Study on airworthiness compliance demonstration method of aeroengine components fabricated through selective laser melting technique

-

摘要:

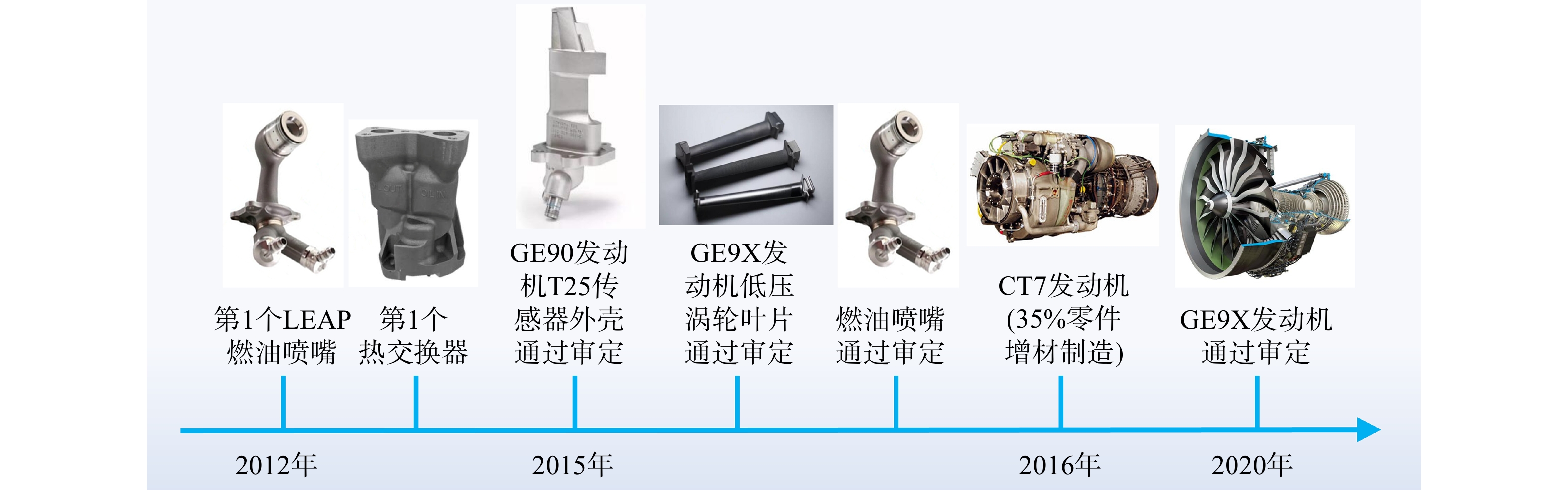

针对民用航空发动机激光选区熔化制件适航符合性验证需求,总结了激光选区熔化技术在航空发动机中的应用现状,分析了激光选区熔化制件适航符合性验证相关参考资料要求,研究了激光选区熔化航空发动机制件适航符合性验证方法。目前,国外已有激光选区熔化航空发动机制件通过了适航审定,而我国在该领域仍处于起步阶段。基于相关参考资料及传统工艺适航符合性验证方法,认为激光选区熔化航空发动机制件的适航符合性验证方法主要应包括:建立激光选区熔化材料规范、认证激光选区熔化工艺、鉴定激光选区熔化成形材料是否合格及确定设计用材料性能。

Abstract:Motivated by the demand of airworthiness compliance of civil aeroengine components fabricated using selective laser melting (SLM) technique, the applications of SLMed aeroengine components were summarized. Additionally, reference related to airworthiness compliance of SLMed components were analyzed. Meanwhile, airworthiness compliance demonstration method of SLMed aeroengine components was investigated. Presently, some SLMed aeroengine components have passed the airworthiness certification in foreign countries. However, China is still in the initial stage in this field. According to the related reference and airworthiness compliance demonstration method of aeroengine components manufactured through traditional processing techniques, the airworthiness compliance demonstration method of SLMed aeroengine components should mainly contain the following parts: establishment of selective laser melted material specifications, certification of selective laser melting process, identification of material quality and determination of material properties.

-

Key words:

- selective laser melting /

- aeroengine /

- component /

- airworthiness /

- compliance demonstration method

-

-

[1] 董鹏,梁晓康,赵衍华,等. 激光增材制造技术在航天构件整体化轻量化制造中的应用现状与展望[J]. 航天制造技术,2018(1): 7-11. DONG Peng,LIANG Xiaokang,ZHAO Yanhua,et al. Research status of laser additive manufacturing in integrity and lightweight[J]. Aerospace Manufacturing Technology,2018(1): 7-11. (in ChineseDONG Peng, LIANG Xiaokang, ZHAO Yanhua, et al. Research status of laser additive manufacturing in integrity and lightweight[J]. Aerospace Manufacturing Technology, 2018(1): 7-11. (in Chinese) [2] 刘书田,李取浩,陈文炯,等. 拓扑优化与增材制造结合: 一种设计与制造一体化方法[J]. 航空制造技术,2017,60(10): 26-31. LIU Shutian,LI Quhao,CHEN Wenjiong,et al. Combination of topology optimization and additive manufacturing: an integration method of structural design and manufacturing[J]. Aeronautical Manufacturing Technology,2017,60(10): 26-31. (in ChineseLIU Shutian, LI Quhao, CHEN Wenjiong, et al. Combination of topology optimization and additive manufacturing: an integration method of structural design and manufacturing[J]. Aeronautical Manufacturing Technology, 2017, 60(10): 26-31. (in Chinese) [3] 王旭葆,曲波. 基于SLM工艺的航空铝合金支架的轻量化设计[J]. 机械设计,2018,35(10): 50-53. WANG Xubao,QU Bo. Lightweight design of aluminum-alloy aero support based on SLM[J]. Journal of Machine Design,2018,35(10): 50-53. (in ChineseWANG Xubao, QU Bo. Lightweight design of aluminum-alloy aero support based on SLM[J]. Journal of Machine Design, 2018, 35(10): 50-53. (in Chinese) [4] 刘景博,刘世锋,杨鑫,等. 金属增材制造技术轻量化应用研究进展[J]. 中国材料进展,2020,39(2): 163-168. LIU Jingbo,LIU Shifeng,YANG Xin,et al. Progress in lightweight application research of additive manufacturing technology[J]. Materials China,2020,39(2): 163-168. (in ChineseLIU Jingbo, LIU Shifeng, YANG Xin, et al. Progress in lightweight application research of additive manufacturing technology[J]. Materials China, 2020, 39(2): 163-168. (in Chinese) [5] 王玉,李帅帅,于颖. 面向增材制造的零件结构及工艺设计[J]. 同济大学学报(自然科学版),2020,48(6): 869-879. WANG Yu,LI Shuaishuai,YU Ying. Structure design and process planning aor additive manufacturing[J]. Journal of Tongji University (Natural Science),2020,48(6): 869-879. (in ChineseWANG Yu, LI Shuaishuai, YU Ying. Structure design and process planning aor additive manufacturing[J]. Journal of Tongji University (Natural Science), 2020, 48(6): 869-879. (in Chinese) [6] 朱继宏,周涵,王创,等. 面向增材制造的拓扑优化技术发展现状与未来[J]. 航空制造技术,2020,63(10): 24-38. ZHU Jihong,ZHOU Han,WANG Chuang,et al. Status and future of topology optimization for additive manufacturing[J]. Aeronautical Manufacturing Technology,2020,63(10): 24-38. (in ChineseZHU Jihong, ZHOU Han, WANG Chuang, et al. Status and future of topology optimization for additive manufacturing[J]. Aeronautical Manufacturing Technology, 2020, 63(10): 24-38. (in Chinese) [7] 王天元,黄帅,周标,等. 航空装备激光增材制造技术发展及路线图[J]. 航空材料学报,2023,43(1): 1-17. WANG Tianyuan,HUANG Shuai,ZHOU Biao,et al. Development and roadmap of laser additive manufacturing technology for aviation equipment[J]. Journal of Aeronautical Materials,2023,43(1): 1-17. (in ChineseWANG Tianyuan, HUANG Shuai, ZHOU Biao, et al. Development and roadmap of laser additive manufacturing technology for aviation equipment[J]. Journal of Aeronautical Materials, 2023, 43(1): 1-17. (in Chinese) [8] 刘伟,李能,周标,等. 复杂结构与高性能材料增材制造技术进展[J]. 机械工程学报,2019,55(20): 128-151,159. LIU Wei,LI Neng,ZHOU Biao,et al. Progress in additive manufacturing on complex structures and high-performance materials[J]. Journal of Mechanical Engineering,2019,55(20): 128-151,159. (in ChineseLIU Wei, LI Neng, ZHOU Biao, et al. Progress in additive manufacturing on complex structures and high-performance materials[J]. Journal of Mechanical Engineering, 2019, 55(20): 128-151, 159. (in Chinese) [9] 郭绍庆,刘伟,黄帅,等. 金属激光增材制造技术发展研究[J]. 中国工程科学,2020,22(3): 56-62. GUO Shaoqing,LIU Wei,HUANG Shuai,et al. Development of laser additive manufacturing technology for metals[J]. Strategic Study of CAE,2020,22(3): 56-62. (in Chinese doi: 10.15302/J-SSCAE-2020.03.009GUO Shaoqing, LIU Wei, HUANG Shuai, et al. Development of laser additive manufacturing technology for metals[J]. Strategic Study of CAE, 2020, 22(3): 56-62. (in Chinese) doi: 10.15302/J-SSCAE-2020.03.009 [10] 卢秉恒. 增材制造技术: 现状与未来[J]. 中国机械工程,2020,31(1): 19-23. LU Bingheng. Additive manufacturing—current situation and future[J]. China Mechanical Engineering,2020,31(1): 19-23. (in ChineseLU Bingheng. Additive manufacturing—current situation and future[J]. China Mechanical Engineering, 2020, 31(1): 19-23. (in Chinese) [11] 顾冬冬,张红梅,陈洪宇,等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光,2020,47(5): 0500002. GU Dongdong,ZHANG Hongmei,CHEN Hongyu,et al. Laser additive manufacturing of high-performance metallic aerospace components[J]. Chinese Journal of Lasers,2020,47(5): 0500002. (in Chinese doi: 10.3788/CJL202047.0500002GU Dongdong, ZHANG Hongmei, CHEN Hongyu, et al. Laser additive manufacturing of high-performance metallic aerospace components[J]. Chinese Journal of Lasers, 2020, 47(5): 0500002. (in Chinese) doi: 10.3788/CJL202047.0500002 [12] 胡凯明,黄洁,李明亮,等. 面向激光增材制造的轻量化设计及适航分析[J]. 应用激光,2023,43(5): 19-28. HU Kaiming,HUANG Jie,LI Mingliang,et al. Lightweight design and airworthiness analysis for laser additive manufacturing[J]. Applied Laser,2023,43(5): 19-28. (in ChineseHU Kaiming, HUANG Jie, LI Mingliang, et al. Lightweight design and airworthiness analysis for laser additive manufacturing[J]. Applied Laser, 2023, 43(5): 19-28. (in Chinese) [13] 常坤,梁恩泉,张韧,等. 金属材料增材制造及其在民用航空领域的应用研究现状[J]. 材料导报,2021,35(3): 3176-3182. CHANG Kun,LIANG Enquan,ZHANG Ren,et al. Status of metal additive manufacturing and its application research in the field of civil aviation[J]. Materials Reports,2021,35(3): 3176-3182. (in ChineseCHANG Kun, LIANG Enquan, ZHANG Ren, et al. Status of metal additive manufacturing and its application research in the field of civil aviation[J]. Materials Reports, 2021, 35(3): 3176-3182. (in Chinese) [14] 孙小峰,荣婷,黄洁,等. 激光增材制造技术在航空制造领域的研究与应用进展[J]. 金属加工(热加工),2021(3): 7-14. SUN Xiaofeng,RONG Ting,HUANG Jie,et al. Research and application progress of laser additive manufacturing technology in aviation manufacturing field[J]. MW Metal Forming,2021(3): 7-14. (in ChineseSUN Xiaofeng, RONG Ting, HUANG Jie, et al. Research and application progress of laser additive manufacturing technology in aviation manufacturing field[J]. MW Metal Forming, 2021(3): 7-14. (in Chinese) [15] 雷力明,侯慧鹏,何艳丽,等. 金属增材制造技术在民用航空领域的应用与挑战[J]. 航空制造技术,2019,62(21): 22-30. LEI Liming,HOU Huipeng,HE Yanli,et al. Application and challenges of metal additive manufacturing in civil aviation[J]. Aeronautical Manufacturing Technology,2019,62(21): 22-30. (in ChineseLEI Liming, HOU Huipeng, HE Yanli, et al. Application and challenges of metal additive manufacturing in civil aviation[J]. Aeronautical Manufacturing Technology, 2019, 62(21): 22-30. (in Chinese) [16] 江武,刘木君,郝晓宁,等. 大型整体金属结构增材制造技术适航验证[J]. 航空材料学报,2019,39(2): 90-97. JIANG Wu,LIU Mujun,HAO Xiaoning,et al. Airworthiness verification of additive manufacturing technology for large integral metallic structure[J]. Journal of Aeronautical Materials,2019,39(2): 90-97. (in ChineseJIANG Wu, LIU Mujun, HAO Xiaoning, et al. Airworthiness verification of additive manufacturing technology for large integral metallic structure[J]. Journal of Aeronautical Materials, 2019, 39(2): 90-97. (in Chinese) [17] 徐亚芳. 增材制造技术在民用飞机上的应用及适航思考[J]. 科技创新导报,2018,15(21): 11-12. XU Yafang. Application of additive manufacturing technology in civil aircraft and airworthiness thinking[J]. Science and Technology Innovation Herald,2018,15(21): 11-12. (in ChineseXU Yafang. Application of additive manufacturing technology in civil aircraft and airworthiness thinking[J]. Science and Technology Innovation Herald, 2018, 15(21): 11-12. (in Chinese) [18] SEIFI M,GORELIK M,WALLER J,et al. Progress towards metal additive manufacturing standardization to support qualification and certification[J]. JOM,2017,69(3): 439-455. doi: 10.1007/s11837-017-2265-2 [19] 冀国锋,李俊励,杨进飞. 风扇/压气机增材制造技术的应用与发展趋势[J]. 航空动力,2020(2): 75-78. JI Guofeng,LI Junli,YANG Jinfei. Additive manufacturing technology for fan and compressor[J]. Aerospace Power,2020(2): 75-78. (in ChineseJI Guofeng, LI Junli, YANG Jinfei. Additive manufacturing technology for fan and compressor[J]. Aerospace Power, 2020(2): 75-78. (in Chinese) [20] 刘业胜,韩品连,胡寿丰,等. 金属材料激光增材制造技术及在航空发动机上的应用[J]. 航空制造技术,2014,57(10): 62-67. LIU Yesheng,HAN Pinlian,HU Shoufeng,et al. Development of laser additive manufacturing with metallic materials and its application in aviation engines[J]. Aeronautical Manufacturing Technology,2014,57(10): 62-67. (in ChineseLIU Yesheng, HAN Pinlian, HU Shoufeng, et al. Development of laser additive manufacturing with metallic materials and its application in aviation engines[J]. Aeronautical Manufacturing Technology, 2014, 57(10): 62-67. (in Chinese) [21] 杨胶溪,吴文亮,王长亮,等. 激光选区熔化技术在航空航天领域的发展现状及典型应用[J]. 航空材料学报,2021,41(2): 1-15. YANG Jiaoxi,WU Wenliang,WANG Changliang,et al. Development status and typical application of selective laser melting technology applications in aerospace field[J]. Journal of Aeronautical Materials,2021,41(2): 1-15. (in ChineseYANG Jiaoxi, WU Wenliang, WANG Changliang, et al. Development status and typical application of selective laser melting technology applications in aerospace field[J]. Journal of Aeronautical Materials, 2021, 41(2): 1-15. (in Chinese) [22] 何艳丽,廖焕文,王禄秀. 商用航空发动机金属增材制造技术及装备应用[J]. 航空制造技术,2014,57(22): 47-51. HE Yanli,LIAO Huanwen,WANG Luxiu. Application of technology and equipment for metallic additive manufacturing in commercial aeroengine[J]. Aeronautical Manufacturing Technology,2014,57(22): 47-51. (in ChineseHE Yanli, LIAO Huanwen, WANG Luxiu. Application of technology and equipment for metallic additive manufacturing in commercial aeroengine[J]. Aeronautical Manufacturing Technology, 2014, 57(22): 47-51. (in Chinese) [23] 吴宇,陈冰清,刘伟,等. 增材制造镍基高温合金在航空发动机与燃气轮机中的研究应用进展[J]. 航空材料学报,2024,44(1): 31-45. WU Yu,CHEN Bingqing,LIU Wei,et al. Progress in research and applications of additively manufactured nickel-based superalloy in aero-engines and gas turbines[J]. Journal of Aeronautical Materials,2024,44(1): 31-45. (in ChineseWU Yu, CHEN Bingqing, LIU Wei, et al. Progress in research and applications of additively manufactured nickel-based superalloy in aero-engines and gas turbines[J]. Journal of Aeronautical Materials, 2024, 44(1): 31-45. (in Chinese) [24] WU Yu,SUN Bingbing,CHEN Bingqing,et al. Cracking mechanism of GH5188 alloy during laser powder bed fusion additive manufacturing[J]. Materials Characterization,2024,207: 113548. doi: 10.1016/j.matchar.2023.113548 [25] ZHANG Dongsheng,LIU Wei,LI Yuxiao,et al. In situ observation of crystal rotation in Ni-based superalloy during additive manufacturing process[J]. Nature Communications,2023,14(1): 2961. doi: 10.1038/s41467-023-38727-8 [26] QU Zhan,ZHANG Zhenjun,LIU Rui,et al. High fatigue resistance in a titanium alloy via near-void-free 3D printing[J]. Nature,2024,626(8001): 999-1004. doi: 10.1038/s41586-024-07048-1 [27] GUO Bojing,ZHANG Yashan,YANG Zhongsheng,et al. Cracking mechanism of Hastelloy X superalloy during directed energy deposition additive manufacturing[J]. Additive Manufacturing,2022,55: 102792. doi: 10.1016/j.addma.2022.102792 [28] 中国航空工业第一集团公司北京航空材料研究院. 金属材料力学性能数据处理与表达: GJB/Z 18 A [S]. 北京: 国防科学技术工业委员会,2005. -

下载:

下载: