Structural optimization design of thrust reverser

-

摘要:

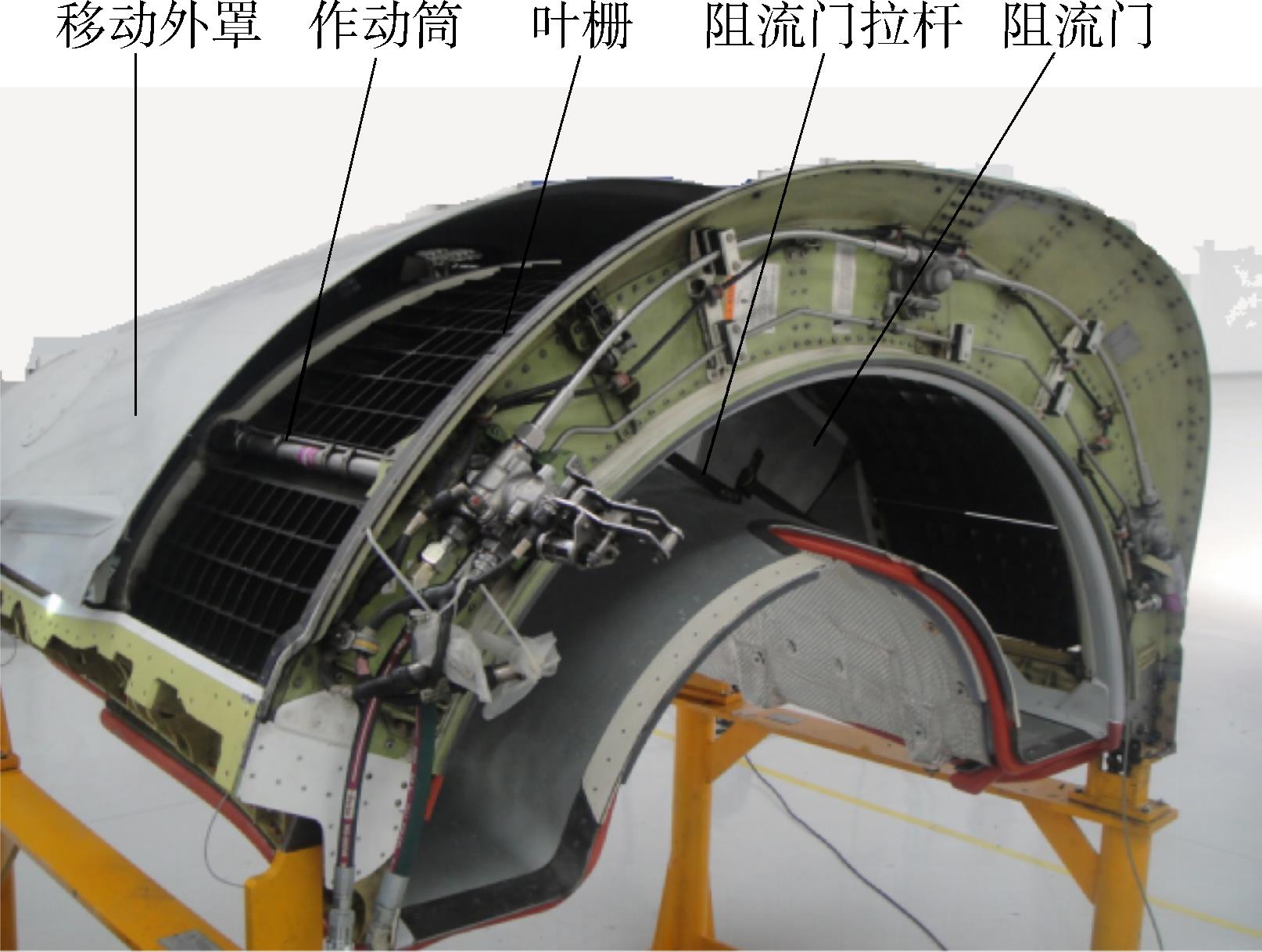

根据叶栅式反推力装置结构及其工作原理,建立了反推力装置运动学与动力学数学模型,以此为基础,取反推力装置对作动系统的最大负载力极小化为目标函数,装置各运动机构满足几何关系为约束条件,建立反推力装置结构优化模型。通过反推力装置运动学及动力学仿真,并分析在不同结构参数下反推力装置运动学及动力学特性,验证了所建立模型的合理性与正确性。在Matlab环境下采用惩罚函数法对反推力装置进行结构优化设计,结果表明:优化后的反推力装置正向最大负载力下降了24.5%,负向最大负载力下降了16.3%,且各个机构运动不出现干涉,整个反推力装置可正常工作。论文建模方法与优化结果可为反推力装置结构设计提供参考。

Abstract:According to the structure and working principle of the cascade thrust reverser,the kinematic and dynamic mathematical model of the thrust reverser was established.On this basis,the maximum load force of the thrust reverser on the actuating system was minimized as the objective function,and the geometric relationship of the moving parts was taken as the constraint condition,the structure optimization model of the thrust reverser was established.Through the kinematics and dynamics simulation of the thrust reverser,and the kinematics characteristics of the thrust reverser under different structural parameters,it was verified that the established model was reasonable and correct.Under the Matlab environment,the structure optimization of the thrust reverser was carried out by the penalty function method.Results showed that the optimized maximum load force of the thrust reverser in the positive direction decreased by 24.5%,and in the negative direction decreased by 16.3%,and the moving parts did not interfere,the whole thrust reverser can work normally.The modeling method and optimization results can provide reference for thrust reverser structural design.

-

表 1 反推力装置各部件结构参数优化范围

Table 1. Components structural parameter range for thrust reverser optimization

参数 初始值 最小值 最大值 l/mm 210 205 215 m/mm 155 50 215 n/mm 53 50 215 /(°) 88 85 90 -

[1] 靳宝林,邢伟红,刘殿春.飞机/发动机推进系统反推力装置[J].航空发动机,2004,30(4):48⁃52,58.JIN Baolin,XING Weihong,LIU Dianchun.Thrust reversers of aircraft engine propulsion system[J].Aeroengine,2004,30(4):48⁃52,58.(in Chinese) [2] 邵万仁,叶留增,沈锡钢,等.反推力装置关键技术及技术途径初步探讨[R].广东 深圳:大型飞机关键技术高层论坛暨中国航空学会学术年会,2007. [3] 饶祺,盛鸣剑,韩涛锋,等.发动机反推力装置研究[J].科技广场,2014(2):91⁃94.RAO Qi,SHENG MingJian,HAN Taofeng,et al.Research on engine thrust reverser[J].Science and Technology Square,2014(2):91⁃94.(in Chinese) [4] 沙江,徐惊雷.发动机反推力装置及其研究进展[R].广东 深圳:大型飞机关键技术高层论坛暨中国航空学会学术年会,2007. [5] 何宝明,罗彬.叶栅式反推力装置平面作动机构运动规律研究[J].机电信息,2020(14):14⁃15.HE Baoming,LUO Bing.Research on the motion law of the plane actuating mechanism of cascade thrust reverse device[J].Electromechanical Information,2020(14):14⁃15.(in Chinese) [6] 陈俊,雷晗,单勇.叶栅式反推力装置推力性能研究[J].航空计算技术,2019,49(2):34⁃36,42.CHEN Jun,LEI Han,SHAN Yong.Research on thrust performance of cascade reverse thrust device[J].Aviation Computing Technology,2019,49(2):34⁃36,42.(in Chinese) [7] 陈著,单勇,沈锡钢,等.叶栅式反推力装置开启过程的三维非稳态数值模拟与分析[J].航空动力学报,2017,32(9):2132⁃2138.CHEN Zhu,SHAN Yong,SHEN Xigang,et al.Three⁃dimensional unsteady numerical simulation and analysis of deployment for cascade thrust reverser[J].Journal of Aerospace Power,2017,32(9):2132⁃2138.(in Chinese) [8] 何杰.飞机反推力装置动力学分析及结构优化[D].西安:西安电子科技大学,2020.HE Jie.Dynamic analysis and structure optimization of aircraft thrust reverser[D].Xi'an:Xidian University,2020.(in Chinese) [9] 张国栋,王强.主要几何参数对叶栅式反推力装置性能的影响[J].航空动力学报,2012,27(1):145⁃151.ZHANG Guodong,WANG Qiang.The influence of main geometric parameters on the performance of cascade reverse thrust device[J].Journal of Aerospace Power,2012,27(1):145⁃151.(in Chinese) [10] 张云浩,额日其太.反推力装置叶栅布置的气动/结构耦合设计[J].沈阳工业大学学报,2012,34(1):56⁃62.ZHANG Yunhao,Eriqitai.Aerodynamic/structural⁃coupling design of the cascade arrangement of thrust reverser[J].Journal of Shenyang University of Technology,2012,34(1):56⁃62.(in Chinese) [11] 谢业平,王强,邵万仁,等.叶栅式反推力装置阻流门运动规律对气动性能的影响[J].航空动力学报,2010,25(6):1297⁃1302.XIE Yeping,WANG Qiang,SHAO Wanren,et al.Effect of kinetic mechanism of blocker doors on aerodynamic performance for a cascade thrust reverser[J].Journal of Aerospace Power,2010,25(6):1297⁃1302.(in Chinese) [12] 陈著,单勇,沈锡钢,等.着陆滑跑状态下的反推力装置重吸入特性数值模拟[J].航空动力学报,2016,31(3):733⁃739.CHEN Zhu,SHAN Yong,SHEN Xigang,et al.Numerical simulation of the suction characteristics of thrust reverser when landing[J].Journal of Aerospace Power,2016,31(3):733⁃739.(in Chinese) [13] 王鹏.民用客机反推装置气动优化设计研究[D].上海:上海交通大学,2019.WANG Peng.Research on aerodynamic optimization design of reverse thruster for civil airlinser[D].Shanghai:Shanghai Jiao Tong University,2019.(in Chinese) [14] 张少军,王汉平,何江军,等.叶栅式反推装置的受载与传力[J].四川兵工学报,2015,36(3):56⁃59.ZHANG Shaojun,WANG Hanping,HE Jiangjun,et al.Load and force transmission of cascade thrust reverser[J].Journal of Sichuan Ordnance,2015,36(3):56⁃59.(in Chinese) [15] 陈永琴,何杰,苏三买.反推力装置运动学与动力学仿真[J].航空动力学报,2019,34(11):2316⁃2323.CHEN Yongqin,HE Jie,SU Sanmai.Kinematics and dynamics simulation of thrust reverser[J].Journal of Aerospace Power,2019,34(11):2316⁃2323.(in Chinese) [16] 汪天兴.飞机反推力装置及其作动系统建模与仿真研究[D].西安:西安电子科技大学,2017.WANG Tianxing.Research on modeling and simulation of aircraft thrust reverse device and its actuation system[D].Xi'an:Xidian University,2017.(in Chinese) [17] 施光林,泮健.飞机地面模拟试验反推力电液加载系统的实现[J].中国工程机械,2010,21(1):42⁃45.SHI Guanglin,PAN Jian.Electro⁃hydraulic force servo system for simulating thrust in reverse of experimental systems on the ground for airplane[J].China Mechanical Engineering,2010,21(1):42⁃45.(in Chinese) [18] LIU Chao,DENG Junxiang,SU Sanmai.Design of loading system for thrust reverser ground simulation test[J].Institute Of Physics Conference Series:Earth and Environmental Science,2018,170(4):042093.1⁃042093.11. [19] 张艳慧,秦浩,王代军.发动机反推力系统安全性设计[J].航空动力学报,2015,30(7):1784⁃1792.ZHANG Yanhui,QIN Hao,WANG Daijun.Engine thrust reverser system safety design[J].Journal of Aerospace Power,2015,30(7):1784⁃1792.(in Chinese) [20] 林强,吴赛龙.基于MATLAB及惩罚函数法的斜齿轮传动优化设计[J].机械工程师,2016(12):112⁃114.LIN Qiang,WU Sailong.Optimal design of helical gear transmission based on MATLAB and penalty function method[J].Mechanical Engineers,2016(12):112⁃114.(in Chinese) -

下载:

下载: