Effect of shock wave on supersonic film cooling under coupled heat transfer

-

摘要:

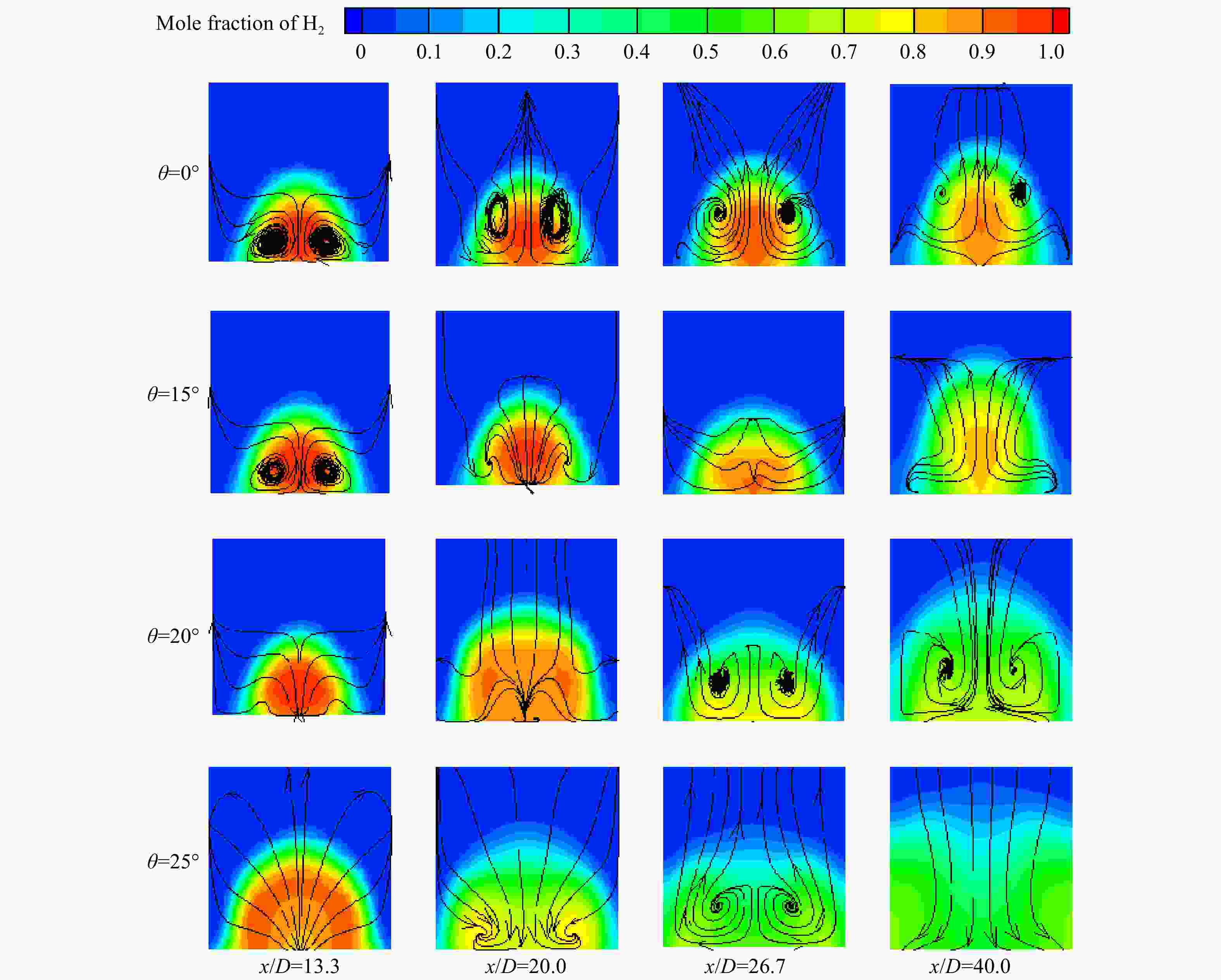

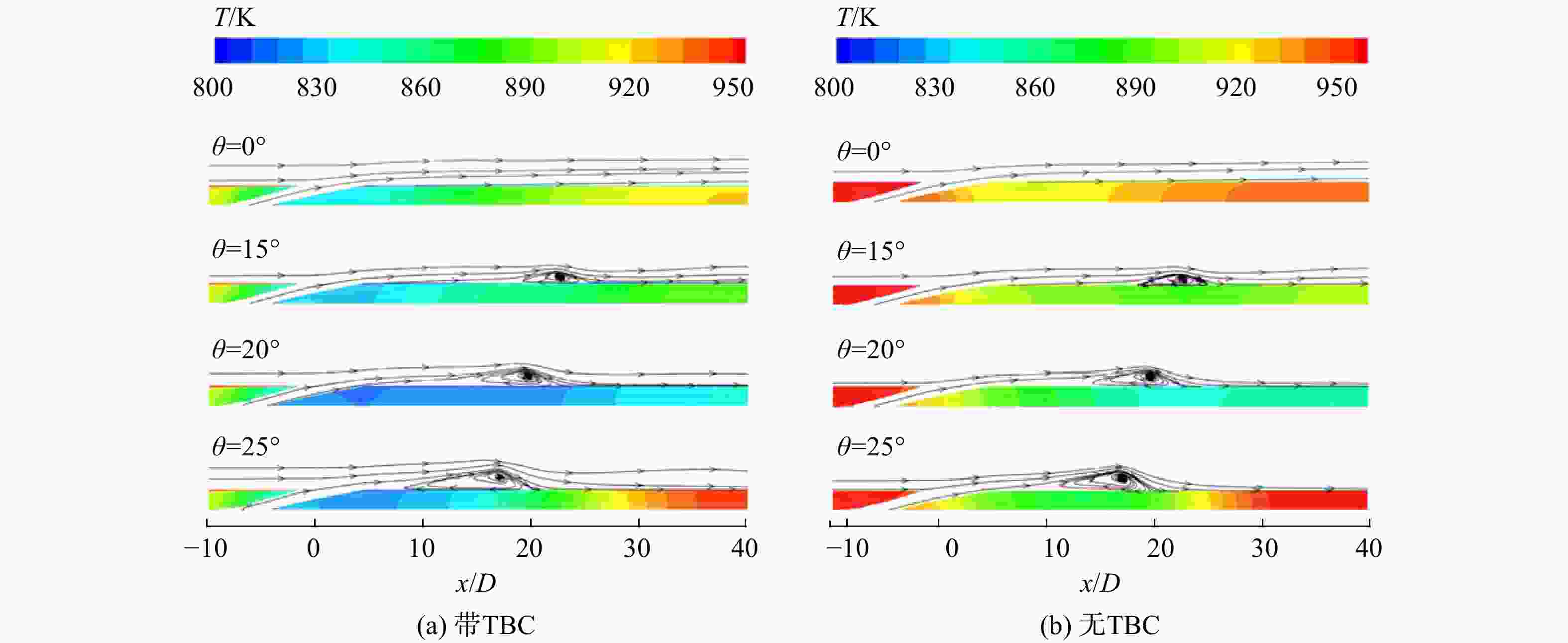

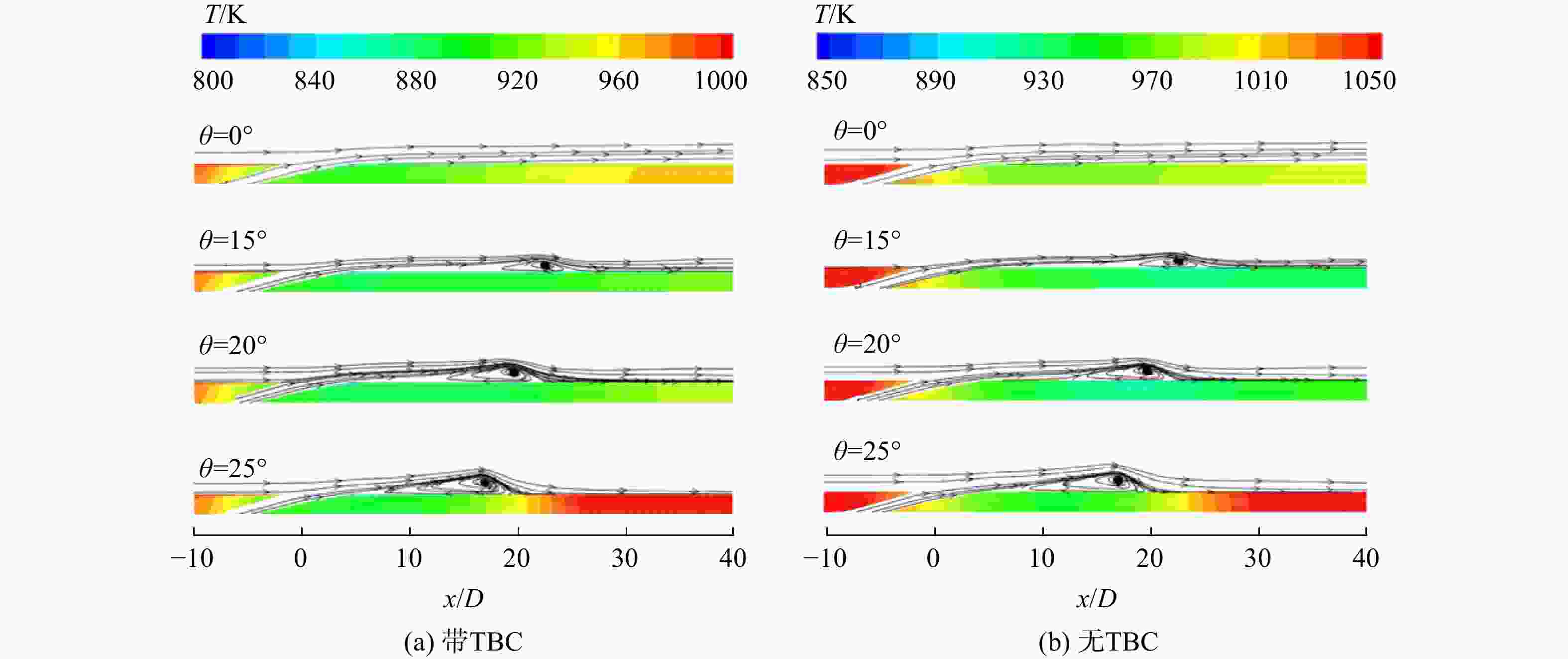

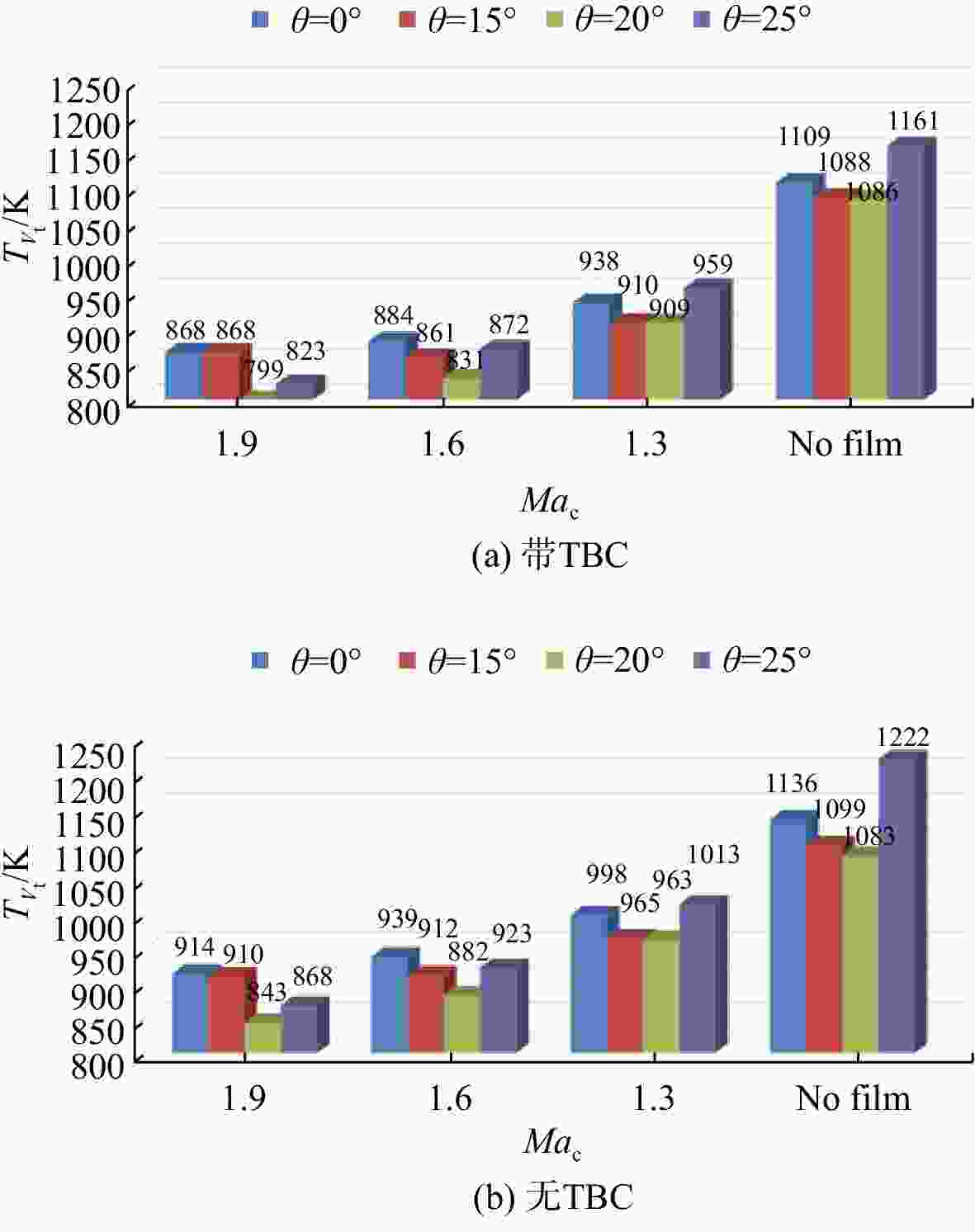

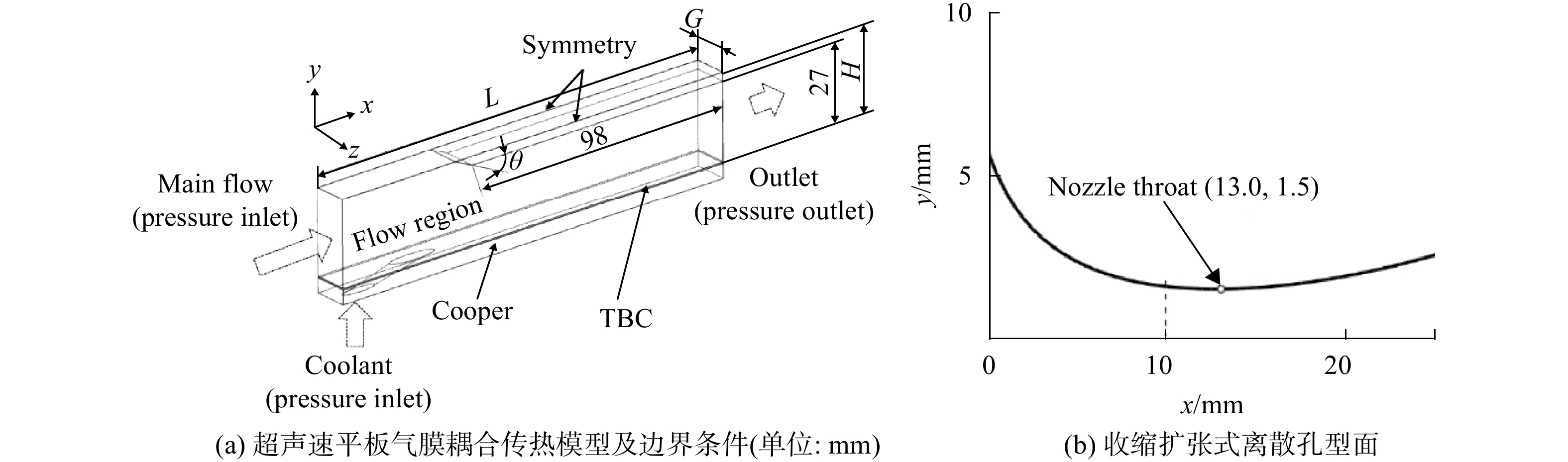

针对离散孔式超声速平板气膜冷却,在主流区引入楔角形成激波环境,以研究激波与超声速气膜之间的相互作用。通过计算楔角在0°、15°、20°和25°产生的四种激波强度下,超声速气膜与高温壁面的耦合传热。所得结果表明:适当强度的激波能够抑制气膜入射后产生的反向涡旋对,降低主流对气膜的卷吸,增大壁面平均H2摩尔分数并降低壁面温度。对金属层温度场的分析表明,壁面冷却效果随着激波角的增加而先增加后降低,其中楔角为20°时的流场结构最有利于壁面温度保护。小楔角生成的激波在低冷流马赫数下对冷却效果的改善更明显,大楔角则在高冷流马赫数下更明显,热障涂层(TBC)不影响这种变化趋势;激波的存在削弱了TBC的影响范围。可以揭示超声速气膜在耦合传热条件下的传热机理,为超声速气膜冷却的设计提供参考,或为现有超声速气膜冷却结构的优化提供依据。

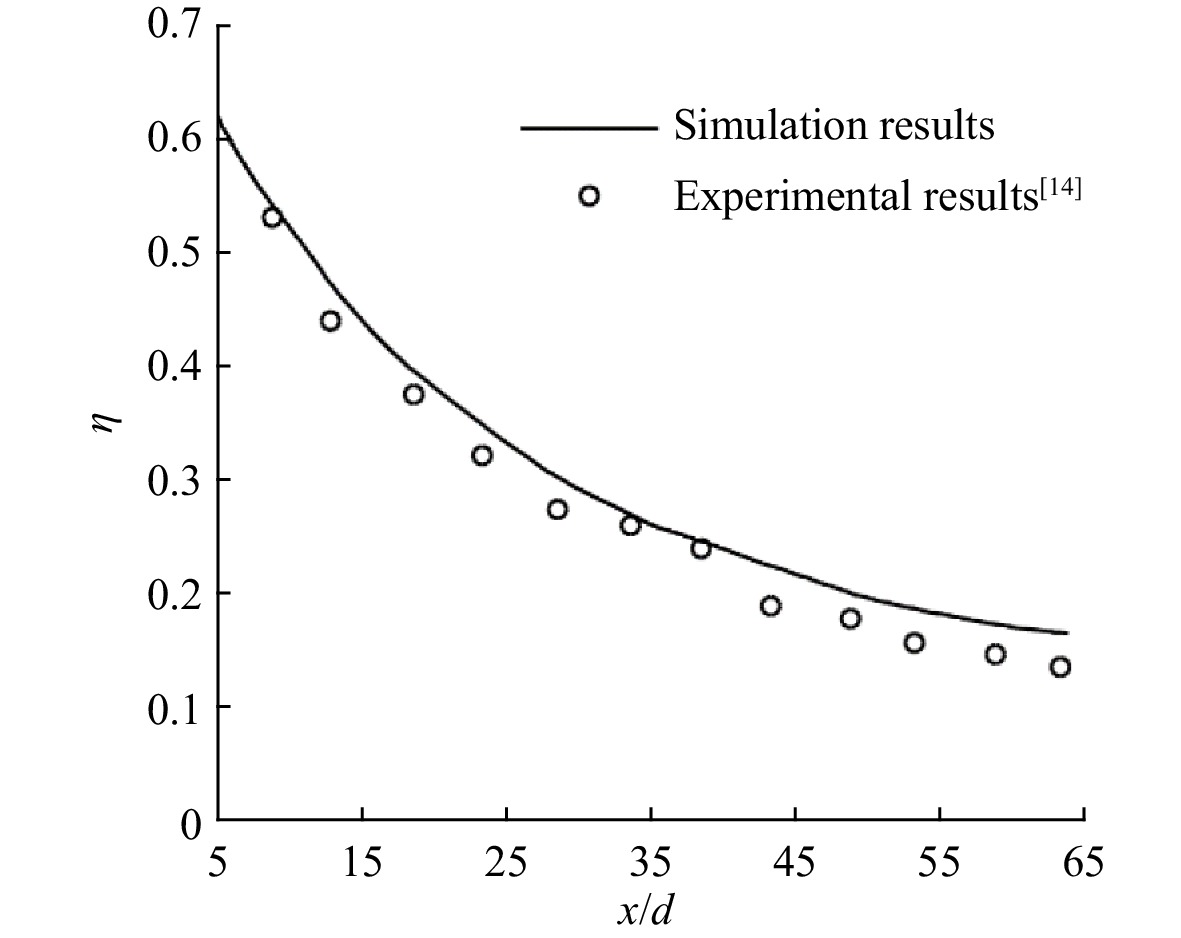

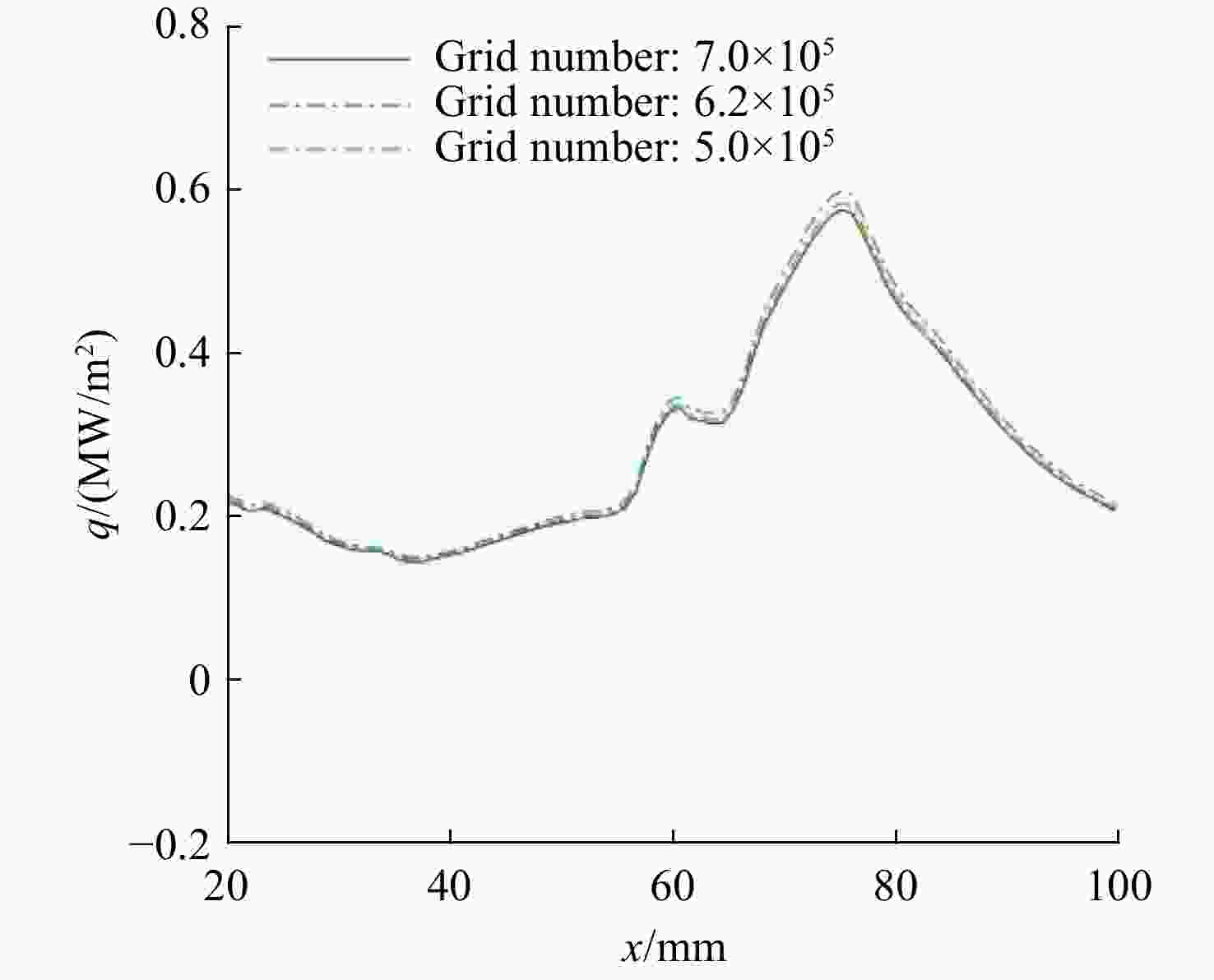

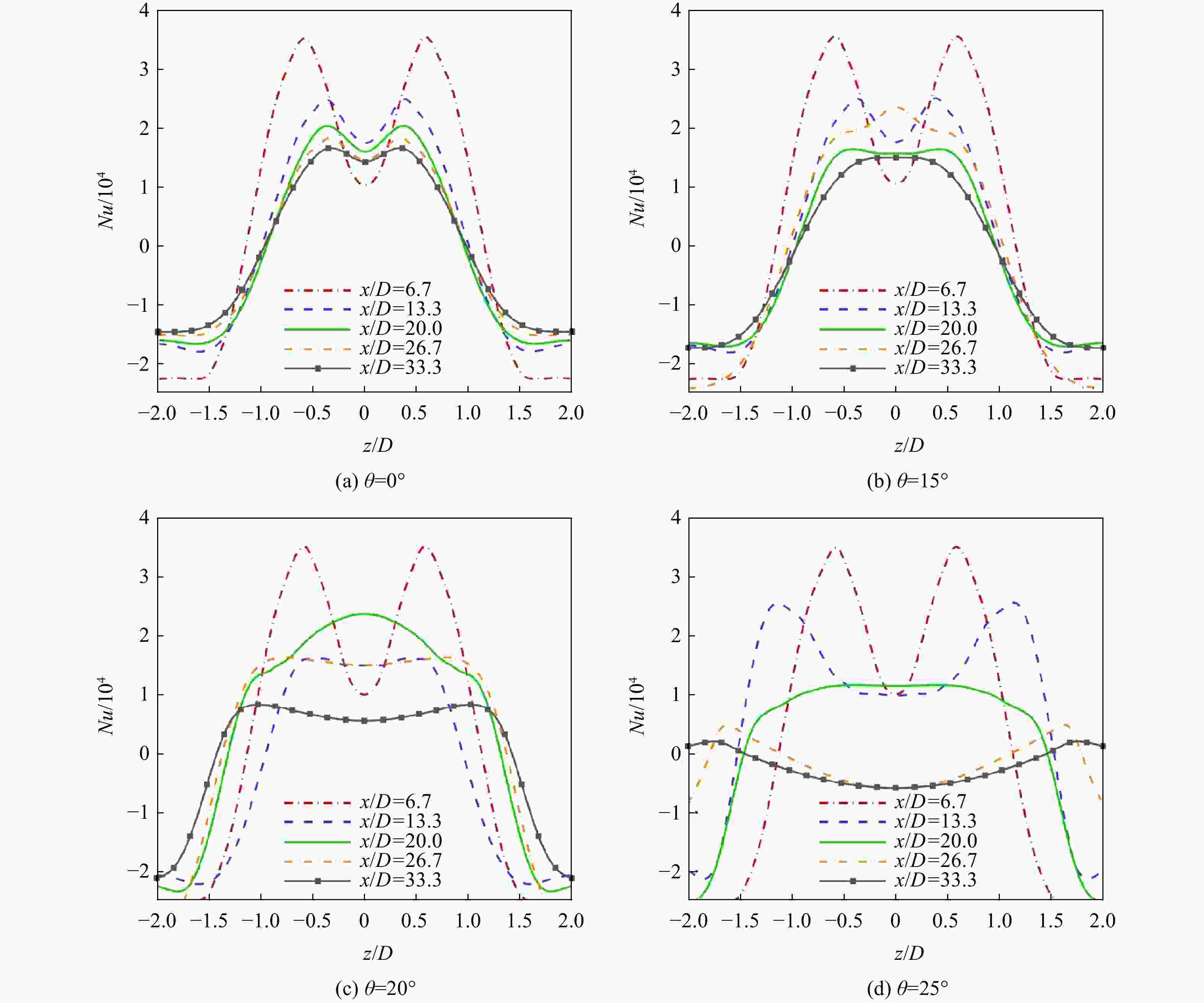

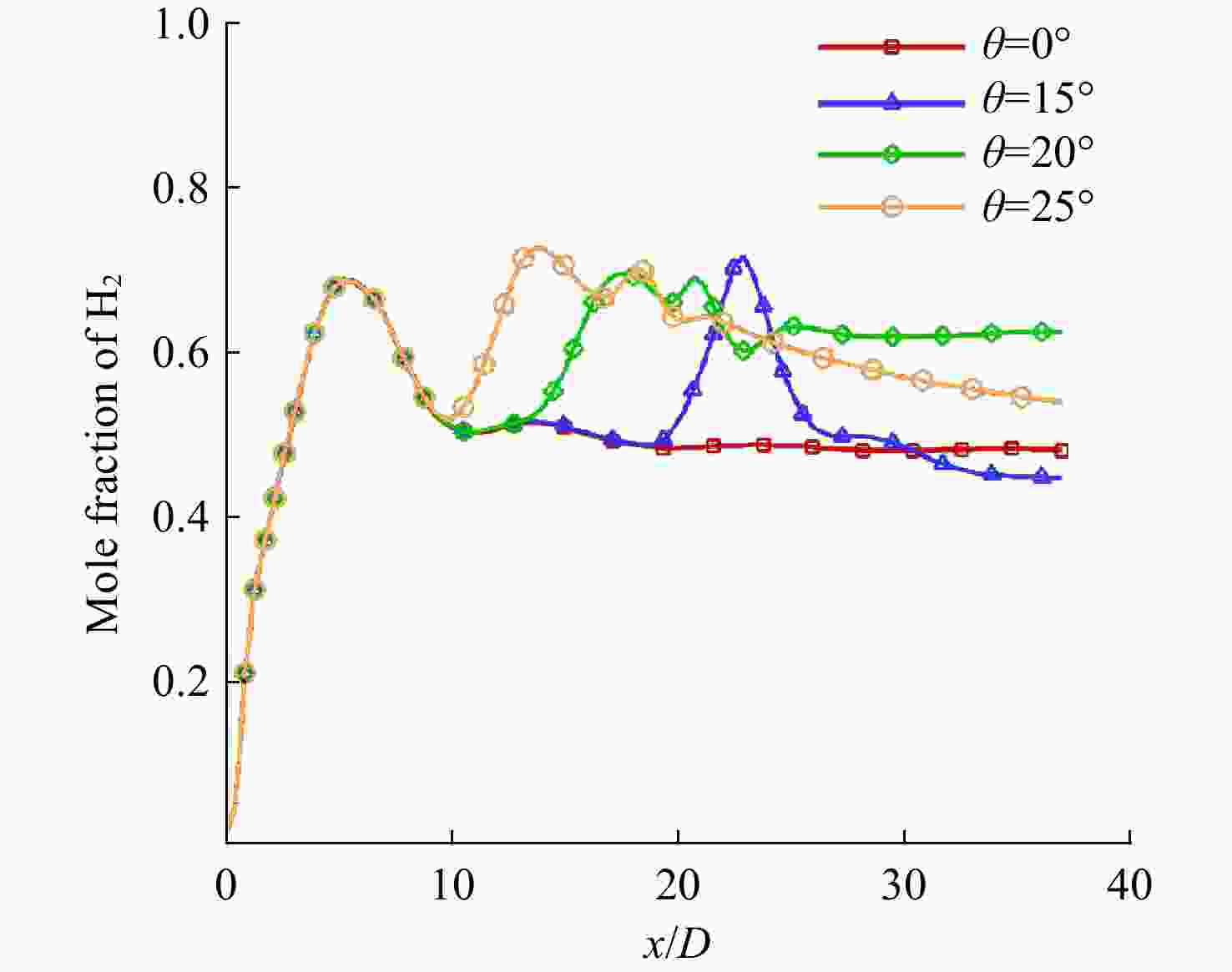

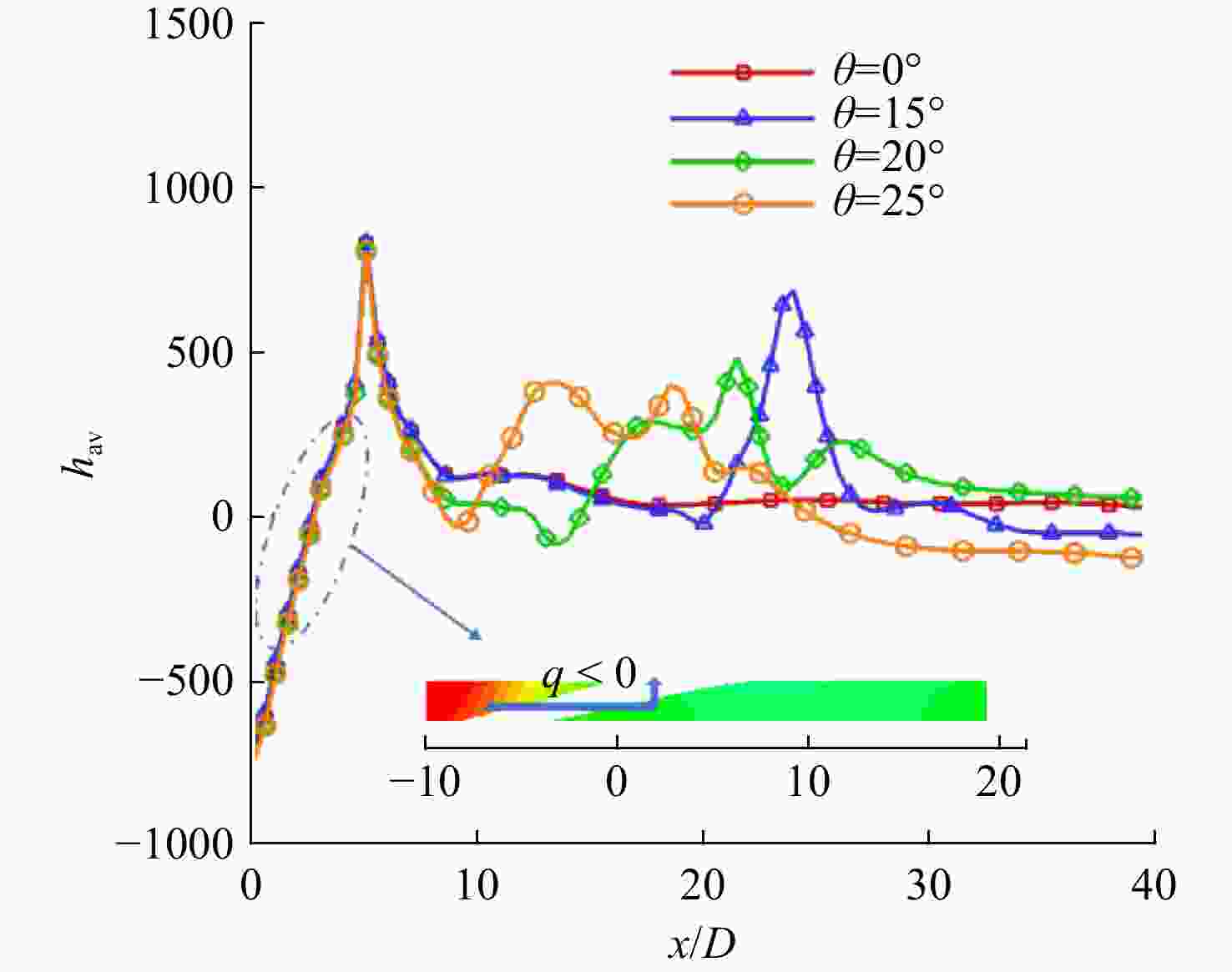

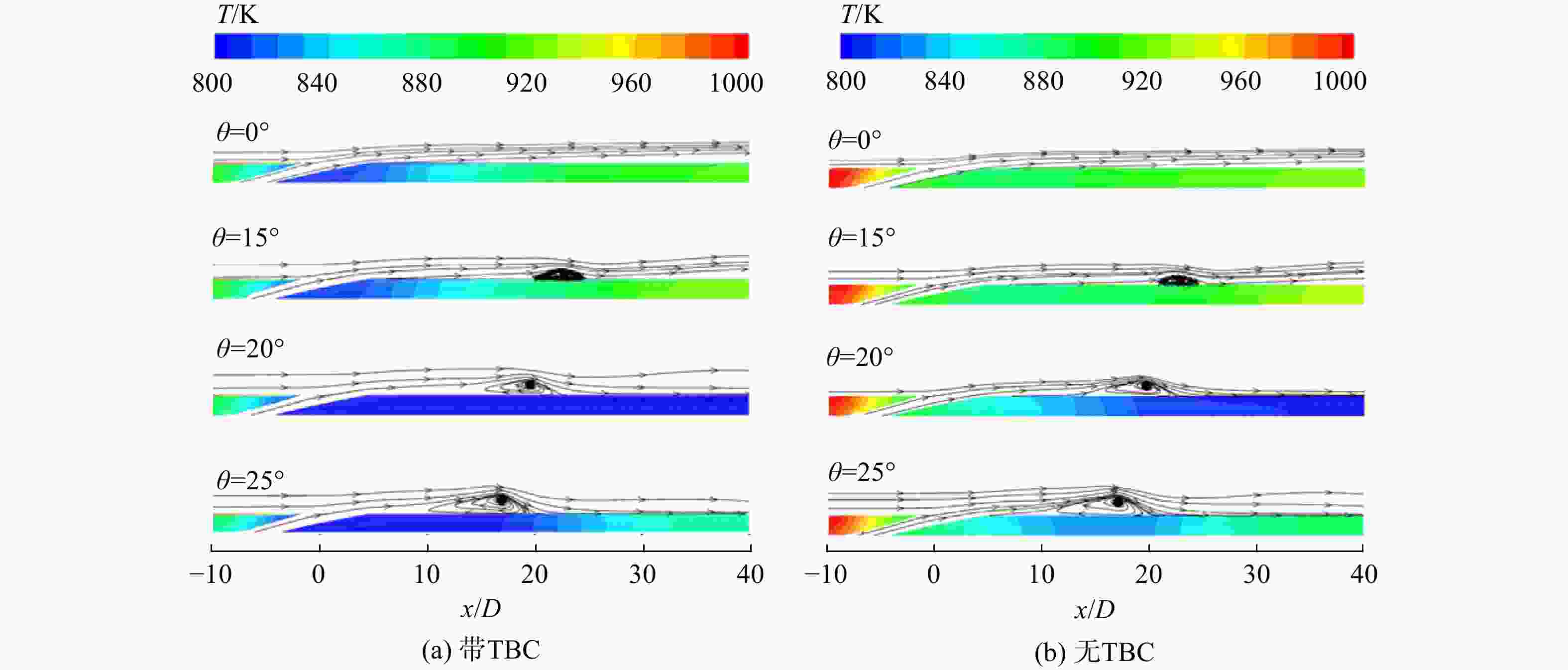

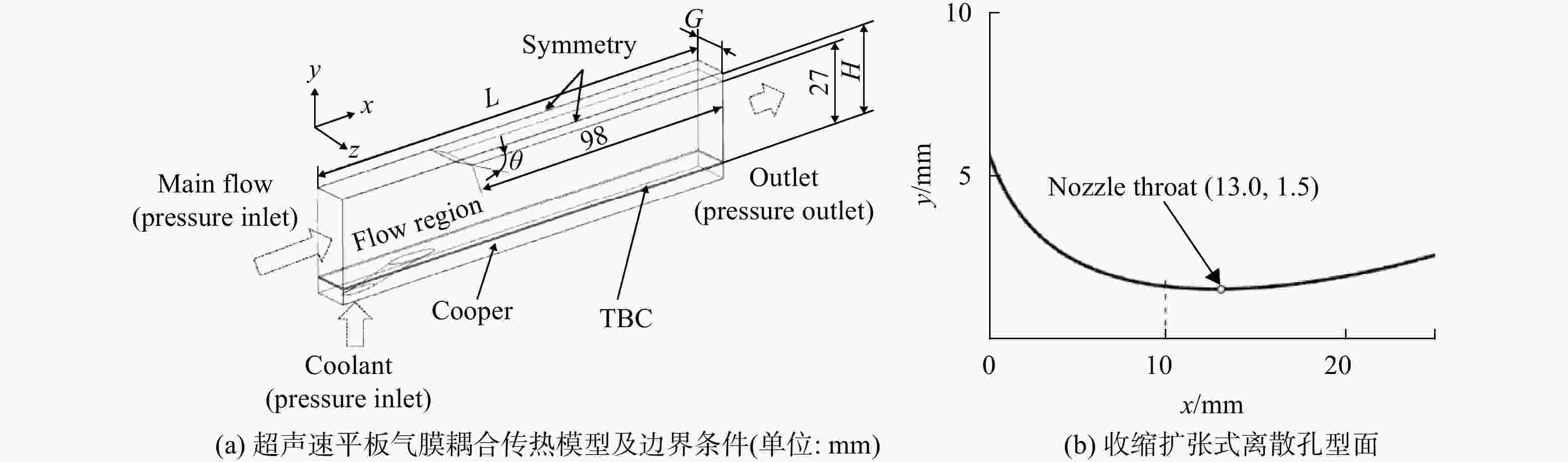

Abstract:To study the interaction between shock wave and supersonic film, a model of supersonic plate film cooling with discrete hole was simulated. A wedge was introduced into the mainstream to create shock wave environment. Coupled heat transfer of supersonic film and high temperature wall was studied under four different shock wave intensities, in which wedge angle was 0°, 15°, 20° and 25° respectively. The simulation result showed that the appropriate intensity of shock wave can effectively eliminate the reverse vortex pairs generated with film injection into mainstream, restrain the entrainment of film, increase the average mole fraction of H2 and also reduce the wall temperature. The analysis of metal temperature field showed that the wall cooling effectiveness first increased and then decreased with the increase of the shock wave angle. The flow field structure with wedge angle of 20° was the most effective to wall temperature protection among all cases. In addition, the cooling effect of coolant at low Mach number could be more easily improved by a smaller wedge angle, whereas the situation was opposite for bigger wedge angles. The results showed that these trends couldn’t be influenced by thermal barrier coating (TBC). The presence of shock waves weakened the scope of TBC’s influence. For revealing the heat transfer mechanism of supersonic film under coupled heat transfer conditions, this method helps to provide a reference for the design of supersonic film cooling, or to provide a basis for the optimization of existing supersonic film cooling structure.

-

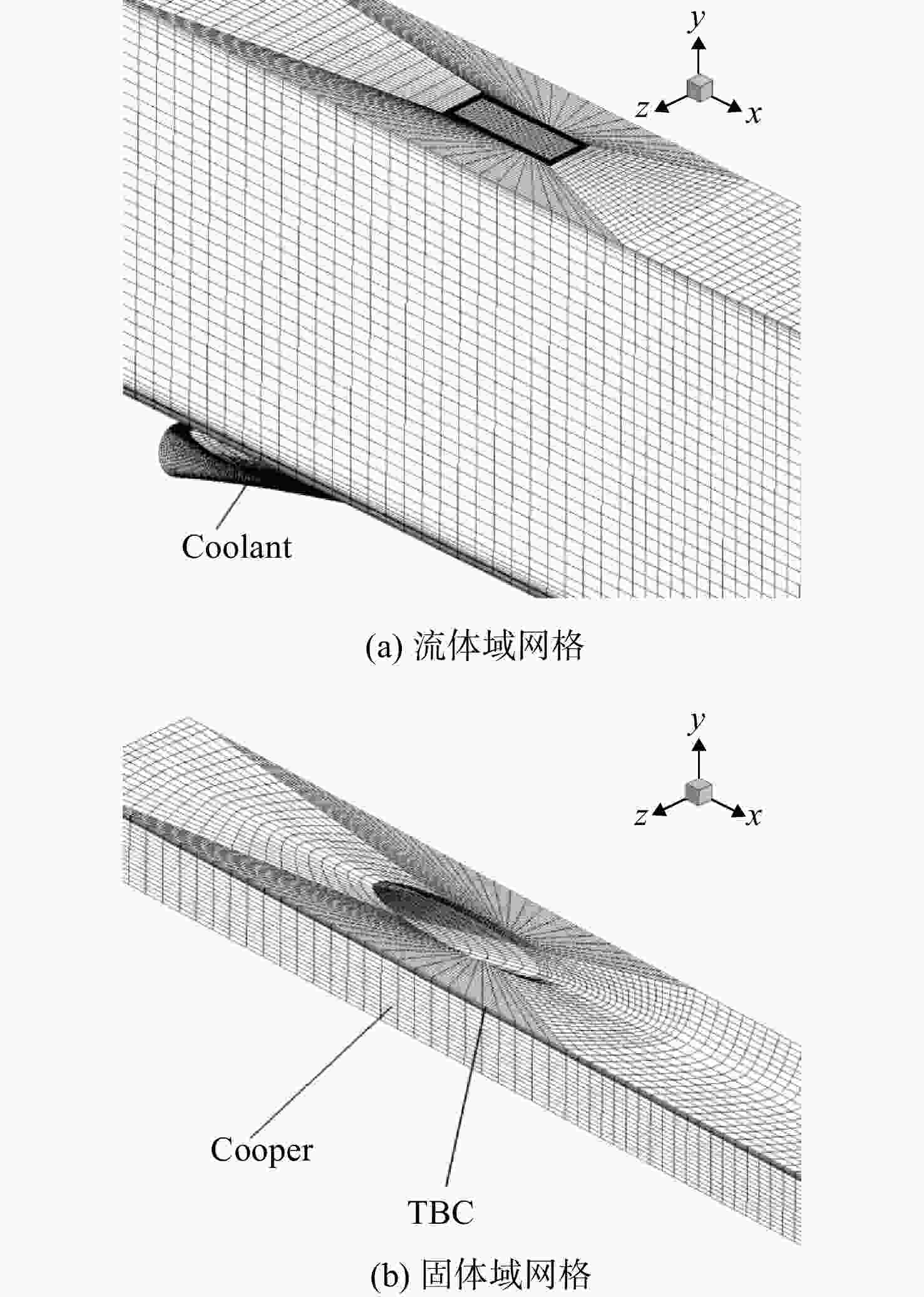

表 1 固体域材料参数

Table 1. Material parameters of solid region

材料 厚度/mm 导热系数/(W/(m·K)) 8YSZ(陶瓷基体) 0.3 2.16 NiCoCrAlY(黏结层) 0.2 4.00 Cooper(金属平板) 5.0 387.60 表 2 不同工况下的入口参数

Table 2. Inlet parameters of different conditions

工质 Ma p*/kPa T*/K M 主流 空气 3.2 4000 1600 冷却剂 工况1 H2 1.9 750 400 0.3 工况2 H2 1.6 500 400 0.25 工况3 H2 1.3 350 400 0.17 -

[1] 葛绍岩,刘登瀛,徐靖中,等.气膜冷却[M].北京: 科学出版社,1985. [2] 商圣飞,向树红,姜利祥,等. 不同孔型对高超声速逆喷流气膜冷却影响[J]. 航空动力学报,2020,35(8): 1612-1621.SHANG Shengfei,XIANG Shuhong,JIANG Lixiang,et al. Numerical simulation of supersonic gaseous film cooling[J]. Journal of Aerospace Power,2020,35(8): 1612-1621. (in Chinese) [3] 王建,孙冰,魏玉坤,等. 超声速气膜冷却数值模拟[J]. 航空动力学报,2008,23(5): 865-870.WANG Jian,SUN Bing,WEI Yukun,et al. Numerical simulation of supersonic gaseous film cooling[J]. Journal of Aerospace Power,2008,23(5): 865-870. (in Chinese) [4] GROSDEMANGE H. Advanced nozzle extension demonstration for Vulcain Mark Ⅱ application[R]. AIAA-1999-2537,1999. [5] FUKUSHIMA Y,NAKATUZI H,KISHIMOTO K,et al. Development status of LE-7A engine[R].AIAA-1997-2817,1997. [6] 丁兆波,孙纪国,路晓红,等. 国外典型大推力氢氧发动机推力室技术方案综述[J]. 导弹与航天运载技术,2012(4): 27-30. doi: 10.3969/j.issn.1004-7182.2012.04.006DING Zhaobo,SUN Jiguo,LU Xiaohong,et al. Review on technical schemes of foreign large LOx/LH2 thrust chamber[J]. Missiles and Space Vehicles,2012(4): 27-30. (in Chinese) doi: 10.3969/j.issn.1004-7182.2012.04.006 [7] 彭威,姜培学. 直通道和弯曲通道中超声速气膜冷却研究[J]. 航空动力学报,2008,23(3): 406-409.PENG Wei,JIANG Peixue. Investigation of supersonic film cooling in flat and convex channels[J]. Journal of Aerospace Power,2008,23(3): 406-409. (in Chinese) [8] KONOPKA M,MEINKE M,WOLFGANG S,et al. Large-eddy simulation of shock/cooling-film interaction[J]. Angewandte Chemie,2013,45(18): 2962-2965. [9] KONOPKA M,MEINKE M,SCHRODER W,et al. Large-eddy simulation of high Mach number film cooling with shock-wave interaction[J]. Progress in Flight Physics,2013,5(6): 309-326. [10] PENG Wei,JIANG Peixue. Influence of shock wave on supersonic flim cooling[J]. Journal of Spacecraft and Rockets,2009,46(1): 67-73. doi: 10.2514/1.38458 [11] SUN Xiaokai,NI Hang,PENG Wei,et al. Influence of shock wave impinging region on supersonic film cooling[J]. Chinese Journal of Aeronautics,2021,34(5): 452-465. doi: 10.1016/j.cja.2020.12.012 [12] 倪航,王明军,彭威,等. 冷却流分段注入对超声速气膜冷却的影响[J]. 工程热物理学报,2021,42(8): 2090-2096.NI Hang,WANG Mingjun,PENG Wei,et al. Effect of segmented cooling-stream injection on supersonic film cooling[J]. Journal of Engineering Thermophysics,2021,42(8): 2090-2096. (in Chinese) [13] 孙冰,王太平,张佳. 离散孔结构超声速气膜冷却数值模拟[J]. 航空动力学报,2017,32(5): 452-465.SUN Bing,WANG Taiping,ZHANG Jia. Numerical simulation of discrete holes supersonic gaseous film cooling[J]. Journal of Aerospace Power,2017,32(5): 452-465. (in Chinese) [14] ZHANG Jia,SUN Bing. Experiments on film cooling with sonic injection into a supersonic flow[J]. Journal of Aerospace Power,2015,30(5): 1084-1091. [15] 曹学强. 热障涂层材料[M].北京:科学出版社,2007. [16] HYDE C R,SMITH B R,SCHETZ J A,et al. Turbulence measurements for heated gas slot injection in supersonic flow[J]. AIAA Journal,1990,28(9): 1605-1614. doi: 10.2514/3.25259 [17] PENG Wei,JIANG Peixue. Effect of shock wave on supersonic film cooling with a slotted wall[J]. Applied Thermal Engineering,2014,62(1): 187-196. doi: 10.1016/j.applthermaleng.2013.09.013 [18] ZUO J,ZHANG S,QIN J,et al. Effects of shock waves interaction on hydrocarbon fueled supersonic film cooling with combustion[J]. Aerospace Science and Technology,2021,113(6): 106693.1-106693.14. -

下载:

下载: