Hypersonic wind tunnel aerodynamic identification method considering noise suppression

-

摘要:

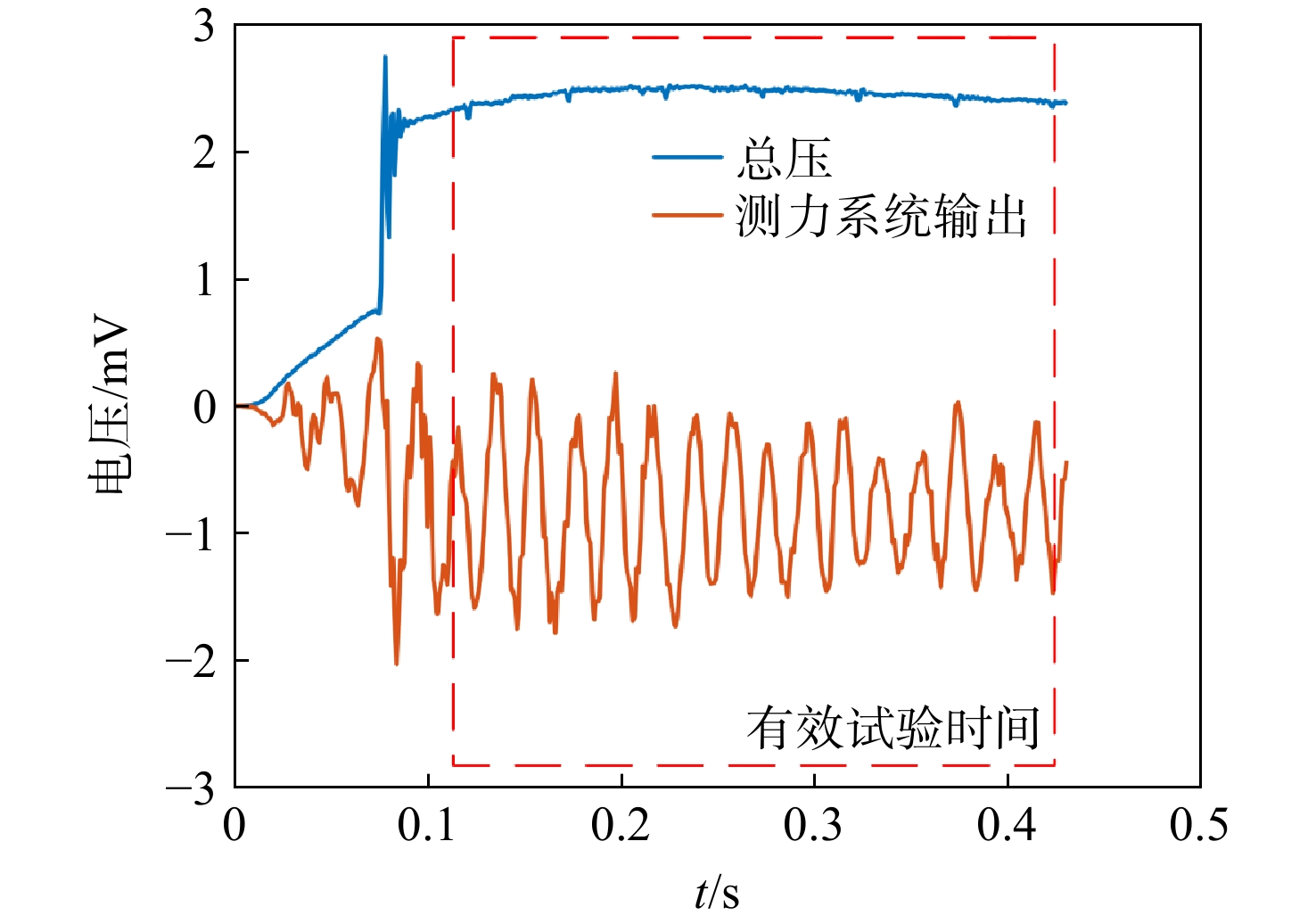

对于风洞试验中全尺寸模型试验的非平稳信号进行载荷辨识仍存在诸多问题。针对全尺度模型试验的非平稳信号载荷辨识提出了一种基于深度残差收缩网络(DRSN)深度学习技术的智能载荷辨识方法,该方法通过深度学习提取测力系统输出数据中的气动力、惯性力和噪声等特征,通过注意力机制对每组数据进行获取阈值,再通过软阈值函数对特征进行滤波降噪,有效辨识出测力系统响应信号中的惯性力分量并进行剔除,实现气动力载荷辨识。在测试验证中,均值法的辨识精度为85%以上,DRSN模型的辨识精度为94%以上,证明DRSN模型能有效降低噪声和惯性力对于载荷辨识的干扰,用于非平稳信号的载荷辨识具有精度高、可靠性好等特点。

Abstract:There are still many problems in load identification of non-stationary signals of full-size model test in wind tunnel test. A full scale model test of non-stationary signal load identification was proposed based on a deep residual shrinkage network (DRSN) deep learning technology of intelligent load identification method. This method extracted load system output data of aerodynamic force and inertial force and noise characteristics by deep learning, through attention mechanism it obtained data access threshold for each group, then the soft threshold function was used to filter the characteristics and reduce the noise. The inertial force component in the response signal of the force measurement system was identified and eliminated effectively, so as to realize the identification of aerodynamic load. In the test and verification, the identification accuracy of the mean value method was above 85%, and that of the DRSN model was above 94%, proving that the DRSN model can effectively reduce the interference of noise and inertia force on the load identification. It presented the characteristics of high accuracy and good reliability for the load identification of non-stationary signals.

-

表 1 DRSN参数

Table 1. DRSN parameters

参数 数值及说明 网络结构 DRSN 优化器 Adam 误差损失 MSE 初始学习率 0.05 最小批量 16 最大训练次数 500 表 2 试验结果对比

Table 2. Comparison of test results

组别序号 载荷识别精度/% DRSN法 均值法 1 97.486 85.170 2 95.563 87.029 3 98.922 85.105 4 99.813 84.127 5 99.746 82.226 6 96.910 85.263 7 98.897 87.492 8 98.214 85.600 9 94.715 83.827 10 96.413 83.690 11 98.673 86.260 12 99.512 85.830 -

[1] 唐志共,许晓斌,杨彦广,等. 高超声速风洞气动力试验技术进展[J]. 航空学报,2015,36(1): 86-97.TANG Zhigong,XU Xiaobin,YANG Yanguang,et al. Progress in aerodynamic test technology of hypersonic wind tunnel[J]. Acta Aeronautica et Astronautica Sinica,2015,36(1): 86-97. (in Chinese) [2] 田建明,景建斌,韩广岐. 高超声速飞行器地面试验方法[J]. 探测与控制学报,2013,35(5): 57-60.TIAN Jianming,JING Jianbin,HAN Guangqi. Ground test method of hypersonic vehicle[J]. Journal of Detection and Control,2013,35(5): 57-60. (in Chinese) [3] LI S,LI K,LIU B,et al. A new dynamic modelling methodology of a force measuring system for hypersonic impulse wind tunnel[J]. Measurement,2020,164(11): 108012.1-108012.15. [4] 李世超,高宏力,刘勃锴,等. 脉冲燃烧风洞测力系统传力特性研究[J]. 振动与冲击,2018,37(21): 117-125,142.LI Shichao,GAO Hongli,LIU Bokai,et al. Force transmission characteristics offorce-measuring system in impulse combustion wind tunnel[J]. Journal of Vibration and Shock,2018,37(21): 117-125,142. (in Chinese) [5] 吕金洲,张小庆,赵晓男,等. 脉冲风洞测力系统结构动力学特性[J]. 西南交通大学学报,2019,54(6): 1305-1313. doi: 10.3969/j.issn.0258-2724.20170737LÜ Jinzhou,ZHANG Xiaoqing,ZHAO Xiaonan,et al. Structural dynamic characteristics of force measurement system in pulse wind tunnel[J]. Journal of Southwest Jiaotong University,2019,54(6): 1305-1313. (in Chinese) doi: 10.3969/j.issn.0258-2724.20170737 [6] 张小庆,乐嘉陵. 脉冲式燃烧风洞起动特性数值研究[J]. 航空动力学报,2008,23(9): 1568-1572.ZHANG Xiaoqing,LE Jialing. Numerical study on starting characteristics of pulse combustion wind tunnel[J]. Journal of Aerospace Power,2008,23(9): 1568-1572. (in Chinese) [7] 张小庆,吕金洲,刘伟雄,等. 脉冲风洞一体化飞行器测力精度分析[J]. 航空动力学报,2018,33(12): 115-120.ZHANG Xiaoqing,LU Jinzhou,LIU Weixiong,et al. Force measurement accuracy analysis of pulse wind tunnel integrated aircraft[J]. Journal of Aerospace Power,2018,33(12): 115-120. (in Chinese) [8] 刘勃锴,高宏力,吴颖川,等. 脉冲燃烧风洞新型悬挂式测力系统[J]. 浙江大学学报(自然科学版),2018,52(4): 619-627.LIU Bokai,GAO Hongli,WU Yingchuan,et al. A new type of suspended force measurement system for pulse combustion wind tunnel[J]. Journal of Zhejiang University (Natural Science Edition),2018,52(4): 619-627. (in Chinese) [9] 吕成涛. 基于频响函数拟合的机械结构动载荷识别[D]. 沈阳: 东北大学, 2019.LÜ Chengtao. Dynamic load identification of mechanical structure based on frequency response function fitting[D]. Shenyang: Northeastern University, 2019. (in Chinese) [10] 唐秀近. 动态力识别的时域方法[J]. 大连工学院学报,1987(4): 21-28.TANG Xiujin. Time-domain method for dynamic force recognition[J]. Journal of Dalian Institute of Technology,1987(4): 21-28. (in Chinese) [11] 周盼,张权,率志君,等. 动载荷识别时域方法的研究现状与发展趋势[J]. 噪声与振动控制,2014,34(1): 6-11. doi: 10.3969/j.issn.1006-1335.2014.01.002ZHOU Pan,ZHANG Quan,LI Zhijun,et al. Research status and development trend of time-domain methods for dynamic load identification[J]. Noise and Vibration Control,2014,34(1): 6-11. (in Chinese) doi: 10.3969/j.issn.1006-1335.2014.01.002 [12] 徐志英,廖旭晖. 动态载荷识别及其进展[J]. 常州工学院学报,2006,19(4): 13-18. doi: 10.3969/j.issn.1671-0436.2006.04.004XU Zhiying,LIAO Xuhui. Dynamic load identification and its progress[J]. Journal of Changzhou Institute of Technology,2006,19(4): 13-18. (in Chinese) doi: 10.3969/j.issn.1671-0436.2006.04.004 [13] ZHOU J M,DONG L,GUAN W,et al. Impact load identification of nonlinear structures using deep recurrent neural network[J]. Mechanical Systems and Signal Processing,2019,133: 106292.1-106292.14. doi: 10.1016/j.ymssp.2019.106292 [14] 王珲玮. 基于神经网络的飞行器力载荷识别算法研究[D]. 杭州: 浙江大学, 2018.WANG Hunwei. Research on recognition algorithm of aircraft force and load based on neural network[D]. Hangzhou: Zhejiang University, 2018. (in Chinese) [15] 张方,朱德懋. 基于神经网络模型的动载荷识别[J]. 振动工程学报,1997,10(2): 156-162.ZHANG Fang,ZHU Demao. Dynamic load identification based on neural network model[J]. Journal of Vibration Engineering,1997,10(2): 156-162. (in Chinese) [16] 汪运鹏,杨瑞鑫,聂少军,等. 基于深度学习技术的激波风洞智能测力系统研究[J]. 力学学报,2020,52(5): 1304-1313. doi: 10.6052/0459-1879-20-190WANG Yunpeng,YANG Ruixin,NIE Shaojun,et al. Research on shock wave wind tunnel intelligent force measurement system based on deep learning technology[J]. Chinese Journal of Theoretical and Applied Mechanics,2020,52(5): 1304-1313. (in Chinese) doi: 10.6052/0459-1879-20-190 [17] LUO C,WANG Y,WANG C,et al. Wave system fitting: a new method for force measurements in shock tunnels with long test duration[J]. Mechanical Systems and Signal Processing,2015,62/63: 296-304. doi: 10.1016/j.ymssp.2015.02.024 [18] HE K, ZHANG X, REN S, et al. Deep residual learning for image recognition[R]. Las Vegas, NV, US: IEEE Conference on Computer Vision and Pattern Recognition (CVPR), 2016. [19] JIE H,LI S,GANG S,et al. Squeeze-and-excitation networks[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence,2020,42(8): 2011-2023. doi: 10.1109/TPAMI.2019.2913372 [20] DONOHO D L. De-noising by soft-thresholding[J]. IEEE Transactions on Information Theory,2002,41(3): 613-627. -

下载:

下载: