Film cooling characteristics and loss mechanism of contracted double-jet hole

-

摘要:

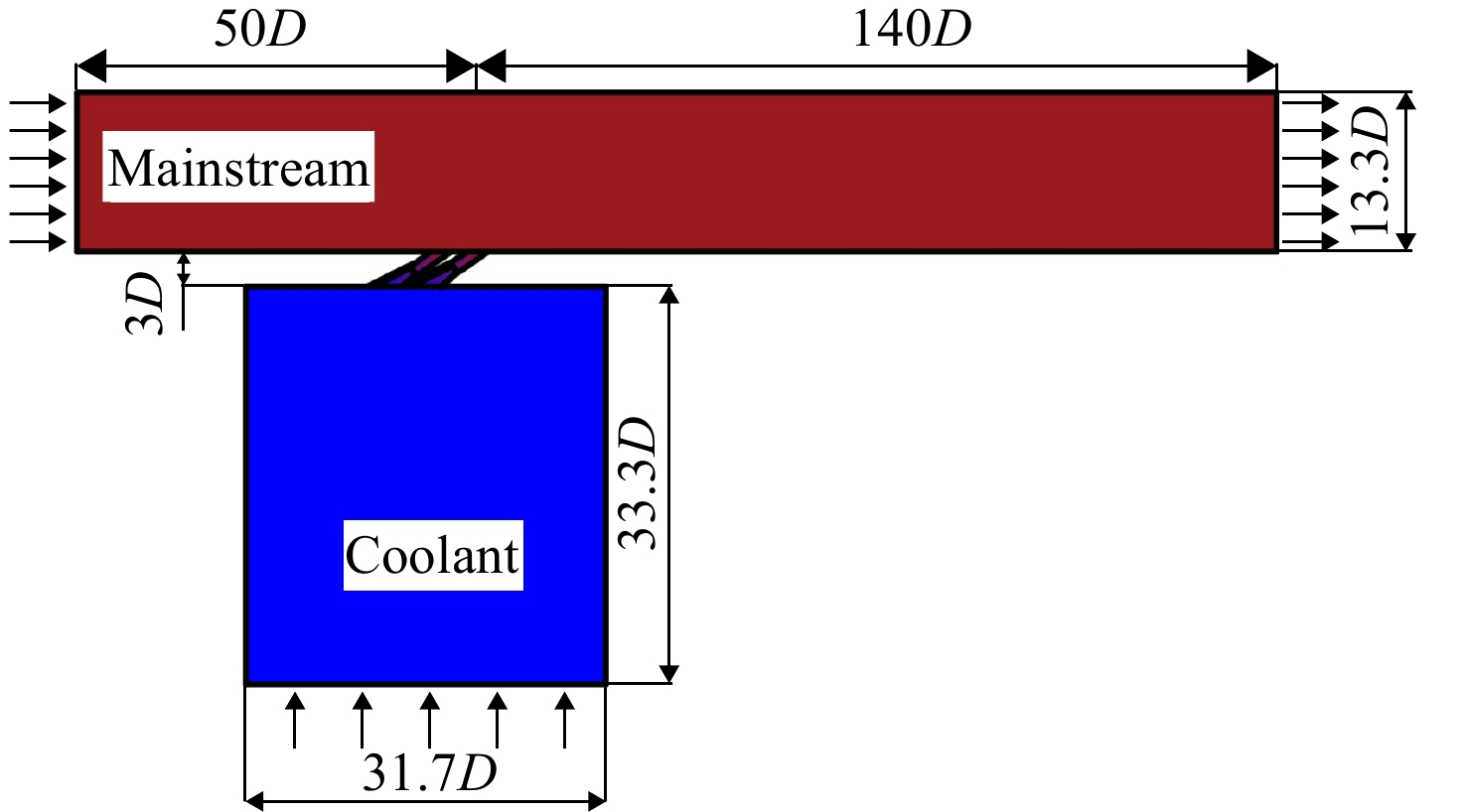

在兼顾气膜冷却效率的条件下,为了降低气膜冷却带来的气动损失,采用数值模拟的方法研究了双射流孔和收缩型双射流孔的气膜冷却特性。对比分析了不同吹风比(0.5~2.0)工况下气膜冷却效率和损失分布规律。结果表明:当吹风比高于1.0时,收缩型双射流孔促进冷气横向发展,冷却效率提高;当吹风比增加到2.0时,收缩型双射流孔可以防止冷气吹离壁面。与双射流孔相比,收缩型双射流孔入口冷气均匀加速,消除了孔内低速区造成的堵塞,流场趋于均匀,孔内损失明显降低,从而整体上降低了气膜冷却引起的总压损失。

Abstract:Film cooling characteristics and loss mechanism of double-jet hole and contracted double-jet hole with blowing ratio varying from 0.5 to 2.0 were numerically simulated. Results showed that the lateral film coverage developed and the film cooling effectiveness was promoted for the Contracted Double-jet hole when the blowing ratio was bigger than 1.0. When the blowing ratio reached 2.0, the Contracted Double-jet hole can prevent the film lift-off. Compared with the Double-jet hole, the cooling flow at the inlet of the Contracted Double-jet hole was accelerated evenly and the blockage caused by the low velocity zone in the hole was eliminated so that the flow field became uniform and the total pressure loss was reduced.

-

Key words:

- film cooling /

- film cooling effectiveness /

- total pressure loss /

- film cooling hole /

- loss mechanism

-

表 1 边界条件设置

Table 1. Boundary conditions

边界条件 设计值 冷气入口总温 Ttc/K 290 主流入口总压 ptg/kPa 128 主流入口马赫数 Ma 0.6 主流出口静压 pout/kPa 96 总温比 Ttc/Ttg 0.54 密度比 ρc/ρg 1.8 吹风比 M 0.5~2.0 表 2 Hole1与Hole2吹风比

Table 2. Calculated blowing ratios of Hole1 and Hole2

模型 M Hole1 Hole2 Mav DJFC 0.5 0.548 0.428 0.488 1.0 0.992 0.966 0.979 1.5 1.473 1.485 1.479 2.0 1.977 1.981 1.979 DJFC7 0.5 0.594 0.386 0.490 1.0 1.017 0.953 0.985 1.5 1.501 1.457 1.479 2.0 1.993 1.963 1.978 -

[1] GOLDSTEIN R J,ECKERT E,BURGGRAF F. Effects of hole geometry and density on three-dimensional film cooling[J]. International Journal of Heat & Mass Transfer,2015,17(5): 595-607. [2] SCHMIDT D L,SEN B,BOGARD D G. Film cooling with compound angle holes: adiabatic effectiveness[J]. Journal of Turbomachinery,1996,118(4): 807-813. doi: 10.1115/1.2840938 [3] GRITSCH M,SCHULZ A,WITTIG S. Adiabatic wall effectiveness measurements of film-cooling holes with expanded exits[J]. Journal of Turbomachinery,1998,120(3): 549-556. doi: 10.1115/1.2841752 [4] FRIC T F,ROSHKO A. Vortical structure in the wake of a transverse jet[J]. Journal of Fluid Mechanics,1994,279: 1-47. doi: 10.1017/S0022112094003800 [5] KUSTERER K, BOHN D, SUGIMOTO T, et al. Influence of blowing ratio on the double-jet ejection of cooling air[R]. ASME Paper GT2007-27301, 2007. [6] 李润东,李明春,贺业光,等. 射流角度对姊妹孔气膜冷却效果影响实验研究[J]. 推进技术,2020,41(8): 1765-1772. doi: 10.13675/j.cnki.tjjs.190448LI Rundong,LI Mingchun,HE Yeguang,et al. Experimental study on effects of injection angles on film cooling performance of sister holes[J]. Journal of Propulsion Technology,2020,41(8): 1765-1772. (in Chinese) doi: 10.13675/j.cnki.tjjs.190448 [7] 刘聪,朱惠人,付仲议,等. 涡轮导叶吸力面簸箕型孔气膜冷却特性实验研究[J]. 推进技术,2016,37(6): 1142-1150. doi: 10.13675/j.cnki.tjjs.2016.06.019LIU Cong,ZHU Huiren,FU Zhongyi,et al. Experimental study of film cooling characteristics for dust-pan shaped holes on suction side in turbine guide vane[J]. Journal of Propulsion Technology,2016,37(6): 1142-1150. (in Chinese) doi: 10.13675/j.cnki.tjjs.2016.06.019 [8] XU Qingzong,DU Qiang,WANG Pei,et al. Computational study of film cooling and flowfields on a stepped vane endwall with a row of cylindrical hole and interrupted slot injections[J]. International Journal of Heat and Mass Transfer,2019,134: 796-806. doi: 10.1016/j.ijheatmasstransfer.2019.01.093 [9] 张盛昌,张靖周,谭晓茗. 利用上游沙丘形斜坡增强气膜冷却[J]. 航空动力学报,2020,35(5): 973-982. doi: 10.13224/j.cnki.jasp.2020.05.009ZHANG Shengchang,ZHANG Jingzhou,TAN Xiaoming. Film cooling enhancement by using upstream sand-dune-shaped ramp[J]. Journal of Aerospace Power,2020,35(5): 973-982. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.05.009 [10] KUSTERER K, ELYAS A, BOHN D, et al. Film cooling effectiveness comparison between shaped- and double jet film cooling holes in a row arrangement[R]. ASME Paper GT2010-22604, 2010 [11] YAO Jiaxu, XU Jin, ZHANG Ke, et al. Interaction of flow and film-cooling effectiveness between double-jet film-cooling holes with various spanwise distances[R]. ASME Paper GT2017-63740, 2017. [12] YAO Jiaxu, LEI Jiang, WU Junmei, et al. Effects of streamwise distance and density ratio on film-cooling effectiveness for double-jet film-cooling on a flat plate[R]. ASME Paper GT2018-75456, 2018. [13] KUSTERER K, ELYAS A, BOHN D, et al. Double-Jet film-cooling for highly efficient film-cooling with low blowing ratios[R]. ASME Paper GT2008-50073, 2008. [14] 王文三,唐菲,赵庆军,等. 新型双射流冷却孔对气膜冷却效率影响的研究[J]. 工程热物理学报,2011,32(8): 1291-1294.WANG Wensan,TANG Fei,ZHAO Qingjun,et al. An investigation of the effect of new-type double-jet film cooling (DJFC) hole on film cooling effectiveness[J]. Journal of Engineering Thermophysics,2011,32(8): 1291-1294. (in Chinese) [15] HARTSEL J. Prediction of effects of mass-transfer cooling on the blade-row efficiency of turbine airfoils[R]. San Diego: In Proceedings of the 10th Aerospace Sciences Meeting, 1972. [16] ITO S,ECKERT E R G,GOLDSTEIN R J. Aerodynamic loss in a gas turbine stage with film cooling[J]. Journal of Engineering for Power,1980,102(4): 964-970. doi: 10.1115/1.3230368 [17] DAY C, OLDFIELD M, LOCK G D, et al. Efficiency measurements of an annular nozzle guide vane cascade with different film cooling geometries[R]. ASME Paper 98-GT-538, 1998. [18] YOUNG J B,HORLOCK J H. Defining the efficiency of a cooled turbine[J]. Journal of Turbomachinery,2006,128(4): 658-667. doi: 10.1115/1.2218890 [19] YOUNG J B,WILCOCK R C. Modeling the air-cooled gas turbine: Part 1 general thermodynamics[J]. Journal of Turbomachinery,2002,124(2): 207-213. doi: 10.1115/1.1415037 [20] YOUNG J B,WILCOCK R C. Modeling the air-cooled gas turbine: Part 2 coolant flows and losses[J]. Journal of Turbomachinery,2002,124(2): 214-221. doi: 10.1115/1.1415038 [21] LIM C H, PULLAN G, IRELAND P. Influence of film cooling hole angles and geometries on aerodynamic loss and net heat flux reduction[R]. ASME Paper GT2011-45721, 2011. [22] LIM C H, PULLAN G, NORTHALL J. Estimating the loss associated with film cooling for a turbine stage[R]. ASME Paper GT2010-22327, 2010. [23] DENTON J D. Loss mechanisms in turbomachines[J]. Trans Asme Journal of Turbomachinery,1993,115(4): 621-656. doi: 10.1115/1.2929299 [24] 高扬,刘建军,安柏涛. 主流马赫数对不同气膜孔结构冷却效果及气动损失影响研究[J]. 燃气轮机技术,2015,28(2): 15-20. doi: 10.3969/j.issn.1009-2889.2015.02.003GAO Yang,LIU Jianjun,AN Baitao. Influence of mainstream Mach number on cooling effectiveness and aerodynamic losses of different film cooling configurations[J]. Gas Turbine Technology,2015,28(2): 15-20. (in Chinese) doi: 10.3969/j.issn.1009-2889.2015.02.003 -

下载:

下载: