et al. A fault monitoring technique for wear of aero-engine rolling bearing[J]. Journal of Aerospace Power,2014,29(9): 2256-2263. (in Chinese WANG Hongwei, CHEN Guo, CHEN Libo, et al . A fault monitoring technique for wear of aero-engine rolling bearing[J]. Journal of Aerospace Power,2014 ,29 (9 ):2256 -2263 . (in Chinese)[16] EPPS I. An investigation into vibrations excited by discrete faults in rolling element bearings[J]. Journal of Vibration and Acoustics,1991,20(4): 901-908. [17] KOGAN G,BORTMAN J,KLEIN R. A new model for spall-rolling-element interaction[J]. Nonlinear Dynamics,2017,87(1): 219-236. doi: 10.1007/s11071-016-3037-1 [18] KULKARNI P G,SAHASRABUDHE A D. A dynamic model of ball bearing for simulating localized defects on outer race using cubic Hermite spline[J]. Journal of Mechanical Science and Technology,2014,28(9): 3433-3442. doi: 10.1007/s12206-014-0804-0 [19] XU Guangju,ZHAO Yang,LI Mingdi,et al. Effects of the lubricating oil and diesel mixture combustion on the oxidation and microphysical properties of particulate matter[J]. Energy Reports,2020,6: 308-314. doi: 10.1016/j.egyr.2020.01.004 [20] BOWEN R,SCOTT D,SEIFERT W,et al. Ferrography[J]. Tribology International,1976,9(3): 109-115. doi: 10.1016/0301-679X(76)90033-5 [21] 安德森D P. 磨粒图谱(修订版)[M]. 北京: 机械工业出版社,1987. [22] SCOTT D,MILLS G H. Spherical debris—its occurrence,formation and significance in rolling contact fatigue[J]. Wear,1973,24(2): 235-242. doi: 10.1016/0043-1648(73)90236-6 [23] SUH N P. The delamination theory of wear[J]. Wear,1973,25(1): 111-124. doi: 10.1016/0043-1648(73)90125-7 -

下载:

下载: