Multi-component coupling optimization for stability improvement of transonic centrifugal compressor

-

摘要:

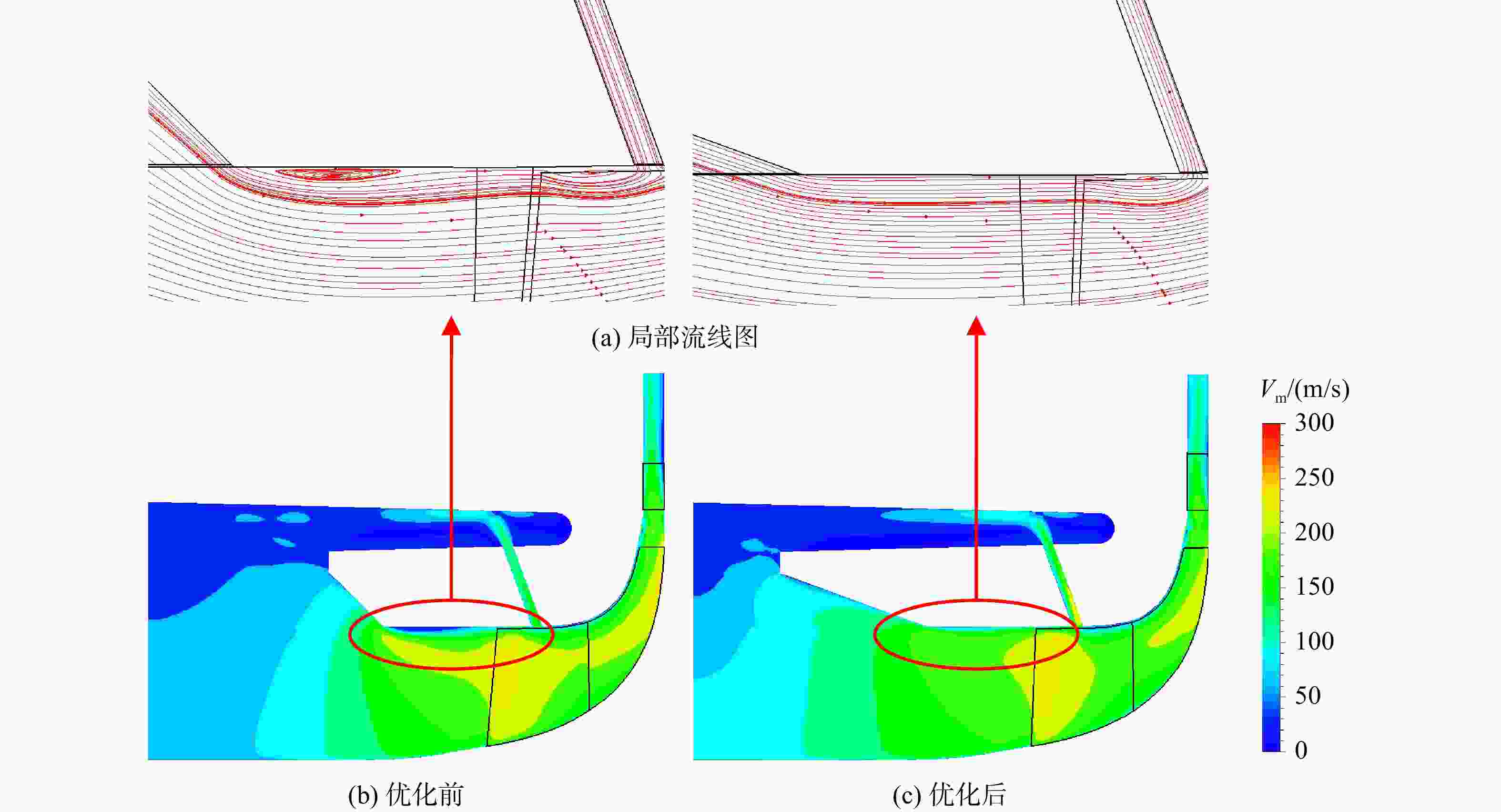

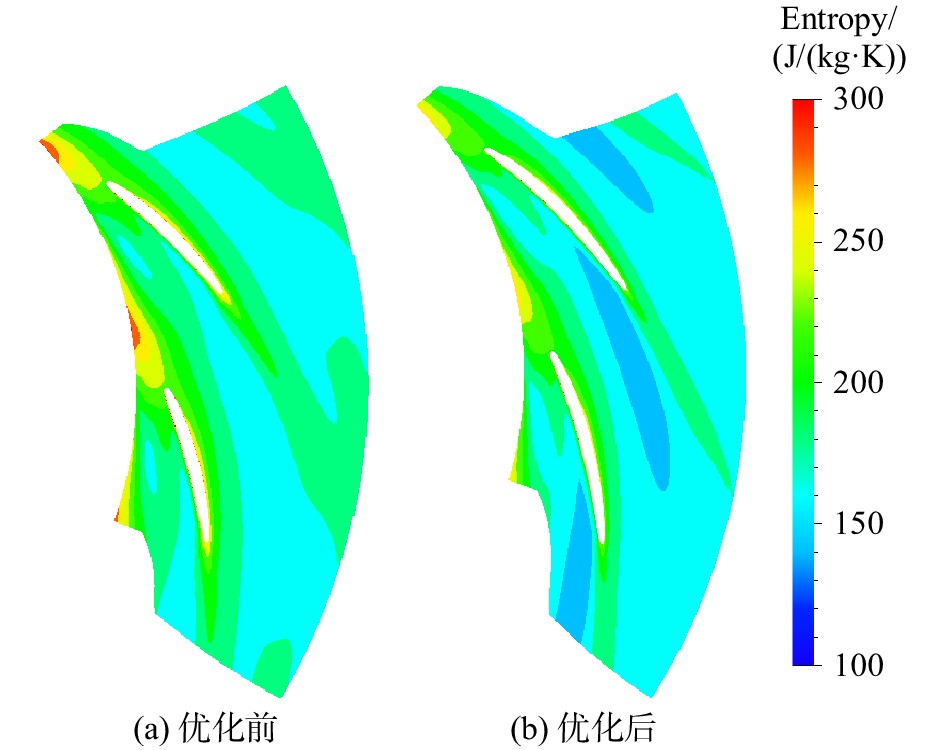

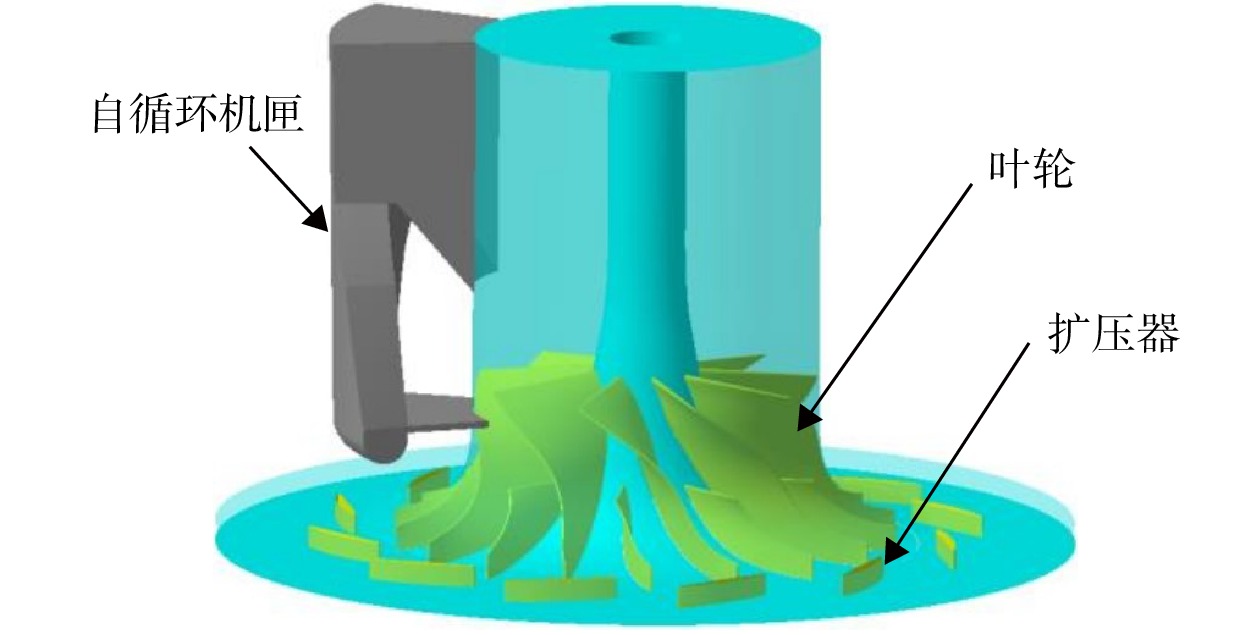

基于最优拉丁超立方采样、多项式代理模型、傅里叶幅值敏感性试验、梯度变异混合优化算法构建了跨声速离心压气机耦合优化方法,实现了自循环机匣处理扩稳的同时不降低等熵效率的目标。耦合优化后压气机气动性能全面提升,设计点和近失速点的等熵效率分别提高2.79%、1.82%,且峰值效率略高于实壁机匣压气机。耦合优化扩稳增效的机理是:自循环机匣抽吸流量增大,更多低能流体被移除;叶轮入口攻角改善,流动分离风险减小;前缘激波与叶尖泄漏涡干涉被抑制,叶轮下游低能流体减少,周向均匀性增强;机匣回流槽入射角增大,叶轮入口径向畸变被削弱;叶轮叶片尾缘安装角及扩压器有叶段尾缘半径的增大弥补了等熵效率损失;叶轮叶片前缘后掠角减小弥补了堵塞流量。

Abstract:Based on the optimal Latin hypercube sampling, polynomial surrogate model, Fourier amplitude sensitivity test, and gradient mutation hybrid optimization algorithm, a coupling optimization method of transonic centrifugal compressors was constructed, and the goal of self-recirculation casing treatment stability improvement without loss of isentropic efficiency was achieved. After the coupling optimization, the aerodynamic performance of the compressor was comprehensively improved. The isentropic efficiency of the design point and near-stall point increased by 2.79% and 1.82%, respectively, and the peak efficiency was slightly higher than the solid compressor. According to the mechanisms of coupling optimization for stabilization and efficiency enhancement: the recirculation flow of self-recirculation casing treatment was increased, and more low-energy fluid was removed; the flow incidence angle of impeller was improved, and the risk of flow separation was reduced; the interaction of leading edge shock wave and the tip leakage vortex was suppressed, the low-energy fluid downstream the impeller was reduced, and the circumferential uniformity of the flow was enhanced; the injection angle of upstream slot of the casing treatment was increased, and the radial distortion of the impeller inlet was weakened; the increases of both the blade angle of the impeller trailing edge and the radius of the diffuser blade trailing edge made up for the isentropic efficiency loss; the reduction of the back sweep of the impeller blade leading edge made up for the choke flow.

-

表 1 离心压气机主要设计参数

Table 1. Key design parameters of the centrifugal compressor

设计参数 数值 设计转速/(r/min) 94500 设计流量/(kg/s) 0.86 设计总压比 5.923 机器马赫数 1.7 叶轮主/分流叶片数 9/9 叶轮叶顶间隙/mm 0.5 叶轮出口直径/mm 118 扩压器叶片数 12 扩压器出口直径/mm

(含有叶与无叶段)200 表 2 不同转速下最大相对误差

Table 2. Maximum relative errors under different rotating speeds

转速 等熵效率

最大误差/%总压比

最大误差/%100%设计转速 1.3 5.4 90%设计转速 1.2 1.9 80%设计转速 0.7 0.7 表 3 基准自循环机匣几何参数范围

Table 3. Value ranges of geometry parameters of the baseline self-recirculation casing

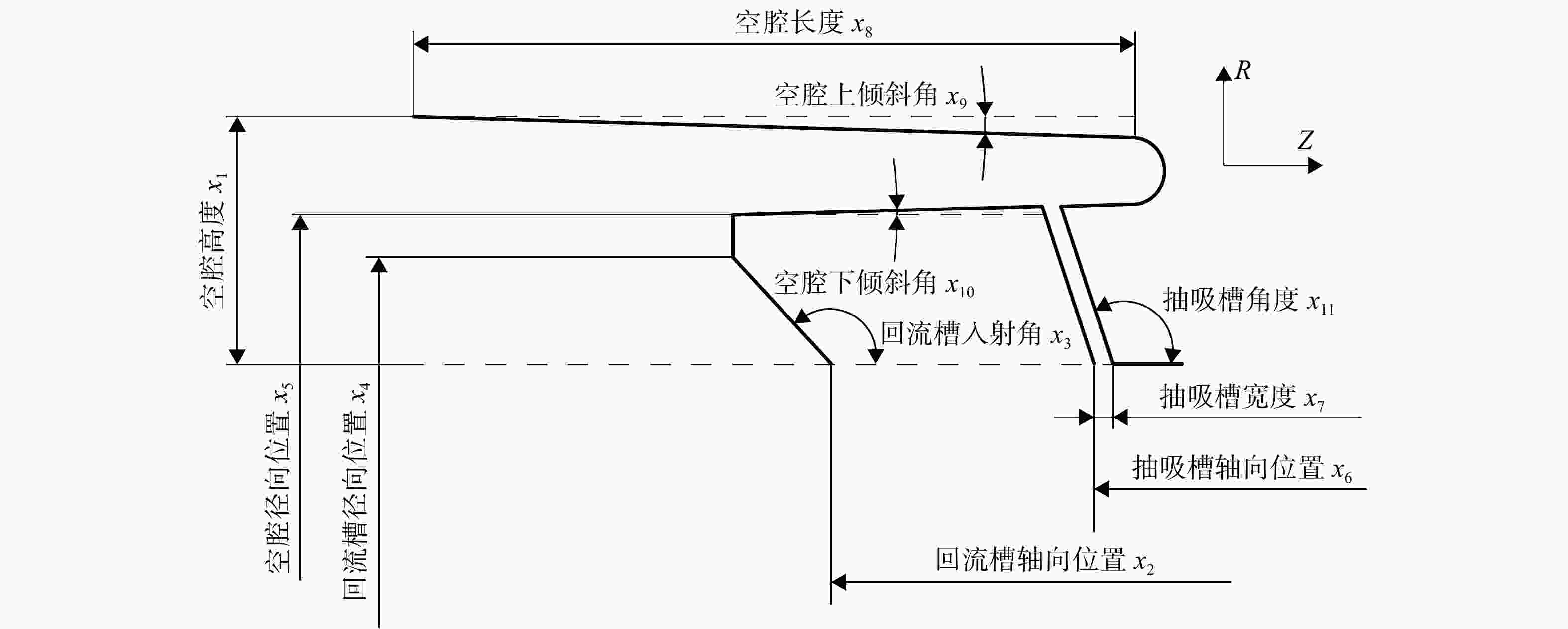

几何参数 下限值 基准值 上限值 空腔高度x1/mm 26 29.39 38 回流槽轴向位置x2/mm −75 −65.32 −55 回流槽入射角x3/(°) 120 135 160 回流槽径向位置x4/mm 45 53.05 61 空腔径向位置x5/mm 59 58.11 64 抽吸槽轴向位置x6/mm −36 −30.83 −25 抽吸槽宽度x7/mm 1 2.5 4 空腔长度x8/mm 85 94.5 104 空腔上倾斜角x9/(°) 0 1.5 3 空腔下倾斜角x10/(°) 0 1.5 3 抽吸槽角度x11/(°) 90 110 132 表 4 不同代理模型方均根误差

Table 4. Root mean square error of different surrogate models

模型 方均根误差 堵塞

流量设计点

等熵效率设计点

总压比近失速点

等熵效率近失速点

总压比高斯过程回归 0.062 0.066 0.065 0.145 0.100 径向基神经网络 0.045 0.055 0.052 0.103 0.090 4阶多项式线性

回归模型0.046 0.063 0.039 0.071 0.096 表 5 压气机耦合优化设计变量基准值及变化范围

Table 5. Baseline values and variation ranges of design variables for compressor coupling optimization

耦合优化设计变量 下限值 基准值 上限值 叶轮叶片前缘后掠角/(°) 1 5 5 叶轮叶片尾缘叶顶安装角/(°) 43 44.8 46 叶轮叶片尾缘叶根安装角/(°) 53.7 55.2 56.2 扩压器有叶段尾缘半径/mm 79 79 82 机匣回流槽入射角/(°) 135 135 160 机匣抽吸槽轴向位置/mm −36 −30.8 −25 机匣抽吸槽宽度/mm 1 2.5 4 表 6 压气机优化前后主要性能指标

Table 6. Key performance indicators of compressor before and after optimization

性能指标 基准机匣 耦合优化 增量/% 设计点等熵效率/% 73.61 75.72 2.79 设计点总压比 5.923 6.183 4.21 近失速点等熵效率/% 71.75 73.08 1.82 近失速点总压比 6.255 6.417 2.52 稳定工况范围/% 20.87 22.92 2.05 表 7 压气机优化前后设计变量对比

Table 7. Comparison of design variables of the compressor before and after optimization

设计变量 基准

机匣耦合

优化叶轮叶片前缘后掠角/(°) 5 2.31 叶轮叶片尾缘叶顶安装角/(°) 44.8 44.81 叶轮叶片尾缘叶根安装角/(°) 55.2 55.75 扩压器有叶段尾缘半径/mm 79 81.3 机匣回流槽入射角/(°) 135 160 机匣抽吸槽轴向位置/mm −30.8 −31.6 机匣抽吸槽宽度/mm 2.50 2.49 -

[1] 张学锋,卢新根,韩戈,等. 高压比离心压气机设计及试验验证[J]. 燃气轮机技术,2014,27(4): 31-36. doi: 10.3969/j.issn.1009-2889.2014.04.006ZHANG Xuefeng,LU Xingen,HAN Ge,et al. Design and experimental validation of a high pressure ratio centrifugal compressor[J]. Gas Turbine Technology,2014,27(4): 31-36. (in Chinese) doi: 10.3969/j.issn.1009-2889.2014.04.006 [2] 李培元,顾春伟. 高压比离心压气机设计与分析[J]. 工程热物理学报,2013,34(10): 1823-1827.LI Peiyuan,GU Chunwei. Design and analysis of high pressure ratio centrifugal compressor[J]. Journal of Engineering Thermophysics,2013,34(10): 1823-1827. (in Chinese) [3] JONNA T,AKI G,AHTI J V,et al. Flow control methods and their applicability in low-Reynolds-number centrifugal compressors: a review[J]. International Journal of Turbomachinery, Propulsion and Power,2018,3(1): 1-38. [4] 郑新前,张扬军,郭宫达,等. 跨声速离心压气机机匣处理扩稳研究[J]. 工程热物理学报,2010,31(12): 2023-2026.ZHENG Xinqian,ZHANG Yangjun,GUO Gongda,et al. Stability improvement of transonic centrifugal compressor by casing treatment[J]. Journal of Engineering Thermophysics,2010,31(12): 2023-2026. (in Chinese) [5] YANG Mingyang,RICARDO M,ZHANG Yangjun,et al. Effect of self-recirculation-casing treatment on high pressure ratio centrifugal compressor[J]. Journal of Propulsion and Power,2016,32(3): 602-610. doi: 10.2514/1.B35438 [6] CHEN Hua,LEI V M. Casing treatment and inlet swirl of centrifugal compressors[J]. Journal of Turbomachinery,2013,135(4): 823-830. [7] QIN Mingxu, HU Leon, SUN Harold, et al. Flow loss mechanism and modeling in a centrifugal compressor casing [R]. Seoul, South Korea: ASME Turbo Expo 2016 Turbomachinery Technical Conference and Exposition, 2016. [8] JUNG S, PELTON R. Numerically derived design guidelines of self recirculation casing treatment for industrial centrifugal compressors [R]. Seoul, South Korea: ASME Turbo Expo 2016 Turbomachinery Techical Conference and Exposition, 2016. [9] HU Liangjun,SUN Harold,YI James,et al. Numerical and experimental investigation of a compressor with active self-recirculation casing treatment for a wide operation range[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering,2013,227(9): 1227-1241. doi: 10.1177/0954407013486741 [10] SIVAGNANASUNDARAM S,SPENCE S,EARLY J,et al. An impact of various shroud bleed slot configurations and cavity vanes on compressor map width and the inducer flow field[J]. Journal of Turbomachinery,2013,135(4): 2009-2021. [11] CHENG Binbin, SAKAGUCHI D. Optimization of a recirculation flow type casing treatment with guide vanes for centrifugal compressors[C]//2019 5th International Conference on Control, Automation and Robotics (ICCAR). Beijing: IEEE, 2019: 702-707. [12] LI Xiaojian,LIU Zhengxian,ZHAO Yijia. Redesign of casing treatment for a transonic centrifugal compressor based on a hybrid global optimization method[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,2021,236(7): 3398-3417. doi: 10.1177/09544062211039878 [13] HAZBY H R, XU Liping. Numerical investigation of the effects of leading edge sweep in a small transonic impeller[R]. Graz, Austria: 8th European Turbomachinery Conference, 2009. [14] 郭龙凯,刘艳明,郑新前,等. 混合型前缘掠对离心压气机气动性能的影响[J]. 内燃机学报,2016,34(3): 281-287. doi: 10.16236/j.cnki.nrjxb.201603038GUO Longkai,LIU Yanming,ZHENG Xinqian,et al. Effect of hybrid leading edge sweep on the aerodynamic performance of small scale transonic centrifugal compressor[J]. Transactions of CSICE,2016,34(3): 281-287. (in Chinese) doi: 10.16236/j.cnki.nrjxb.201603038 [15] 郭龙凯,刘艳明,崔庆,等. 叶片前缘不同后掠角对离心压气机气动性能的影响[J]. 热能动力工程,2016,31(4): 45-51. doi: 10.16146/j.cnki.rndlgc.2016.04.008GUO Longkai,LIU Yanming,CUI Qing,et al. Back-swept leading edge effects on aerodynamic performance of small scale transonic centrifugal compressure[J]. Journal of Engineering for Thermal Energy and Power,2016,31(4): 45-51. (in Chinese) doi: 10.16146/j.cnki.rndlgc.2016.04.008 [16] HE Xiao,ZHENG Xinqian. Mechanisms of sweep on the performance of transonic centrifugal compressor impellers[J]. Applied Sciences,2017,7(10): 1-22. [17] LI Xianjian,ZHAO Yijia,LIU Zhengxian. A novel global optimization algorithm and data-mining methods for turbomachinery design[J]. Structural and Multidisciplinary Optimization,2019,60(2): 581-612. doi: 10.1007/s00158-019-02227-5 [18] LI Xiaojian,LIU Zhengxian,LIN Yujing. Multipoint and multiobjective optimization of a centrifugal compressor impeller based on genetic algorithm[J]. Mathematical Problems in Engineering,2017,2017(1): 6263274.1-6263274.18. [19] LIANG Qi,ZUO Zhitao,ZHOU Xin,et al. Design of a centrifugal compressor with low solidity vaned diffuser (LSVD) for large-scale compressed air energy storage (CAES)[J]. Journal of Thermal Science,2020,29(2): 423-434. doi: 10.1007/s11630-019-1204-7 [20] 赵磊,陈顺,高天宇,等. 稠度对跨音速叶片扩压器流场影响的数值研究[J]. 风机技术,2019,61(5): 13-18. doi: 10.16492/j.fjjs.2019.05.0003ZHAO Lei,CHEN Shun,GAO Tianyu,et al. Numerical investigation on the effect of solidity on the flow field of transonic radial diffuser[J]. Chinese Journal of Turbomachinery,2019,61(5): 13-18. (in Chinese) doi: 10.16492/j.fjjs.2019.05.0003 [21] BOCCAZZ A, SALA R, GAETAN P. Influence of the diffuser vane setting angle on the flow field in a radial pump[C]// Proceedings of the 9th European Turbomachinery Conference. Istanbul: ETC, 2011: 721-731. [22] ZHANG Yingjie,ZHANG Ziqing,DONG Xu,et al. Effects of unsteady interaction on the performance of an ultra-high-pressure-ratio centrifugal compressor[J]. Aerospace Science and Technology,2020,105: 1-13. [23] CHO I,LEE Y,RYU D,et al. Comparison study of sampling methods for computer experiments using various performance measures[J]. Structural and Multidisciplinary Optimization,2017,55(1): 221-235. doi: 10.1007/s00158-016-1490-6 [24] Scikit-Learn, Machine learning in Python.Supervised learning[EB/OL]. [2021-07-09]. https://scikit-learn.org/stable/supervised_learning.html#supervised-learning. [25] JIN R,CHEN W,SIMPSON T W. Comparative studies of metamodelling techniques under multiple modelling criteria[J]. Structural and Multidisciplinary Optimization,2001,23(1): 1-13. doi: 10.1007/s00158-001-0160-4 [26] CANNAVÓ F. Sensitivity analysis for volcanic source modeling quality assessment and model selection[J]. Computers and Geosciences,2012,44: 52-59. [27] 李红祺. 随机平衡设计傅里叶振幅敏感性分析方法和拓展傅里叶振幅敏感性分析方法在陆面过程模式敏感性分析中的应用探索[J]. 物理学报,2015,64(6): 069201.1-069201.7. doi: 10.7498/aps.64.069201LI Hongqi. Applications of random balance design Fourier amplitude sensitive test and extended Fourier amplitude sensitive text in the parameter sensitivity analysis of land surface process model[J]. Acta Physica Sinica,2015,64(6): 069201.1-069201.7. (in Chinese) doi: 10.7498/aps.64.069201 [28] CUKIER R I,FORTUIN C M,SHULER K E. Study of the sensitive of coupled reaction systems to uncertainties in rate coefficients. I Theory[J]. The Journal of Chemical Physics,1973,59(8): 3973-3878. [29] ZHOU Tao,LIU Zhengxian,LI Xiaojian,et al. Thermodynamic design space data-mining and multi-objective optimization of SCO2 Brayton cycles[J]. Energy Conversion and Management,2021,249: 1-14. -

下载:

下载: