Mathematical calculation method for hysteresis characteristics of arc⁃shaped finger seal

-

摘要:

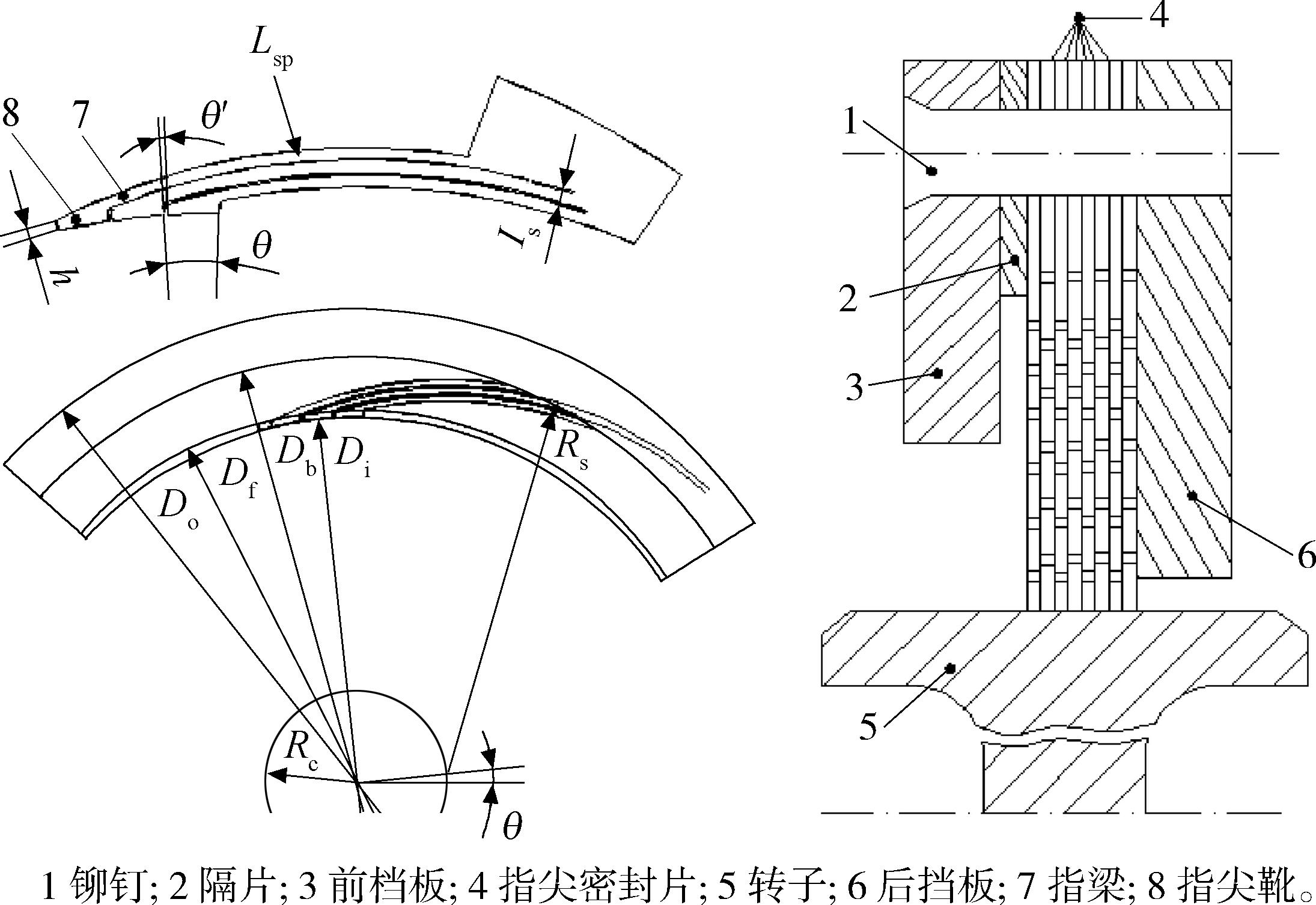

为了预测指尖密封迟滞特性,提出了用能够直观反映指尖密封迟滞特性的最小迟滞量来表征指尖密封的迟滞,建立了指尖密封最小迟滞量计算的数学模型,确定了模型中的修正系数,并进行了试验验证,采用修正后的计算模型研究并获得了结构和工况参数对指尖密封迟滞的影响规律。研究结果表明:采用修正后的模型进行考虑迟滞效应的泄漏特性数值计算与试验结果误差最大为7.64%,最小迟滞量的计算模型合理可靠;指尖密封结构参数对其最小迟滞量影响程度从小到大依次为:指梁型线圆、指梁间隙、指梁根圆、指梁顶圆、指梁基圆、周向角、指尖片厚度。研究结果为进一步开展迟滞对指尖密封泄漏特性影响和指尖密封结构优化设计的研究提供了依据和理论基础。

Abstract:In order to predict the hysteresis characteristics of finger seal accurately,minimum hysteresis representing hysteresis characteristics of finger seal was proposed.Then minimum hysteresis mathematical calculation method was established,the correction coefficient of model was determined and verified by experiments.The influence rules of the structure and working condition parameters of finger seals on the hysteresis characteristics were studied and obtained based on the modified calculation model.Results showed that the maximum error between the numerical calculation of leakage characteristics considering the hysteresis effect based on modified calculation model and the test results was 7.64%,and the conclusion of model was reliable.The degree of influence of various structural parameters on the hysteresis characteristics of finger seal was in descending order: thickness of each finger laminate,finger repeat angle,arc radius of the finger beam arcs centers,diameter of the finger base circle,width of the interstice between fingers,and arc radius of finger beam.The results provide a theoretical basis and basis for further research on the influence of hysteresis on the finger seal leakage characteristics and the optimal design of finger seal structure.

-

表 1 指尖密封的结构参数

Table 1. Structure parameters of finger seal

结构参数 参数取值 D0/mm 190 Di/mm 150 Df/mm 152 Db/mm 170 Rc/mm 17.5 Rs/mm 75 θ/(°) 6 /(°) 6 Is/mm 0.3 Z/个 60 b/mm 0.25 表 2 单位参数变化量下指尖密封最小迟滞量的变化量

Table 2. Variation of the minimum hysteresis of finger seal under change of the unit parameter

结构参数 变化量 结构参数 变化量 Df/mm 0.063 3 Is/mm 0.029 7 Db/mm 0.045 4 b/mm 1.121 5 Rc/mm 0.075 θ/(°) 0.243 7 Rs/mm 0.011 5 -

[1] 王强,吉洪湖,胡娅萍,等.考虑磨损效应的指尖密封瞬态泄漏特性分析[J].推进技术,2020,41(12):2815⁃2825.WANG Qiang,JI Honghu,HU Yaping,et al.Transient leakage characteristics analysis of finger seal considering wear effects[J].Journal of Propulsion Technology, 2020,41(12):2815⁃2825.(in Chinese) [2] ARORA G K,PROCTOR M P,STEINETZ B M,et al.Pressure balanced,low hysteresis,finger seal test results[R].AIAA 99⁃2686,1999. [3] BRAUN M J,PIERSON H M,DENG D.Thermofluids considerations and the dynamic behavior of a finger seal assembly[J].Tribology Transactions,2005,48(4):531⁃547. [4] 王莉娜,陈国定,苏华,等.考虑泄漏间隙有压流体作用的指式密封瞬态性能分析[J].航空动力学报,2015,30(8):2004⁃2010.WANG Lina,CHEN Guoding,SU Hua,et al.Transient performance analysis of finger seal considering compressed fluid in the leakage gap effect[J].Journal of Aerospace Power,2015,30(8):2004⁃2010.(in Chinese) [5] 王莉娜,陈国定,苏华,等.考虑装配条件的C/C复合材料指式密封动态性能[J].哈尔滨工业大学学报,2016,48(7):135⁃139.WANG Lina,CHEN Guoding,SU Hua,et al.Dynamic performance of C/C composite finger seal considering assembly condition[J].Journal of Harbin Institute of Technology,2016,48(7):135⁃139.(in Chinese) [6] CHEW J W,HOGG S I.Porosity modeling of brush seals[J].ASME Journal of Tribology,1997,119(4):769⁃775. [7] 胡廷勋,周坤,力宁,等.指尖密封泄漏特性数值计算与试验研究[J].推进技术,2020,41(5):1089⁃1096.HU Tingxun,ZHOU Kun,LI Ning,et al.Numerical calculation and experimental study on leakage characteristic of finger seal[J].Journal of Propulsion Technology,2020,41(5):1089⁃1096.(in Chinese) [8] WANG Qiang,HU Yaping,JI Honghu,et al.An anisotropic porous media model for leakage analysis of finger seal[J].Proceedings of the Institution of Mechanical Engineers,2020,234(2):280⁃292. [9] 白花蕾,王伟,张振生,等.基于多孔介质模型的指式密封泄漏流动分析[J].航空动力学报,2016,31(6):1303⁃1306.BAI Hualei,WANG Wei,ZHANG Zhensheng,et al.Analysis of leakage on flow through finger seal based porous medium[J].Journal of Aerospace Power,2016,31(6):1303⁃1306.(in Chinese) [10] 白花蕾,吉洪湖,纪国剑,等.指式密封泄漏特性的实验研究[J].航空动力学报,2009,24(3):532⁃536.BAI Hualei,JI Honghu,JI Guojian,et al.Experimental investigation on leakage characteristics of finger seal[J].Journal of Aerospace Power,2009,24(3):532⁃536.(in Chinese) [11] 曹静,吉洪湖,金峰,等.指尖密封结构中气流流动与传热特性分析[J].航空发动机,2011,37(4):33⁃36.CAO Jing,JI Honghu,JIN Feng,et al.Analysis of air flow and heat transfer characteristics in fingertip sealing structure[J].Aeroengine,2011,37(4):33⁃36. [12] 张延超,刘凯,胡海涛,等.基于有限元仿真的指尖密封准动态性能分析方法[J].推进技术,2016,37(12):2352⁃2358.ZHANG Yanchao,LIU Kai,HU Haitao,et al.Quasi⁃dynamic performances analysis of finger seal based on finite element simulation[J].Journal of Propulsion Technology,2016,37(12):2352⁃2358.(in Chinese) [13] 王璐,苏华.具有一般型线的指式密封性能优化设计[J].机械科学与技术,2015,34(4):544⁃548.WANG Lu,SU Hua.Optimization design of the finger sealing performance with general profile[J].Mechanical Science and Technology for Aerospace Engineering,2015,34(4):544⁃548.(in Chinese) [14] 杜春华,吉洪湖,胡娅萍,等.指尖密封的转子轴心轨迹与泄漏特性的试验[J].航空动力学报,2016,31(11):2575⁃2584.DU Chunhua,JI Honghu,HU Yaping,et al.Experiment on axis locus of rotor and leakage characteristics of finger seal[J].Journal of Aerospace Power,2016,31(11):2575⁃2584.(in Chinese) [15] 杜春华,吉洪湖,胡娅萍,等.指尖封严磨损特性及其对泄漏影响的试验[J].航空动力学报,2017,32(1):53⁃59.DU Chunhua,JI Honghu,HU Yaping,et al.Experiment of wearing characteristics and its effect on leakage of finger seal[J].Journal of Aerospace Power,2017,32(1):53⁃59.(in Chinese) [16] 陈国定,徐华,虞烈,等.指式密封的迟滞特性分析[J].机械工报,2003,39(5):121⁃124.CHEN Guoding,XU Hua,YU Lie,et al.Analysis on hysteresis characteristics of finger seal[J].Journal of Mechanical engineering,2003,39(5):121⁃124.(in Chinese) [17] 朱三朋.基于多工况要求的低迟滞指尖密封结构优化[J].润滑与密封,2007,32(12):40⁃46.ZHU Sanpeng.Structural optimization of finger seal with low hysteresis based on multi⁃operating condition[J].Lubrication Engineering,2007,32(12):40⁃46.(in Chinese) [18] 苏华,陈国定.指尖密封迟滞特性的机理分析[J].机械工程学报,2009,45(5):57⁃61.SU Hua,CHEN Guoding.Analysis on hysteresis characteristics of finger seal[J].Chinese Journal of Mechanical Engineering,2009,45(5):57⁃61.(in Chinese) [19] 雷艳妮,陈国定.基于动力学模型的指尖密封迟滞特性[J].机械工程学报,2007,43(5):122⁃126.LEI Yanni,CHEN Guoding.Finger seal's hysteresis characteristic based on dynamical model[J].Chinese Journal of Mechanical Engineering,2007,43(5):122⁃126.(in Chinese) [20] 白花蕾.圆弧型线指尖密封结构的形成方法和迟滞性能分析[J].航空发动机,2014,40(3):49⁃51.BAI Hualei.Analysis of hysteresis and forming method for finger seal with arc shape curve[J].Aeroengine,2014,40(3):49⁃51.(in Chinese) -

下载:

下载: