Characteristics and experimental verification of “critical following speed” on rotor system

-

摘要:

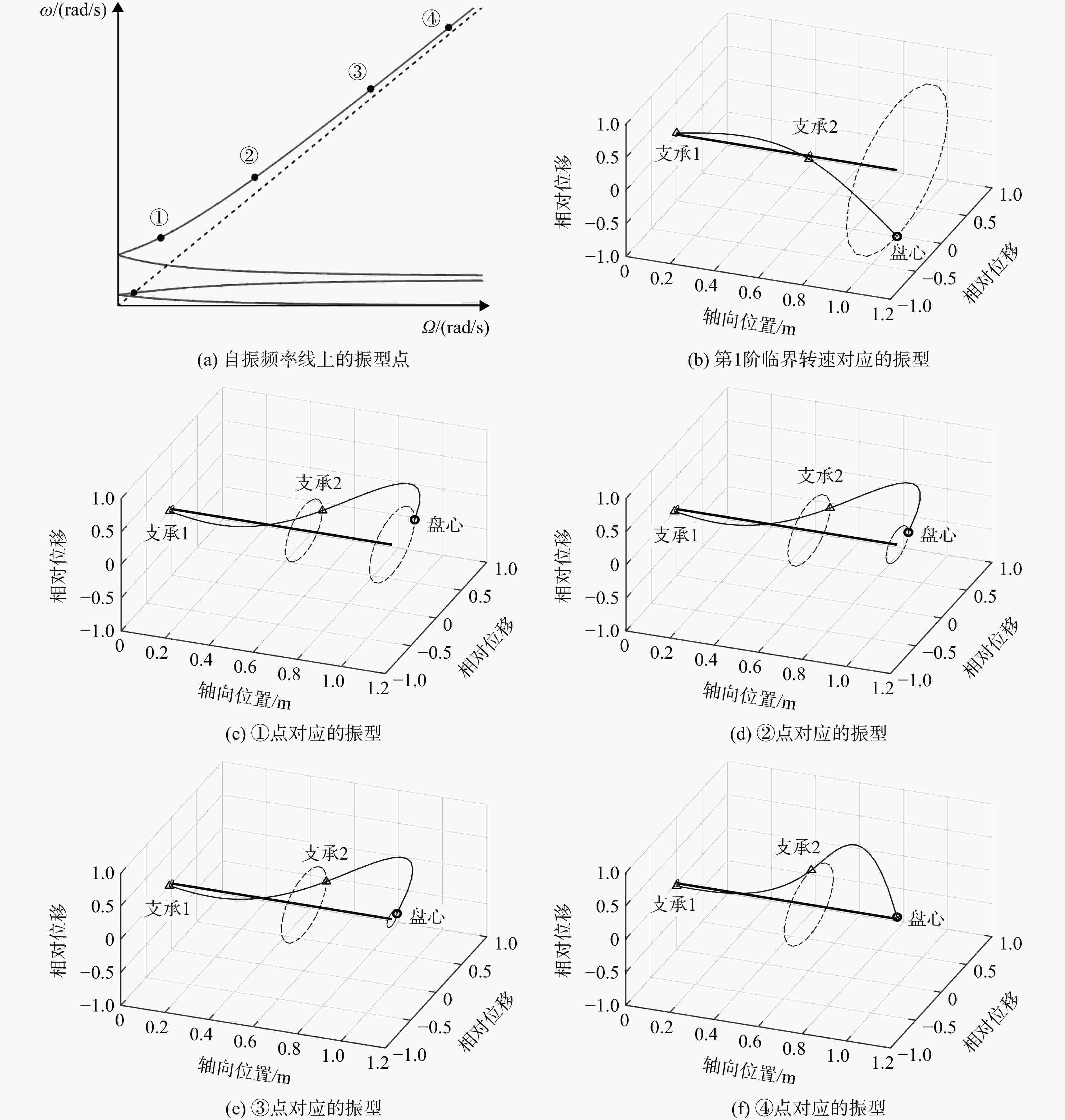

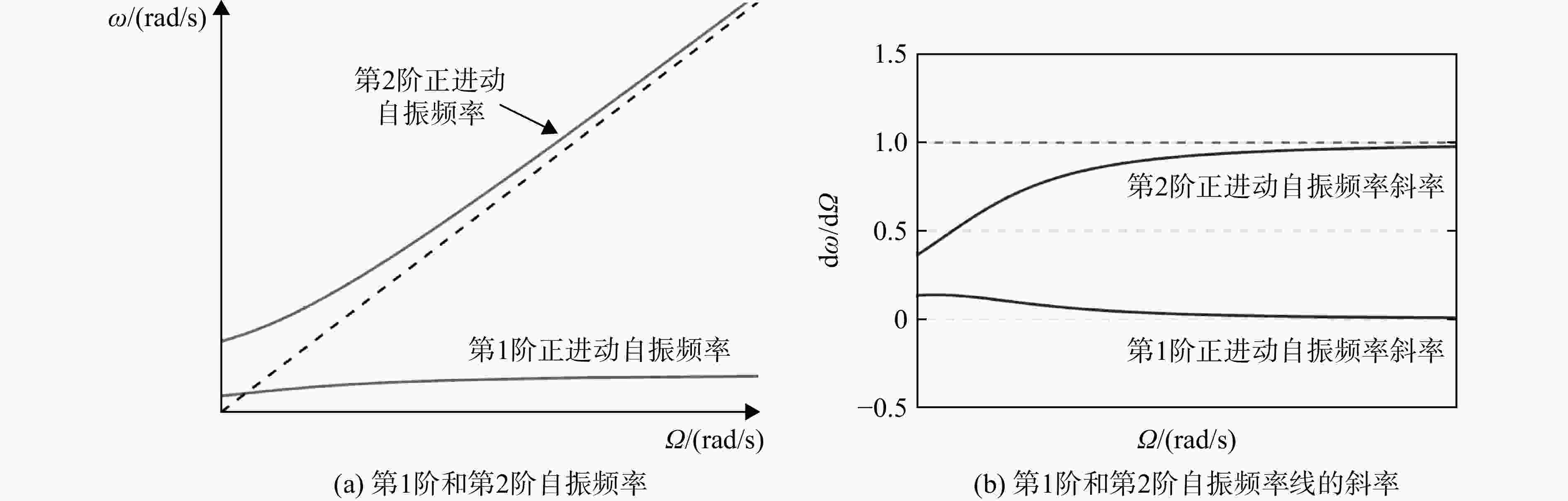

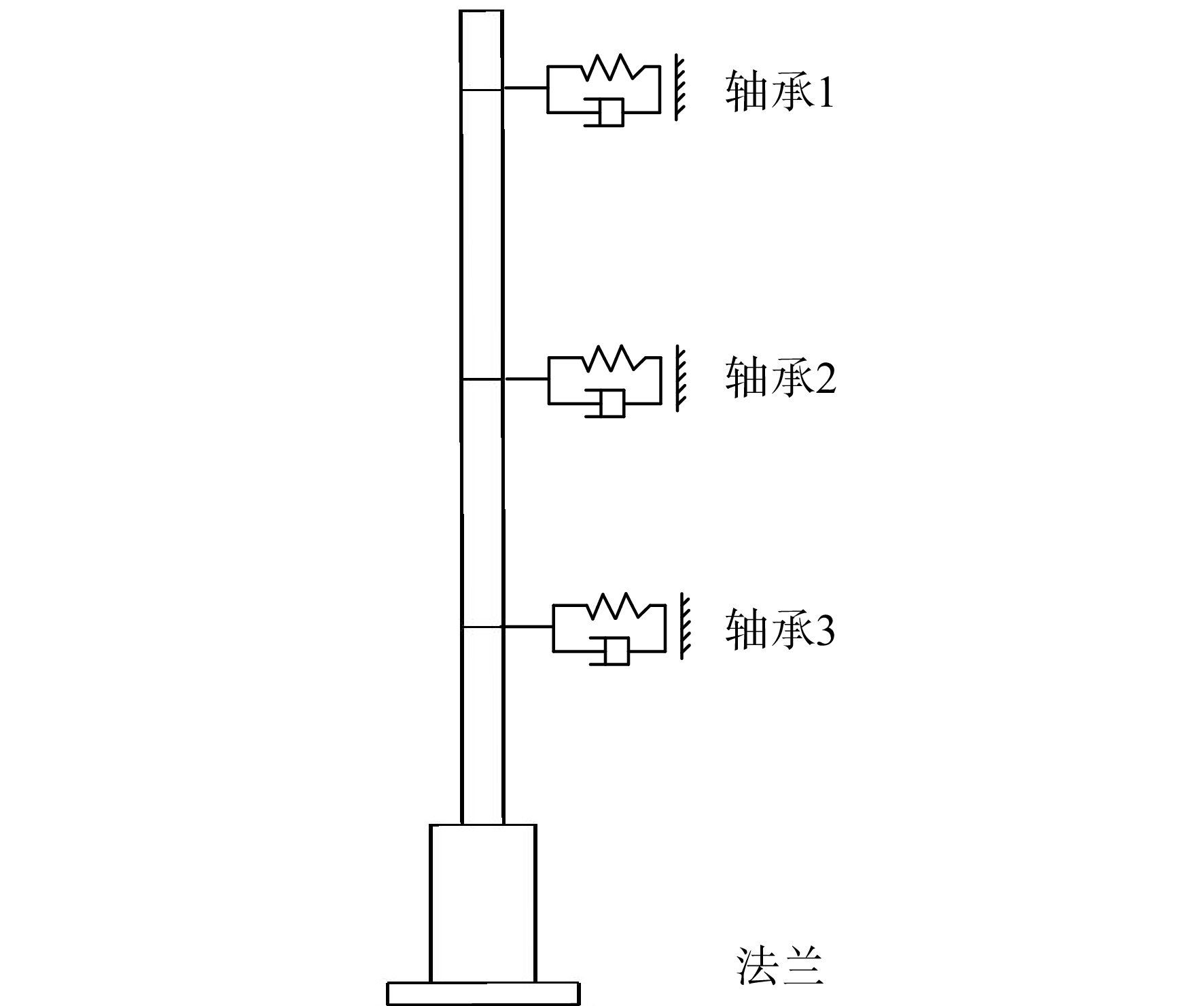

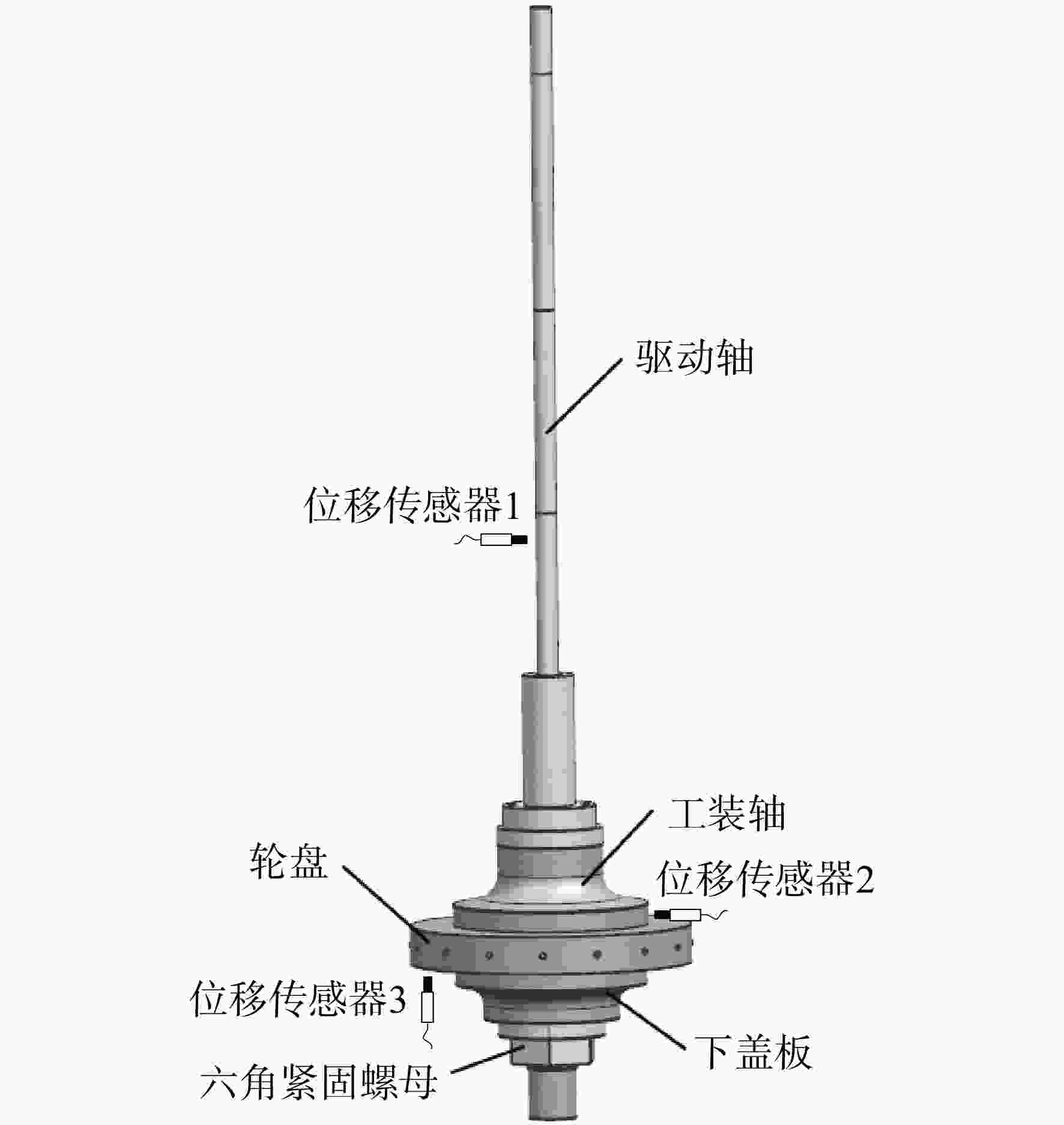

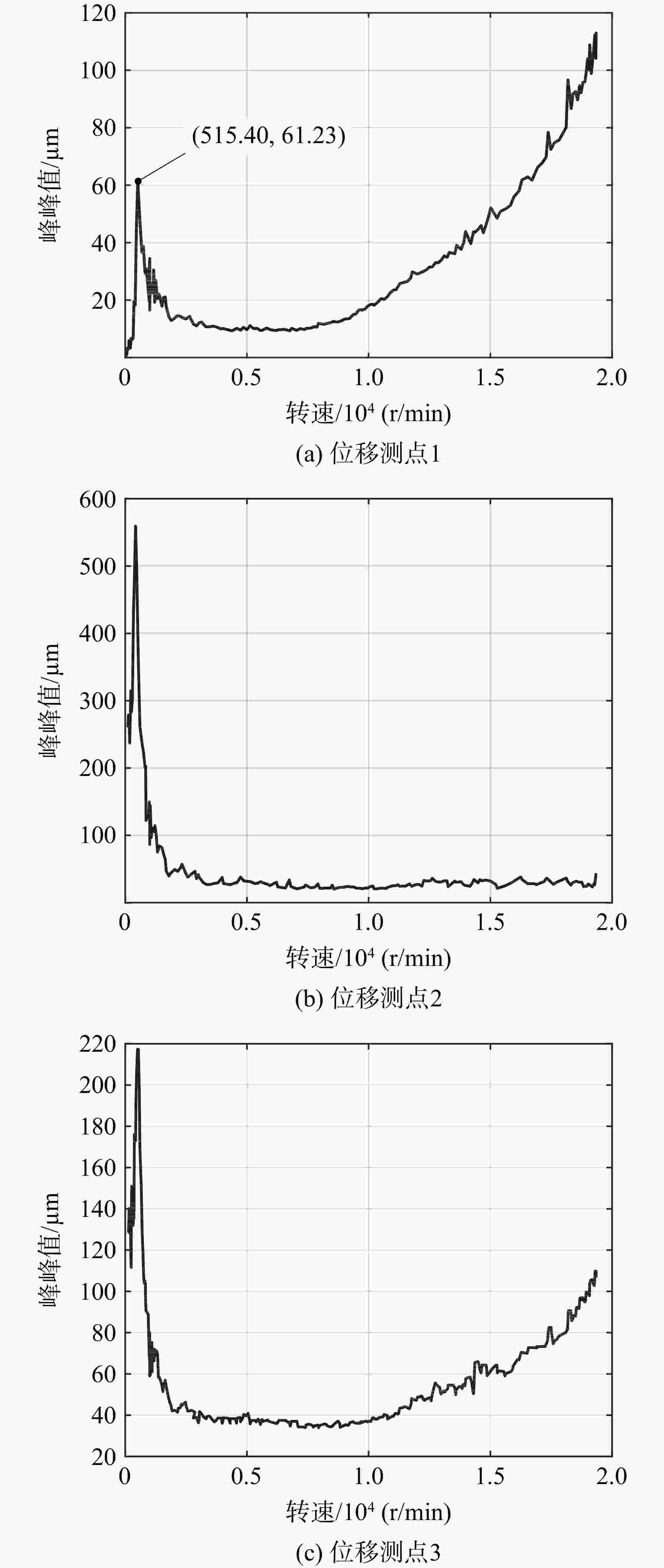

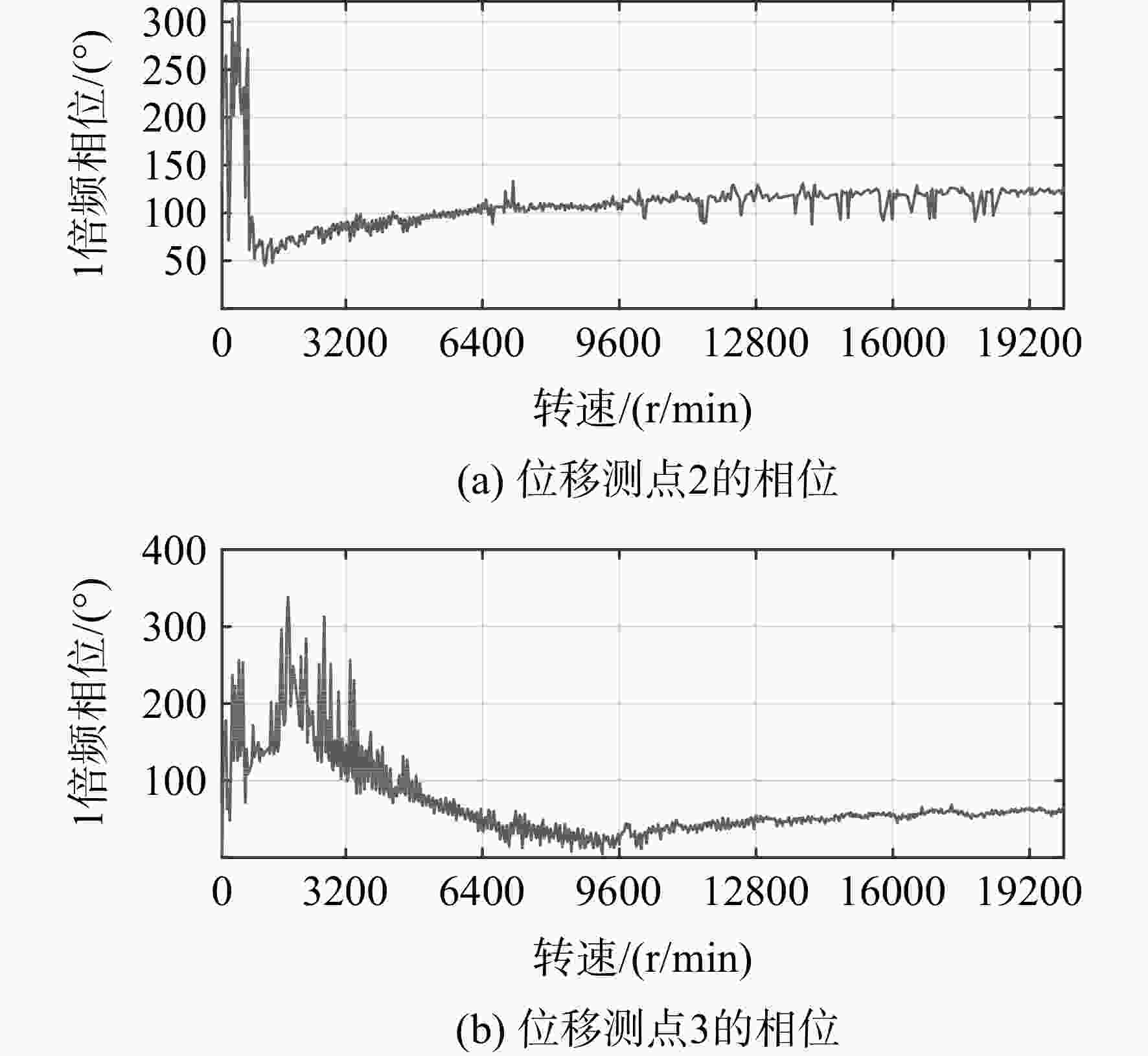

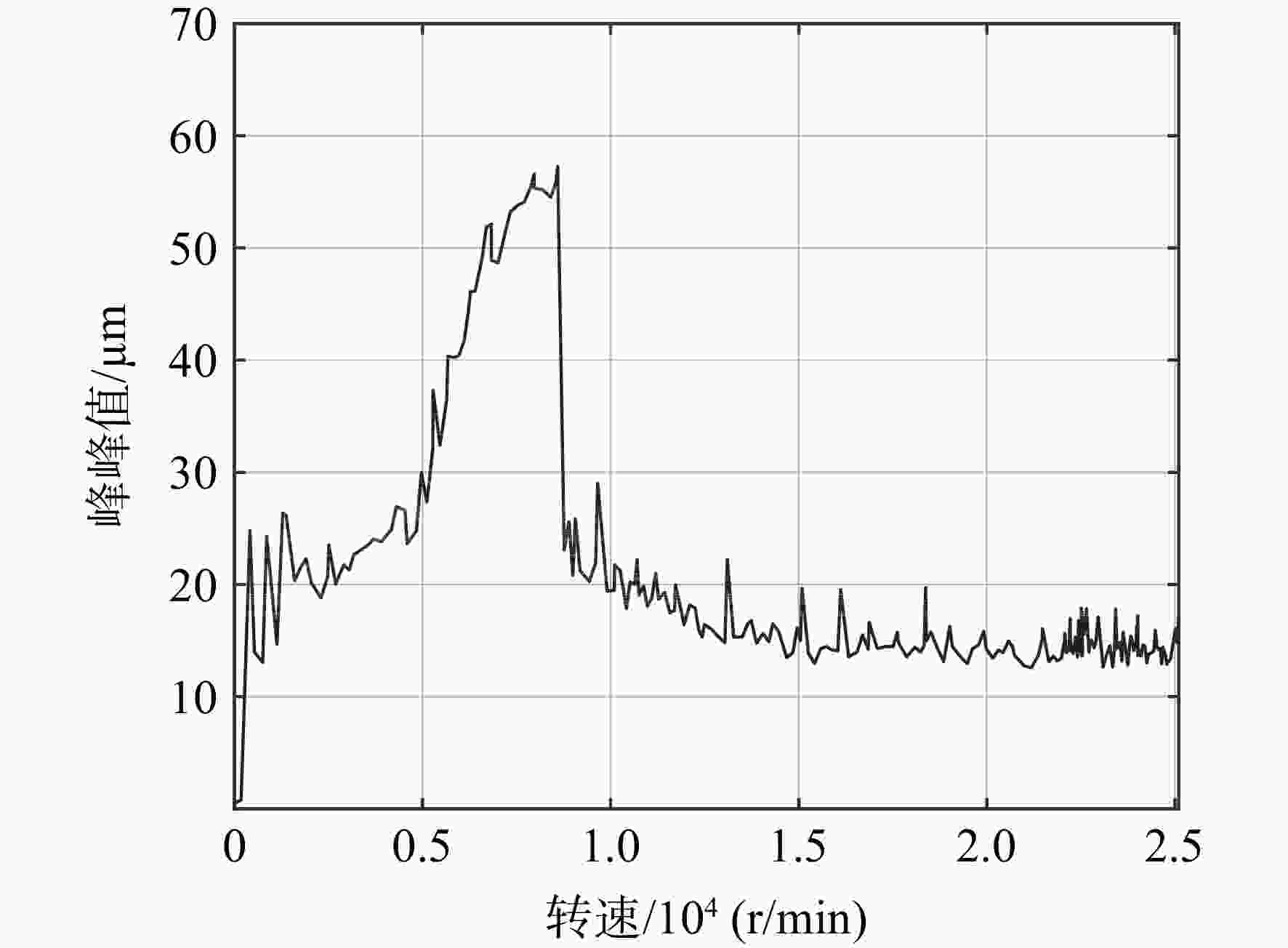

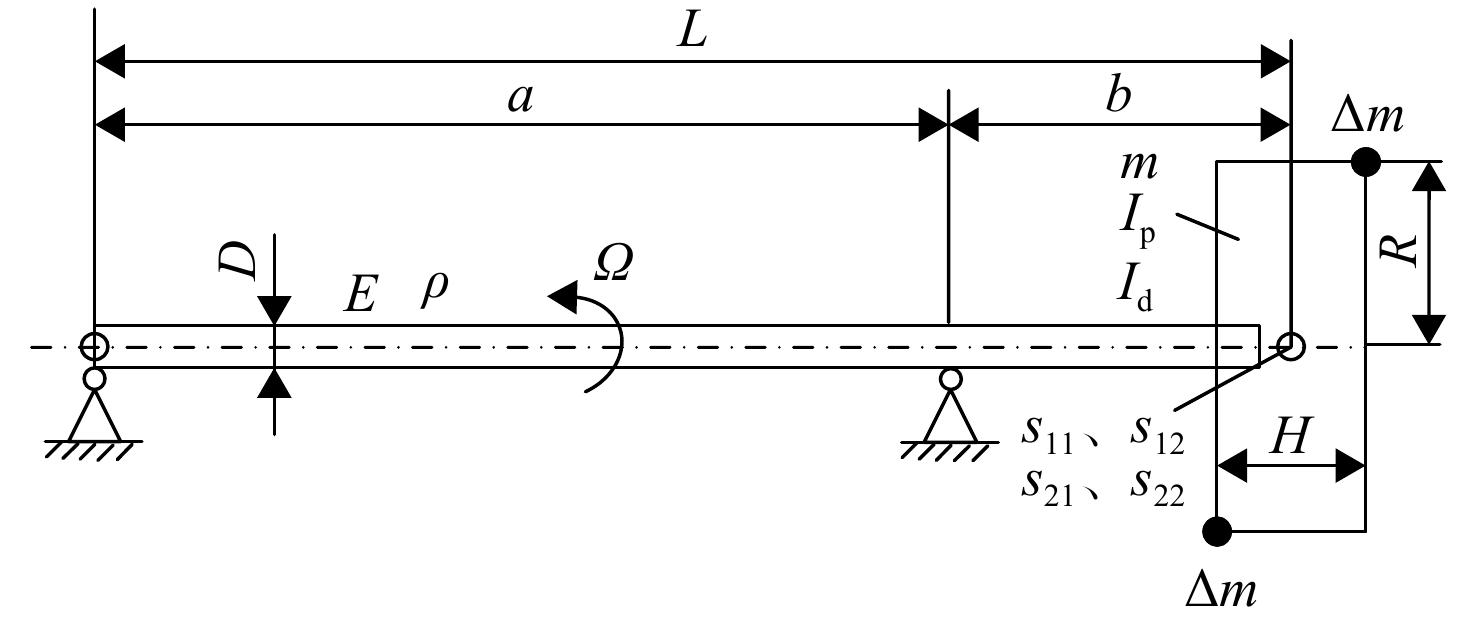

为了深入探究转子系统“临界跟随”现象的机理,建立悬臂转子模型,分析“临界跟随”状态下的转子动力学特性,设计搭建了悬臂转子试验器,并在高速超转试验台上进行试验验证。研究结果表明:当直径转动惯量与极转动惯量相等时,从一定的转速开始,盘的振动摆角响应会随转速持续增大;具有“临界跟随”特征的模态振型表现为,直径转动惯量与极转动惯量相等的盘位于振型节点,在不平衡力矩作用下,盘心振动位移为零,但盘的摆角不为零且随转速增加而增大,其相位角维持不变;若转子结构并非简单的单盘,则需计算组件的直径转动惯量与极转动惯量,以此检验是否会出现“临界跟随”;考虑转轴质量时,盘的惯量符合直径转动惯量与极转动惯量相等时,不会出现“临界跟随”现象,但会出现自振频率在较宽的范围与转子转速靠近,使“共振”区域变宽;“临界跟随”使得转子对不平衡激励非常敏感,应在转子动力学设计时予以避免。

Abstract:In order to deeply investigate the mechanism of “critical following speed”, a cantilever rotor dynamic model was established. The dynamic characteristics of the rotor system under “critical following speed” were analyzed. The cantilever rotor experimental system was designed and established, and experimental verification was finished on the overspeed test bench. The analysis results showed that from a certain rotational speed, when the diameter rotational inertia was equal to polar rotational inertia, the vibration pendulum angle response of the disk increased with the increasing rotational speed. The characteristics of the mode shape under “critical following speed” lied in that the disk (diameter rotational inertia was equal to polar rotational inertia) was located at the node of mode shape. The vibration displacement of the disk center was 0, but the pendulum angle of the disk was not 0 and increased with the increasing rotational speed, and the phase angle was kept constant. If the rotor was not a single-disk structure, the diameter rotational inertia and polar rotational inertia of the component should be calculated to determine whether the “critical following speed” phenomenon occurred. Considering the mass of the rotating shaft, when the disk satisfied the condition which diameter rotational inertia was equal to polar rotational inertia, the phenomenon of “critical following speed” did not occur, and the natural frequency line could be close to the speed line within a wide range, which would widen the “resonance vibration” region. “critical following speed” made vibration extremely sensitive to unbalanced load, which should be avoided in rotor dynamics design.

-

表 1 转子模型参数

Table 1. Parameters of rotor system

参数 数值 参数 数值 L/m 1.0 a/m 0.6 b/m 0.4 D/m 0.03 E/1011 Pa 2.09 H/m 0.2 Δm/kg 0.001 R/m 0.1 m/kg 40.0 Ip/(kg·m2) 0.4 sb1/106 (N/m) 4.0 sb2/106 (N/m) 5.0 c b1/(N·s/m) 200 c b2/(N·s/m) 200 ρ/(kg/m3) 7870 表 2 两件试验件的惯量参数

Table 2. Inertia parameters of two rotor test rigs

试验件 质量/

kg极转动惯量

Ip/(kg·m2)直径转动惯量

Id/(kg·m2)Ip/Id 1 9.18 0.0173 0.0168 1.02976 2 8.17 0.017 0.206 0.0825 -

[1] GASCH R,NORDMANN R,PFÜTZNER H. Rotordynamik[M]. Berlin: Springer Berlin Heidelberg,2002. [2] 廖明夫. 航空发动机转子动力学[M]. 西安: 西北工业大学出版社,2015. LIAO Mingfu. Rotor dynamics of aero-engine[M]. Xi’an: Northwestern Polytechnical University Press,2015. (in ChineseLIAO Mingfu. Rotor dynamics of aero-engine[M]. Xi’an: Northwestern Polytechnical University Press, 2015. (in Chinese) [3] 李岩,廖明夫,蒋云帆,等. 航空发动机双转子系统“临界跟随” 现象的机理及影响[J]. 航空动力学报,2019,34(11): 2403-2413. LI Yan,LIAO Mingfu,JIANG Yunfan,et al. Mechanism and effect of “critical follower speed” on dual-rotor system of aero-engines[J]. Journal of Aerospace Power,2019,34(11): 2403-2413. (in ChineseLI Yan, LIAO Mingfu, JIANG Yunfan, et al. Mechanism and effect of “critical follower speed” on dual-rotor system of aero-engines[J]. Journal of Aerospace Power, 2019, 34(11): 2403-2413. (in Chinese) [4] 廖明夫,王四季,李全坤,等. 航空发动机转子-支承系统的振动-下册[M]. 北京: 科学出版社,2023. LIAO Mingfu,WANG Siji,LI Quankun,et al. Vibration of aeroengine rotor-support system-volume Ⅱ[M]. Beijing: Science Press,2023. (in ChineseLIAO Mingfu, WANG Siji, LI Quankun, et al. Vibration of aeroengine rotor-support system-volume Ⅱ[M]. Beijing: Science Press, 2023. (in Chinese) [5] 李岩. 航空发动机转子系统可容模态优化设计方法与实验研究[D]. 西安: 西北工业大学,2020. LI Yan. Optimization design and experimental verification of bearable modes of aero-engine rotor system [D]. Xi’an: Northwestern Polytechnical University,2020. (in ChineseLI Yan. Optimization design and experimental verification of bearable modes of aero-engine rotor system [D]. Xi’an: Northwestern Polytechnical University, 2020. (in Chinese) [6] 侯理臻,王伟,王珺,等. 轮盘超转研究中的“临界跟随”现象[J]. 西安交通大学学报,2023,34(11): 2403-2413. HOU Lizhen,WANG Wei,WANG Jun,et al. The phenomenon of “critical follower speed” on disk overspeed research[J]. Journal of Xi’an Jiaotong University,2023,34(11): 2403-2413. (in ChineseHOU Lizhen, WANG Wei, WANG Jun, et al. The phenomenon of “critical follower speed” on disk overspeed research[J]. Journal of Xi’an Jiaotong University, 2023, 34(11): 2403-2413. (in Chinese) [7] ALLMON B L,GLYNN C C,FISHER K L,et al. Method and apparatus for supporting rotor assemblies during unbalances: US6491497[P]. 2002-12-10. [8] DOERFLEIN T M,WILTON S A,ALLMON B L. Method and apparatus for supporting rotor assemblies during unbalances: US6783319[P]. 2004-08-31. [9] STORACE A F. Fan assembly support system: US6325546[P]. 2001-12-04. [10] HARRIS C M. The shock and vibration handbook [M]. New York: McGraw Hill,1996. [11] 蒋云帆,廖明夫,刘永泉,等. 同转/对转双转子系统的动力学特性[J]. 航空动力学报,2013,28(12): 2771-2780. JIANG Yunfan,LIAO Mingfu,LIU Yongquan,et al. Dynamic characteristics of co-rotating/counter-rotating dual-rotor system[J]. Journal of Aerospace Power,2013,28(12): 2771-2780. (in ChineseJIANG Yunfan, LIAO Mingfu, LIU Yongquan, et al. Dynamic characteristics of co-rotating/counter-rotating dual-rotor system[J]. Journal of Aerospace Power, 2013, 28(12): 2771-2780. (in Chinese) [12] 张大义,刘烨辉,洪杰,等. 航空发动机整机动力学模型建立与振动特性分析[J]. 推进技术,2015,36(5): 768-773. ZHANG Dayi,LIU Yehui,HONG Jie,et al. Investigation on dynamical modeling and vibration characteristics for aero engine[J]. Journal of Propulsion Technology,2015,36(5): 768-773. (in ChineseZHANG Dayi, LIU Yehui, HONG Jie, et al. Investigation on dynamical modeling and vibration characteristics for aero engine[J]. Journal of Propulsion Technology, 2015, 36(5): 768-773. (in Chinese) [13] 廖明夫,谭大力,耿建明,等. 航空发动机高压转子的结构动力学设计方法[J]. 航空动力学报,2014,29(7): 1505-1519. LIAO Mingfu,TAN Dali,GENG Jianming,et al. Structure dynamics design method of aero-engine high pressure rotor[J]. Journal of Aerospace Power,2014,29(7): 1505-1519. (in ChineseLIAO Mingfu, TAN Dali, GENG Jianming, et al. Structure dynamics design method of aero-engine high pressure rotor[J]. Journal of Aerospace Power, 2014, 29(7): 1505-1519. (in Chinese) [14] 蔡全卓. 典型航空发动机轮盘破裂失效研究[D]. 杭州: 浙江大学,2017. CAI Quanzhuo. Research on burst failure of typical aeroengine disk[D]. Hangzhou: Zhejiang University,2017. (in ChineseCAI Quanzhuo. Research on burst failure of typical aeroengine disk[D]. Hangzhou: Zhejiang University, 2017. (in Chinese) [15] 胡清清. 基于失效模式的轮盘破裂转速预测方法研究[D]. 杭州: 浙江大学,2020. HU Qingqing. Research on disk burst speed prediction method based on failure mode[D]. Hangzhou: Zhejiang University,2020. (in ChineseHU Qingqing. Research on disk burst speed prediction method based on failure mode[D]. Hangzhou: Zhejiang University, 2020. (in Chinese) [16] 金小杰. 航空发动机转子超转破裂预测方法评估与应用[D]. 南京: 南京航空航天大学,2018. JIN Xiaojie. Evaluation and application of the overspeed burst prediction method on aero-engine rotor[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2018. (in ChineseJIN Xiaojie. Evaluation and application of the overspeed burst prediction method on aero-engine rotor[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018. (in Chinese) [17] 谢文涛. 航空发动机动力涡轮包容设计与验证技术研究[D]. 上海: 上海交通大学,2017. XIE Wentao. Containment design and verification technology research on powerturbine of aeroengine[D]. Shanghai: Shanghai Jiao Tong University,2017. (in ChineseXIE Wentao. Containment design and verification technology research on powerturbine of aeroengine[D]. Shanghai: Shanghai Jiao Tong University, 2017. (in Chinese) [18] 王浩然. 航空发动机轮盘破裂分析方法研究与应用[D]. 南京: 南京航空航天大学,2016. WANG Haoran. Research and application of analysis method of aero-engine disc fracture[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2016. (in ChineseWANG Haoran. Research and application of analysis method of aero-engine disc fracture[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016. (in Chinese) -

下载:

下载: