Bolt loosening characteristics based on change of slip-adhesion contact state under shear load

-

摘要:

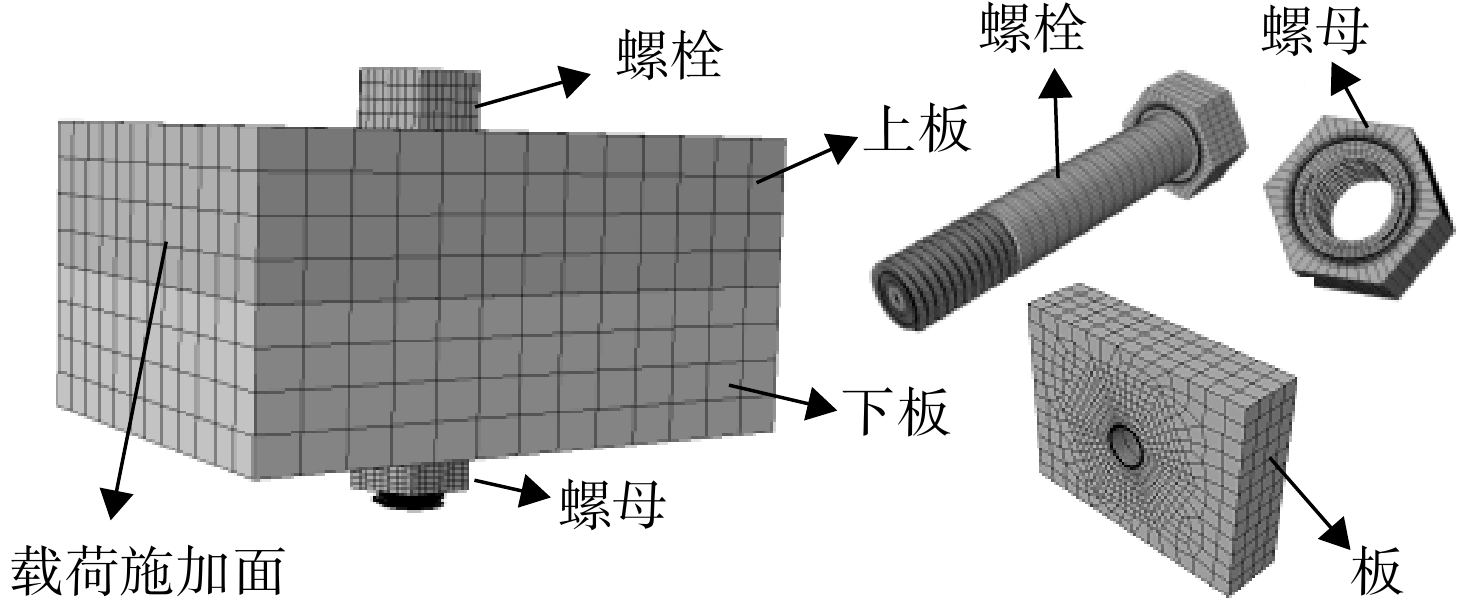

为研究螺栓松动特性,首先建立了带升角螺纹螺栓连接结构精细有限元模型,采用施加力矩法施加了初始预紧力,然后进行了螺栓松动特性仿真分析,提出了基于螺栓头接触面和螺纹接触面滑移-接触状态变化分析螺栓松动特性的方法,最后对该方法进行了准确性验证。结果表明:螺栓头接触面和螺纹接触面滑移-黏着接触状态变化规律能准确表征螺栓松动特性;两接触面滑移-黏着接触状态的交替变化是造成螺栓松动的主要因素,若始终存在黏着区域,螺栓松动不会发生;接触面处于滑移状态区域面积越大,增长速率越快,螺栓松动越容易发生;振幅越大、偏心距离越大,两接触面进入滑移状态的区域面积越大、速率越快,螺栓松动越容易发生;两接触面摩擦因数相差越大,螺栓松动越不容易发生,并存在一个两接触面摩擦因数匹配值范围,使螺栓松动最容易发生。

Abstract:In order to study the bolt looseness characteristics, a fine finite element model of bolt connection structure with raised angle was established, and the initial preload was applied by means of applying torque method. Then, simulation analysis of bolt looseness characteristics was carried out, Finally, the accuracy of this method was verified. The results showed that: the change law of slip adhesion contact state of bolt head contact surface and thread contact surface can accurately characterize the bolt loosening characteristics; the alternate change of slip adhesion contact state of two contact surfaces is the main factor causing bolt loosening; if there is always an adhesion area, no bolt loosening occurs; the larger area of contact surface in the sliding state indicated the faster growth rate, the faster bolt loosening and higher likeliness of loosening; the larger amplitude and the greater eccentricity distance indicated the larger area and the faster speed of two contact surfaces entering the sliding state, and the easier bolt loosening; the greater difference of friction coefficient between the two contact surfaces indicated the higher likeliness of bolt loosening.

-

-

[1] IBRAHIM R A, PETTIT C L. Uncertainties and dynamic problems of bolted joints and other fasteners[J]. Journal of Sound and Vibration, 2003, 279(3): 857- 936. [2] 王志,李吉凯,刘玉. 带止口法兰连接结构刚度特性对结构振动影响[J]. 航空动力学报,2019,34(6): 1201-1208.WANG Zhi,LI Jikai,LIU Yu. Influence of structural stiffness characteristics on structural vibration of flanged connections with flanges[J]. Journal of Aerospace Power,2019,34(6): 1201-1208. (in Chinese) [3] 白聪儿,宣海军,米栋,等. 离心压气机包容结构连接螺栓建模方法[J]. 航空动力学报,2019,34(2): 313-320.BAI Conger,XUAN Haijun,MI Dong,et al. Modeling method for connecting bolts of centrifugal compressor containment structure[J]. Journal of Aerospace Power,2019,34(2): 313-320. (in Chinese) [4] JUNKER G H. New criteria for self-loosening of fasteners under vibration[J]. Society Automotive Engineering,1969,78(12): 314-335. [5] PAI N G,HESS D P. Experimental study of loosening of threaded fasteners due to dynamic shear loads[J]. Journal of Sound and Vibration,2002,253(3): 585-602. doi: 10.1006/jsvi.2001.4006 [6] 巩浩,刘检华,丁晓宇. 振动条件下螺纹预紧力衰退机理和影响因素研究[J]. 机械工程学报,2019,55(11): 138-148. doi: 10.3901/JME.2019.11.138GONG Hao,LIU Jianhua,DING Xiaoyu. Study on the mechanism and influencing factors of preload decline for bolted joints under vibration[J]. Journal of Mechanical Engineering,2019,55(11): 138-148. (in Chinese) doi: 10.3901/JME.2019.11.138 [7] DINGER G,FRIEDRICH C. Avoiding self-loosening failure of bolted joints with numerical assessment of local contact state[J]. Engineering Failure Analysis,2011,18(8): 2188-2200. doi: 10.1016/j.engfailanal.2011.07.012 [8] DINGER G. Design of multi-bolted joints to prevent self-loosening failure[J]. Journal of Mechanical Engineering Science,2016,230(15): 2564-2578. doi: 10.1177/0954406215612813 [9] IZUMI S,YOKOYAMA T,IWASAKI A,et al. Three-dimensional finite element analysis of tightening and loosening mechanism of threaded fastener[J]. Engineering Failure Analysis,2005,12: 604-615. doi: 10.1016/j.engfailanal.2004.09.009 [10] IZUMI S,KIMURA M,SAKAI S. Small loosening of bolt-nut fastener due to micro bearing-surface slip: a finite element method study[J]. Journal of Solid Mechanics and Materials Engineering,2007,1(11): 1374-1384. doi: 10.1299/jmmp.1.1374 [11] KASEI S. A study of self-loosening of bolted joints due to repetition of small amount of slippage at bearing surface[J]. Journal of Advanced Mechanical Design Systems and Manufacturing,2007,1(3): 358-367. doi: 10.1299/jamdsm.1.358 [12] NASSAR S A,YANG X J. A mathematical model for vibration-induced loosening of preloaded threaded fasteners[J]. Journal of Vibration and Acoustics,2009,131(2): 9-21. [13] ZHANG M,JIANG Y,LEE C. Finite element modeling of self-loosening of bolted joints[J]. Journal of Mechanical Design,2007,129(2): 218-226. doi: 10.1115/1.2406092 [14] IBRAHIM R A,PETTIT C L. Uncertainties and dynamic problems of bolted joints and other fasteners[J]. Journal of Sound and Vibration,2005,279(3/4/5): 857-936. doi: 10.1016/j.jsv.2003.11.064 [15] LIU Jianhua,OUYANG Huajiang,PENG Jinfang,et al. Experimental and numerical studies of bolted joints subjected to axial excitation[J]. Wear,2016,346(11): 66-77. [16] LIU Jianhua,OUYANG Huajiang,FENG Zhiqiang,et al. Study on self-loosening of bolted joints excited by dynamic axial load[J]. Tribology International,2017,115: 432-451. doi: 10.1016/j.triboint.2017.05.037 [17] 杜永强,刘建华,刘学通,等. 偏心载荷作用下螺栓连接结构的松动行为研究[J]. 机械工程学报,2018,54(14): 74-81.DU Yongqiang,LIU Jianhua,LIU Xuetong,et al. Research on self-loosening behavior of bolted joints under eccentric excitation[J]. Journal of Mechanical Engineering,2018,54(14): 74-81. (in Chinese) [18] 王开平, 闫明, 孙自强, 等. 剪切载荷下航空发动机螺栓松动行为及其临界值的数值模拟研究[J]. 推进技术, 2022, 43(2): 43-54.WANG Kaiping, YAN Ming, SUN Ziqiang, et al. Numerical simulation study on the loosening behavior and critical value of aeroengine bolts under shear load[J]. Propulsion Technology, 2022, 43(2): 43-54. (in Chinese) -

下载:

下载: