Investigation on test modeling criteria for multistage turbine

-

摘要:

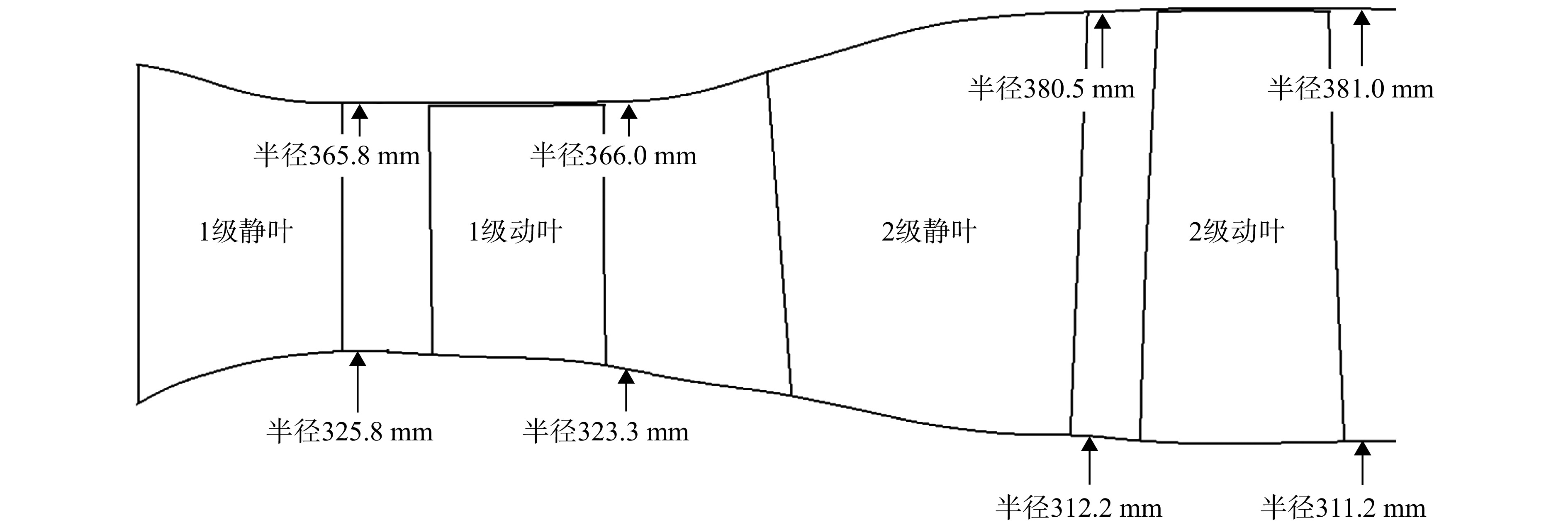

为提升多级透平中温模化试验的流场相似性,构建并校验了两级透平三维数值模型,定量研究试验模化准则选取对流场相似性的影响,提出了一种调整工质比热比的新方法。结果表明:中温模化条件下的工质比热比与设计值不相等,导致多级透平流场相似性沿流动方向逐渐下降;保证膨胀比模化准则时,末级透平动叶气动载荷系数降低4.78%,出口气流角偏差达3°~5°;保证折合功率模化准则时,末级透平折合转速偏大1.29%,动叶气膜冷气出流背压下降2.5%~6.5%;将空气燃烧转变为燃气再与水蒸气掺混,可以得到与不同等级重型燃气轮机真实燃气比热比相等的试验工质;在中温试验条件下使用该工质,多级透平的折合转速、折合功率、膨胀比相等三个模化准则同时满足,气动参数与设计值偏差不超过−0.54%~0.52%。

Abstract:For the improvement of the flow field similarity in multi-stage turbine modeling tests operating at medium temperature level, a three-dimensional numerical model of a two-stage turbine was constructed and validated. The influence of the test modeling criteria selection on the flow field similarity was quantitatively studied and a new method for adjusting the specific heat ratio of working fluid was proposed. Results indicated that, the specific heat ratio of working fluid under medium temperature modeling conditions was not equal to the design value, resulting in a gradual decrease of the flow field similarity along the flow direction in the multi-stage turbine; When ensuring the similarity criterion of expansion ratio, the aerodynamic load coefficient of the last stage turbine blade was reduced by 4.78%, and the blade outlet flow angle deviated by 3°—5°; When ensuring the similarity criterion of corrected power, the corrected speed of the last turbine stage is 1.29% higher, and the back pressure for the film cooling flow of the blade decreased by 2.5%—6.5%; The test working fluid generated by combusting air into a gas and mixing with vapor had the same values of specific heat ratio to the real gas used in the different classes of heavy duty gas turbine. As this working fluid was used in the test condition at medium temperature level, the three modeling criteria including the corrected speed, the corrected power and the expansion ratio were satisfied together, and the deviation of aerodynamic parameters from the design values were within the range of −0.54% to 0.52%.

-

表 1 计算边界条件

Table 1. Boundary conditions for calculation

参数 试验工况 数值计算 $ {p}_{\mathrm{t},0} $/kPa 345.97 345.97 $ {T}_{\mathrm{t},0} $/K 709.3 709.3 总-静膨胀比 5.289 5.289 转速/(r/min) 8283 8283 冷气流量/(kg/s) 2.08 2.08 表 2 性能参数对比

Table 2. Comparison of performance parameters

参数 试验

(RDG29工况)数值计算 总-总膨胀比 4.933 4.909 动叶进口流量/(kg/s) 11.82 11.96 总-总效率/% 92.55 92.04 表 3 算例设置与边界条件

Table 3. Calculations setting and boundary conditions

参数 算例A 算例B 算例C 比热比 1.308 1.354 1.354 进口总温/K 1588 794 794 进口总压/kPa 1303 650 650 转速/(r/min) 12630 8931 8931 总-静膨胀比 5.289 5.289 5.53 表 4 首级透平参数对比

Table 4. Comparison of first turbine stage parameters

参数 算例A 算例B 算例C 数值 与算例A的偏差/% 数值 与算例A的偏差/% 进口总温/K 1588 794 794 比热比 1.308 1.354 1.354 折合转速n1 33.19 33.19 0 33.19 0 折合功率l 0.2089 0.2087 −0.10 0.2094 0.24 载荷系数ψ 1.586 1.585 −0.06 1.590 0.25 流量系数φ 0.4904 0.4898 −0.12 0.4909 0.10 表 5 末级透平参数对比

Table 5. Comparison of last turbine stage parameters

参数 算例A 算例B 算例C 数值 与算例A的偏差/% 数值 与算例A的偏差/% 进口总温/K 1312.9 640.39 639.9 比热比 1.318 1.371 1.371 折合转速n1 36.50 36.96 1.25 36.97 1.29 折合功率l 0.1675 0.1635 −2.39 0.1715 2.39 载荷系数ψ 1.051 1.001 −4.78 1.049 −0.20 流量系数φ 0.5535 0.5363 −3.10 0.5541 0.12 表 6 工质组分调整结果

Table 6. Working fluid components adjusting results

参数 数据 天然气与空气质量比 0.0236 燃烧温升/K 985 燃烧后质量占比/% 氮气* 75.09 氧气 13.41 水蒸气 5.18 二氧化碳 6.32 水蒸气与燃气质量比 0.5411 掺混后质量占比/% 氮气* 48.01 氧气 8.57 水蒸气 39.38 二氧化碳 4.04 注:*表示大气原有二氧化碳和氩气已折算入氮气的质量占比。 表 7 透平参数对比

Table 7. Comparison of turbine parameters

参数 算例A 算例D 偏差/% 气体常数/(J/(kg·K)) 287.05 353.38 首级透平 入口比热比 1.308 1.307 −0.08 折合转速n2 1.840 1.845 0.27 折合功率l2 0.0009160 0.0009196 0.39 载荷系数ψ 1.586 1.591 0.32 流量系数φ 0.4904 0.4897 −0.14 总-静膨胀比 2.608 2.613 0.19 首级透平和末级透平入口温度之比 1.210 1.211 0.15 末级透平 入口比热比 1.318 1.320 0.15 折合转速n2 2.020 2.026 0.30 折合功率l2 0.0009283 0.0009332 0.52 载荷系数ψ 1.051 1.049 −0.19 流量系数φ 0.553 0.550 −0.54 总-静膨胀比 2.195 2.190 −0.23 -

[1] 吴法勇,马宏伟,马磊,等. 航空发动机涡轮试验[M]. 北京: 科学出版社,2022. WU Fayong,MA Hongwei,MA Lei,et al. Aircraft engine turbine test[M]. Beijing: Science Press,2022. (in ChineseWU Fayong, MA Hongwei, MA Lei, et al. Aircraft engine turbine test[M]. Beijing: Science Press, 2022. (in Chinese) [2] TSUKUDA Y,AKITA E,ARIMURA H,et al. The operating experience of the next generation M501G/M701G gas turbine: ASME Paper 2001-GT-0546[R]. New Orleans: ASME,2001. [3] 周禹彬,赵旺东,杨锐. 某型高压涡轮级性能试验研究[J]. 燃气涡轮试验与研究,2005,18(4): 20-23,29. ZHOU Yubin,ZHAO Wangdong,YANG Rui. An experimental study on the stage performance of a high-pressure turbine[J]. Gas Turbine Experiment and Research,2005,18(4): 20-23,29. (in ChineseZHOU Yubin, ZHAO Wangdong, YANG Rui. An experimental study on the stage performance of a high-pressure turbine[J]. Gas Turbine Experiment and Research, 2005, 18(4): 20-23, 29. (in Chinese) [4] 陈强,郝晟淳,丁健,等. 气冷高压涡轮模拟试验研究[J]. 航空发动机,2019,45(6): 75-80. CHEN Qiang,HAO Shengchun,DING Jian,et al. Simulation test study of air-cooled high-pressure turbine[J]. Aeroengine,2019,45(6): 75-80. (in ChineseCHEN Qiang, HAO Shengchun, DING Jian, et al. Simulation test study of air-cooled high-pressure turbine[J]. Aeroengine, 2019, 45(6): 75-80. (in Chinese) [5] 刘网扣,范雪飞,蒋俊,等. 某燃气涡轮多级空气透平试验研究[J]. 热能动力工程,2021,36(7): 27-31. LIU Wangkou,FAN Xuefei,JIANG Jun,et al. Experimental research on a gas turbine multi-stage air turbine[J]. Journal of Engineering for Thermal Energy and Power,2021,36(7): 27-31. (in ChineseLIU Wangkou, FAN Xuefei, JIANG Jun, et al. Experimental research on a gas turbine multi-stage air turbine[J]. Journal of Engineering for Thermal Energy and Power, 2021, 36(7): 27-31. (in Chinese) [6] 卫刚,王永明,王松涛,等. 高性能低压涡轮设计与试验[J]. 燃气涡轮试验与研究,2013,26(2): 6-11. WEI Gang,WANG Yongming,WANG Songtao,et al. Design and experiment of a high performance low-pressure turbine[J]. Gas Turbine Experiment and Research,2013,26(2): 6-11. (in ChineseWEI Gang, WANG Yongming, WANG Songtao, et al. Design and experiment of a high performance low-pressure turbine[J]. Gas Turbine Experiment and Research, 2013, 26(2): 6-11. (in Chinese) [7] 《航空发动机设计手册》编委会. 航空发动机设计手册: 第10册 涡轮[M]. 北京: 航空工业出版社,2001. Editorial Board of aviation Engine Design Manual. Aviation engine design manual: Volume 10 turbine[M]. Beijing: Aviation Industry Press,2001. (in ChineseEditorial Board of aviation Engine Design Manual. Aviation engine design manual: Volume 10 turbine[M]. Beijing: Aviation Industry Press, 2001. (in Chinese) [8] 中国燃气涡轮研究院,中国航空综合技术研究所. 航空燃气涡轮发动机轴流涡轮气动性能试验方法: HB7081-2012 [S]. 北京: 国家国防科技工业局,2013: 4-5. China Gas Turbine Research Institute,China Aviation Integrated Technology Research Institute. Test method for aerodynamic performance of axial flow turbines in aviation gas turbine engines: HB7081-2012 [S]. Beijing: State Administration of Science,Technology and Industry for National Defense,2013: 4-5. (in ChineseChina Gas Turbine Research Institute, China Aviation Integrated Technology Research Institute. Test method for aerodynamic performance of axial flow turbines in aviation gas turbine engines: HB7081-2012 [S]. Beijing: State Administration of Science, Technology and Industry for National Defense, 2013: 4-5. (in Chinese) [9] 张健,邱绪光. 论涡轮级气动和传热试验的相似准则[J]. 燃气涡轮试验与研究,1995,8(3): 34-38. ZHANG Jian,QIU Xuguang. On similarity criteria of aerodynamic and heat transfer tests of turbine stage[J]. Gas Turbine Experiment and Research,1995,8(3): 34-38. (in ChineseZHANG Jian, QIU Xuguang. On similarity criteria of aerodynamic and heat transfer tests of turbine stage[J]. Gas Turbine Experiment and Research, 1995, 8(3): 34-38. (in Chinese) [10] 邹滋祥. 相似理论在叶轮机械模型研究中的应用[M]. 北京: 科学出版社,1984. ZOU Zixiang. Application of similarity theory in turbomachinery model research[M]. Beijing: Science Press,1984. (in ChineseZOU Zixiang. Application of similarity theory in turbomachinery model research[M]. Beijing: Science Press, 1984. (in Chinese) [11] 邸亚超,胡应交,张星,等. 涡轮试验准则数对流场相似性的影响[J]. 航空动力学报,2018,33(1): 193-200. DI Yachao,HU Yingjiao,ZHANG Xing,et al. Influence of turbine test criterion parameters on flow similarity[J]. Journal of Aerospace Power,2018,33(1): 193-200. (in ChineseDI Yachao, HU Yingjiao, ZHANG Xing, et al. Influence of turbine test criterion parameters on flow similarity[J]. Journal of Aerospace Power, 2018, 33(1): 193-200. (in Chinese) [12] EPSTEIN A H,GUENETTE G R,NORTON R J G. The MIT blowdown turbine facility: ASME Paper 84-GT-116 [R]. Amsterdam,Netherlands: ASME,1984. [13] ITO E,OKADA I,TSUKAGOSHI K,et al. Development of key technologies for the next generation 1700C-class gas turbine: ASME Paper GT2009-59783 [R]. Orlando,Florida,US: ASME,2009. [14] 刘永泉. 国外航空发动机试验设备概览[M]. 北京: 航空工业出版社,2017. LIU Yongquan. Test facilities manual of overseas aviation engine[M]. Beijing: Aviation Industry Press,2017. (in ChineseLIU Yongquan. Test facilities manual of overseas aviation engine[M]. Beijing: Aviation Industry Press, 2017. (in Chinese) [15] TIMKO L P. Energy efficient engine high pressure turbine component test performance report: NASA CR-16289[R]. West Virginia,US: NASA,1990. [16] 邹正平. 航空燃气轮机涡轮气体动力学: 流动机理及气动设计[M]. 上海: 上海交通大学出版社,2014. ZOU Zhengping. Turbine aerodynamics for aviation engine[M]. Shanghai: Shanghai Jiao Tong University Press,2014. (in ChineseZOU Zhengping. Turbine aerodynamics for aviation engine[M]. Shanghai: Shanghai Jiao Tong University Press, 2014. (in Chinese) [17] 刘志刚,刘咸定,赵冠春,等. 工质热物理性质计算程序的编制及应用[M]. 北京: 科学出版社,1992. LIU Zhigang,LIU Xianding,ZHAO Guanchun,et al. Compilation and application of calculation program for thermophysical properties of working fluids[M]. Beijing: Science Press,1992. (in ChineseLIU Zhigang, LIU Xianding, ZHAO Guanchun, et al. Compilation and application of calculation program for thermophysical properties of working fluids[M]. Beijing: Science Press, 1992. (in Chinese) [18] SCHNIEDER M,SOMMER T. Turbines for industrial gas turbine systems[M]//JANSOHN P. Modern gas turbine systems. Cambridge: Woodhead Publishing,2013. [19] 清华大学热能工程系动力机械与工程研究所,深圳南山热电股份有限公司. 燃气轮机与燃气-蒸汽联合循环装置[M]. 北京: 中国电力出版社,2007. Institute of Power Machinery and Engineering in Department of Thermal Energy Engineering,Tsinghua University,Shenzhen Nanshan Thermal Power Company Limited. Gas turbine and gas-steam combined cycle device[M]. Beijing: China Electric Power Press,2007. (in ChineseInstitute of Power Machinery and Engineering in Department of Thermal Energy Engineering, Tsinghua University, Shenzhen Nanshan Thermal Power Company Limited. Gas turbine and gas-steam combined cycle device[M]. Beijing: China Electric Power Press, 2007. (in Chinese) -

下载:

下载: