Influence of coolant inlet angle on endwall leakage flow film cooling performance

-

摘要:

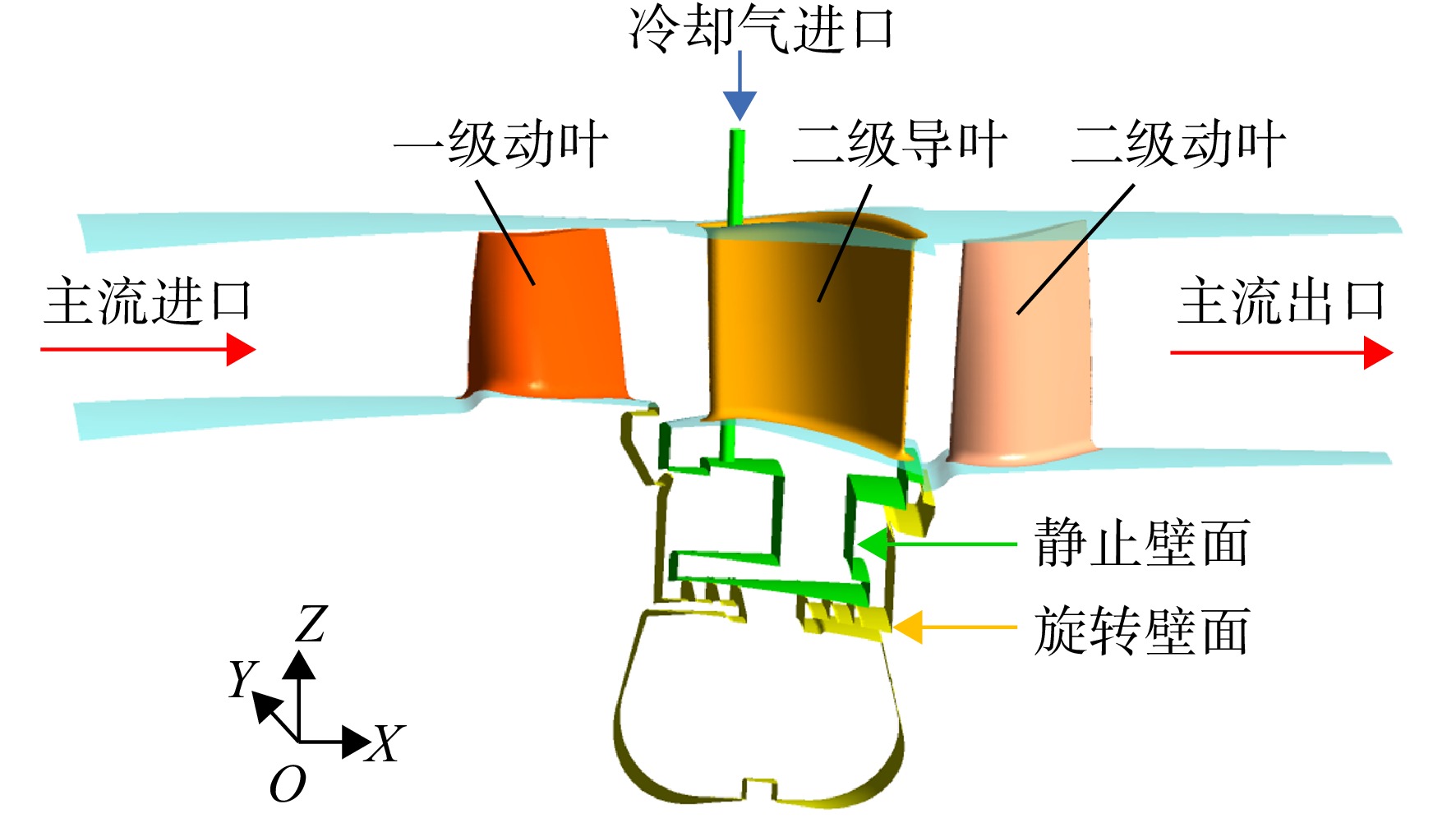

基于叶盘一体化模型,通过使用切应力输运(SST)模型对雷诺平均Naiver-Stokes(RANS)方程进行求解的方式研究了涡轮叶片端壁泄漏流气膜冷却特性,盘腔出口处的旋转雷诺数为1.5×105。为保证冷气与主流的密度比,冷却气使用二氧化碳来模拟,其在盘腔和主流中的扩散通过求解湍流输运方程得到。通过传质模拟传热的方式研究了由二级导向器进入盘腔的冷却气进气角度(−45°,0°,+45°)对端壁绝热气膜冷却效率的影响。研究发现:改变冷却气进气角度对端壁冷却特性影响明显,−45°进气角度能明显提高各冷却气与主流质量流量比下的端壁气膜冷却效率。

Abstract:By using an integrated model with disc cavity and turbine blade, the endwall film cooling effectiveness was investigated numerically by using the shear stress transfer (SST) model to solve the Reynolds-averaged Naiver-Stokes (RANS) equation. The rotational Reynolds number at the outlet of the disc cavity was 1.5×105. Carbon dioxide was chosen as the coolant to maintain the coolant-to-mainstream density ratio. The diffusion process of coolant was characterized by solving the turbulent transport equation. The effect of coolant inlet angle (−45°, 0°, +45°) on the endwall film cooling effectiveness was investigated. It was found that the inlet angle of coolant had a significant impact on the endwall film cooling effectiveness, and the −45° inlet angle can significantly improve the endwall film cooling effectiveness at various coolant-to-mainstream mass flow rates.

-

Key words:

- gas turbine engine /

- turbine blade /

- endwall /

- leakage flow /

- film cooling

-

表 1 数值仿真模型结构参数

Table 1. Structural parameters of numerical simulation model

mm 参数 数值 涡轮盘半径R 180 二级导向器叶片轴向弦长Lcx 52 相邻二级导向器叶片周向距离D 40 AC 1 0 AC 2 0 SC 1 1.6 SC 2 3.6 SC 3 0.4 SC 4 0.4 表 2 数值仿真边界条件

Table 2. Boundary conditions of numerical simulation

参数 数值 主流平均进气角度/(°) 19 主流进口总压/Pa 98467 主流进口静温/K 298 涡轮转速/(r/min) 750 主流出口静压/Pa 98000 冷却气主流质量流量比Rmf/% 1.0,1.5,2.0,2.5,3.0 冷却气进气角度/(°) −45,0,+45 冷却气进口温度/K 298 表 3 气膜冷却效率试验测量不确定度

Table 3. Uncertainty in test measurement of film cooling effectiveness

$ \eta $ $ (\mathrm{\delta}\eta) /\eta $/% 0.9 0.0864 0.7 0.4143 0.5 1.244 0.3 3.705 0.1 17.86 表 4 从上游腔室流出的泄漏流Rmf1

Table 4. Rmf1 of leakage flow flowing out from upstream cavity

进气角度/(°) 从上游腔室流出的泄漏流Rmf1/% 冷却气Rmf=1.5% 冷却气Rmf=2.5% −45 1.102 2.036 0 1.262 2.248 +45 1.384 2.427 -

[1] UMESH U,VIGOR Y. A review of cooling technologies for high temperature rotating components in gas turbine[J]. Propulsion and Power Research,2022,11(3): 293-310. doi: 10.1016/j.jppr.2022.07.001 [2] SHARMA O P,BUTLER T L. Predictions of endwall losses and secondary flows in axial flow turbine cascades[J]. Journal of Turbomachinery,1987,109(2): 229-236. doi: 10.1115/1.3262089 [3] HAWTHORNE W R. Secondary circulation in fluid flow[J]. Proceedings of the Royal Society of London Series A Mathematical and Physical Sciences,1951,206(1086): 374-387. [4] GOLDSTEIN R J,SPORES R A. Turbulent transport on the endwall in the region between adjacent turbine blades[J]. Journal of Heat Transfer,1988,110(4a): 862-869. doi: 10.1115/1.3250586 [5] NICKLAS M. Film-cooled turbine endwall in a transonic flow field: Part Ⅱ heat transfer and film-cooling effectiveness[J]. Journal of Turbomachinery,2001,123(4): 720-729. doi: 10.1115/1.1397308 [6] 李宁坤,闻洁. 跨声速涡轮静子端壁气膜冷却数值研究[J]. 航空发动机,2011,37(3): 50-54. LI Ningkun,WEN Jie. Numerical study on flim cooling of transonicturbine vane endwall[J]. Aeroengine,2011,37(3): 50-54. (in Chinese doi: 10.3969/j.issn.1672-3147.2011.03.015 LI Ningkun, WEN Jie . Numerical study on flim cooling of transonicturbine vane endwall[J]. Aeroengine,2011 ,37 (3 ):50 -54 . (in Chinese) doi: 10.3969/j.issn.1672-3147.2011.03.015[7] BLAIR M F. An experimental study of heat transfer and film cooling on large-scale turbine endwalls[J]. Journal of Heat Transfer,1974,96(4): 524-529. doi: 10.1115/1.3450239 [8] 刘高文,刘松龄,朱惠人,等. 涡轮叶栅前缘上游端壁气膜冷却的传热实验研究[J]. 航空动力学报,2001,16(3): 249-255. LIU Gaowen,LIU Songling,ZHU Huiren,et al. Endwall heat transfer and film cooling measurements in a turbine cascade with injection upstream of leading edge[J]. Journal of Aerospace Power,2001,16(3): 249-255. (in Chinese doi: 10.3969/j.issn.1000-8055.2001.03.010 LIU Gaowen, LIU Songling, ZHU Huiren, et al . Endwall heat transfer and film cooling measurements in a turbine cascade with injection upstream of leading edge[J]. Journal of Aerospace Power,2001 ,16 (3 ):249 -255 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2001.03.010[9] 刘高文,刘松龄,许都纯,等. 涡轮叶栅前缘上游端壁气膜冷却的流场实验研究[J]. 航空动力学报,2001,16(2): 135-141. LIU Gaowen,LIU Songling,XU Duchun,et al. Experimental investigation of flow fields in a turbine cascade with endwall film-cooling upstream of leading edge[J]. Journal of Aerospace Power,2001,16(2): 135-141. (in Chinese doi: 10.3969/j.issn.1000-8055.2001.02.009 LIU Gaowen, LIU Songling, XU Duchun, et al . Experimental investigation of flow fields in a turbine cascade with endwall film-cooling upstream of leading edge[J]. Journal of Aerospace Power,2001 ,16 (2 ):135 -141 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2001.02.009[10] PAPA M,SRINIVASAN V,GOLDSTEIN R J. Film cooling effect of rotor-stator purge flow on endwall heat/mass transfer[J]. Journal of Turbomachinery,2012,134(4): 041014. [11] LI Xueying,REN Jing,JIANG Hongde. Influence of different film cooling arrangements on endwall cooling[J]. International Journal of Heat and Mass Transfer,2016,102: 348-359. doi: 10.1016/j.ijheatmasstransfer.2016.06.047 [12] 姚韵嘉,祝培源,陈云,等. 间隙位置对叶片端壁气膜冷却性能影响的实验研究[J]. 工程热物理学报,2019,40(10): 2327-2333. YAO Yunjia,ZHU Peiyuan,CHEN Yun,et al. Experimental study on the effect of the locations of slot jet on film cooling performance of endwall[J]. Journal of Engineering Thermophysics,2019,40(10): 2327-2333. (in Chinese YAO Yunjia, ZHU Peiyuan, CHEN Yun, et al . Experimental study on the effect of the locations of slot jet on film cooling performance of endwall[J]. Journal of Engineering Thermophysics,2019 ,40 (10 ):2327 -2333 . (in Chinese)[13] ZHU Peiyuan,SONG Liming,LI Jun,et al. Effects of upstream slot geometry on the endwall aerothermal performance of a gas turbine blade under different ejection angle conditions[J]. International Journal of Heat and Mass Transfer,2017,115: 652-669. doi: 10.1016/j.ijheatmasstransfer.2017.08.072 [14] 杜昆,李军,晏鑫. 槽缝射流对静叶端壁冷却性能的影响[J]. 西安交通大学学报,2015,49(1): 21-26. DU Kun,LI Jun,YAN Xin. Effect of the slot jet impingement on the cooling performance of the vane endwall[J]. Journal of Xi’an Jiaotong University,2015,49(1): 21-26. (in Chinese DU Kun, LI Jun, YAN Xin . Effect of the slot jet impingement on the cooling performance of the vane endwall[J]. Journal of Xi’an Jiaotong University,2015 ,49 (1 ):21 -26 . (in Chinese)[15] 高庆,屈杰,王汀,等. 轮缘间隙出流对下游动叶端壁气膜冷却特性的影响[J]. 动力工程学报,41(5): 374-379. GAO Qing,QU Jie,WANG Ting,et al. Effects of rim seal purge flow on film cooling characteristics of downstream rotor endwall[J]. Journal of Chinese Society of Power Engineering,41(5): 374-379. (in ChineseGAO Qing, QU Jie, WANG Ting, et al. Effects of rim seal purge flow on film cooling characteristics of downstream rotor endwall[J]. Journal of Chinese Society of Power Engineering, 41(5): 374-379. (in Chinese) [16] 张垲垣,杜昆,宋立明,等. 预旋槽缝流及间隙射流对端壁冷却性能的影响[J]. 工程热物理学报,2019,40(6): 1250-1255. ZHANG Kaiyuan,DU Kun,SONG Liming,et al. Effect of swirled purge flow and slashface leakage flow on endwall cooling performance[J]. Journal of Engineering Thermophysics,2019,40(6): 1250-1255. (in Chinese ZHANG Kaiyuan, DU Kun, SONG Liming, et al . Effect of swirled purge flow and slashface leakage flow on endwall cooling performance[J]. Journal of Engineering Thermophysics,2019 ,40 (6 ):1250 -1255 . (in Chinese)[17] REZASOLTANI M,SCHOBEIRI M T,HAN J C. Experimental investigation of the effect of purge flow on film cooling effectiveness on a rotating turbine with nonaxisymmetric end wall contouring[J]. Journal of Turbomachinery,2014,136(9): 091009. doi: 10.1115/1.4027196 [18] SURYANARAYANAN A,OZTURK B,SCHOBEIRI M T,et al. Film-cooling effectiveness on a rotating turbine platform using pressure sensitive paint technique[J]. Journal of Turbomachinery,2010,132(4): 1-13. [19] GAO Feng,CHEW J,CHANA K S,et al. Unsteady flow phenomena in turbine rim seals[J]. Journal of Engineering for Gas Turbines and Power,2016,139(3): 032501. [20] SANGAN C M,POUNTNEY O J,SCOBIE J A,et al. Experimental measurements of ingestion through turbine rim seals: Part Ⅲ single and double seals[J]. Journal of Turbomachinery,2013,135(5): 051011. doi: 10.1115/1.4007504 [21] POPOVÍC I,HODSON H P. Improving turbine stage efficiency and sealing effectiveness through modifications of the rim seal geometry[J]. Journal of Turbomachinery,2013,135(6): 061016. doi: 10.1115/1.4024872 [22] DA SOGHE R,BIANCHINI C,SANGAN C M,et al. Numerical characterization of hot-gas ingestion through turbine rim seals[J]. Journal of Engineering for Gas Turbines and Power,2017,139(3): 032602. doi: 10.1115/1.4034540 [23] ZHANG Feng,WANG Xinjun,LI Jun,et al. Numerical investigation on the effect of radial location of sealing air inlet and its geometry on the sealing performance of a stator-well cavity[J]. International Journal of Heat and Mass Transfer,2017,115: 820-832. doi: 10.1016/j.ijheatmasstransfer.2017.08.053 [24] 陶加银,高庆,宋立明,等. 基于附加示踪变量法的涡轮轮缘密封非定常封严特性研究[J]. 工程热物理学报,2014,35(11): 2154-2158. TAO Jiayin,GAO Qing,SONG Liming,et al. Numerical investigations on the unsteady mainstream ingestion characteristics of turbine rim seals with additional passive tracer method[J]. Journal of Engineering Thermophysics,2014,35(11): 2154-2158. (in Chinese TAO Jiayin, GAO Qing, SONG Liming, et al . Numerical investigations on the unsteady mainstream ingestion characteristics of turbine rim seals with additional passive tracer method[J]. Journal of Engineering Thermophysics,2014 ,35 (11 ):2154 -2158 . (in Chinese)[25] XIE Gang,TAO Zhi,ZHOU Zhiyu,et al. Hole arrangement effect to film cooling performance on leading edge region of rotating blade[J]. International Journal of Thermal Sciences,2021,169: 107034. doi: 10.1016/j.ijthermalsci.2021.107034 [26] LIU T,SULLIVAN J P. Pressure and temperature sensitive paints[M]. Berlin,Germany: Springer,2005. [27] NATSUI G,LITTLE Z,KAPAT J S,et al. A detailed uncertainty analysis of adiabatic film cooling effectiveness measurements using pressure-sensitive paint[J]. Journal of Turbomachinery,2016,138(8): 081007. doi: 10.1115/1.4032674 -

下载:

下载: