Conceptual design of ceramic matrix composites turbine blade for typical turbofan engine

-

摘要:

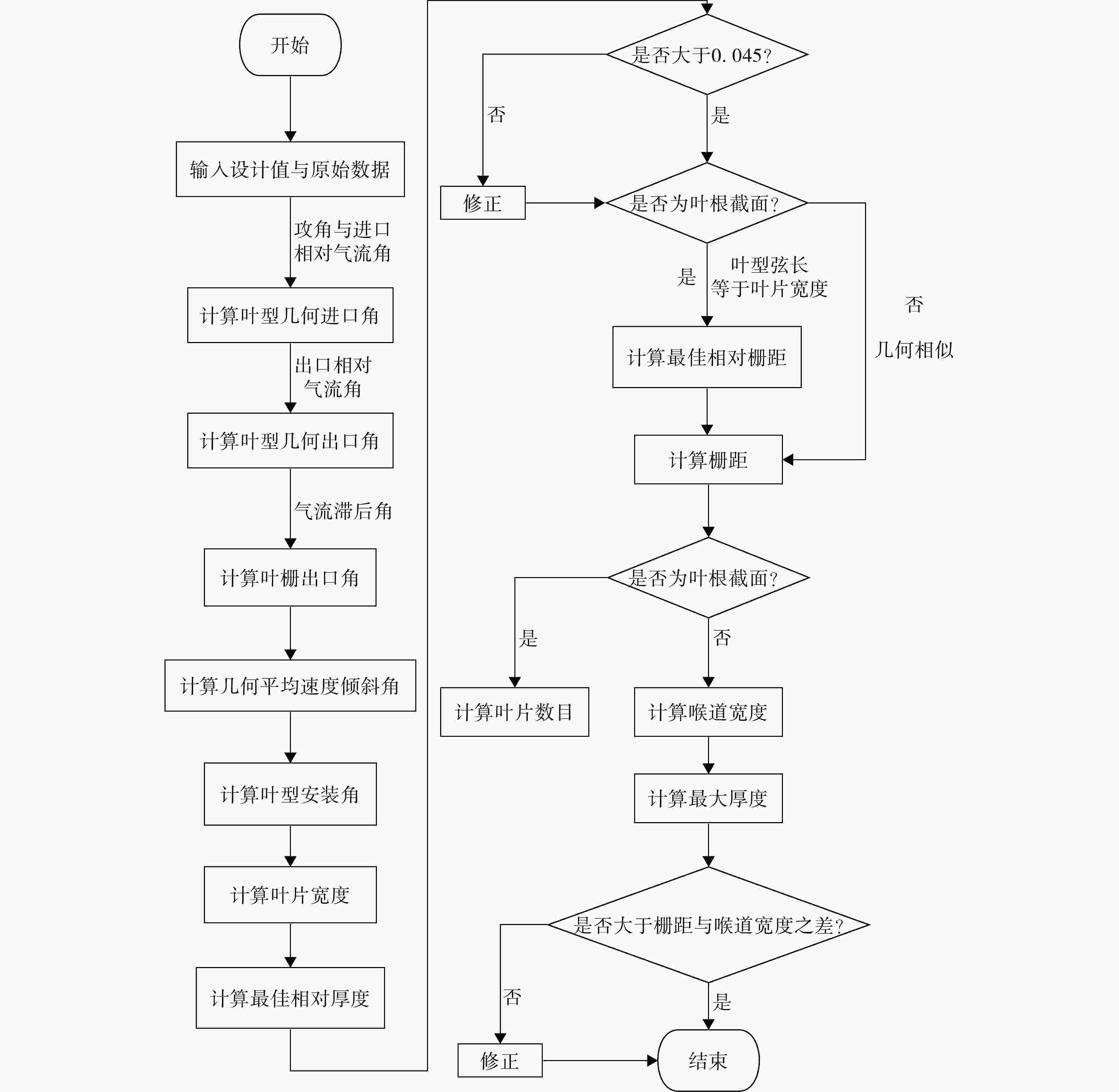

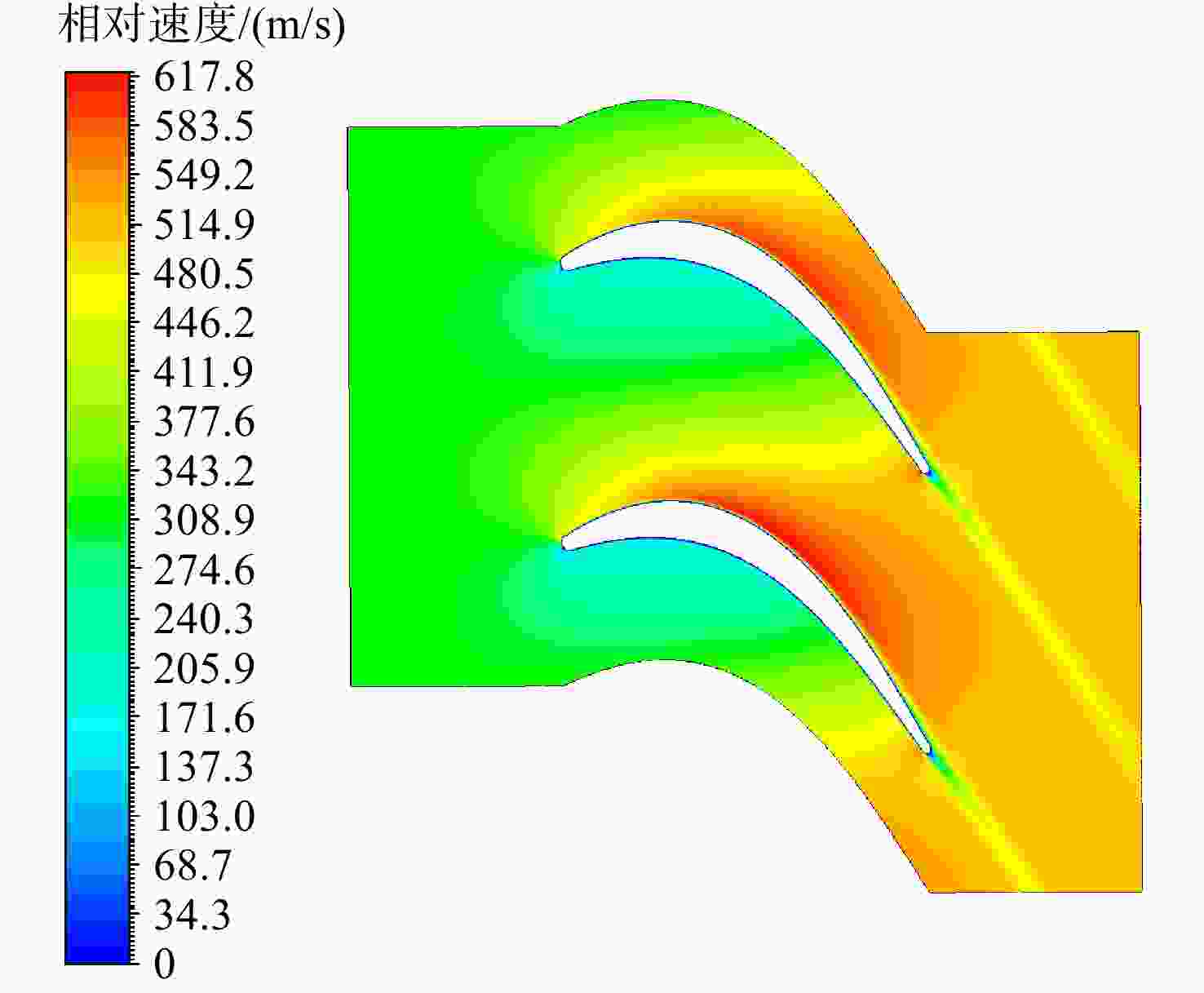

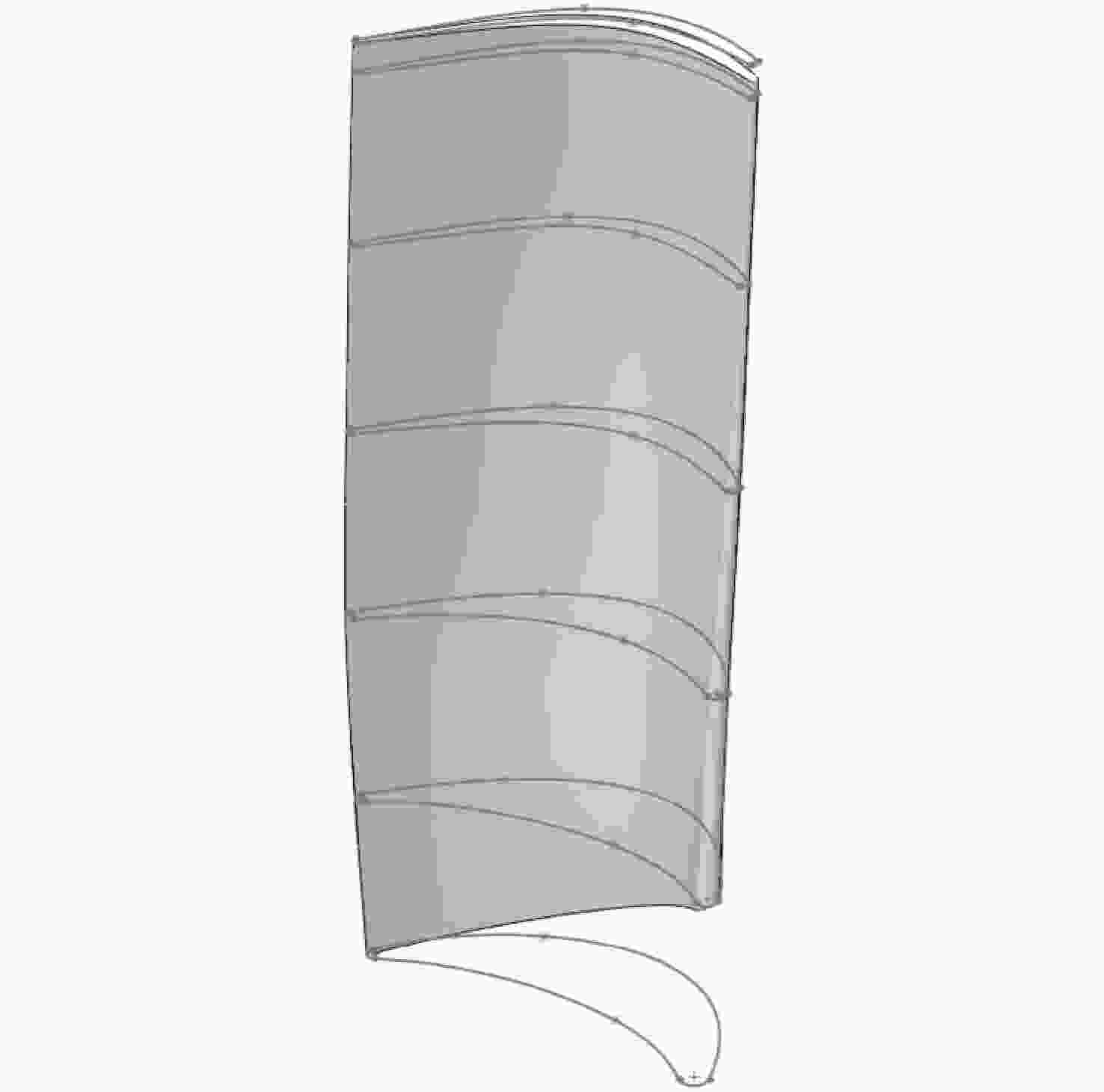

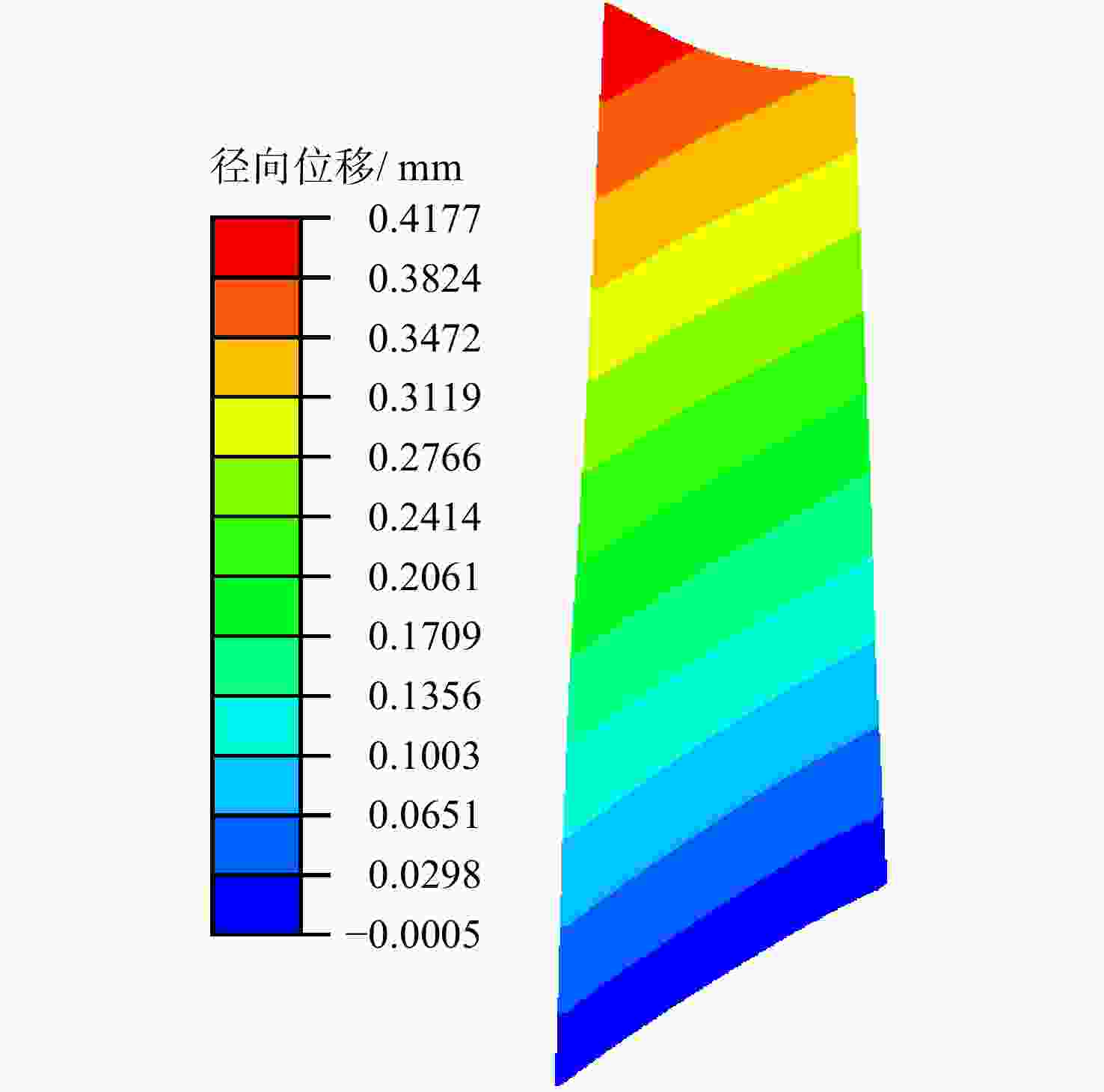

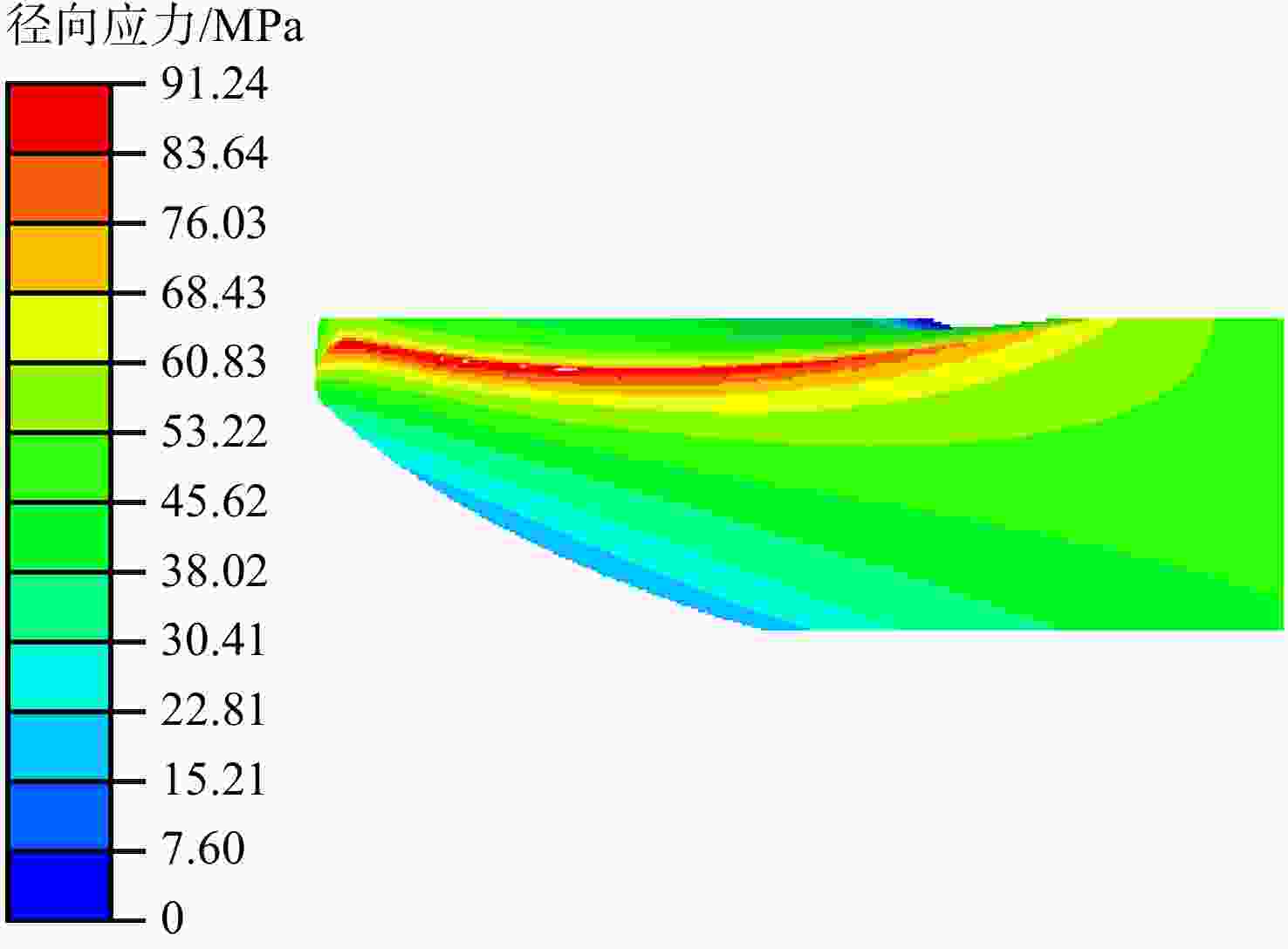

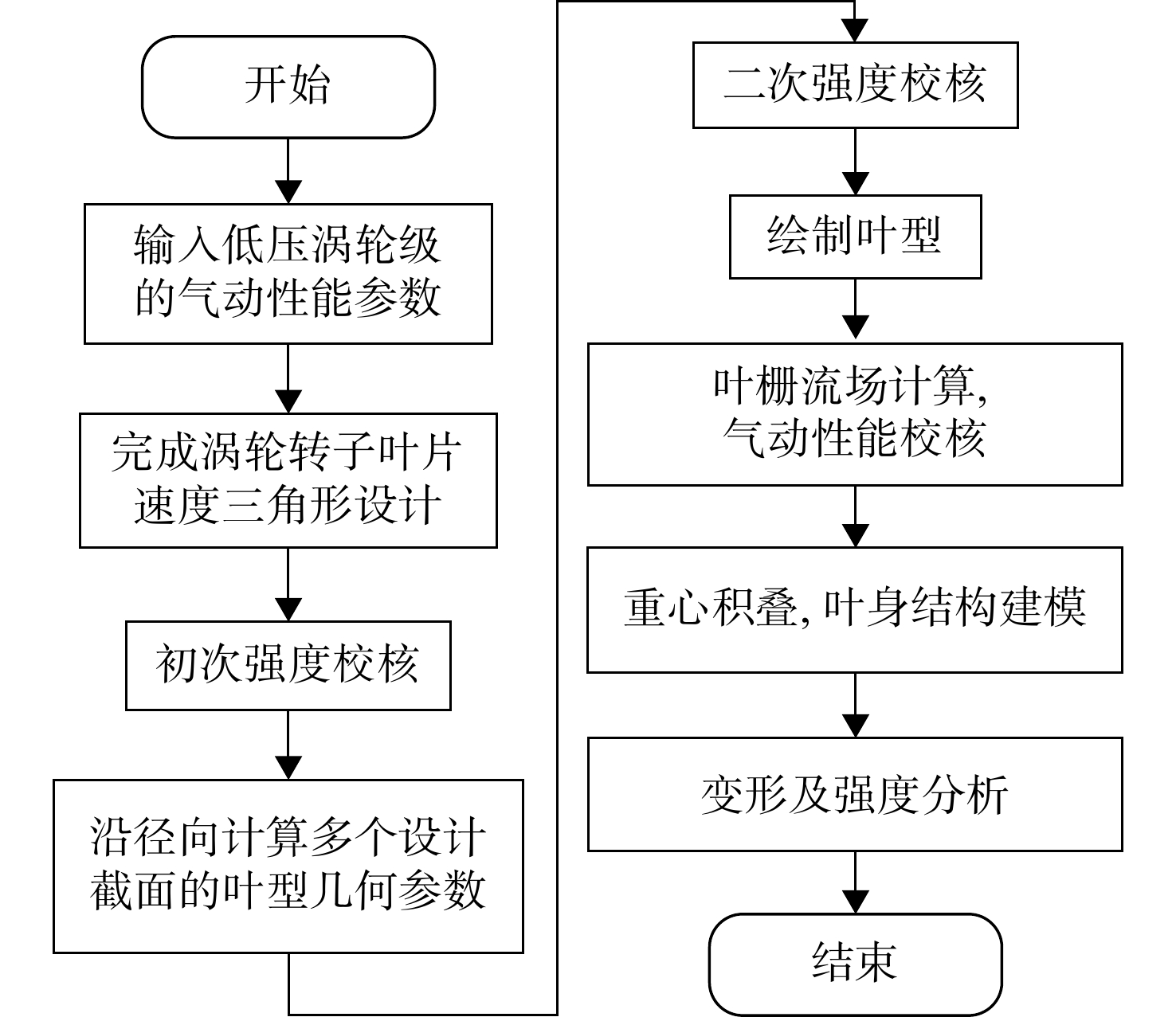

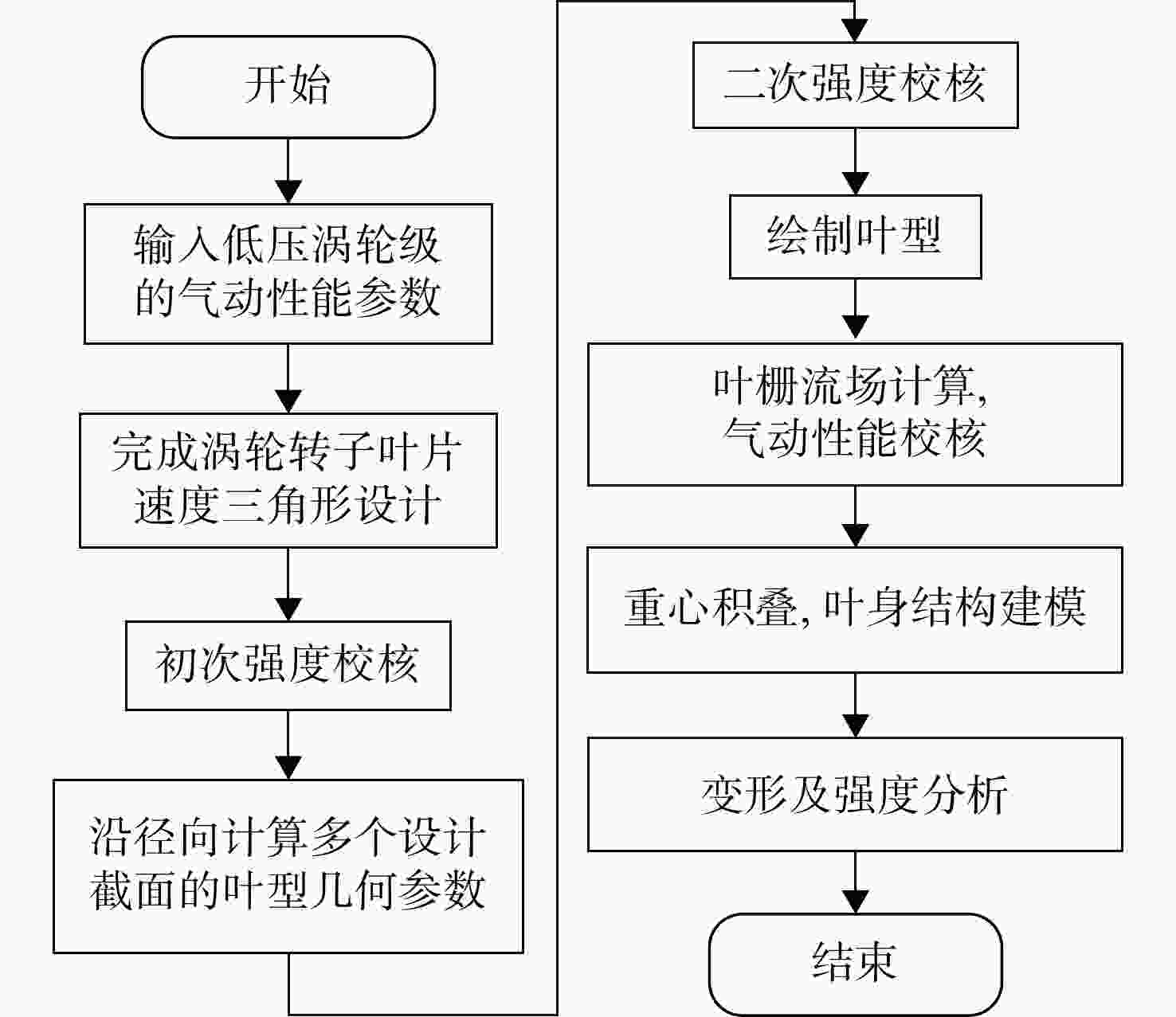

为了推动先进航空发动机陶瓷基复合材料(CMCs)涡轮叶片设计技术进步,以典型涡扇发动机基准性能参数为原始数据,按照涡轮叶片正向设计流程,从气动设计,到结构设计,再到变形及强度分析,梳理出以材料强度为约束,发动机推力和耗油率为输入值,涡轮叶片叶身模型为结果的概念设计方法。设计了一种陶瓷基复合材料低压涡轮转子叶片,该叶片实心无冷却,设计工况下的气动性能、强度和振动特性仿真结果满足设计要求。安全储备系数可达1.8,涡轮盘外载预估减少50%,验证了陶瓷基复合材料用于先进航空发动机热端部件的可行性。涡轮效率提高0.98%~1.17%表明陶瓷基复合材料具有提升先进航空发动机热端部件性能的潜力。

Abstract:For the purpose of technological progress for ceramic matrix composites (CMCs) turbine blade design in advanced aero-engines, based on main performance parameters of typical turbofan engine, and according to the forward turbine blade design process, a conceptual design method was established from aerodynamic design to structural design finally to deformation and strength analysis, and a CMCs low pressure turbine rotor blade was designed, which was solid without cooling. In the conceptual design method, strength was taken as the major constraint, aero-engine thrust and specific fuel consumption taken as inputs, and model of turbine blade body taken as output. The simulation results indicated that aerodynamic performance, strength and vibration performance of the designed blade under design conditions satisfy the design requirements. Reserve factor of safety reached 1.8 and the external load level of the turbine disk was estimated to be reduced by 50%, proving the feasible application of CMCs on advanced aero-engines. Turbine efficiency increased approximately 0.98%—1.17%, which demonstrated the potential of CMCs to promote the performance of high-temperature components in advanced aero-engines.

-

表 1 设计点计算结果

Table 1. Calculation results of design point

参数 验算值 基准值[3] 中间状态推力/kN 105.5 105.5 中间耗油率/(kg/(daN·h)) 0.8371 0.837 换算空气流量/(kg/s) 124.02 126.50 总压比 27.1695 26.1 涵道比 0.3112 0.3 涡轮前温度/K 1802.9 1860 表 2 低压涡轮级性能参数值

Table 2. Performance parameters of low pressure turbine

参数 导向器进口 转子出口 流量/(kg/s) 96.10 96.10 总温/K 1379.33 1181.41 静温/K 1347.15 1137.49 总压/Pa 960877 458286 静压/Pa 867043 390233 绝对速度/(m/s) 283.56 327.06 焓/(J/kg) 1237530 992312 转速/(r/min) 11000 出口面积/m2 0.25 表 3 转子叶片进出口径向尺寸

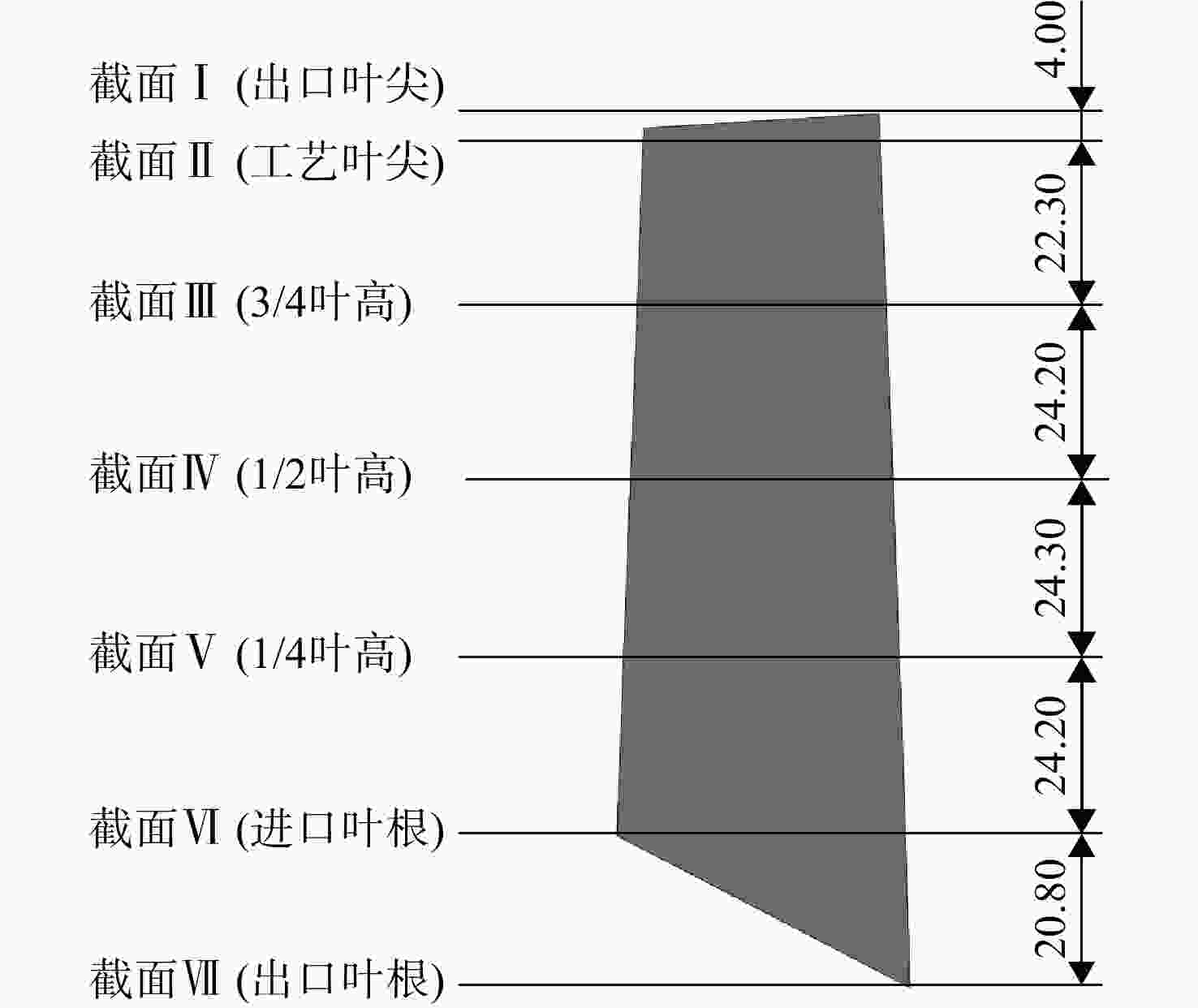

Table 3. Radial dimension of inlet and outlet rotor blade

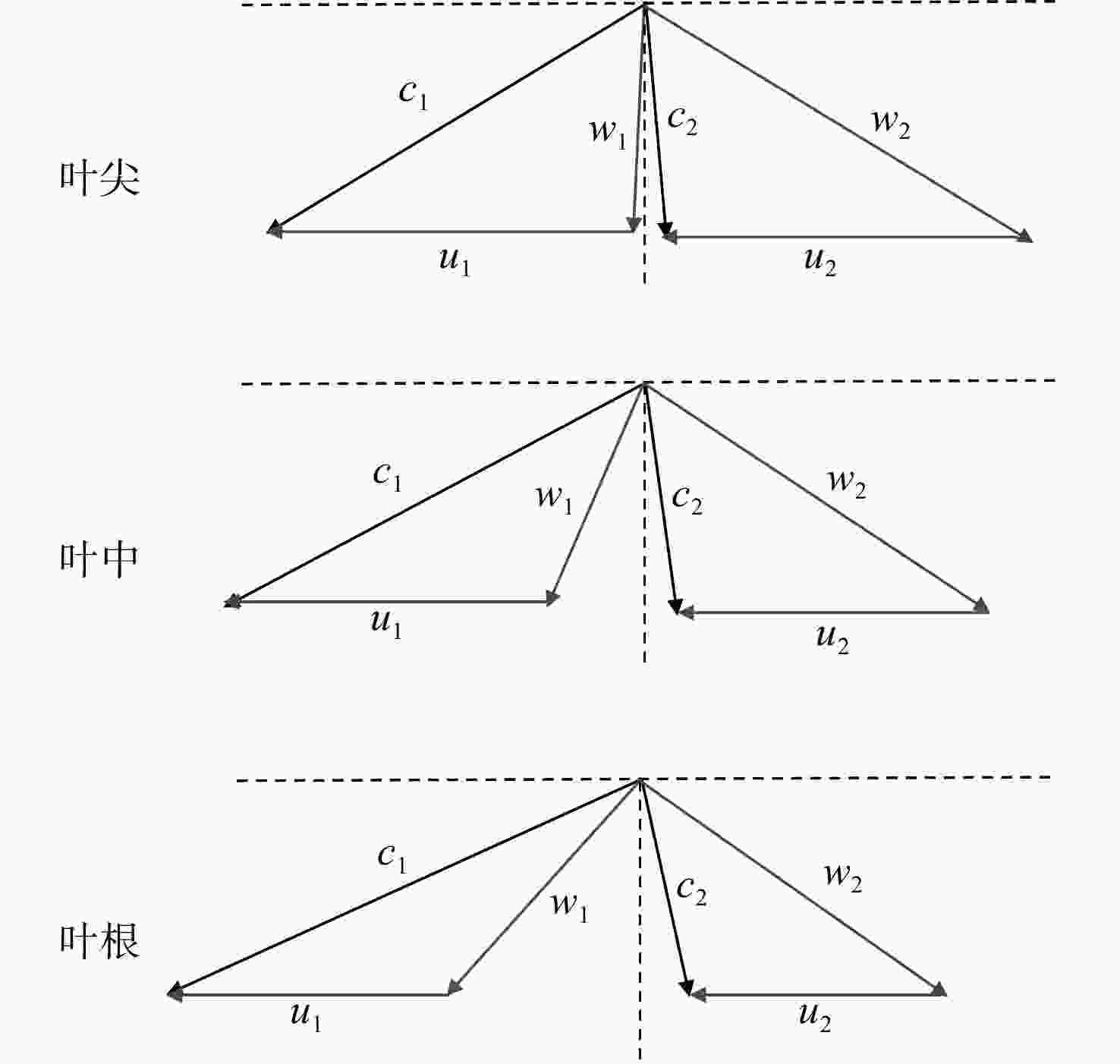

参数 进口 出口 内径/m 0.315 0.294 外径/m 0.412 0.414 叶片长度/cm 9.7 12.0 轮毂比 0.76 0.71 截面面积/m2 0.22 0.27 表 4 叶中处速度三角形设计值

Table 4. Value of velocity triangle design at average position

参数 进口 出口 $ {c}_{\mathrm{a}} $ 288.99 297.23 $ {c}_{\mathrm{u}} $ 543.17 41.51 $ c $ 615.27 300.11 $ {w}_{\mathrm{u}} $ 124.84 449.09 $ w $ 314.81 539.61 $ \alpha $ 28.02 82.05 $\,\beta$ 66.64 33.67 表 5 截面Ⅳ叶型几何参数

Table 5. Blade profile geometric parameters at section Ⅳ

参数 数值 相对栅距 0.66 相对厚度 0.09 进口攻角/(°) −1 叶栅出口角/(°) 32.10 弦长/mm 40.91 栅距/mm 27.20 叶型安装角/(°) 119.75 叶片宽度/mm 35.80 最大厚度/mm 3.70 进气边小圆半径/mm 0.77 排气边小圆半径/mm 0.44 进气边楔角/(°) 16 排气边楔角/(°) 4 喉道宽度/mm 14.50 几何进口角/(°) 65.64 几何出口角/(°) 32.88 叶背出口弯折角/(°) 9 表 6 三维四向编织某KD- Ⅰ SiC/SiC复合材料参数[30]

Table 6. Material parameters of three dimensional-four directional braided the KD- Ⅰ SiC/SiC composites[30]

参数 数值 弹性模量/GPa $ {E}_{1} $ 89 $ {E}_{2} $ 89 $ {E}_{3} $ 107 泊松比 $ {v}_{12} $ 0.27 $ {v}_{13} $ 0.24 $ {v}_{23} $ 0.24 切变模量/GPa $ {G}_{12} $ $ 38.60 $ $ {G}_{13} $ 38.20 $ {G}_{23} $ 38.20 热膨胀系数/10−6 K−1 $ {\alpha }_{1} $ 2.40 $ {\alpha }_{2} $ 2.40 $ {\alpha }_{3} $ 2.50 密度/(g/cm3) 2.00 表 7 设计截面的叶片表面温度

Table 7. Blade surface temperature of design sections

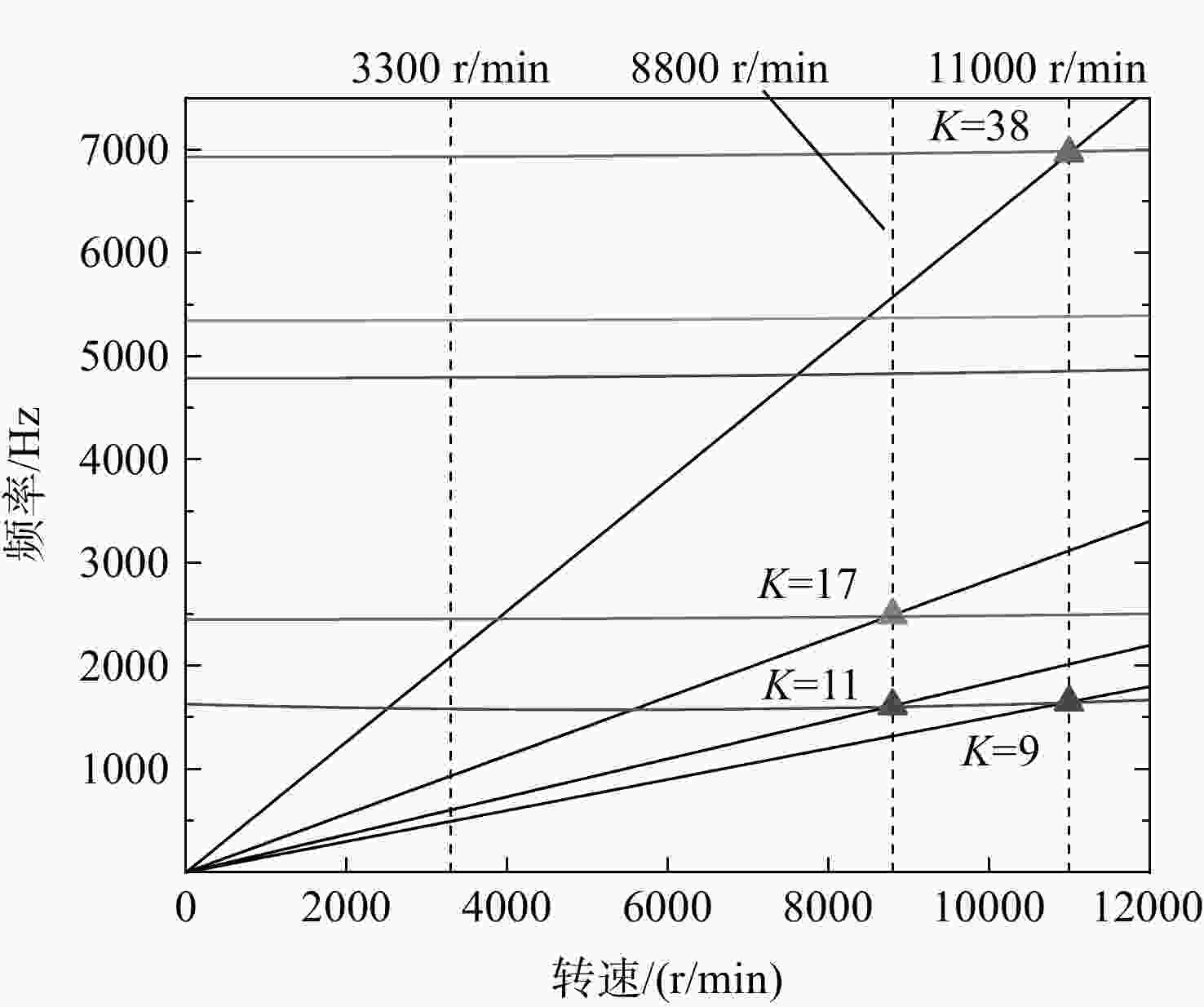

径向位置 r/cm 叶片表面温度 T/K 29.39 1240 31.47 1245 33.89 1252 36.32 1259 38.74 1268 40.97 1276 41.37 1278 表 8 叶片前5阶振型

Table 8. The first five mode shapes of blade

固有频率/Hz 振型 振型图 1644(1阶) 1阶弯曲振型

2503(2阶) 1阶扭转振型

4871(3阶) 1阶弯曲振型

5386(4阶) 2阶扭转振型

7006(5阶) 弯扭复合振型

-

[1] 晏武英. 美国新一代国家级军用航空动力预研计划分析[J]. 航空动力,2018(2): 35-39.YAN Wuying. Analysis of U. S. new generation military aeronautical propulsion research program[J]. Aerospace Power,2018(2): 35-39. (in Chinese) [2] 刘大响,程荣辉. 世界航空动力技术的现状及发展动向[J]. 北京航空航天大学学报,2002,28(5): 490-496. doi: 10.3969/j.issn.1001-5965.2002.05.002LIU Daxiang,CHENG Ronghui. Current status and development direction of aircraft power technology in the world[J]. Journal of Beijing University of Aeronautics and Astronautics,2002,28(5): 490-496. (in Chinese) doi: 10.3969/j.issn.1001-5965.2002.05.002 [3] 陈仲光,张志舒,李德旺,等. F119发动机总体性能特点分析与评估[J]. 航空科学技术,2013(3): 39-42. doi: 10.3969/j.issn.1007-5453.2013.03.012CHEN Zhongguang,ZHANG Zhishu,LI Dewang,et al. Analysis and evaluation of F119 engine overall performance[J]. Aeronautics Science and Technology,2013(3): 39-42. (in Chinese) doi: 10.3969/j.issn.1007-5453.2013.03.012 [4] PENG Y,LI J,PENG X,et al. Interfacial microstructure evolution and formation process of the joints prepared by diffusion bonding on DD6 nickel-based single crystal superalloy[J]. Journal of Materials Research and Technology,2020,9(6): 16317-16328. doi: 10.1016/j.jmrt.2020.11.083 [5] 刘海龙,张大旭,祁荷音,等. 基于X射线CT原位试验的平纹SiC/SiC复合材料拉伸损伤演化[J]. 上海交通大学学报,2020,54(10): 1074-1083. doi: 10.16183/j.cnki.jsjtu.2019.274LIU Hailong,ZHANG Daxu,QI Heyin,et al. Tensile damage evolution of plain weave SiC/SiC composites based on in-situ X-ray CT tests[J]. Journal of Shanghai Jiao Tong University,2020,54(10): 1074-1083. (in Chinese) doi: 10.16183/j.cnki.jsjtu.2019.274 [6] WANG X,GAO X,ZHANG Z,et al. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review[J]. Journal of the European Ceramic Society,2021,41(9): 4671-4688. doi: 10.1016/j.jeurceramsoc.2021.03.051 [7] 张立同,成来飞,徐永东. 新型碳化硅陶瓷基复合材料的研究进展[J]. 航空制造技术,2003(1): 24-32. doi: 10.3969/j.issn.1671-833X.2003.01.009ZHANG Litong,CHENG Laifei,XU Yongdong. Progress in research work of new CMC-SiC[J]. Aeronautical Manufacturing Technology,2003(1): 24-32. (in Chinese) doi: 10.3969/j.issn.1671-833X.2003.01.009 [8] 邹豪,王宇,刘刚,等. 碳化硅纤维增韧碳化硅CMCs的发展现状及其在航空发动机上的应用[J]. 航空制造技术,2017(15): 76-84, 91.ZHOU Hao,WANG Yu,ZHAO Long,et al. Development situation and application of SiC/SiC ceramic matrix composites in aeroengine[J]. Aeronautical Manufacturing Technology,2017(15): 76-84, 91. (in Chinese) [9] BANSAL N P, LAMON J. Ceramic matrix composites: materials, modeling and technology[M]. New York: John Wiley and Sons Incorporation, 2015. [10] General Electric (GE) Aerospace. GE aviation moving to apply ceramic matrix composites to the heart of future engines[EB/OL].[2022-04-26]. https://www.geaerospace.com/press-release/other-news-information/ge-aviation-moving-apply-ceramic-matrix-composites-heart. [11] WATANABE F, NAKAMURA T, MIZOKAMI Y. Design and testing for ceramic matrix composite turbine vane[R]. ASME Paper GT 2017-63264, 2017. [12] General Electric (GE) Aerospace. GE successfully tests world’s first rotating ceramic matrix composite material for Next-Gen combat engine[EB/OL].[2022-04-26]. https://www.geaerospace.com/press-release/military-engines/ge-successfully-tests-worlds-first-rotating-ceramic-matrix-composite. [13] 石多奇, 程震, 杨晓光, 等. 一种CMCs涡轮转子叶片: CN108119188B [P]. 2020-04-17. [14] 程震. 连续增韧CMCs强度与结构设计[D]. 北京: 北京航空航天大学, 2021.CHEN Zhen. Continuous fiber reinforced ceramic matrix composite strength and structure design[D]. Beijing: Beihang University, 2021. (in Chinese) [15] CHAMPASAK P,PANAGANT N,PHOLDEE N,et al. Aircraft conceptual design using metaheuristic-based reliability optimization[J]. Aerospace Science and Technology,2022,129: 107803.1-107803.13. doi: 10.1016/j.ast.2022.107803 [16] YADAV M,MISRA A,MALHOTRA A,et al. Design and analysis of a high-pressure turbine blade in a jet engine using advanced materials[J]. Materials Today: Proceedings,2020,25: 639-645. doi: 10.1016/j.matpr.2019.07.530 [17] ALSHAMMARI F,ELASHMAWY M,HAMIDA M B B. Effects of working fluid type on powertrain performance and turbine design using experimental data of a 7.25ℓ heavy-duty diesel engine[J]. Energy Conversion and Management,2021,231: 113828.1-113828.20. [18] QIAN Z,LI G. Structure design and optimization of a gas turbine blade[J]. Journal of Physics ,2022,2252(1): 12025.1-12025.7. [19] DHIMOLE V K,CHEN Y,SERRAO P,et al. A design feasibility study of a turbine blade disc interface (dovetail) made by four-directional braided ceramic matrix composite (SiC/SiC)[J]. International Journal of Aeronautical and Space Sciences,2022,23(1): 66-76. doi: 10.1007/s42405-021-00421-8 [20] 杨天媛. CMCs金属榫连结构试验件设计与分析[D]. 北京: 北京航空航天大学, 2018.YANG Tianyuan. Design and analysis of CMCs/metal dovetail joint test specimens[D]. Beijing: Beihang University, 2018. (in Chinese) [21] 陈光. F119发动机的设计特点[J]. 航空发动机,2000,26(1): 21-29.CHEN Guang. Design features of F119 engine[J]. Aeroengine,2000,26(1): 21-29. (in Chinese) [22] BOYLE R,GNANASELVAM P,PARIKH A H,et al. Design of stress constrained SiC/SiC ceramic matrix composite turbine blades[J]. Journal of Engineering for Gas Turbines Power,2021,143(5): 051013.1-051013.9. [23] 柯别列夫, С. З, 吉洪诺夫, 等. 航空发动机涡轮计算: 气动计算及叶片造型[M]. 施永立, 译. 北京: 国防工业出版社, 1978. [24] 罗尔斯·罗伊斯公司. 斯贝MK202发动机应力标准: EGD-3[M]. 丁爱祥, 吴君可, 译. 北京: 国际航空编辑部, 1979. [25] 杨晓光,胡晓安,石多奇,等. 概念设计时影响涡轮转子叶片强度的关键因素[J]. 航空动力学报,2012,27(10): 2314-2320. doi: 10.13224/j.cnki.jasp.2012.10.016YANG Xiaoguang,HU Xiaoan,SHI Duoqi,et al. Strength considerations for concept design of turbine blade[J]. Journal of Aerospace Power,2012,27(10): 2314-2320. (in Chinese) doi: 10.13224/j.cnki.jasp.2012.10.016 [26] XIONG X,QUAN D,DAI P,et al. Tensile behavior of nickel-base single-crystal superalloy DD6[J]. Materials Science and Engineering:A,2015,636: 608-612. doi: 10.1016/j.msea.2015.03.125 [27] 罗磊. 涡轮高效冷却结构设计方法及换热机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.LUO Lei. On the design method and heat transfer mechanism of high efficiency cooling structure in a gas turbine[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [28] 《航空发动机设计用材料数据手册》编委会编. 航空发动机设计用材料数据手册[M]. 北京: 航空工业出版社, 2010. [29] 张盛. 编织陶瓷基复合材料力学行为的多尺度分析[D]. 南京: 南京航空航天大学, 2018.ZHANG Sheng. Analysis of the mechanical behavior for braided ceramic matrix composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018. (in Chinese) [30] 程震,石多奇,景鑫,等. 三维四向编织CMCs改进模型及刚度预报[J]. 复合材料学报,2016,33(6): 1287-1296.CHEN Zhen,SHI Duoqi,JING Xin,et al. Numerical prediction of tensile properties and damage evolution of three dimensional-four directional braided CMCs[J]. Acta Materiae Compositae Sinica,2016,33(6): 1287-1296. (in Chinese) [31] SHI D,JING X,YANG X. Low cycle fatigue behavior of a 3D braided KD-I fiber reinforced ceramic matrix composite for coated and uncoated specimens at 1 100 ℃ and 1 300 ℃[J]. Materials Science and Engineering: A,2015,631: 38-44. doi: 10.1016/j.msea.2015.01.078 [32] LIU C,SHI D,JING X,et al. Multiscale investigation on fatigue properties and damage of a 3D braided SiC/SiC+PyC/SiC composites in the full stress range at 1 300 ℃[J]. Journal of the European Ceramic Society,2022,42(4): 1208-1218. doi: 10.1016/j.jeurceramsoc.2021.11.045 [33] ZHU S,MIZUNO M,KAGAWA Y,et al. Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: a review[J]. Composites Science and Technology,1999,59: 833-851. doi: 10.1016/S0266-3538(99)00014-7 [34] 刘长奇. 编织SiC/SiC复合材料结构强度和寿命分析方法[D]. 北京: 北京航空航天大学, 2022.LIU Changqi. Analysis methods for structural strength and service life of braided SiC/SiC composites[D]. Beijing: Beihang University, 2022. (in Chinese) [35] 方祥军,刘思永,王屏,等. 大扩张通道超声高载荷对转涡轮动叶三维设计方法研究[J]. 航空学报,2007,28(1): 25-31. doi: 10.3321/j.issn:1000-6893.2007.01.004FANG Xiangjun,LIU Siyong,WANG Ping,et al. Research of 3D design method for rotor of supersonic high loaded contra-rotating turbine with large expansile meridional channel[J]. Acta Aeronautica et Astronautica Sinica,2007,28(1): 25-31. (in Chinese) doi: 10.3321/j.issn:1000-6893.2007.01.004 [36] 张清,郝勇,张大义,等. 大涵道比涡扇发动机低压涡轮间隙分析与设计[J]. 航空发动机,2014,40(2): 56-60. doi: 10.13477/j.cnki.aeroengine.2014.02.011ZHANG Qing,HAO Yong,ZHANG Dayi,et al. Analysis and design of low pressure turbine tip clearance for high bypass ratio turbofan engine[J]. Aeroengine,2014,40(2): 56-60. (in Chinese) doi: 10.13477/j.cnki.aeroengine.2014.02.011 [37] 谷雪花,郝晟淳,张东海,等. 叶尖间隙对涡轮性能影响的试验研究[J]. 航空发动机,2020,46(4): 78-81. doi: 10.13477/j.cnki.aeroengine.2020.04.014GU Xuehua,HAO Shengchun,ZHANG Donghai,et al. Experimental study on influence of tip clearance on turbine performance[J]. Aeroengine,2020,46(4): 78-81. (in Chinese) doi: 10.13477/j.cnki.aeroengine.2020.04.014 [38] 林垲,高庆,黄维娜. Ⅰ级涡轮叶片振动特性研究[J]. 燃气涡轮试验与研究,2002,15(3): 28-32, 46. doi: 10.3969/j.issn.1672-2620.2002.03.008LIN Kai,GAO Qing,HUANG Weina. Study on vibration characteristics of 1st stage turbine rotor blade[J]. Gas Turbine Experiment and Research,2002,15(3): 28-32, 46. (in Chinese) doi: 10.3969/j.issn.1672-2620.2002.03.008 [39] 欧阳德,付小平,宋兆泓. 某发动机二级涡轮叶片共振断裂可靠性分析[J]. 燃气涡轮试验与研究,1997,10(4): 39-41.OUYANG De,FU Xiaoping,SONG Zhaohong. Reliable analysis of resonant fracture of the 2nd stage turbine blade of an engine[J]. Gas Turbine Experiment and Research,1997,10(4): 39-41. (in Chinese) [40] 赵陈伟,毛军逵,屠泽灿,等. 纤维增韧陶瓷基复合材料热端部件的热分析方法现状和展望[J]. 航空学报,2021,42(6): 136-161.ZHAO Chenwei,MAO Junkui,TU Zecan,et al. Thermal analysis methods for high-temperature ceramic matrix composite components: review and prospect[J]. Acta Aeronautica et Astronautica Sinica,2021,42(6): 136-161. (in Chinese) -

下载:

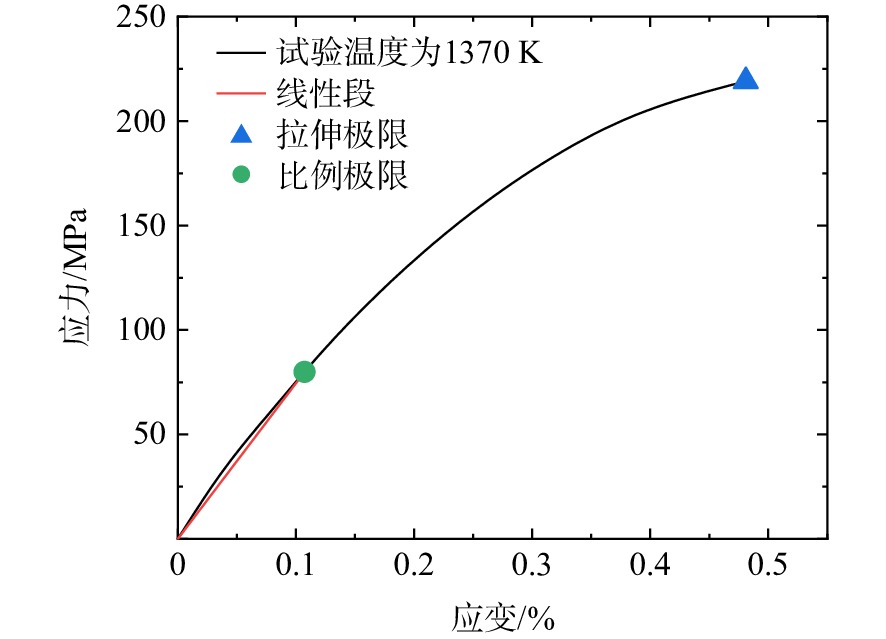

下载: